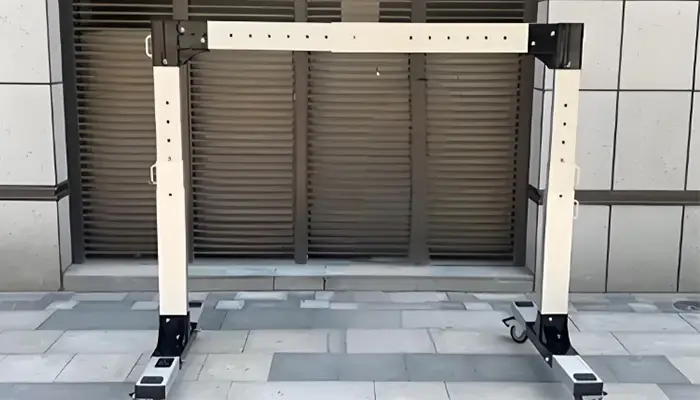

Space-Limited Workshop Cranes, Adjustable Gantry Crane for Sale

Adjutable gantry crane for space limited workshops.Check buyer’s guide to adjustable gantry cranes for space-limited workshops to save your space!

Category: Featured

Your Trusted Adjustable Gantry Crane Manufacturer & Supplier

Adjustable Gantry Cranes for Small Workshops: How to Choose the Right Portable Lifting Solution

The Complete Buyer's Guide to Adjustable Gantry Cranes for Space-Limited Workshops

Introduction – Why Adjustable Gantry Cranes Are Perfect for Small Spaces

Let's face it—space is tight in most small workshops. Whether you're fixing engines, welding parts, or assembling machines, there's rarely enough room to install a permanent overhead crane. And even if you could, it might not make sense for a job that only comes up now and then.

That's where adjustable gantry cranes come in. They offer a smart, portable way to lift and move heavy items without getting in your way when you don't need them.

Why They Work So Well in Tight Workspaces:

- They're height-adjustable, which means you can set the lifting beam lower when the ceiling is a problem or raise it up when you need more clearance.

- The span can be adjusted too, so if you're working between two benches or inside a small garage bay, you can narrow the footprint without losing the lifting function.

- Most models roll easily on casters, so you can bring the crane to the load, not the other way around.

- Assembly is usually straightforward, especially for lighter aluminum models. Some can be set up by just one person.

These cranes aren't just for lifting engines or compressors either. Plenty of people use them to move molds, tools, fabrication parts, HVAC units, and even pallets of components. If you've ever said, "I just need something simple to lift this without installing a full crane system," you're exactly who this guide is for.

What Makes a Workshop "Space-Limited"?

If you've ever struggled to fit even a ladder between machines, or had to duck under a pipe just to reach a workbench, you're working in a space-limited environment. It's more common than you think—especially in older buildings, converted garages, or compact production shops.

Before choosing any lifting equipment, it's important to look at how space is restricted in your shop—not just where the crane will go, but how it will move and function in your day-to-day work.

Vertical Space Limitations - Height Adjustable Gantry Crane

These are the most common in workshops with low ceilings or overhead systems. You may have the floor space, but height is another story.

- Ceilings under 3 meters (around 10 feet) often limit lifting height.

- HVAC ducting, fire sprinklers, or cable trays may interfere with overhead movement.

- Lighting fixtures or ceiling fans can become obstacles for tall frames.

- Gantry cranes with fixed heights may be too tall to roll in or operate effectively.

If any of this sounds familiar, you'll want a height-adjustable gantry crane—so you can lower the frame when moving and raise it when lifting.

Horizontal Space Limitations - Span Adjustable Gantry Crane Solution

Sometimes the ceiling's fine, but the floor layout is just too tight. You might have narrow aisles, wall-to-wall equipment, or support columns that get in the way.

- Workbenches or machines lined up side by side limit travel width.

- Storage racks or parts bins create obstacles for wide-span cranes.

- Doors, posts, or low-clearance zones can make it hard to turn or roll a standard crane.

- Even when the crane fits, the load may not have room to swing or clear nearby equipment.

In this case, look for a span-adjustable gantry crane, or better yet, a model with beam-center rotation, which keeps the footprint narrow while still allowing full lifting motion.

Combined Vertical and Horizontal Limitations - Span and Height of Adjustable Gantry Crane

Some shops are just tight in every direction. This is especially true in tool rooms, repair stations, or containerized workspaces.

- Ceiling clearance is limited and floor space is cluttered.

- There's barely room to turn around, let alone lift a bulky item.

- Any lifting solution needs to be compact, mobile, and easy to tuck away when not in use.

Here, your best bet is a compact adjustable aluminum gantry crane. These lightweight models are easy to roll in, height and span adjustable, and simple to fold or disassemble after use.

If your space is tight—up, down, or both—there's a crane setup that can still work for you. You just need to match it to your layout before you buy.

Quick Selector: Match Your Space with the Right Gantry Crane Type

When it comes to choosing the right gantry crane, there's no one-size-fits-all—especially in space-constrained workshops. The key is to first identify how your space is limited: is it height, width, or both? Once you understand that, the decision becomes much easier.

If Your Space Is Vertically Limited

A lot of workshops, especially garages or converted spaces, have low ceilings. You might only have 2.4 to 3 meters (8 to 10 feet) of clearance. That's not much room for a full-sized gantry crane—especially if you plan to use a hoist or slings that add extra height.

Recommended solution: Height-adjustable gantry crane

- You can lower the beam to roll the crane through doors or under obstructions.

- Once in place, raise it to gain as much lifting height as the ceiling allows.

- Some models allow incremental adjustments in as little as 100 mm (4 inches).

- Ideal for workshops with overhead piping, HVAC ducts, or storage lofts.

Practical tip: Choose a model with low overall frame height but high lifting clearance under the beam. That gives you better lifting height without wasting space above the beam.

If Your Space Is Horizontally Limited

Some shops have tall ceilings but very little floor room to work with. You might have narrow aisles, equipment packed wall-to-wall, or tight clearances between support columns. In these cases, the challenge is not height—it's how wide your gantry crane can go without getting stuck or blocking access.

Recommended solution: Span-adjustable gantry crane with beam-center rotation

- Adjustable span lets you shorten the width when working between machines.

- Beam-center rotating designs take up less floor space while still allowing lift rotation.

- Great for moving loads across aisles, around workbenches, or between fixed stations.

- Allows positioning the crane directly over the load—even in awkward layouts.

Practical tip: Beam-center rotation gives you the smallest turning radius—a big advantage in cramped shops. Some models even rotate within their own frame footprint.

If Your Space Is Limited Both Vertically and Horizontally

This is often the case in small garages, repair containers, and portable job sites. You don't just lack ceiling height—you also have no room to maneuver a wide crane. When both space directions are tight, every inch counts.

Recommended solution: Compact aluminum adjustable gantry crane

- Lightweight frame makes it easy to roll into tight spots.

- Height and span can both be adjusted to fit your exact space.

- Many models are foldable or break down into components for quick storage.

- Easier to transport if you need to take it from job to job.

Example use case:

A CNC machine shop with a ceiling height of just 2.4 meters and narrow floor paths selected a 1000 lb capacity aluminum adjustable gantry crane. They needed something light enough to move between work areas, tall enough to lift spindles, but short enough to roll under existing ductwork. It was set up in under 30 minutes and stored flat against the wall when not in use.

| Space Type | Recommended Gantry Crane | Why It Works |

|---|---|---|

| Vertical Limit | Height-adjustable gantry crane | Avoids contact with ceiling or obstructions while maximizing lifting height. |

| Horizontal Limit | Span-adjustable gantry crane with beam-center rotation | Fits between machines and tight paths, using minimal floor area. |

| Vertical + Horizontal Limit | Compact aluminum adjustable gantry crane | Lightweight, foldable, and space-efficient for the most restricted workspaces. |

Example: A machine shop with a 2.4-meter ceiling and narrow access paths selected a 1000 lb capacity aluminum adjustable gantry crane for easy setup and compact storage.

Adjustable Steel vs. Aluminum Gantry Cranes

When picking an adjustable gantry crane, one of the biggest choices is the frame material. Steel and aluminum each have their strengths and drawbacks, so understanding these differences will help you get the right crane for your workshop.

Lifting Capacity and Strength

Steel gantry cranes can handle much heavier loads, often up to 10 tons or 4000 pounds and more. They're built tough for heavy-duty industrial jobs where strength and durability are essential. If you're lifting large machinery, engines, or heavy molds regularly, steel is usually the safer bet.

Aluminum gantry cranes, on the other hand, typically support up to around 2000 pounds. They're great for lighter loads—things like small engines, tools, parts, or equipment that needs to be moved around frequently.

Durability and Maintenance

Steel frames are rugged and built to last, but they're heavier and can rust if not properly painted or maintained. They're best suited for environments where the crane stays in place most of the time, such as in manufacturing plants or repair shops.

Aluminum is naturally corrosion-resistant and much lighter, making it a popular choice for workshops where the crane needs to be portable or used outdoors. Because aluminum won't rust, it requires less maintenance, which can save time and money in the long run.

Portability and Setup

Because steel is heavier, these gantry cranes are harder to move around. Setting up a steel gantry crane usually needs two or more people and sometimes tools, especially for the larger capacities.

Aluminum cranes are designed with portability in mind. They can often be assembled by one person and moved easily on caster wheels. This makes them ideal for mobile workshops, service teams, or jobs that require frequent setup and teardown.

Ideal Applications

- Adjustable Steel Gantry Cranes

Best for heavy equipment, permanent or semi-permanent installations, and environments where maximum lifting capacity is a priority. - Adjustable Aluminum Gantry Cranes

Perfect for lighter loads, flexible workspaces, mobile setups, and temporary lifting needs.

Summary Table

| Feature | Adjustable Steel Gantry Crane | Adjustable Aluminum Gantry Crane |

|---|---|---|

| Lifting Capacity | Up to 10 tons (4000+ lb) | Typically up to 2000 lb |

| Durability | High-strength, rugged, requires maintenance | Lightweight, corrosion-resistant, low maintenance |

| Portability | Heavy, less mobile | Easy to move and assemble |

| Setup Time | Usually requires 2 or more people | Often a one-person job |

| Ideal Use | Heavy, permanent setups | Mobile or temporary lifting |

Choosing the Right Adjustable Gantry Crane Capacity

Picking the right lifting capacity for your gantry crane is crucial. Too little, and you risk overloading the crane—never a good idea. Too much, and you might be paying for features you don't actually need.

Adjustable Gantry Crane with 1000 lb Capacity

This is the light-duty option. Great for lifting smaller items like tools, machine parts, and light repair work. If you mostly handle small motors, hand tools, or components that weigh less than half a ton, a 1000 lb capacity crane will usually be enough.

- Perfect for maintenance shops or electronics repair.

- Easy to maneuver and set up, especially aluminum models.

- Ideal if you're looking for portability and quick lifts rather than heavy loads.

Gantry Crane with 2000 lb Capacity

If your work involves slightly heavier machines or equipment, this mid-range capacity is often the sweet spot. It fits well in shops dealing with small fabrication parts, HVAC units, pumps, or motors.

- Can handle more varied workloads without being bulky.

- Suitable for small machine shops and industrial service teams.

- Offers a good balance between lifting power and portability.

Gantry Crane with 4000 lb Capacity

For workshops that handle heavier materials—like large molds, steel dies, or sizeable assemblies—a 4000 lb capacity gantry crane is common. These cranes are usually steel-framed for extra strength and stability.

- Used in manufacturing plants, automotive shops, or heavy repair centers.

- Requires more space and possibly multiple people for setup.

- Designed to handle consistent heavy lifting safely.

Safety Margin: Always Build in Extra Capacity

No matter what your load is, it's important to add a safety margin. A good rule of thumb is to pick a crane with 20 to 25 percent more capacity than your heaviest expected load.

For example, if your maximum load is 1600 pounds, a 2000 lb capacity crane will give you the safety buffer you need. This helps prevent strain on the crane components and protects everyone in your workshop.

Beam-Center Rotating Gantry Cranes: A Smart Design for Tight Floor Space

When floor space is limited, every inch counts. That's why the design of your gantry crane's rotation mechanism can make a big difference.

What Is Beam-Center Rotation?

Beam-center rotating gantry cranes pivot around the middle of the beam rather than at the ends. This means the crane turns within a much smaller footprint.

- The crane swings in a tight circle, requiring less clearance around it.

- It can rotate without the legs getting in the way or needing extra room to turn.

- This makes it easier to work in narrow aisles or congested workspaces.

Why This Matters for Tight Workshops

In many small shops, the aisles are narrow and the equipment is packed close together. Traditional gantry cranes with leg-end rotation need extra space for the legs to swing as the crane turns.

- That extra space isn't always available and can block access or slow down workflow.

- Beam-center rotation keeps the crane more compact during turns.

- It lets operators move loads smoothly without repositioning the entire crane.

How Beam-Center Rotation Compares to Traditional Designs

| Feature | Beam-Center Rotation | Leg-End Rotation |

|---|---|---|

| Turning Radius | Smaller, more compact | Larger, needs more floor space |

| Floor Space Usage | Efficient, ideal for tight aisles | Requires wider clearance |

| Maneuverability | Easier in confined layouts | Can be difficult in narrow spaces |

| Setup Complexity | Slightly more complex design | Simpler but bulkier mechanism |

Key Buying Considerations for Portable Adjustable Gantry Cranes

Buying a portable adjustable gantry crane isn't just about picking the right size or capacity. There are several important factors to consider to make sure the crane works well in your specific workspace and keeps your team safe.

Lifting Capacity

First things first—know your heaviest load. The crane's lifting capacity should comfortably handle the maximum weight you expect to lift, plus a safety margin.

- Don't guess—measure or weigh your heaviest parts or equipment.

- Choose a crane rated at least 20–25% above that weight for safety and longevity.

- Overloading risks damage to the crane and safety hazards.

Height and Span Adjustability

Make sure the crane's adjustable height and span fit within your workshop's dimensions.

- Measure your ceiling height and available floor space carefully.

- Check the minimum and maximum height range of the crane.

- Confirm the adjustable span covers the width you need to work between machines or benches.

Portability

Portability is often why people choose adjustable gantry cranes in the first place. But not all portable cranes are equally easy to move.

- Look for sturdy locking casters that hold the crane in place during lifting.

- Consider the type of flooring in your workspace—smooth concrete, rough shop floors, or uneven surfaces—and choose casters accordingly.

- A crane that rolls smoothly will save time and reduce strain during daily use.

Setup and Storage

If you don't have space to leave the crane set up all the time, easy assembly and compact storage are essential.

- Foldable legs and removable beams make cranes easier to store.

- Tool-free or quick-release parts speed up setup and teardown.

- Some cranes break down small enough to fit in a closet or vehicle for transport.

Material

The crane's frame material affects weight, durability, and maintenance.

- Steel frames provide strength and stability for heavy-duty use but are heavier.

- Aluminum frames are lighter and resist corrosion, making them easier to move and good for outdoor or mobile jobs.

- Choose the material that fits your lifting needs and how often you'll move the crane.

Safety Features

Never overlook safety when selecting a gantry crane.

- Look for brakes on caster wheels to prevent unwanted movement.

- Anti-tip leg designs add stability during lifting and moving.

- Verify that the crane and any included hoists meet CE, ISO, or other recognized safety certifications.

- Check for overload protection features on the hoist.

Hoist Compatibility

The crane should work seamlessly with the hoist you plan to use.

- Confirm the crane's height allows enough headroom for your hoist and load.

- Ensure the beam and trolley system are compatible with manual chain hoists or electric hoists.

- Consider if you'll need a low-headroom hoist for limited vertical space.

Taking the time to review these points will help you pick an adjustable portable gantry crane that fits your shop, your lifting needs, and keeps your workspace safe and efficient.

Portability and Storage for Small Workshop Use

One of the biggest advantages of adjustable portable gantry cranes is their ease of movement and compact design. Small workshops often have limited space—not just for lifting, but also for storing equipment when it's not in use. A crane that's hard to move or takes up too much space can quickly become more of a hassle than a help.

Designed for Easy Movement

- Many adjustable gantry cranes come with heavy-duty caster wheels that roll smoothly across shop floors, whether concrete or painted surfaces.

- Locking casters keep the crane safely in place when you're lifting or working, preventing accidental movement.

- Some models feature swivel casters for better maneuverability around tight corners or cluttered areas.

Space-Saving Storage Options

- Removable beams allow you to take apart the crane quickly, making it easier to store in smaller spots like a corner, closet, or tool room.

- Folding legs are common on lightweight aluminum gantry cranes. They fold inward, reducing the footprint and allowing the crane to fit through narrow doorways or even into vehicles.

- Some gantry cranes break down into manageable parts without tools, making setup and teardown fast and simple.

Perfect for Mobile Service and Shared Workspaces

- Mobile service technicians who travel between job sites benefit from lightweight, foldable cranes that fit in the back of a van or pickup.

- In shared workshops or rental spaces where permanent installations aren't allowed, portable adjustable gantry cranes provide a flexible lifting option without needing fixed infrastructure.

- The ability to roll the crane out of the way or completely disassemble it means you can keep your workspace organized and clutter-free.

Practical Considerations

- When choosing a portable gantry crane, consider the total weight—lighter cranes are easier to move but might have lower capacity.

- Make sure the storage dimensions (folded or disassembled) fit your available space.

- Think about how often you'll need to move or store the crane—if it's daily, quick setup and teardown are essential.

A well-chosen portable adjustable gantry crane can save you valuable workspace, reduce fatigue when moving equipment, and make your lifting jobs safer and more efficient.

Common Mistakes to Avoid When Choosing an Adjustable Gantry Crane

Buying an adjustable gantry crane might seem straightforward, but there are several common pitfalls that can cause headaches down the line. Avoiding these mistakes will save you time, money, and frustration.

Selecting an Oversized Model That Doesn't Fit Your Workshop

- Bigger isn't always better. A crane that's too large for your space can block aisles, doorways, or work areas.

- Measure your workshop carefully—both floor space and ceiling height—before you buy.

- Remember, if the crane can't move around easily, it won't get used as often and might slow down your workflow.

Overlooking Overhead Obstructions

- Low-hanging lights, ductwork, pipes, and sprinklers can interfere with the crane's frame or hoist movement.

- Always check for these before deciding on your crane's maximum height.

- Failing to account for overhead obstacles can lead to costly modifications or, worse, unsafe working conditions.

Choosing a Fixed-Span Model When Your Layout May Change

- Fixed-span cranes have set widths and can't adjust to different work areas.

- If your workshop layout changes or you work on different-sized loads, this can be a big limitation.

- Opt for span-adjustable cranes if you want flexibility to work in multiple spaces or with varying load sizes.

Not Matching Wheel Type to Your Floor Surface

- Casters come in different materials—hard rubber, polyurethane, steel wheels, and more.

- Smooth concrete floors work well with most wheels, but rough or uneven floors need tougher casters to roll smoothly.

- Using the wrong wheel type can make moving the crane difficult, cause damage to floors, or create unsafe conditions.

Forgetting to Account for Future Capacity Needs or Hoist Integration

- It's tempting to buy a crane that fits your current load, but think about future projects or heavier equipment.

- A crane with too little capacity may need replacing sooner than expected.

- Also, make sure the crane's beam and trolley design fit the hoist you plan to use—whether manual or electric.

- Check the maximum hook height and trolley travel to ensure smooth operation.

Avoiding these common mistakes means you'll get a crane that fits your space, works safely, and stays useful for years to come.

Conclusion – Fit the Gantry Crane to Your Workshop, Not the Other Way Around

Adjustable gantry cranes offer a straightforward, flexible solution for workshops and small industrial spaces where traditional overhead cranes just won't fit. They help you lift and move heavy loads without taking up more space than necessary.

Key Takeaways to Remember

- Always match the crane's size to your actual workspace dimensions—both floor area and ceiling height.

- Choose the right lifting capacity based on your heaviest loads, with a safe margin built in.

- Adjustability in height and span is essential to get the most out of a gantry crane in a tight area.

- Beam-center rotating designs help save floor space and improve maneuverability in narrow aisles.

- Aluminum frames offer lightweight, corrosion-resistant options, especially if portability is important.

- Don't forget to factor in how often you'll move, store, or set up the crane when choosing your model.

The right adjustable gantry crane fits your workshop's unique needs—not the other way around. Taking the time to measure, plan, and select carefully means safer lifts, smoother workdays, and equipment that lasts.

Request a Free Crane Sizing and Quote

Choosing the right adjustable gantry crane can be tricky, especially when you need the perfect fit for your unique workspace and lifting needs. That's why getting professional advice can make all the difference.

How We Can Help

Whether you need a 1000 lb capacity, 2000 lb capacity, or up to 4000 lb capacity adjustable gantry crane, we're here to guide you. We offer expert recommendations to make sure you get the safest, most efficient crane for your workshop or job site.

What Information You Should Provide

To give you an accurate quote and the best crane options, we'll need some details from you:

- Ceiling Height: Knowing your maximum vertical clearance helps us suggest cranes with the right height adjustment.

- Working Width: Tell us how wide your workspace is or the span you need between supports or equipment.

- Load Weight: The weight of the heaviest item you plan to lift determines the crane's required capacity.

- Floor Type: Is your floor smooth concrete, rough or uneven? This helps us recommend the right casters for mobility.

What You Can Expect

- A tailored crane recommendation based on your exact needs—steel or aluminum, fixed or adjustable span, and the right lifting capacity.

- Clear guidance on setup, portability, and storage options that fit your shop's size and workflow.

- A detailed quote with all costs upfront—no surprises.

- Support answering any questions you have about installation, maintenance, or customization.

Getting the right crane starts with the right information. If you're ready to find the best adjustable gantry crane for your small workshop or mobile job site, just reach out. We're happy to help you every step of the way.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch