3 to 30 Ton Overhead Cranes for Complex Plastic Molds Handling

3 to 30-ton overhead cranes with special attachments designed for safe, precise handling of irregular molds in plastic manufacturing. Get your eot crane!

Category: General Manufacturing

Your Trusted Overhead Crane Manufacturer & Supplier

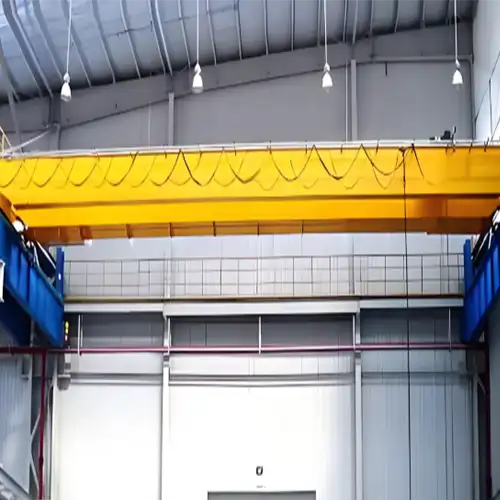

3 to 30 Ton overhead cranes Customized for Complex Mold Handling In Plastic Manufacturing

Tailored 3 ton to 30 Ton Overhead crane designs, special attachments, and handling irregular loads

Introduction

Mold Handling Is at the Heart of Plastic Production

In any plastic manufacturing plant—whether it's for car parts, containers, medical devices, or household goods—molds are everywhere. They form the shape, define the surface finish, and control the dimensions of the final product. These molds are often made from hardened steel or aluminum and are used in processes like injection molding, blow molding, and compression molding.

But here's the thing—these molds aren't lightweight. They can range from a few hundred kilograms to over 30 tons, depending on their complexity and size. What's more, they're not always uniform. Some are bulky, others are long and narrow, and many have an uneven center of gravity.

Why Lifting Molds Isn't So Straightforward

A mold isn't just a heavy block of metal. It's a precision tool. That means when it needs to be moved—whether for installation, maintenance, or changeover—it must be handled with care. Improper lifting can cause internal damage, alignment issues, or even accidents.

Standard lifting setups don't always cut it. A generic crane without proper attachment or control features may lift the mold, sure—but not without risks.

That's where custom crane systems come in. They're not just about higher lifting capacity. They're designed to solve practical challenges specific to mold handling.

Key Points That Make Custom Cranes Necessary

- Varied Mold Sizes and Shapes: One day, you're lifting a 10-ton rectangular injection mold. The next, a 3-ton asymmetrical blow mold.

- Tight Production Spaces: Many plastic factories are already packed with machines. Lifting equipment must fit and work within those constraints.

- Precision Matters: Molds often need to be rotated or aligned within millimeters before they can be secured into position.

- Workplace Safety: One wrong move can damage a mold worth tens of thousands of dollars—or worse, hurt someone.

So, if you're in plastic manufacturing and rely on cranes or hoists to move molds, off-the-shelf solutions may not be enough. You'll need something tailored—not just to your load, but to your workshop, workflow, and work pace.

Complex Mold Handling Requirements

Plastic manufacturing uses a wide variety of molds—each with its own handling demands. You've got injection molds used for high-pressure precision parts, compression molds for large, heavy components, and blow molds for hollow containers like bottles and tanks. While they all serve the same end goal—shaping plastic—they're built differently, weigh differently, and behave differently when lifted.

What Makes Mold Handling So Tricky

These molds aren't just heavy—they're complex. You can't treat them like uniform steel blocks. They require a careful approach that takes their size, weight distribution, and fragility into account.

- Irregular Shapes and Dimensions: Molds may be tall and narrow or short and wide. Some have protrusions, handles, or uneven edges that make them hard to balance on a hook or sling.

- Center of Gravity Challenges: Lifting from the wrong point? That mold will tilt or swing dangerously. The actual balance point isn't always at the center—it may be offset due to internal channels, cores, or moving parts.

- Precise Alignment Needs: Once lifted, molds often need to be installed with tight tolerances. That means the lifting system must allow slow, controlled movements. No jerks. No sway. And sometimes, rotation or tilt is needed before lowering it into place.

Mold Movement Isn't Just Up and Down

Handling a mold in a production setting means more than just lifting it off the ground. You might need to:

- Lift it vertically from a mold rack or storage base.

- Rotate it horizontally to align with the machine bed.

- Tilt it slightly for inspection or fitting.

- Transfer it across the shop without disturbing other machines or operators.

These aren't optional movements—they're part of the daily routine in many plastic plants. And without the right crane setup, they become time-consuming, risky, and frustrating. That's why crane systems used for mold handling must be planned with these motion requirements in mind—right from the start.

Types of Loads Handled in Complex Mold Handling

| Load Type | Description | Handling Notes |

|---|---|---|

| Injection Molds | Steel molds for plastic injection; may be 1–20 tons | Require multi-point lifting and precise alignment |

| Blow Molds | Lighter molds for hollow items; often 1–5 tons | Often irregularly shaped; handled carefully to avoid surface damage |

| Compression Molds | Heavy-duty molds used in thermosetting plastics | Usually bulky; need strong lifting beams or spreaders |

| Hot Molds (Preheated) | Heated molds for processing thermoplastics | Require thermal-resistant attachments and careful movement |

| Mold Halves | Mold components separated for maintenance or cleaning | Often handled in pairs with rotation and tilting |

| Rotated/Tilted Molds | Molds requiring repositioning during lifting | Use of rotating trolleys or motorized turning devices |

| Spare Molds & Mold Inserts | Lighter mold parts or inserts | Handled with light hoists or jib cranes in tool change stations |

| Tooling Fixtures & Plates | Base plates or support fixtures for mold setup | Flat or long; sometimes require horizontal lifting attachments |

| Palletized Mold Units | Mold units on skids or pallets for storage or transport | Forklift + crane coordination; hooks or vacuum lifters used |

Selecting the Right Overhead Crane Type and Capacity

Choosing the right crane for mold handling is essential to ensure smooth operations, safety, and efficiency. Different cranes serve different functions depending on the mold size, weight, and the area where they are used. Understanding typical crane capacities and their common applications can help you pick the best solution for your plastic manufacturing setup.

| Crane Type | Typical Capacity Range | Common Usage Areas |

|---|---|---|

| Overhead Cranes | 5–30 tons | Mold assembly areas, large injection molding halls |

| Double Girder Cranes for Mold Handling | 10–30 tons | Heavy mold lifting with precise movement |

| Single Girder Overhead EOT Cranes | 3–10 tons | Medium-duty handling for mold transport |

| Die / Mold handling Gantry Cranes | 2–20 tons | Outdoor or mobile mold handling zones |

| Jib Cranes for small Plastic Mold Hoisting | 0.5–5 tons | Localized workstations, mold repair, tool change |

| Electric Wire Rope Hoists for Mold Handling Cranes | 1–20 tons | Integrated with overhead or gantry cranes |

| Electric Chain Hoists | 0.5–5 tons | Light mold maintenance or positioning tasks |

Practical Tips for Crane Selection

- Match the crane type and capacity to the specific zones and tasks in your workshop.

- Use dual-speed hoists or frequency-controlled motors to achieve smooth, precise lifting movements.

- Double girder cranes are ideal for long-span, heavy mold handling to ensure rigidity and safety.

By selecting the right crane and features for your molds and layout, you can improve workflow and reduce risks in your plant.

Customizing Crane Structures for Workshop Layouts

Custom crane structures must fit your workshop space and mold handling needs. Let's break down the main options.

Low-Headroom Designs for Compact or Retrofitted Workshops

Many plastic factories have low ceilings or older buildings where vertical space is tight. Low-headroom cranes use compact hoists and slim trolleys to maximize lifting height without needing building modifications. This means you get full lifting capacity even in cramped spaces.

Telescopic Design vs Adjustable Span

Unlike some assumptions, overhead bridge cranes, gantry cranes, and jib cranes generally do not have adjustable spans. Instead, they are often designed with telescopic features or fixed spans.

- Telescopic cranes have girders or arms that can extend or retract within a set range, allowing some flexibility for different tasks or to fit varying workspace sizes.

- Fixed-span cranes are custom-built to fit the exact width of the workspace and mold storage areas.

As for adjustable gantry cranes, this term usually applies to small, portable gantry cranes with capacities under 2 tons. These portable units often have legs or beams that can be moved to different widths manually, offering some versatility for light-duty, temporary lifting tasks.

Modular Structures for Temporary or Growing Production Facilities

Modular cranes use standardized components and can be assembled, disassembled, or expanded easily. They are ideal for:

- Factories that expect production lines to change or grow.

- Temporary installations where permanent cranes are not feasible.

- Reducing upfront costs by allowing gradual expansion.

Floor-Mounted Gantries and Wall-Mounted Jib Cranes for Limited Space

When overhead space or building support is limited:

- Floor-mounted gantry cranes run on rails or wheels on the floor. They don't require ceiling or wall support, making them great for outdoor or temporary setups.

- Wall-mounted jib cranes attach to columns or walls, offering lifting in tight spots like mold repair areas. They save floor space by swinging loads in and out.

Tailoring your overhead bridge crane system with these considerations helps you make the most of your workshop space and keeps your mold handling efficient and safe.

Special Crane Attachments for Irregular Load Handling

Vacuum Lifters and Magnetic Pads

Handling molds isn't always as simple as hooking them up and lifting. Many molds have irregular shapes, uneven weight distribution, or delicate surfaces that need extra care. Special attachments make a big difference in safely managing these challenges.

Flat mold plates or inserts can be handled with vacuum lifters or magnets, especially when hooks or clamps aren't practical.

- Vacuum lifters use suction to hold the mold's surface without causing damage.

- Magnetic pads are effective for steel molds, providing strong grip without physical clamps.

- Both systems speed up handling by reducing setup time.

Lifting Beams and Spreader Bars

When molds are large or have multiple lifting points, lifting beams and spreader bars help distribute the load evenly. This prevents stress on any single point and keeps the mold balanced during the lift.

- Designed to fit specific mold shapes and lifting requirements.

- Help avoid deformation or damage by supporting the mold across multiple points.

- Improve safety by reducing the risk of swinging or tipping.

Mold Clamps and Mechanical Grippers

For molds that can't be lifted by hooks alone, clamps and grippers hold the load securely without slipping.

- Clamps are custom-sized to grip mold edges firmly without damaging surfaces.

- Mechanical grippers can adjust automatically for different mold profiles.

- Ideal for irregular or asymmetrical molds that require secure handling.

Rotating Trolleys and Motorized Tilters

Often, molds need to be rotated or tilted during installation, maintenance, or inspection.

- Rotating trolleys allow smooth 360-degree rotation along the crane runway.

- Motorized tilters provide controlled tilting angles, making it easier to access different mold sides.

- These features improve precision and reduce manual labor risks.

Custom Suspension Systems

To reduce sway and improve control during lifting, some molds require specially designed suspension systems.

- These systems stabilize the load and absorb shocks from crane movement.

- Useful in workshops with narrow aisles or where precise placement is critical.

- Enhance safety for both operators and molds.

Using the right attachments ensures your molds are handled safely, efficiently, and without damage—even when their shapes or weights aren't straightforward.

Smart Features and Automation Options

Modern crane systems can be equipped with smart features and automation to make mold handling easier, safer, and more efficient. Here's a closer look at some useful technologies:

Anti-Sway Control

Swaying loads can be dangerous and make precise positioning difficult, especially in tight spaces.

- Anti-sway systems use sensors and control algorithms to minimize load swing.

- This results in smoother starts and stops, better control, and safer handling.

- Essential when molds need to be positioned accurately near machines or in narrow aisles.

Variable Frequency Drives (VFDs)

VFDs allow smooth, adjustable crane speeds for both lifting and travel motions.

- Operators can slow down movements for fine positioning or speed up for transport.

- Reduces mechanical stress on crane components and molds.

- Enhances safety by avoiding sudden jerks or stops.

PLC and Semi-Automated Systems

Programmable Logic Controllers (PLCs) can automate repetitive tasks like mold transfers or position holds.

- Ideal for plants with high production volumes and consistent workflows.

- Reduces operator fatigue and errors.

- Can be programmed for specific lifting sequences or safety protocols.

Integration with Mold Handling and CNC Systems

For full production line efficiency, cranes can connect with mold handling and CNC machine controls.

- Enables synchronized operations, where molds are moved automatically between stations.

- Improves throughput and reduces manual intervention.

- Supports real-time monitoring and diagnostics to prevent downtime.

Remote Pendant or Wireless Control Systems

These controls give operators flexibility to move around the workspace while operating the crane. Wireless systems improve visibility and safety by allowing the operator to choose the best vantage point when lifting or positioning molds.

- Operators can control all crane functions from a distance.

- Improves precision by allowing clear views of the load and surroundings.

- Reduces the risk of accidents caused by limited line of sight.

Incorporating these smart and automated features helps plastic manufacturers handle molds more reliably, safely, and efficiently—saving time and reducing costs.

Applications and Use Cases

Understanding how customized crane solutions work in actual plastic manufacturing settings can help you visualize their benefits. Here are some practical examples:

Case 1: 20-Ton Double Girder Crane with Rotating Trolley in Automotive Injection Mold Hall

In a busy automotive plant, a heavy 20-ton double girder crane handles large injection molds used for engine parts and body panels. The crane is equipped with a rotating trolley that allows operators to precisely turn molds during installation or maintenance without having to reposition the entire crane. This setup improves safety and speeds up the mold change process in a high-volume environment.

Case 2: Jib Crane with 3-Ton Chain Hoist in Mold Repair Zone

A plastic factory's mold repair area uses a jib crane with a 3-ton chain hoist to lift and move molds quickly during servicing. The jib crane's compact footprint fits neatly in a tight repair bay, giving workers easy access to molds without taking up valuable floor space. This arrangement allows fast, safe lifting and repositioning of molds during repair or tooling changes.

Case 3: Outdoor Gantry Crane with Vacuum Lifter for Flat Compression Mold Plates

For large, flat compression mold plates stored outdoors, a gantry crane equipped with a vacuum lifter is used to pick up and move these molds gently and efficiently. The vacuum lifter grips the flat surface without damaging the mold, while the gantry crane's mobility provides coverage over a wide outdoor area. This combination is ideal for handling bulky molds in environments where overhead cranes are not practical.

Safety, Maintenance, and Support

When handling heavy and irregular molds, safety should always come first. It's important to select cranes with a 20–30% safety margin above the mold's actual weight to prevent overloading.

- Use load limiters and emergency stop systems to protect both operators and equipment.

- Make sure all operators are properly trained to handle the cranes safely.

- Regular maintenance is essential—check hoists, rotating parts, and lifting accessories often to avoid unexpected failures.

- Work with suppliers who offer reliable after-sales support, quick access to spare parts, and remote diagnostics to keep your crane system running smoothly.

Send Us An Inquiry for Crane for Your Facility

Custom-designed cranes make a real difference in plastic mold handling. They improve efficiency, boost safety, and streamline workflow by addressing the specific challenges of heavy and irregular molds. Early collaboration with crane specialists during your plant design or upgrade phase helps ensure the best fit for your production needs.

If you're a plastic manufacturer, sharing your mold specifications and plant layout details can help us design the ideal crane solution for you. We offer free design consultations and layout proposals to integrate cranes seamlessly into your workflow. Reach out today to get started!

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch