Advanced Cranes & Smart Hoist | Electric Crane & Electric Hoist

Advanced overhead cranes with smart electric hoists for sale,designed based on European Standards, a cost-effective substitution of Demag Hoist and Crane.

Category: Euro Hoist Crane

Your Trusted Advanced Overhead Crane and Electric Hoist Manufacturer & Supplier

Advanced Cranes & Smart Hoist, Custom Electric Cranes & Electric Hoists

Advanced overhead cranes with smart electric hoists for sale. Custom electric cranes & electric hoists designed based on European Standards, a cost-effective substitution of Demag overhead crane & electric hoist.

Intelligent Crane with Advanced Crane Design with Smart Features

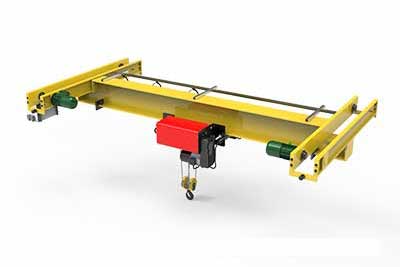

Double girder overhead crane with rotary trolley for sale

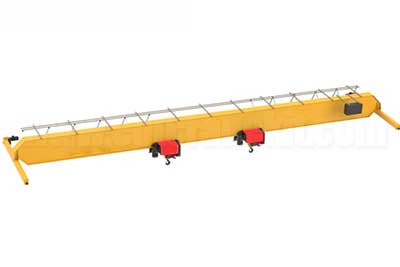

Double girder gantry cranes with intelligent hoists including main hoist and auxialiry

Intelligent Crane and Smart Hoist Parts and Components

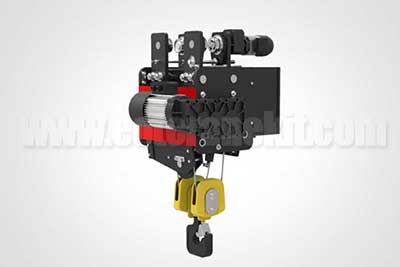

NR mode standard headroom electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

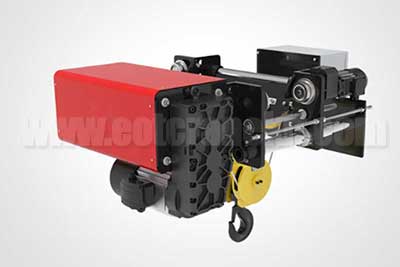

NR mode low headroom electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

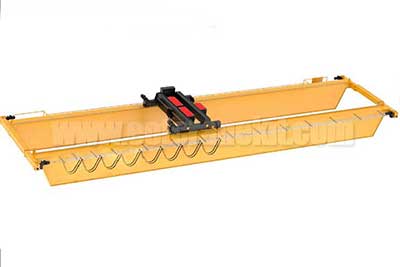

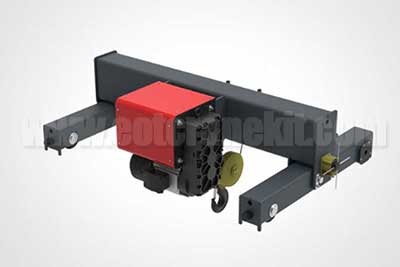

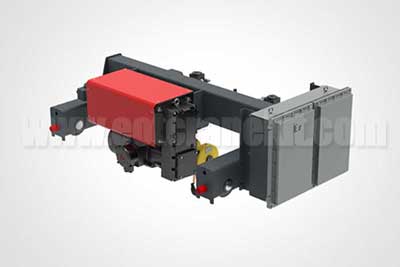

NRT crab electric hoist

Lifting capacity: 3t~80t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Double Girder Cranes

Explosion Proof Electric Wire Rope Hoists

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

BNR low headroom explosion-proof electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

BNRT crab model explosion-proof electric hoist

Lifting capacity: 3t~30t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Double Girder Cranes

Main Parts of Advanced Cranes

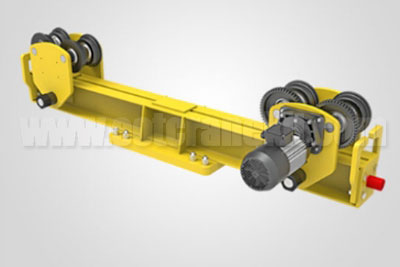

Modular End Carriage

Flexible Design , Easy Assembly, Wide Applications

The various combinations of 2 wheels,4 wheels,8 wheels, and 16 wheels will be satisfied withdifferent wheel pressure.

The various combinations of end carriage and main girder are easily adapted to different workshop space.

Top running single girder crane end carriage

Underhung single girder crane end carriage

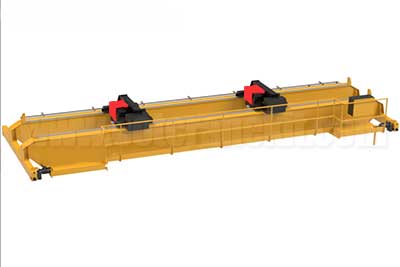

Top running double girder crane end carriage

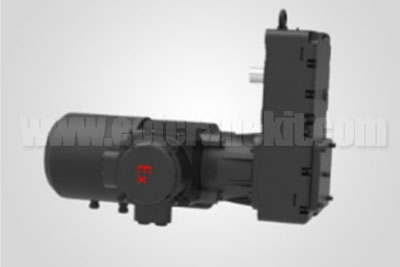

Gear Motor

Silent technology ,enjoy handling.We lead the way of drive for cranes.

You will enjoy silent handling with our new technology of drive.We advocate energy saving with our new technology of drive.

Electric motor

3-in-1 electric motor

Driven electric hoist

Explosion proof motor

Crane Wheels, Rope Guide and Pulley

crane wheel group

driven wheel

wire rope guide

Pulley

Electrical Panel

electrical panel

electrical panel

electrical panel

electrical panel

Smart Features of Advanced Overhead Crane and Electric Hoists

Enhanced speed flexibility

Consistent peak performance

Increased productivity

Efficient time utilization

Quicker hoisting for lighter loads

Precision in movement

Accurate load control

Prevention of inadvertent acceleration

Applicable to hoist, trolley, and crane functions

Adjustable speed range: 1% to 99% of maximum

Ensures precise load positioning through reduced and predefined maximum speeds for all operations.

Slack rope prevention

Minimizes the risk of damage to crossbeams, ropes, slings, and sheaves

Optimizes load handling and loading cycles

Enhances productivity and safety

Automatically halts the lowering movement upon ground contact.

Inching

Ensures precise load positioning

Prevents collisions

Applicable to hoist, trolley, and crane movements

Enhances overall safety

Achieves accurate load positioning in predefined increments between 2 and 100 mm for hoist, trolley, and crane operations.

Restricted load

Safeguards the building structure from overloading

Establishes sturdy, secure boundaries for load areas

Ensures strict adherence to load restrictions during cross and long travel.

Sway control

Achieves maximum speed

Minimizes load sway

Enhances accuracy in load positioning

Reduces the risk of damage and injury

Controls load sway during cross and long travel.

Load floating

Extends the service life of brakes, steel construction, crane runway, mechanical components, etc.

Ensures safer and gentler load handling

Provides protection for fragile loads

Enables a faster and smoother restart of the hoisting or lowering process when the brake is open.

Shock load prevention

Extends the service life of steel construction, crane runway, ropes, crossbeams, and slings

Ensures safer and stabilized load handling

Provides protection for fragile loads

Enables smooth load lifting through reduced hoisting speed.

Tandem

Achieves synchronized start/stop of hoisting and cross travel

Enables simultaneous control of up to four hoists on a bridge

Facilitates load summation and high-safety operation

Allows simultaneous start and stop of hoist movements and cross travel for up to four hoists in tandem.

Synchronization

Continuously monitored synchronization, even with asymmetrical loads

Reduces the risk of accidents

Enhances productivity and safety

Allows simultaneous lifting of several hoists on a bridge, even with asymmetrical loads.

Ensures high operational safety

Facilitates simultaneous long travel and hoisting movements

Achieves synchronized lifting and lowering

Provides anti collision safety

Incorporates frequency inverter features and overload protection

Allows simultaneous long and cross travel, including lifting and lowering.

Modular Crane Design

Modular crane for light and medium material handling

Easy and quick manufacutring and assembly

Standard parts for easy maintenace

Processed Crane Design for Heavy & Special Application

Ensured safety, efficiency and durability

Modular design + processed design for efficient and economical solution

Smart Crane Features and Benifits for Your Material Handling Operations

Smart cranes are designed to enhance precision, safety, efficiency, and versatility, giving operators full control over lifting operations while protecting both loads and equipment. These advanced features help handle delicate, heavy, or oversized loads safely and efficiently across varied industrial tasks.

Key Features and Benefits:

- Extended Speed Range: Flexible speed adjustment for efficiency and precise handling.

- Micro Speed: Extremely slow, controlled movements for delicate loads.

- Slack Rope Prevention: Maintains rope tension, preventing swinging and instability.

- Inching: Fine, incremental movements for accurate load placement.

- Restricted Load: Limits maximum capacity to ensure safety and protect equipment.

- Sway Control: Reduces load swinging for safer, more precise operation.

- Load Floating: Keeps consistent load height despite weight variations.

- Shock Load Prevention: Absorbs sudden jolts to protect crane and load.

- Tandem Synchronization / Cranes in Tandem: Coordinated operation of multiple cranes for lifting oversized or heavy loads efficiently.

Extended Speed Range:

This feature allows the crane to operate within an extended speed range. It provides flexibility in adjusting the speed of crane movements, catering to different operational requirements.

- The Extended Speed Range feature is designed to provide the crane with a broader range of operating speeds. Traditional cranes typically have fixed speed settings, but with the Extended Speed Range feature, the crane can operate at varying speeds within a wider spectrum.

- Flexibility in Speed Adjustment: This feature offers a high degree of flexibility in adjusting the speed of different crane movements. These movements can include lifting, lowering, trolley travel, and bridge travel. The crane operator has the ability to choose a speed that is most suitable for the specific task at hand.

- Adaptability to Operational Requirements: The primary advantage of the Extended Speed Range is its adaptability to diverse operational requirements. Depending on the nature of the load, the precision needed, and the overall operational conditions, the crane operator can select an optimal speed setting.

- Enhanced Precision and Safety: In applications where precision is crucial, such as placing delicate or sensitive loads, the operator can utilize slower speeds to ensure accurate positioning. Conversely, when efficiency is a priority, faster speeds can be employed for tasks that do not require the same level of precision.

- Versatility in Crane Operations: The ability to operate within an extended speed range adds to the versatility of the crane. This is particularly valuable in industrial settings where tasks can vary widely, and the crane needs to adapt to different scenarios.

- Improved Efficiency: By allowing for variable speed control, the Extended Speed Range feature contributes to improved operational efficiency. The crane can perform tasks more effectively, and the operator has the tools to optimize speed based on the specific requirements of each lifting operation.

- User Control: The feature is typically controlled by the crane operator through the crane's control system. The operator can seamlessly adjust the speed settings based on real-time needs, making the crane more responsive and user-friendly.

In summary, the Extended Speed Range feature empowers crane operators with the ability to fine-tune the speed of crane movements, offering a versatile solution that enhances precision, safety, and overall operational efficiency in a variety of industrial applications.

Micro Speed:

Micro speed refers to the ability of the crane to move at extremely slow and controlled speeds. This precision is beneficial when handling delicate or sensitive loads that require careful positioning.

- Micro Speed is a specialized feature that allows the crane to move at extremely slow and controlled speeds. Unlike standard speed settings, which may still be relatively fast for delicate operations, Micro Speed provides a level of precision and control that is essential when handling sensitive loads or when precise positioning is required.

- Extremely Slow Movements: The Micro Speed feature enables the crane to perform movements at a fraction of its normal operating speed. This is particularly beneficial in situations where even the slightest abrupt movement could have a significant impact on the load or the operation.

- Handling Delicate or Sensitive Loads: The primary use case for Micro Speed is in handling delicate or sensitive loads. Examples include fragile materials, precision machinery, or components that require careful and controlled positioning. By allowing the crane to move at micro speeds, operators can ensure a smooth and gradual approach, minimizing the risk of damage to the load.

- Positioning Accuracy: Micro Speed is especially valuable when it comes to achieving precise positioning. In scenarios where the load must be accurately placed or aligned, the crane operator can utilize Micro Speed to make minute adjustments, ensuring that the load is positioned with the utmost accuracy.

- Enhanced Safety: The slow and controlled movements provided by Micro Speed contribute to enhanced safety, both for the load being lifted and for the surrounding environment. This feature minimizes the risk of sudden shifts or swings, reducing the likelihood of accidents or damage during the lifting process.

- User-Controlled: Typically, the Micro Speed feature is user-controlled, allowing the crane operator to engage this mode as needed. The operator can activate Micro Speed when approaching a critical phase of the operation that requires heightened precision and control.

- Versatility in Operations: While Micro Speed is crucial for delicate operations, it also adds versatility to the crane's capabilities. The crane can seamlessly transition between standard operating speeds and Micro Speed, adapting to the specific requirements of different tasks.

In summary, Micro Speed is a precision-oriented feature that enhances the crane's ability to handle delicate loads and achieve accurate positioning. It provides crane operators with the necessary tools to perform intricate operations with a high level of control and safety.

Slack Rope Prevention:

Slack rope prevention is a safety feature that ensures there is no slack or loose rope during crane operations. This helps prevent accidents or load instability caused by slack in the lifting mechanism.

Slack Rope Prevention is a safety feature designed to ensure that there is no slack or loose rope in the lifting mechanism during crane operations. The presence of slack in the rope can lead to a loss of control, instability in load handling, and increased risk of accidents. The Slack Rope Prevention feature is implemented to mitigate these risks and enhance overall safety.

- Constant Tension Monitoring: This feature involves constant monitoring of the tension in the lifting rope. The crane's control system is equipped with sensors or mechanisms that detect any slackening of the rope in real-time.

- Immediate Response to Slackening: If the system detects any slack or loosening of the rope, the Slack Rope Prevention feature triggers an immediate response. This response may include activating brakes, halting movements, or taking corrective actions to eliminate the slack and restore tension to the lifting rope.

- Prevention of Load Swinging: Slack rope not only poses a risk of load dropping but can also lead to uncontrolled swinging of the load. The Slack Rope Prevention feature helps prevent such swinging motions, which could be dangerous, especially in confined or busy work areas.

- Emergency Stop Functionality: In cases where slack is detected and poses an imminent risk, the Slack Rope Prevention feature may initiate an emergency stop, bringing all crane movements to a halt to prevent further complications.

- Integration with Load Monitoring: Slack Rope Prevention is often integrated with load monitoring systems. This ensures that not only is the rope tension monitored, but the system also takes into account the weight of the load being lifted to make real-time adjustments.

- Compliance with Safety Standards: Implementation of Slack Rope Prevention is in line with safety standards and regulations. It reflects a proactive approach to minimizing the risk of accidents associated with slack in the lifting mechanism.

- Operator Alerts: In addition to automated responses, the crane operator may receive alerts or notifications when the Slack Rope Prevention feature is activated. This keeps the operator informed about the status of the lifting mechanism and encourages swift corrective actions if needed.

In summary, Slack Rope Prevention is a critical safety feature that actively monitors and prevents the occurrence of slack or loose rope during crane operations. By ensuring constant tension and immediate response to any slackening, this feature plays a crucial role in preventing accidents, load instability, and enhancing overall safety in crane operations.

Inching:

Inching is a control mechanism that allows the crane operator to make very small, incremental movements. This is particularly useful for fine-tuning the crane's position when dealing with precise load placement.

- Precise Control: Inching provides the crane operator with a high level of precision in controlling the crane's movements. Instead of relying on larger, standard movements, the operator can make minute adjustments to ensure the accurate positioning of the load.

- Step-by-Step Movement: The Inching feature allows the crane to move in a step-by-step fashion. This means that the crane can be advanced or retracted in small increments, providing the operator with fine control over the crane's positioning.

- Critical for Delicate Operations: Inching is especially crucial in delicate operations where the load requires careful handling and precise placement. Examples include placing a load on a narrow surface, aligning components in manufacturing processes, or handling fragile materials.

- Adaptability to Varied Conditions: The ability to make small and controlled movements is valuable in varied operational conditions. Whether the crane is navigating through tight spaces, avoiding obstacles, or positioning a load with precision, Inching allows the operator to adapt to the specific requirements of the task.

- Reduced Risk of Overcorrection: Inching minimizes the risk of overcorrection, which can be a concern when dealing with sensitive or high-precision tasks. The operator can make gradual adjustments, reducing the likelihood of overshooting the desired position.

- Enhanced Operator Confidence: With Inching, the crane operator gains confidence in handling challenging tasks that demand a high degree of accuracy. The feature empowers operators to achieve optimal load positioning even in intricate or demanding work environments.

- Integration with Other Control Features: Inching is often integrated with other control features, allowing seamless transitions between standard movements and precise inching. This integration enhances the overall control and versatility of the crane.

- User-Friendly Operation: The Inching feature is typically designed for user-friendly operation. Crane operators can engage Inching mode easily and intuitively, making it a practical tool in various crane operations.

In summary, Inching is a valuable feature that provides crane operators with the capability to make small, incremental movements, ensuring precise load placement and alignment. This control mechanism is essential for tasks that require a high level of accuracy and adaptability to varied operational conditions.

Restricted Load:

The restricted load feature imposes limitations on the maximum load capacity the crane can handle. This helps prevent overloading and ensures that the crane operates within its specified limits for safety and equipment longevity.

- The Restricted Load feature is a safety mechanism that imposes limitations on the maximum load capacity the crane can handle. This feature is designed to prevent overloading, ensuring that the crane operates within its specified limits for safety and equipment longevity.

- Maximum Load Capacity Setting: The crane operator can set a maximum load capacity within the crane's control system. This setting represents the maximum weight that the crane is authorized to lift. It takes into account the crane's structural integrity, components, and the load-bearing capacity of the lifting mechanism.

- Automatic Load Monitoring: The Restricted Load feature continuously monitors the weight of the load being lifted. If the weight exceeds the pre-set maximum load capacity, the feature activates and takes appropriate actions to prevent the crane from lifting the excessive load.

- Safety Compliance: Implementation of the Restricted Load feature aligns with safety standards and regulations. It serves as a proactive measure to avoid overloading situations, which can lead to equipment failure, structural damage, or accidents.

- Prevention of Structural Strain: Overloading can subject the crane's structure and components to excessive stress, potentially leading to structural strain and damage. The Restricted Load feature helps prevent these issues by enforcing load limitations.

- Alerts and Notifications: When the Restricted Load feature is activated due to an overload condition, it may generate alerts or notifications for the crane operator. This provides immediate feedback, allowing the operator to take corrective actions and ensure safe crane operation.

- Enhanced Equipment Longevity: By preventing overloading, the Restricted Load feature contributes to the longevity of the crane's components and overall equipment. It reduces the likelihood of premature wear and tear, extending the operational life of the crane.

- Customizable Settings: The maximum load capacity setting is often customizable based on the specific requirements of different tasks. This allows the crane operator to adapt the crane's capabilities to the unique demands of various lifting operations.

- Integration with Load Monitoring Systems: The Restricted Load feature is often integrated with broader load monitoring systems. This integration enhances the accuracy of load measurements and ensures that the crane's load capacity is dynamically adjusted based on real-time conditions.

In summary, the Restricted Load feature is a safety-oriented mechanism that prevents overloading, safeguarding the crane's structural integrity and ensuring compliance with safety standards. It is an essential component of crane intelligence that promotes safe and efficient lifting operations.

Sway Control:

Sway control is a technology designed to minimize the swinging or swaying of the load during lifting or movement. This feature enhances safety and precision, especially when dealing with heavy or sensitive loads.

- Sway Control is a technology implemented to minimize the swinging or swaying of the load during the lifting or movement process. This feature is particularly beneficial when dealing with heavy or sensitive loads, enhancing safety and precision in crane operations.

- Real-Time Monitoring: Sway Control involves real-time monitoring of the load's movements as it is lifted or transported. The crane's control system utilizes sensors and feedback mechanisms to detect any swaying or swinging of the load.

- Automated Corrections: Upon detecting sway or swing, the Sway Control feature automatically initiates corrective actions. These actions may include adjusting the speed and direction of the crane's movements, applying counterweights, or employing other mechanisms to stabilize the load.

- Reduced Risk of Load Collisions: Sway Control is instrumental in reducing the risk of collisions between the load and surrounding structures or obstacles. By minimizing swaying, the feature ensures that the load follows a controlled and predictable trajectory, preventing unintended contact.

- Enhanced Safety: The primary goal of Sway Control is to enhance safety in crane operations. Uncontrolled swinging of a load can pose significant safety risks to both personnel and equipment. Sway Control mitigates these risks by maintaining load stability throughout the lifting and movement process.

- Optimized Load Placement: For tasks that require precise load placement, such as placing a load on a specific point or aligning components, Sway Control contributes to achieving optimal positioning. The reduction in swaying allows for more accurate and controlled load placement.

- Adaptability to Different Conditions: Sway Control is adaptable to various operational conditions. Whether the crane is lifting loads in confined spaces, navigating through obstacles, or working with irregularly shaped loads, the technology adjusts to ensure stable load handling.

- Integration with Other Crane Features: Sway Control is often integrated with other crane features, such as load sensors and automation systems. This integration enhances the overall coordination of crane movements and contributes to a seamless and controlled lifting process.

- User-Friendly Operation: While Sway Control operates autonomously, it is designed to be user-friendly for crane operators. The operator may have the ability to adjust settings or activate/deactivate the feature based on the specific requirements of the task.

In summary, Sway Control is a critical technology that minimizes load swinging or swaying during crane operations. By enhancing safety, precision, and load stability, this feature is essential for tasks involving heavy or sensitive loads where controlled movements are paramount.

Load Floating:

Load floating allows the crane to maintain a consistent load height regardless of variations in the load weight. This feature is useful in applications where maintaining a constant height is critical.

- Load Floating is a feature that allows the crane to maintain a consistent load height regardless of variations in the load weight. This technology is particularly useful in applications where maintaining a constant height is critical for the success of the operation.

- Automatic Load Height Adjustment: Load Floating involves an automatic adjustment mechanism that continuously monitors the load weight. As the load weight changes, the system adjusts the crane's lifting mechanism to ensure that the load maintains a constant height above the ground.

- Stability During Lifting and Lowering: The primary purpose of Load Floating is to provide stability during both the lifting and lowering phases of crane operations. This is particularly important when working with sensitive or precision-loaded materials that require a uniform and controlled approach.

- Prevention of Unwanted Variations: Without Load Floating, changes in load weight could result in unwanted variations in load height. This could lead to challenges in load placement, potential collisions, or difficulties in achieving precise alignment. Load Floating mitigates these issues by actively maintaining a consistent load height.

- Ideal for Delicate Operations: Load Floating is especially beneficial in delicate operations where maintaining the integrity of the load is crucial. Examples include the handling of fragile or sensitive materials that require a steady and controlled approach throughout the lifting and lowering process.

- Integration with Load Sensors: Load Floating is often integrated with load sensors that provide real-time feedback on the weight of the load. This integration ensures accurate and immediate adjustments to the lifting mechanism, allowing for seamless load height maintenance.

- Enhanced Precision in Load Placement: For tasks that demand precision in load placement, such as placing a load on a specific platform or aligning components during manufacturing, Load Floating contributes to achieving optimal precision by maintaining a constant load height.

- Efficient Operation in Variable Load Conditions: Load Floating allows the crane to operate efficiently in conditions where the load weight may vary, such as in manufacturing processes where different components are lifted consecutively with varying weights.

- Safety Enhancement: By maintaining a consistent load height, Load Floating enhances overall safety in crane operations. It reduces the risk of unexpected changes in load dynamics, contributing to a safer working environment.

In summary, Load Floating is a valuable feature that ensures a constant load height despite variations in load weight. This technology is particularly advantageous in applications where precision, stability, and consistency in load handling are critical requirements.

Shock Load Prevention:

Shock load prevention is a safety feature that protects the crane and the load from sudden jolts or impacts. It helps absorb and mitigate shocks, reducing the risk of equipment damage or load instability.

- Shock Load Prevention is a safety feature implemented to protect both the crane and the load from sudden jolts or impacts during lifting or movement. This feature is designed to absorb and mitigate shocks, reducing the risk of equipment damage, structural strain, or load instability.

- Real-Time Monitoring: Shock Load Prevention involves real-time monitoring of the load dynamics, including acceleration and deceleration. The crane's control system utilizes sensors and feedback mechanisms to detect sudden changes in load conditions that could lead to shocks.

- Automatic Adjustment of Lifting Mechanism: Upon detecting a potential shock or impact, the Shock Load Prevention feature initiates automatic adjustments to the crane's lifting mechanism. These adjustments may include controlled deceleration, changes in braking force, or other measures to absorb and reduce the impact forces.

- Protection Against Structural Damage: Sudden shocks or impacts can subject the crane's structure and components to excessive stress, leading to structural damage over time. Shock Load Prevention helps prevent these issues by actively mitigating the forces associated with sudden load changes.

- Load Stability: In addition to protecting the crane, Shock Load Prevention contributes to load stability. By minimizing sudden movements or shocks, the feature ensures that the load remains secure and stable throughout the lifting and movement process.

- Enhanced Safety for Personnel: The primary objective of Shock Load Prevention is to enhance safety for both crane operators and personnel working in the vicinity. Sudden shocks can pose significant safety risks, and this feature helps minimize those risks by maintaining controlled load dynamics.

- Intelligent Braking Systems: Shock Load Prevention often involves the use of intelligent braking systems. These systems may include adjustable braking force or dynamic braking capabilities that respond to real-time load conditions.

- Customizable Settings: The sensitivity and response of the Shock Load Prevention feature are often customizable based on the specific requirements of different tasks. This allows crane operators to adapt the feature to the unique demands of various lifting operations.

- Integration with Load Monitoring: Shock Load Prevention is typically integrated with load monitoring systems. This integration ensures that the feature responds dynamically to changes in load conditions, providing effective shock prevention across a range of lifting scenarios.

In summary, Shock Load Prevention is a crucial safety feature that actively monitors and prevents the occurrence of sudden shocks or impacts during crane operations. By absorbing and mitigating these forces, the feature contributes to the overall safety, stability, and longevity of the crane and the loads it handles.

Tandem Synchronization

Tandem synchronization involves the coordinated operation of multiple cranes working together. This feature ensures that multiple cranes move in sync, allowing for the lifting and movement of larger and more complex loads.

- Tandem Synchronization is a feature that facilitates the coordinated operation of multiple cranes working together. This technology ensures that two or more cranes move in sync, allowing for the lifting and movement of larger and more complex loads that may exceed the capacity of a single crane.

- Coordinated Movement: In Tandem Synchronization, the cranes operate in tandem, meaning they move simultaneously and in coordination with each other. This synchronization is crucial for maintaining stability, balance, and precision when lifting oversized or heavy loads that require the combined capabilities of multiple cranes.

- Common Control System: Tandem Synchronization typically involves a common control system that allows the crane operator to control all synchronized cranes through a centralized interface. This centralized control ensures that the cranes move in harmony, responding to the operator's commands as a unified system.

- Load Sharing: The feature includes load-sharing mechanisms, distributing the weight of the load evenly between the synchronized cranes. This ensures that each crane contributes proportionally to the lifting effort, preventing uneven loading and potential strain on individual cranes.

- Optimized Lift Capacity: Tandem Synchronization allows for the optimization of lift capacity by combining the capabilities of multiple cranes. This is particularly beneficial in scenarios where a single crane may not have sufficient capacity to lift a large or heavy load independently.

- Versatility in Load Handling: The synchronized movement of multiple cranes enhances versatility in load handling. It enables the lifting, positioning, and movement of loads with complex shapes or dimensions that may be challenging for a single crane to manage effectively.

- Increased Efficiency: When working with large loads, Tandem Synchronization increases operational efficiency by streamlining the lifting process. The coordinated movement of cranes reduces the time and effort required to complete complex lifting tasks.

- Safety Considerations: Tandem Synchronization includes safety features to ensure that the synchronized operation is performed within safe parameters. This may involve real-time monitoring, emergency stop functionalities, and communication systems to maintain safe crane operations.

- Adaptability to Varied Conditions: Tandem Synchronization is adaptable to various operational conditions, allowing for synchronized crane movements in diverse settings, such as construction sites, manufacturing facilities, or shipyards.

- Integration with Automation: Tandem Synchronization is often integrated with automation systems, allowing for precise and automated control of synchronized crane movements. Automation enhances accuracy and repeatability in the handling of large and complex loads.

In summary, Tandem Synchronization is a sophisticated feature that enables the coordinated operation of multiple cranes, optimizing lift capacity and increasing efficiency in handling larger and more complex loads. This feature is particularly valuable in industries where heavy and oversized loads are commonplace.

Smart Elecrtric Cranes in Tandem

This feature specifically addresses the simultaneous operation of multiple cranes to lift and transport heavy or oversized loads. Cranes in tandem work together, often synchronized, to achieve a common lifting goal.

- The "Cranes in Tandem" feature specifically addresses the simultaneous operation of multiple cranes to lift and transport heavy or oversized loads. This advanced feature allows multiple cranes to work together, often in synchronization, to achieve a common lifting goal that may exceed the capacity of a single crane.

- Coordinated Lifting: Cranes in Tandem involve the coordinated lifting of a single load by multiple cranes. These cranes work together to ensure that the load is lifted evenly and with precise control. Coordination is crucial for maintaining stability and preventing uneven loading.

- Common Control System: The feature often utilizes a common control system that enables the crane operator to control all cranes involved in the tandem operation through a centralized interface. This centralized control ensures that the cranes move in harmony, responding to the operator's commands as a unified system.

- Load Distribution: Cranes in Tandem typically include load distribution mechanisms to ensure that the weight of the load is evenly distributed among the participating cranes. This prevents individual cranes from bearing excessive loads and helps maintain balance during the lifting process.

- Enhanced Lift Capacity: The primary advantage of Cranes in Tandem is the ability to achieve an enhanced lift capacity. By combining the lifting capabilities of multiple cranes, this feature allows for the handling of heavier loads that would be beyond the capacity of a single crane.

- Versatility in Load Handling: The synchronized operation of multiple cranes enhances versatility in load handling. It enables the lifting and transportation of loads with complex shapes, large dimensions, or significant weights that may pose challenges for a single crane.

- Efficient and Time-Saving: Cranes in Tandem contribute to operational efficiency and time savings, especially when dealing with large and time-sensitive projects. The simultaneous operation of multiple cranes allows for quicker completion of lifting tasks.

- Safety Features: Safety considerations are integral to Cranes in Tandem. The feature includes safety mechanisms, such as real-time monitoring, emergency stop functionalities, and communication systems, to ensure that the synchronized operation is performed within safe parameters.

- Adaptability to Varied Conditions: Cranes in Tandem are adaptable to various operational conditions and settings, making them suitable for construction sites, manufacturing facilities, shipyards, and other environments where heavy or oversized loads need to be lifted.

- Integration with Automation: The feature may be integrated with automation systems, allowing for precise and automated control of synchronized crane movements. Automation enhances accuracy and repeatability in the handling of large and complex loads.

In summary, Cranes in Tandem is an advanced feature that allows multiple cranes to work together in a synchronized manner, expanding lift capacity and improving efficiency in handling heavy or oversized loads. This feature is particularly valuable in industries where large-scale lifting operations are common.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch