1 Ton KBK System + 54-Meter Runway Steel Structure - Philippines

Complete KBK crane system in the Philippines offering efficient 1-ton lifting, long 54-meter travel, and durable steel runway.

Category: Featured

Your Trusted Overhead KBK Crane Manufacturer & Supplier

1 Ton KBK Crane System with 54-Meter Runway Steel Structure for Sale the Philippines

Complete KBK crane system in the Philippines offering efficient 1-ton lifting, long 54-meter travel, and durable steel runway.

Introduction- What Is a KBK System?

A KBK system is a flexible, overhead crane system designed for light to medium lifting tasks. It consists of modular steel or aluminum tracks—called runway beams—mounted on columns or walls. A trolley runs along these beams, carrying an electric hoist that lifts and moves loads smoothly. Because the system is modular, it can be customized easily to fit different shapes and sizes of workshops or factories.

The KBK system is known for:

- Lightweight but strong construction

- Smooth and quiet operation

- Easy installation and future expansion

- Low maintenance requirements

This makes the KBK system a great choice where traditional heavy cranes may be too bulky or expensive.

Applications of the KBK System

The KBK system is widely used in:

- Manufacturing plants where parts need to be moved along a production line

- Workshops that require precise, repetitive lifting

- Warehouses that benefit from flexible material handling

- Assembly areas where space is tight but lifting tasks are frequent

Its modular design means the KBK system can be adapted to fit unique floor plans and operational needs.

Why Customized KBK Systems Are Essential in the Philippines

In the Philippines, many factories and workshops face challenges such as limited floor space and varying power supplies. Off-the-shelf crane systems often don't match these specific conditions. That's why a customized KBK system is so valuable.

Customization allows:

- Designing the KBK system to perfectly fit the available space, including long runway lengths or specific column placements

- Selecting a crane capacity that matches the actual load requirements—in this case, 1 Ton—avoiding over or under-sizing

- Ensuring the KBK system is compatible with local electrical standards, such as 400V, 60Hz, 3-phase power

- Providing a complete package with runway steel structure and crane columns to simplify installation

By tailoring the KBK system, businesses get a safer, more efficient crane that boosts productivity without wasting space or money.

Purpose of This Case Study

This case study highlights a successful installation of a complete 1 Ton KBK system with a 54-meter runway steel structure in the Philippines. It aims to:

- Detail the technical specifications of the KBK system provided

- Explain how the installation was planned and executed

- Show the benefits the client gained from using a customized KBK system

- Help other businesses understand how a KBK system can solve similar lifting and space challenges

1 Ton KBK System Project Background in the Philippines

Client Industry and Application

The client is a manufacturing workshop in the Philippines, focusing on light industrial assembly and material handling. Their operations require frequent lifting and moving of parts and equipment along a production line. The work involves lifting loads up to 1 Ton, with the need for precise positioning during assembly.

This kind of application demands a crane system that is reliable, safe, and flexible enough to fit their workshop layout.

Reason for Choosing a KBK Crane System

The client chose the KBK system because it offers several advantages that traditional overhead cranes or jib cranes could not provide:

- Space efficiency: The KBK system's lightweight and modular design fits well into the limited workshop space without requiring heavy, bulky structures.

- Customizable runway length: The system could be extended to a 54-meter travelling length, allowing coverage of the entire production area.

- Ease of installation: The modular components and included crane columns made onsite installation faster and less disruptive to ongoing operations.

- Smooth operation: The electric chain hoist integrated into the KBK system delivers smooth lifting and positioning, important for delicate assembly tasks.

- Cost-effective maintenance: The KBK system requires minimal upkeep, which is critical for keeping operational costs low.

Key Challenges and Client Requirements

The client had some important requirements and challenges to address:

- Limited floor and ceiling space: The workshop had a low ceiling and narrow aisles, meaning the crane system had to be compact without sacrificing capacity.

- 1 Ton lifting capacity: The system needed to handle loads safely up to 1 Ton, which matches the client's maximum load weight.

- Long travel length: A total travelling length of 54 meters was required to cover the entire production line.

- Crane span: The 9.5-meter crane span was needed to allow effective coverage across the width of the workshop.

- Power compatibility: The crane had to operate on the local electrical supply — 400V, 60Hz, 3-phase power — without additional modifications.

- Structural support: The installation required strong crane columns and a robust runway steel structure to support the KBK system safely over the long span.

By choosing a customized KBK system tailored to these needs, the client was able to overcome space constraints and operational demands effectively.

Technical Specifications

- KBK system type: KBK crane system with electric chain hoist

- Capacity: 1 Ton

- Crane span: 9.5 meters

- Crane lifting height: 4 meters

- Crane travelling length: 54 meters

- Runway steel structure: Complete 54 meters runway steel structure provided

- Crane columns: Included for supporting the KBK crane system

- Power supply: 400V, 60Hz, 3 Phase

KBK System Components and Features

This 1 Ton KBK system is made up of several key components that work together to ensure smooth operation, safety, and ease of use. Below are the main features and the roles each component plays in this setup.

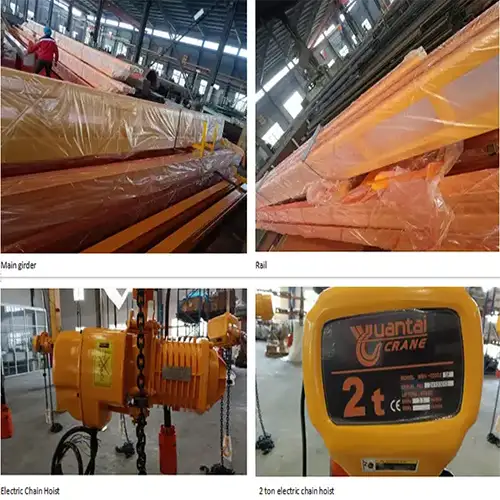

Electric Chain Hoist – Reliable 1-Ton Lifting

The KBK crane system includes an electric chain hoist, chosen specifically for 1-ton lifting tasks. This hoist provides steady and smooth lifting performance, which is especially important for handling parts during assembly or processing.

Key benefits include:

- Precise lifting and lowering control

- Quiet operation for indoor environments

- Safety features like limit switches and thermal protection

- Low maintenance design

- Smooth chain handling, reducing wear and tear on the system

electric chain hoist, and pendant control

Electric motorized hoist trolley

The hoist runs on a trolley that travels along the KBK track, making it easy to move loads across the full span of the crane.

Modular Design – Easy Installation and Flexible Configuration

The KBK system is built using a modular design. This means each part is pre-fabricated and assembled on-site using bolts instead of welding. It helps reduce installation time and allows flexibility in system layout.

Highlights of the modular design:

- Standard track profiles that can be easily extended or adjusted

- Pre-drilled holes for fast assembly

- Flexibility to install around existing equipment or obstacles

- Easy replacement of individual components in the future

This design allowed the entire system to be installed quickly and with minimal disruption to the client's operations.

54-Meter Runway Steel Structure – Long and Stable Travel Path

To support the crane's movement, a complete 54-meter runway steel structure was supplied. This structure forms the track on which the crane runs back and forth.

Features of the runway structure:

- Strong steel construction for reliable support

- Accurate alignment for smooth crane travel

- Surface protection to prevent rust and corrosion

- Adjustable design to fit the site precisely

The long runway allowed the crane to cover the entire length of the client's production area.

kbk rails

kbk system-steel structure columns

Crane Columns – Self-Supporting Structure

Because the workshop did not have ceiling beams suitable for suspension, freestanding crane columns were included. These vertical steel supports carry the weight of the runway and the crane system.

The crane columns provided:

- Independence from the existing building structure

- Custom height to match the required lifting height and crane span

- Secure baseplates for bolting to the ground

- Flexibility in layout based on workshop needs

This ensured the KBK system was fully self-supporting and adaptable to the facility.

Power Supply Compatibility – Built for the Local Standard

The crane was designed to operate on the Philippine power standard of 400V, 60Hz, 3-phase. This avoided any electrical mismatch or the need for conversion equipment.

Electrical considerations included:

- Pre-installed wiring and control box designed for local voltage

- Safe and organized cable systems to avoid tangling during movement

- Built-in motor protection and emergency stop systems

- Simple power hookup for fast commissioning

This made installation easier and ensured stable, safe operation from the first day.

Electrical cable

kbk crane system parts and accessories

Operational Benefits – Questions Buyers Often Ask

How did the KBK crane system improve material handling?

The 1 Ton KBK system made everyday lifting tasks much easier and safer for the client. It allowed workers to move heavy items quickly across the shop floor without relying on forklifts or manual labor.

Key results:

- Safe lifting with electric chain hoist and limit protection

- Reduced operator fatigue and fewer workplace risks

- Faster material transfers, improving production efficiency

The system offered a big upgrade from older, less efficient handling methods.

What makes the KBK system suitable for long distances like 54 meters?

Thanks to its modular track and stable steel structure, the KBK crane system easily covered the entire 54-meter length of the client's workshop.

Why it works:

- Lightweight, low-friction track allows long, smooth travel

- Full-area coverage from start to end of the runway

- Simple expansion or adjustment possible if the layout changes

This flexibility is hard to achieve with traditional overhead cranes.

Is the KBK system easy to maintain?

Yes, it's very low maintenance. The client chose this system partly because they didn't want to deal with heavy service work or complicated parts.

Maintenance benefits:

- Electric chain hoist requires minimal lubrication and tuning

- Long-life components reduce part replacement needs

- Easy access to all parts without disassembling the whole system

This helped the client lower their operating costs and reduce downtime.

Did the system meet safety and regulatory requirements?

Absolutely. From power compatibility to load safety, the entire KBK system was designed with compliance in mind.

Compliance features:

- Matches local electrical standards: 400V, 60Hz, 3-phase

- CE and ISO-compliant components used throughout

- Factory load testing and local safety checks passed

- Clear documentation provided for inspection and approval

This allowed the client to get the crane up and running without delay or concern.

Client Feedback

After installation, the client shared positive feedback about the 1 Ton KBK system. They were satisfied with both the crane's performance and the overall service.

Smooth Performance from Day One

The KBK crane system started working immediately after setup. The electric chain hoist operated smoothly, and the crane traveled the full 54-meter length without any issues. The client noted that lifting and moving materials became much easier.

They were especially pleased with:

- How quiet and stable the system ran

- The precise control when lifting parts

- The safety features, which gave operators more confidence

Noticeable Boost in Productivity

The client reported a clear improvement in their workflow. Before installing the KBK system, they had to rely on more manual labor and slower handling methods. With the new setup, work moved faster and more smoothly across the shop.

Key results they shared:

- Reduced time for moving parts between stations

- Less physical strain on workers

- More efficient use of space in the workshop

They also appreciated how the modular design allowed for future expansion, making the system a good long-term investment.

Overall, the client viewed the KBK system as a reliable, low-maintenance, and cost-effective solution for their material handling needs.

Conclusion

This 1 Ton KBK crane system project in the Philippines was a strong example of how the right crane solution can improve both safety and productivity in a workshop setting.

Project Success with the KBK System

The project was completed on time and fully met the client's expectations. From design to installation, each part of the KBK system was tailored to match the workshop's space, workflow, and lifting needs.

Key points of success:

- Smooth installation with minimal disruption

- Reliable lifting performance across a 54-meter area

- Operators quickly adapted to the system due to its simple and user-friendly design

- Low noise and low maintenance—ideal for day-to-day use

The client experienced improved workflow and safer operations from the very first day of use.

Ideal for Light to Medium Lifting Needs

This project clearly showed why KBK systems are a great fit for workshops and light manufacturing industries in the Philippines. The 1 Ton KBK crane system provides the right balance between performance, cost, and flexibility.

Why it's a smart choice:

- Handles up to 1 ton with ease and precision

- Compact system layout works well in limited spaces

- Freestanding support structure avoids building modification

- Electric chain hoist is quiet, safe, and efficient

For businesses handling light to medium loads—whether in assembly, repair, storage, or small production lines—this KBK system offers both reliability and room to grow.

Ready for Future Upgrades

One of the biggest advantages of the KBK system is its modular structure. If the client needs changes in the future, such as:

- Adding more workstations

- Increasing crane span or lifting height

- Upgrading to a dual-hoist system

- Expanding the runway length beyond 54 meters

These upgrades can be done with minimal changes to the existing setup. That's what makes KBK systems a long-term investment—not just a one-time purchase.

In short, this project proves that a well-designed KBK crane system can deliver immediate results and continue to support future business growth.

Contact: Send Us An Inquiry to Get Your KBK System

If you're planning to improve material handling in your workshop or facility, now is a great time to explore a customized KBK crane system.

We offer complete solutions, just like the 1 Ton KBK system with a 54-meter runway shown in this case. Every project is designed to meet the specific needs of your workspace, load capacity, and workflow.

Why Choose Our KBK Systems

- Custom designs for light to medium lifting tasks

- Easy installation with modular components

- Reliable performance with low maintenance

- Certified quality with CE and ISO standards

- Clear support throughout design, shipping, and after-sales

We'll help you find a KBK system that fits your layout, lifting height, and travel requirements.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch