2 Ton Modular KBK Crane Extended Order from Australia

Australia’s coal mining company expands with economical modular KBK crane system, showcasing scalability and flexibility for growing operational needs.

Category: Modular Cranes and Hoists

Your Trusted Overhead Modular Crane Manufacturer & Supplier

2 Ton Modular KBK Crane Extended Order from Australia

Modular KBK Cranes Win Repeat Order, Power of Modularity to Expand KBK Crane System

Introduction: KBK Modular Crane – A Smart Choice That Grows with You

KBK modular cranes are becoming a popular choice for industrial users who want flexible, efficient, and easy-to-expand lifting systems. They're especially useful in workshops or service areas where layout and future changes matter.

One of our customers in Australia's coal mining service sector recently showed just how valuable this kind of system can be. They first ordered a 2-ton KBK crane in 2023. It worked well for their daily lifting needs—so well, in fact, that they placed a second order in 2024 to extend the same system.

Australian Project with a Growing Need

The customer works in a heavy-duty environment, moving parts, equipment, and tools regularly. Their first KBK crane helped streamline material handling inside the workshop. But as operations grew, so did the need for more lifting coverage. That's where the modular design made all the difference.

The Power of Modularity

Why did they reorder instead of replacing the whole setup? It comes down to one key feature: modularity.

Here's how it helped:

- Expandable Design: They added new sections to the existing track—no need to remove or redo anything.

- Same Specs, Simple Upgrade: The crane extension matched the original: 2-ton capacity, 6-meter span, with a slightly higher lifting height.

- Fast Integration: The new parts fit right into the old system, saving time and reducing disruption.

- Better Long-Term Value: They saved money while gaining more coverage and efficiency.

This case proves that KBK modular cranes are more than just lifting tools—they're scalable systems that grow with your business needs.

Original Order Details: 2023/4/15 – 2023/3/14

In early 2023, we received an order from a coal mining service company in Australia. Their team needed a reliable crane system to improve material handling inside their workshop.

Modular KBK Crane Type and Configuration

They chose a rigid KBK modular crane with a hook-type chain hoist. The system was designed for small-span lifting but with high reliability.

Here are the main specs of that first order:

- Lifting Capacity: 2 Ton

- Span: 6 Meters

- Lifting Height: 5 Meters

- Power Supply: 415V, 50Hz, 3-Phase

This setup was ideal for their indoor workspace. The crane could handle heavy components and tools without taking up too much space.

Purpose of the Crane

The crane was installed in a support facility for coal mining operations. Workers use it to lift and move parts, repair tools, and perform service work on mining equipment. The layout had limited headroom, so the compact KBK system was a good fit.

Initial Project Highlights

- Smooth Installation: The modular design allowed quick assembly with minimal on-site work.

- Stable Performance: The crane worked consistently under daily use with very few maintenance needs.

- Positive Feedback: The customer was satisfied with both the lifting efficiency and the build quality.

They saw right away how the KBK system made their daily operations easier. And most importantly, they knew they could expand the system later if needed—which they eventually did.

Extended Order: Order 2343 (2024/10/30 – 2024/9/30)

After a year of smooth operation, the customer came back with a new request. Their workload had increased. More lifting points were needed in the same workshop. Instead of starting from scratch, they chose to extend the original KBK system.

This is exactly where modular cranes shine.

Why the Extension Was Needed

- The company's operations had grown.

- Workers needed more flexibility to move parts across a wider area.

- Instead of replacing the existing crane, they wanted to expand it.

That's what KBK modular design is made for—adding to what's already there.

New Configuration for the Extension

The extension was designed to match the existing setup, with only a slight update in lifting height:

- Lifting Capacity: 2 Ton

- Span: 6 Meters

- Lifting Height: 5.9 Meters (increased from 5M)

- Power Supply: 415V, 50Hz, 3-Phase

Seamless System Integration

The new KBK section was connected directly to the original system:

- No major structural changes were needed.

- Rails and hoist matched perfectly with the existing components.

- Installation was fast, and downtime was minimal.

The customer didn't need to change their workflow. They simply gained more coverage and increased efficiency with a smart upgrade.

The Power of Modularity of KBK Crane

The real strength of the KBK modular crane system lies in its modular design. This design is built around bolt-together components, which allows for easy assembly, expansion, and reconfiguration.

How the Modular KBK System Works

- Bolt-Together Design: The crane is made up of individual, pre-engineered parts that are easily assembled on-site. This eliminates the need for welding or complex structural work.

- Flexible Layout: The system can be adapted to fit the specific layout of any workshop. You can adjust the rails, hoists, and other components to create the best solution for your space.

- Scalable System: The KBK crane is perfect for operations that may grow over time. You can add more tracks, increase the lifting capacity, or change the span without replacing the entire system.

Benefits of the Modular Design

- Easy to Expand or Reconfigure

Whether you need more lifting points or a new layout, the modular KBK system lets you add to the system as needed. You don't have to tear everything down and start over. Just extend the rails or add new hoists where necessary. - Minimal Downtime During Upgrades

Upgrading or expanding the crane is quick and doesn't disrupt operations. Since the modular pieces fit together so easily, the customer can add parts to the crane system without taking it offline for long periods. That means more uptime for your business. - Cost-Effective Scalability

Instead of investing in a completely new crane system, you can scale your existing setup. The modular design allows for affordable upgrades over time, so you only pay for what you need. There's no need to invest in a whole new system, just extend what's already there.

Case-in-Point: Australian Project Expansion

Take the Australian project as an example. Initially, the customer ordered a 2-ton crane with a 6-meter span and 5-meter lifting height. As their business grew, they needed more lifting coverage. Instead of purchasing a whole new crane, they simply extended their existing KBK system—adding a new section with an increased lifting height (5.9 meters).

This expansion was seamless:

- The new components fit perfectly with the original system.

- There were no major engineering changes required.

- Installation was quick and caused minimal disruption to the customer's operations.

This is the power of modularity—effortless scaling that works with your business needs as they grow.

Application in the Coal Mining Sector

The coal mining service industry presents unique challenges. Work environments are often tough, with demanding tasks and less-than-ideal conditions for equipment. For our Australian customer, these included dusty environments, rugged use, and low ceiling spaces in their workshop.

So, how does the modular KBK crane system fit in? Let's break it down.

Challenges in the Coal Mining Service Industry

- Dusty Environment: The air in coal mining workshops can be full of dust, which makes it hard on machinery. Equipment needs to be durable and easy to clean.

- Rugged Use: The crane will be frequently used to lift heavy, sometimes awkwardly shaped components. The system has to be reliable, even under heavy loads.

- Low Ceiling Spaces: Many workshops in this sector have limited headroom. Traditional cranes might not fit, or they may need to be bulky to handle loads effectively.

Why Modular KBK Cranes Are a Smart Fit

- Compact Design

KBK modular cranes are designed to be compact without sacrificing strength or lifting capacity. This was crucial for our customer's workshop, where space is limited, and every inch counts. The crane fits well under low ceilings and maximizes available space. - Efficient Material Handling

In mining facilities, there's a constant need to move heavy equipment, spare parts, and materials. The KBK crane system handles all types of lifts with ease, boosting productivity and minimizing delays. Its smooth operation reduces effort and improves efficiency for workers. - Low Maintenance Needs

The tough working conditions in coal mining require equipment that can handle minimal maintenance. The modular design of the KBK crane means fewer moving parts, reducing wear and tear. It also makes maintenance simpler and less costly, which is key in this demanding industry. - Flexible Routing Options

The modular system allows for customizable layouts to fit any space. Our customer was able to adapt the crane system's routes to their specific workshop layout. Whether they need to reroute the crane rails or extend them, KBK cranes offer the flexibility needed to meet changing demands.

Why It Works for Coal Mining Support

With the KBK crane's compact and modular design, the customer can handle more lifts, in tighter spaces, and with less downtime. It's an ideal solution for the unique challenges of the coal mining service sector—delivering both power and precision.

Technical Highlights: 2 Ton KBK Crane for Australia

The 2-ton KBK modular crane ordered by our Australian customer is built to handle their demanding work environment with efficiency and reliability. Let's dive into the detailed specs that make this crane the right choice for the job.

Detailed Specifications

- Lifting Capacity: 2 Ton

The crane is designed to lift up to 2 tons of material. This capacity is perfect for the heavy lifting needs in a coal mining support workshop, where equipment parts, tools, and machinery need frequent handling. - Span: 6 M

The crane's 6-meter span provides enough coverage for a typical workshop, allowing it to move items across the entire workspace. The relatively compact span is especially useful in tight spaces where larger cranes might not fit or be practical. - Lifting Height: 5.9 M

The 5.9-meter lifting height gives operators plenty of room for handling equipment and materials overhead. This additional height (slightly increased from the original 5 meters) allows for a greater vertical reach within the limited headroom of their facility, optimizing storage and operational flexibility. - Power Supply: 415V, 50Hz, 3-Phase

The crane operates on a 415V 50Hz 3-phase power supply, which is standard for industrial settings in Australia. This ensures the crane runs efficiently, providing the necessary power for heavy lifting without compromising on performance.

Optional Features for Customization

To make sure the crane fits the customer's specific needs, there are several optional features available:

- Chain Hoist Type

This option provides smooth and reliable lifting, ideal for moving heavy components and tools in a rugged workshop environment. The chain hoist is easy to operate and maintains high performance under continuous use. - Suspension Type

The crane can be mounted on a suspension system, which ensures it hangs from the ceiling or other structural elements, saving valuable floor space in the workshop. This is a great choice for environments with limited ceiling height. - Rail System

The crane's rail system can be customized to suit the facility's layout, allowing the crane to move seamlessly along the track. The modular rail system is easy to expand, which is perfect for future upgrades, making this crane system highly flexible.

These technical specifications and optional features provide a high level of customization to fit the specific needs of the Australian coal mining service workshop. Whether it's a compact, efficient system for tight spaces or the ability to scale and upgrade as operations grow, the 2-ton KBK modular crane is designed to perform consistently and reliably in challenging environments.

Production of Modular KBK Crane

The production of a Modular KBK Crane is designed to be efficient, flexible, and durable, making it perfect for a wide range of industries. The process includes several key steps to ensure the crane is built to high standards.

Design and Engineering

The process starts with designing the crane to fit specific customer needs. The modular design means that the crane can be easily customized and expanded.

- Custom Layouts: The crane is tailored to fit the customer's space and lifting requirements.

- Modular Parts: Pre-engineered parts make it easy to assemble and adjust.

Material Selection and Fabrication

High-quality materials, mostly steel, are used for the crane's frame and other parts, ensuring strength and longevity.

- Durable Steel: Strong steel ensures the crane can handle heavy loads.

- Corrosion Protection: Special coatings are applied to prevent rust, making the crane suitable for tough environments.

Manufacturing Process

In the manufacturing stage, parts are carefully cut, welded, and assembled.

- Precision Cutting and Welding: Components like beams and crossbeams are made with exact measurements for strength and accuracy.

- Modular Assembly: Parts are assembled in stages, allowing for easy adjustments.

Quality Control

Each crane is carefully checked to ensure it meets safety and performance standards.

- Inspection: Every part is checked for defects.

- Testing: The crane is tested under load conditions to ensure it performs correctly.

- Certification: The crane is certified to meet CE and ISO safety standards.

Customization and Configuration

The modular crane can be easily customized based on the customer's needs:

- Size and Height: The crane's span and lifting height can be adjusted.

- Hoist Types: Different hoists can be selected based on the type of work.

Assembly and Final Testing

The crane is then assembled, and final tests are carried out to make sure everything works as it should.

- Quick Assembly: The crane is easy to put together, using standardized parts.

- Final Checks: The crane is tested for safety and performance before being shipped.

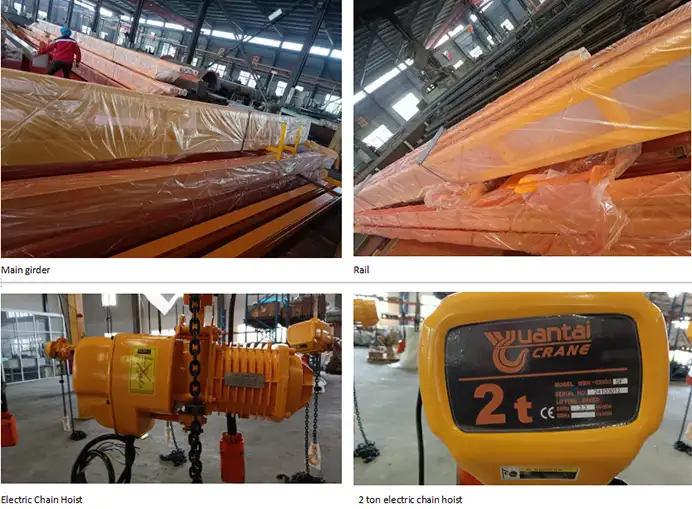

Packaging and Shipping

Once fully assembled and tested, the crane is packed and shipped. The modular parts are easy to transport and can be quickly put together on-site.

- Efficient Packaging: Parts are packed carefully to avoid damage during shipping.

- Quick Setup: The crane is easy to assemble once it reaches the customer's location.

The production of the Modular KBK Crane focuses on efficiency, strength, and flexibility. By using high-quality materials and a modular design, these cranes are easy to customize, expand, and install, making them a reliable choice for a wide range of industries.

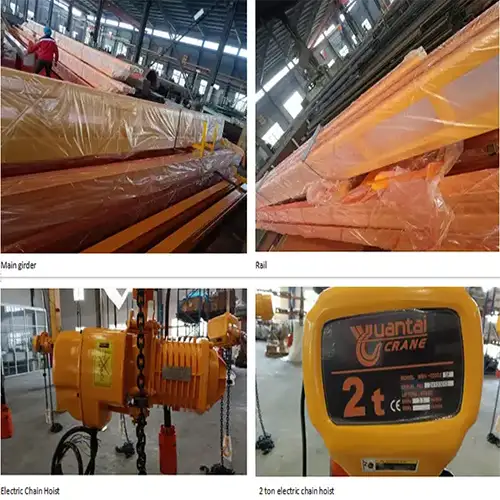

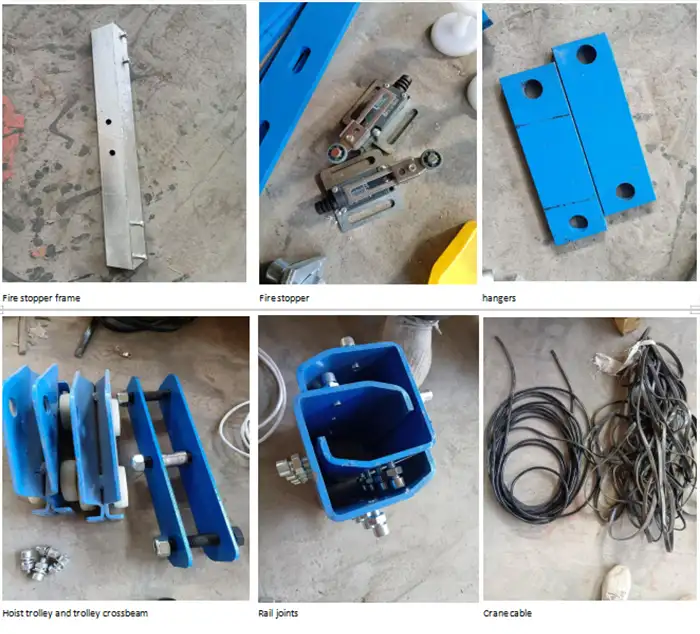

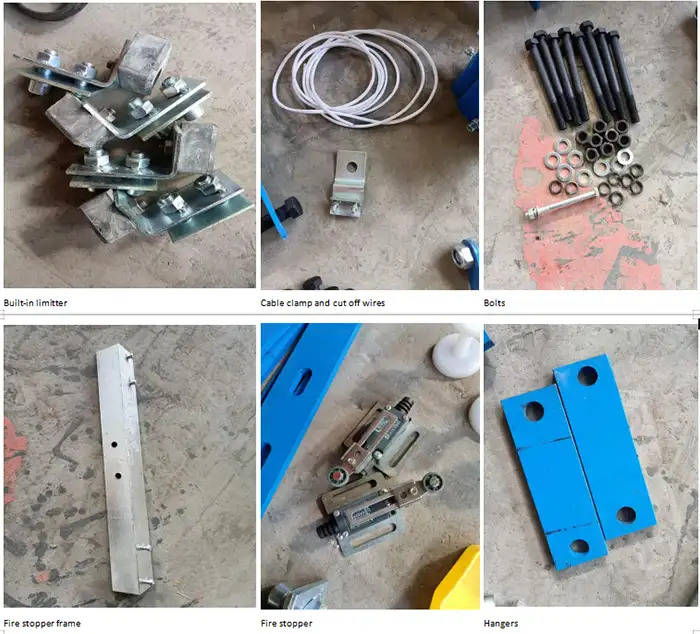

2 Ton KBK Modular Crane Kit Accessories for Austrilia Client

This kit includes all essential components for the crane's assembly and operation, ensuring optimal performance and safety.

kbk modular crane steel structrues

KBK crane girder, rail, electric chain hoist

2 Ton KBK Modular Crane Kit Accessories

Modular kbk crane parts and components

2 Ton KBK Crane Components:

- Hoist Trolley (Set) – 2

Facilitates movement of the hoist along the crane's rail system. - Trolley Crossbeam (Pcs) – 1

Supports the hoist trolley, connecting crane components for stability. - End Cap (Pcs) – 2

Covers the ends of the crane rails for added security. - Built-in Limiter (Set) – 4

Prevents over-travel by limiting crane movement. - Sliding Block-Cable Trolley (Pcs) – 14

Ensures smooth cable movement, preventing tangling during crane operation.

Electrical and Wiring:

- Electric Cables (M) – 29

Provides necessary power to the crane's motor and control systems. - Electrical Box (Set) – 1

Houses the electrical components for safe and efficient operation. - Electric Cables (M) – 17

Additional cables for extending or replacing existing wiring. - Cable Clamp (Pcs) – 1

Secures cables to prevent sagging or tangling.

Structural Components:

- Rail Joints (Pcs) – 2

Connects crane rail segments for smooth travel. - Square Tube Joint (Pcs) – 2

Joins the crane's structural components for secure assembly. - Hanging Components (Pcs) – 2

Provides stability by suspending the crane from the overhead structure.

Fasteners:

- M16*160 Bolt (Set) – 8

Heavy-duty bolts for secure structural assembly. - M16*380 Bolt (Set) – 4

Long bolts used for connecting large crane components. - M10*25 Bolt (Set) – 4

Smaller bolts for general assembly tasks. - M16*320 Bolt (Set) – 4

Larger bolts for strong, durable connections. - M10*120 Bolt (Set) – 1

Medium-sized bolt for precise fastening.

Fire Safety Components:

- Fire Stopper (Pcs) – 2

Prevents fire from spreading within the crane system. - Fire Stopper Cut-off Wires (M) – 4

Used to disconnect electrical power during fire emergencies. - Fire Stopper Frame (Pcs) – 1

The frame housing the fire stopper mechanism for protection.

Other Accessories:

- Trolley Traction Frame (Pairs) – 1

Provides stability and support for the trolley, ensuring smooth motion. - Circular Disc (Pcs) – 8

Serves as spacers or washers to ensure smooth operation during assembly.

These components are designed for easy assembly and ensure the crane's safety, efficiency, and long-term reliability. Let me know if you'd like any further details!

Why Customers Choose Modular KBK Cranes

When it comes to choosing the right crane supplier, customers need a partner they can trust.

CE and ISO Certifications

One of the key reasons customers choose Yuantai is our commitment to quality and safety.

- CE Certification: This certifies that our cranes meet European safety, health, and environmental protection standards. It's a mark of trust for industries around the world, ensuring that all our cranes are safe, reliable, and built to last.

- ISO Certification: Yuantai holds ISO certifications for our manufacturing processes, ensuring we follow strict international standards for quality management and product consistency. This means customers get top-tier products every time.

These certifications not only boost trust but also ensure that our cranes meet the highest industry standards.

Proven Export Experience to Australia

Yuantai has extensive experience working in international markets, particularly in Australia.

- We understand the local requirements and industry standards in Australia, which ensures our cranes are tailored to meet the country's specific needs.

- Our previous successful projects in Australia speak for themselves. Our customers know that when they choose us, they're working with a supplier who understands the local market and can deliver products that meet their exact requirements.

Professional Engineering Support for Overseas Projects

We don't just supply cranes – we provide full engineering support to ensure every project is successful.

- Tailored Solutions: Our engineers work closely with customers to design cranes that fit their unique needs. From layout to load capacity, we help ensure the crane operates efficiently in the given environment.

- On-site Consultation: For overseas projects, including in Australia, we offer on-site consultation to guide installation, ensure proper configuration, and help with any adjustments.

- After-Sales Support: We don't leave customers hanging after the sale. Our dedicated support team is available to assist with any maintenance, upgrades, or troubleshooting needed to keep your system running smoothly.

Fast Lead Times, Flexible Designs

- Fast Lead Times: Our streamlined production process ensures that we can quickly deliver the modular KBK cranes without compromising on quality. This means you get the equipment you need, when you need it.

- Flexible Designs: Every customer is different, and our cranes can be easily customized to fit a wide range of applications. Whether it's adjusting lifting height, span, or adding features like chain hoists or suspension types, we offer flexible design options to match your exact specifications.

By choosing Yuantai, customers benefit from timely, reliable solutions that are both cost-effective and adaptable to their changing needs.

Conclusion

Modular KBK cranes are proving their worth time and time again, especially with the repeat business we're seeing from customers like the Australian coal mining service company. This kind of ongoing partnership demonstrates that these cranes aren't just a one-time solution—they continue to deliver value over time.

Proven Value Through Repeat Business

The success of the 2-ton modular KBK crane system in Australia highlights the effectiveness of this design. Our customer's decision to extend their order and add more cranes to their operations speaks volumes about the system's reliability, efficiency, and cost-effectiveness.

- Proven Performance: The ability of these cranes to meet the customer's initial needs, followed by the ease of expansion, shows that modular KBK cranes aren't just a quick fix—they're a long-term investment.

- Repeat Orders: When customers return for additional units, it's a clear indication of satisfaction and trust in the system. This repeat business builds on the initial success, creating a lasting relationship.

Easy System Expansion with Customer Needs

One of the most significant benefits of the modular KBK crane system is its expandability.

- Scalable Design: The modular system allows our customers to expand their crane setup as their business grows. In this case, the Australian customer was able to seamlessly extend their existing system without needing major modifications. They simply added more cranes to keep up with increasing demands—proof that the system grows with the business.

- Minimal Engineering Changes: Expanding the system was straightforward, requiring minimal engineering adjustments. The crane components fit together easily, allowing for quick, efficient upgrades to meet operational changes.

Ideal for Industries Like Coal Mining

The coal mining sector, in particular, benefits greatly from modular KBK cranes due to the unique demands of the industry.

- Adaptability: Coal mining involves a range of tasks that require reliable, adaptable equipment. Whether it's handling heavy machinery or working in limited space, the modular design offers the flexibility needed to adjust to different challenges.

- Reliability: The harsh conditions of coal mining—dust, rugged use, and limited space—require equipment that won't fail under pressure. The KBK crane system is designed for these conditions, providing continuous, dependable performance.

- Future-Proof: As businesses grow, so too do their material handling needs. The modular KBK system is designed to evolve with those needs, making it an ideal long-term solution for industries that depend on continuous, efficient operation.

The modular KBK crane system continues to prove its value in industries like coal mining, where adaptability and reliability are key. With the ability to expand easily and integrate seamlessly into existing setups, it offers flexibility and cost-effectiveness that stand the test of time. The Australian case exemplifies how this crane system supports long-term growth and operational efficiency, making it a solid choice for companies looking to future-proof their material handling needs. Contact us today to get your modular crane solution!

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch