Adjustable Gantry Cranes, Span Adjustable Portale Gantry Crane

Adjutable gantry crane for sale. Explore portable gantry crane types with adjustable spans, i.e., steel & aluminum gantry, for lifting in tight spaces.

Category: Featured

Your Trusted Adjustable Gantry Crane Manufacturer & Supplier

Adjustable Gantry Cranes for Sale

Span Adjustable Portable Gantry Cranes - Adjustable Steel Gantry Crane & Adjustable Aluminum Gantry Cranes

Introduction to Adjustable Gantry Cranes

What Is an Adjustable Gantry Crane?

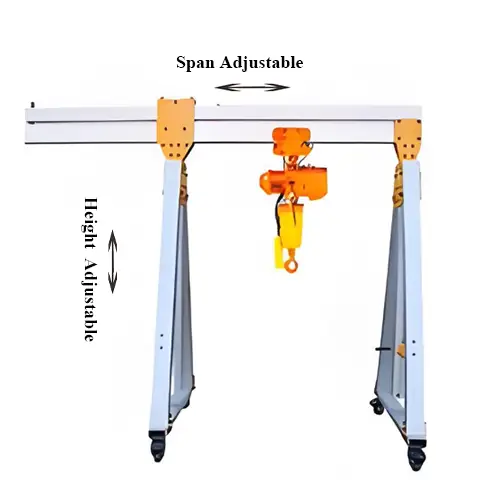

An adjustable gantry crane is a type of mobile crane system designed with the flexibility to modify its height, span, or both. It typically consists of two vertical supports (legs), a horizontal beam (also called the crossbeam or girder), and wheels or casters for mobility. The key feature? You can adapt the crane's structure to fit the task or workspace — especially helpful when dealing with space limitations or various lifting points.

- Most adjustable gantry cranes are used indoors but can be used outdoors if designed for it.

- They are common in workshops, warehouses, equipment repair bays, and small-scale manufacturing.

- Available in steel or aluminum structures depending on load requirements and mobility needs.

Why Adjustable Span Matters in Real-World Use

In industrial settings, space is not always open and uniform. You may need to lift a machine in a tight corner one day and shift molds through a narrow door the next. That's where adjustable span becomes valuable — it allows you to narrow or widen the width between the crane legs to fit the site.

Use Cases Where Adjustable Span Solves Problems:

- Passing Through Doorways or Gateways: Narrow the span to move the crane between sections of a facility.

- Handling Loads in Confined Areas: Adjust span to match the area around machinery or work tables.

- Temporary Work Zones: When crane setups need to change weekly or daily depending on the operation.

Let's be real — not all workshops have perfect layouts. An adjustable gantry crane saves time and frustration by adapting to your layout, not the other way around.

Types of Adjustable Gantry Cranes Based on Materials

When selecting an adjustable gantry crane, one of the first things to consider is the material of the frame — typically steel or aluminum. Each type has its own strengths, limitations, and ideal use cases. Your choice should match your work environment, lifting needs, and mobility requirements.

Adjustable Steel Gantry Cranes

Steel adjustable gantry cranes are built for strength. They're designed to handle heavier loads and withstand the rough conditions often found in industrial environments. While not as easy to move as aluminum models, they make up for it with stability and capacity.

Where They Work Best:

- Heavy-duty workshops and factories

- Steel fabrication plants

- Equipment repair bays

- Places where cranes need to lift loads regularly above 1–2 tons

Key Features:

- Durable, Heavy-Duty Frame: Steel frames can support lifting capacities ranging from 1 ton up to 10 tons or more, depending on configuration.

- Higher Load Stability: Ideal for repeated lifting cycles and long-term use in fixed locations.

- Less Portable: Due to their weight, steel gantry cranes are often moved with a forklift or disassembled when relocation is needed.

Useful Tips:

- Choose steel if your lifting tasks are frequent and the loads are heavy.

- Some models offer adjustable height and fixed or adjustable span.

- Not ideal if you need to move the crane daily or pass through narrow doors.

Adjustable Aluminum Gantry Cranes

Aluminum adjustable gantry cranes are known for being lightweight, easy to move, and fast to set up. They're designed for lighter lifting jobs and environments where crane mobility is more important than heavy-duty strength.

Where They Work Best:

- Maintenance departments

- Mobile repair units

- Small workshops

- Cleanrooms and light-duty production areas

Key Features:

- Lightweight and Portable: Typically supports load capacities from 250 kg up to 2 tons, depending on the model.

- Quick Assembly and Disassembly: Perfect for contractors or service technicians who need to bring the crane on-site and pack it away after use.

- Corrosion-Resistant: Great for outdoor environments, marine applications, or humid areas where rust is a concern.

Useful Tips:

- Look for models with adjustable height and span to maximize flexibility.

- Check caster type and quality — some models include locking polyurethane wheels for smooth, safe movement.

- Ideal for temporary lifting needs and limited space situations.

Quick Comparison Table:

| Feature | Adjustable Steel Gantry Crane | Adjustable Aluminum Gantry Crane |

|---|---|---|

| Load Capacity | Up to 10 tons+ | Up to 5 tons |

| Weight | Heavy | Lightweight |

| Portability | Low to moderate | High |

| Environment | Industrial, harsh | Light-duty, clean or outdoor |

| Assembly | May require tools | Tool-less or quick setup |

In Summary:

- Use a steel gantry crane when strength and durability are your top priorities.

- Go with an aluminum gantry crane when mobility, corrosion resistance, or temporary setups are more important.

Span Adjustment Mechanism of Adjustable Portable Gantry Cranes

Not all gantry cranes have the same flexibility, especially when it comes to adjusting the span — the distance between the crane's vertical legs. For portable gantry cranes used in workshops, small factories, or maintenance departments, the ability to adjust span is valuable. But there are limits based on lifting capacity.

Adjustable Gantry Cranes with Telescoping Span

For cranes with a capacity of 2 tons or less, the span can often be adjusted by using a telescoping tube girder. This is a popular feature for buyers who need mobility and workspace flexibility.

How it works:

- The main beam is made from two or more steel or aluminum tubes that slide into each other.

- You can extend or shorten the beam manually by pulling out the inner tube or sliding it inward.

- After adjusting, the beam is secured using bolts, locking pins, or clamps.

Advantages:

- Useful when space varies between jobs, such as in tight corners or temporary work areas.

- Makes it easier to move the crane through doorways or narrow spaces.

- Adjustments can be done on-site without needing new parts or modifications.

Limitations:

- Only safe for lighter loads — typically up to 2 tons.

- Beam span should never be adjusted while a load is suspended.

- The telescoping structure can become unstable if overloaded or used improperly.

Capacity Limitations for Adjustable Span Designs

There are important structural reasons why only smaller gantry cranes allow full span adjustment. Once you go beyond 2 tons, the forces acting on a telescoping beam become too high to ensure safe operation.

For adjustable gantry cranes up to 2 tons:

- Telescoping span is possible and widely used.

- Span and height are both typically adjustable.

- Ideal for maintenance tasks, mold handling, or mobile assembly work.

For Adjustable gantry cranes above 2 tons:

- The beam must remain a fixed length due to strength and bending requirements.

- Only the leg position (distance between wheels) may be adjusted slightly inward for certain installations.

- Span cannot be changed dynamically; if doorway clearance is a concern, custom beam sizing must be considered at the time of purchase.

Summary: What's Possible and What's Not

| Feature | Cranes up to 2 tons | Cranes above 2 tons |

|---|---|---|

| Telescoping beam (adjustable span) | Yes | No |

| Adjustable leg spacing | Yes | Yes |

| Beam length change | Yes (manually) | No (fixed beam only) |

| Doorway or narrow space access | Good compatibility | Limited unless custom-designed |

| Common structure materials | Aluminum or light steel | Heavier steel only |

Final Tips for Crane Buyers

- If you regularly work in changing environments or tight spaces and your lifting needs are 2 tons or less, a telescoping-span gantry crane is the best fit.

- If you need to lift more than 2 tons, plan your layout ahead of time. Choose a fixed-span crane that can fit your most restrictive area, or consult your supplier for a custom leg frame solution.

- Never attempt to modify a fixed-span crane for span flexibility beyond its original design — it's a safety risk and will void structural integrity.

Let me know if you'd like to move on to the next section, such as "Types of Adjustable Gantry Cranes Based on Lifting Capacity" or "Industry-Specific Use Cases."

Benefits of Adjustable Gantry Cranes with Telescoping Span

For many buyers across different industries, one of the key reasons to choose a portable gantry crane is its adjustability — and telescoping span designs provide the kind of flexibility that fixed-span cranes simply can't offer. Whether you're moving between tight factory spaces, passing through doorways, or handling loads of varying widths, telescoping-span gantry cranes make operations simpler, safer, and more efficient.

Flexible Span Adjustment for Changing Workspace Layouts

One major challenge in many production and maintenance environments is space. Doorways, machinery placement, and narrow aisles can vary from one area to another. Telescoping span designs help crane users adapt to these constraints without needing to swap out equipment.

Practical Benefits:

- Pass through tight areas by narrowing the beam when relocating the crane.

- Expand the span only when necessary to handle larger items or wider pallets.

- Adapt to non-uniform working areas, such as mixed-use workshops or facilities undergoing layout changes.

- Reduce floor clutter, since you don't need to store multiple fixed-span cranes for different zones.

This is especially useful for mobile service teams, maintenance crews, or shops that frequently reconfigure their workflow zones.

Portability and Ease of Use in Industrial Applications

An adjustable gantry crane with telescoping span is specifically designed to be movable and user-friendly — and that's a major plus in industries where tasks change daily.

Highlights:

- Most models can be rolled across smooth floors using swivel casters.

- Aluminum variants (especially under 2 tons) can be disassembled and reassembled on-site within minutes.

- No need for fixed runways or structural installation — making them ideal for short-term lifting or temporary setups.

- The crane can be stored compactly when not in use, reducing warehouse congestion.

Industries like plastic molding, light manufacturing, automotive service, and warehouse operations often benefit from this easy deployment and reconfiguration.

Suitable for Both Light-Duty and Medium-Heavy Operations

Telescoping span is commonly available in light-duty gantry cranes (500 kg to 2 tons), but that doesn't mean heavier operations are left behind. With some structural adaptations, adjustable systems can still provide flexibility for larger capacities — just in different ways.

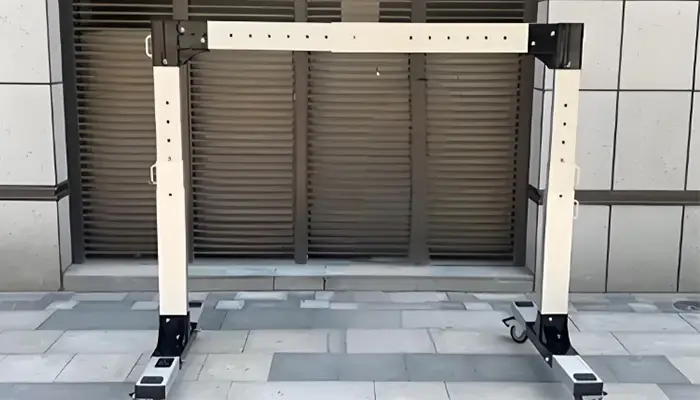

adjustable aluminum gantry crane with telescopic span and lifting height with capacity up to 2 ton

Span adjustable gantry crane with adjustable span but fixed length beam

For Light-Duty (500 kg to 2 ton):

- Full telescoping beam adjustment is possible.

- Ideal for mold lifting, precision part handling, or compact work areas.

- Lightweight aluminum or small steel frames allow frequent movement and quick span resizing.

For 2 Tons and Above:

- Beam span is fixed, but leg spacing can be narrowed in (within structural limits).

- Height adjustment still offers flexibility for different load clearances or tool heights.

- Though less mobile, these cranes can be custom-designed to match the maximum allowable width in constrained environments.

In heavier-duty cases, buyers should discuss leg-width configurations and available headroom to ensure the crane still fits their workspace requirements.

Summary for Buyers

If you often find yourself saying, "we need more space" or "this crane doesn't fit through the next door," then a gantry crane with a telescoping span is likely a smart move — especially for capacities under 2 tons. These cranes are designed to give you:

- More flexibility

- Easier mobility

- Better use of your space

- Fewer equipment limitations across different work zones

Choosing the Right Adjustable Gantry Crane

Selecting the right adjustable gantry crane isn't just about picking a lifting capacity — it's about matching the crane to your actual working environment, movement needs, and material handling frequency. If you're a buyer looking to make a sound investment, here's what to pay attention to before placing an order.

1. Load Capacity — Start with What You're Lifting

First things first — what's the heaviest item you'll need to lift on a regular basis?

- For light jobs like mold changes, equipment maintenance, or parts transfer, a 500 kg to 2 ton adjustable gantry crane is usually sufficient.

- For heavier applications like machine body handling, steel components, or lifting larger dies, you may need a 3 ton, 5 ton, or higher capacity crane — though these typically won't have an adjustable span.

Keep in mind:

- It's not just about the max weight — consider how often you'll lift that load and whether precise positioning is needed.

- Always add a safety margin of 20–25% over your heaviest load for durability and safety.

2. Span Adjustment Mechanism — Does It Need to Be Telescoping?

If your workspace is tight, or you plan to move the crane between different locations, span adjustability can be a huge benefit — but only within capacity limits.

Span adjustment options:

- Telescoping beam (up to 2 tons): Lets you change the length of the main beam manually. Useful for passing through doorways or adjusting crane width for different equipment sizes.

- Fixed beam with movable legs (above 2 tons): The span doesn't change, but you may be able to shift the leg positions inward to fit a specific space — usually done during initial setup, not on the fly.

- Custom spans: If you're working in a very narrow or unusual layout, ask the supplier about building a beam to fit your required maximum span.

Quick tip: Telescoping cranes are best if your load widths and travel paths vary a lot. If everything is fixed in place, a fixed-span model with solid legs may serve better.

3. Material Type — Steel or Aluminum?

The material you choose affects the weight, durability, and ease of movement of the crane. Your decision should be based on how often you'll move the crane and where it's being used.

Aluminum Adjustable Gantry Cranes:

- Lightweight, easy to move by hand

- Ideal for mobile workstations, outdoor job sites, or temporary service zones

- Corrosion-resistant — suitable for chemical, food, or cleanroom use

- Best for capacities below 2 tons

Steel Adjustable Gantry Cranes:

- Heavier, more stable — better for higher lifting loads

- Durable for continuous, daily use in industrial settings

- Typically used for 2 tons and above

- May require forklift or multiple people to relocate

Choose aluminum if your priority is mobility. Choose steel if your priority is strength and heavier operation.

4. Application Requirements — Think About Your Daily Use

Every factory, warehouse, or workshop has its own quirks. Make sure your crane choice fits how you actually plan to use it.

Questions to ask yourself:

- Will I move the crane frequently from one area to another?

- Do I need to lift and position molds, motors, or components in tight spaces?

- Is there enough headroom and floor clearance in the operating area?

- Will this be used indoors, outdoors, or both?

- Do I need the crane to be collapsible for transport?

If you said yes to many of these, a portable, telescoping-span gantry crane under 2 tons is a good fit.

If most answers were no, and you'll lift heavy loads in a fixed bay, a larger-capacity fixed-span gantry might be better.

Summary — Match the Crane to Your Real Work

Choosing an adjustable gantry crane means balancing four key factors:

- Load capacity: Don't under- or over-spec.

- Span adjustability: Choose telescoping only when really needed.

- Material: Lighter aluminum or heavy-duty steel.

- Real-world usage: Consider your workflow, space, and movement needs.

If you're unsure between two models, it's best to get a layout drawing or photo of your workspace and consult your crane supplier. The right decision here saves money, space, and time down the road.

Conclusion

Choosing the right adjustable gantry crane may seem straightforward at first glance — but once you start factoring in load requirements, workspace limitations, portability, and adjustment options, the details matter more than most buyers expect.

Key Points to Remember

Adjustable Span Is Not Universal: Telescoping spans are typically only available for cranes up to 2 tons. Anything heavier will likely have a fixed beam, though leg spacing or height might still be adjustable.

Material Matters:

- Use adjustable aluminum gantry cranes if portability is your top priority.

- Choose adjustable steel gantry cranes for heavier, more permanent operations.

Capacity Guides Design:

- Light-duty models (500 kg–2 ton) offer full adjustability in span and height.

- Heavier models (above 2 ton) are stronger but less flexible — usually fixed-span and harder to move.

Match the Crane to the Work: Think about how often you'll move it, what you're lifting, and where the crane will operate. Don't assume "bigger is better" if the environment doesn't support it.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch