Transport & Storage Solutions for Foldable Aluminum Gantry Crane

Discover practical transport and compact storage methods ensuring foldable aluminum gantry cranes remain safe, portable, and efficient for diverse applications.

Transport and Storage Solutions for Foldable Aluminum Gantry Cranes

Foldable aluminum gantry cranes are built with portability in mind. Unlike fixed overhead cranes, these lightweight cranes can be folded, transported, and deployed quickly without requiring heavy equipment or permanent installation. This makes them a practical choice for workshops, maintenance teams, construction sites, and temporary lifting tasks.

Efficient transport and storage are not just conveniences—they directly affect productivity and crane longevity. A crane that is easy to move, set up, and store minimizes downtime, reduces the risk of damage during transit, and saves valuable floor space in workshops or storage areas.

This guide is designed to give buyers and operators practical tips for moving, storing, and setting up foldable aluminum gantry cranes safely and efficiently. By following these suggestions, you can make the most out of your portable crane investment, keep your workflow smooth, and ensure the equipment stays in good condition for years to come.

Key Points Covered in This Section:

- Benefits of portability and foldable design

- How proper transport and storage protect the crane

- Purpose of the guide: practical, actionable tips for users

Foldable Design Features of Aluminum Gantry Crane

Foldable aluminum gantry cranes are designed to make life easier for operators who need flexible, portable lifting solutions. Unlike traditional fixed cranes, their design allows for quick setup, efficient transport, and compact storage. Understanding these features helps buyers see why these cranes are practical for workshops, fieldwork, and temporary lifting tasks.

Key Design Features:

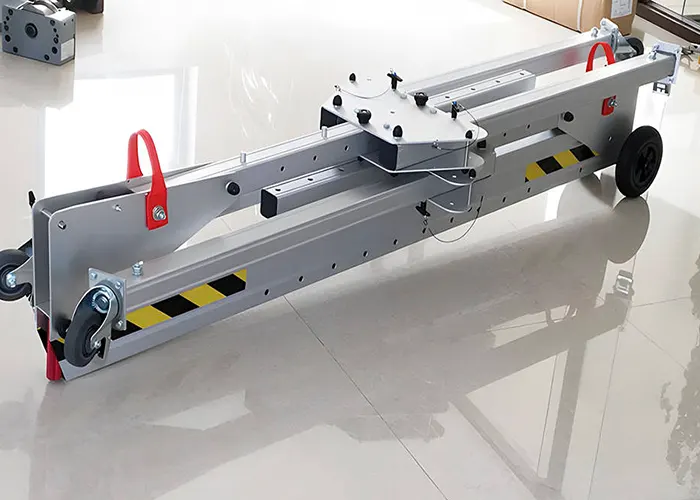

- Foldable Legs: The legs collapse inward, reducing the crane's overall footprint. This makes it easier to transport in trucks or vans and saves space when storing the crane in workshops or storage rooms. Foldable legs also help prevent damage during transit.

- Lightweight Aluminum Alloy: The crane is constructed from high-strength aluminum alloy, making it light enough for a small team to move manually. Despite its lightweight design, it maintains strong load-bearing capacity and corrosion resistance, suitable for both indoor and outdoor use.

- Caster Wheels: Heavy-duty swivel or brake casters enable smooth movement across floors, whether they are concrete, slightly uneven, or workshop surfaces. Brakes provide stability during lifting, keeping loads and operators safe, while allowing easy repositioning when needed.

Together, these design features make foldable aluminum gantry cranes highly versatile and user-friendly. Their portability, durability, and ease of movement allow operators to quickly deploy and adjust the crane to meet various on-site or workshop requirements, improving efficiency and safety.

Preparing for Transport

Even though foldable aluminum gantry cranes are built for portability, moving them safely requires a bit of planning and care. Proper preparation protects the crane from damage, ensures safe handling, and makes setup at the destination quicker and easier. Skipping these steps can lead to scratches, bent components, or unnecessary downtime on-site.

Practical Transport Tips:

Disassemble Optional Components: Before transport, remove any detachable parts such as trolleys, pluggable pins, hooks, or other accessories.

- Prevents small components from getting lost or damaged.

- Reduces overall weight for safer lifting and loading.

- Makes the crane more compact for storage or vehicle transport.

Secure Folding Legs: Lock the legs firmly in their folded position to maintain a stable, compact shape.

- Prevents the legs from swinging or shifting while moving the crane.

- Minimizes the risk of damaging the floor, vehicle, or crane frame.

- Ensures a predictable and safe footprint for transport planning.

Use Protective Covers or Padding: Wrap the crane in blankets, foam padding, or tarps to protect the aluminum surfaces.

- Shields against scratches, dents, and minor impacts.

- Provides protection from moisture, dust, or corrosion during transit.

- Helps preserve the appearance and longevity of the crane.

Transport Vehicles: Choose a suitable van, small truck, or trailer that accommodates the folded crane dimensions.

- Ensure enough space for secure strapping and to prevent shifting.

- Plan for a loading method that avoids lifting heavy sections manually.

- Double-check height and width clearance for doors, ramps, or tight spaces.

By taking these practical steps, operators can ensure a smooth and safe transport of foldable aluminum gantry cranes. Not only does this protect your investment, but it also reduces setup time on-site, helping teams get to work faster and more efficiently.

Safe Storage Practices

Proper storage is just as important as careful transport. Even a durable foldable aluminum gantry crane can suffer damage or wear if stored incorrectly. Taking a few extra steps ensures the crane remains ready for use, maintains its load-bearing capacity, and extends its service life.

Practical Storage Tips:

Indoor Storage: Keep the crane in a dry, clean environment.

- Protects the aluminum from moisture, corrosion, and weather-related damage.

- Reduces the accumulation of dust, debris, or chemical residues that could affect moving parts.

Stacking and Footprint Considerations: Folded legs make it possible to stack multiple cranes safely in a small space.

- Maximize storage efficiency without compromising crane stability.

- Use proper padding or separators between stacked units to avoid scratches or dents.

- Ensure weight limits are respected when stacking heavier models.

Floor Surface: Store the crane on a flat, stable surface.

- Avoid rough, uneven floors that could damage casters or bend lightweight aluminum frames.

- For long-term storage, slightly elevate the crane to prevent contact with moisture or spills.

Regular Checks: Even while idle, inspect the crane periodically.

- Check bolts, welds, and moving parts for looseness or signs of wear.

- Test casters and folding mechanisms to ensure smooth operation.

- Lubricate joints or moving parts if necessary to prevent stiffness or rust.

Tips to Maximize Portability

Foldable aluminum gantry cranes are designed to be portable, but planning and careful handling make moving them even easier and safer. Small adjustments and preparation can save time, reduce strain, and prevent damage to both the crane and surrounding workspace.

Practical Portability Tips:

Plan the Route: Before moving the crane, check doorways, narrow aisles, ramps, and stairs.

- Identify obstacles that could block the path.

- Ensure there is enough clearance for the folded crane and any accessories.

- Reduce the risk of accidental bumps or collisions during transport within the facility.

Use Two-Person Lifting: Even though the crane is lightweight, handling it with two operators is safer.

- Helps balance weight during loading, unloading, or repositioning.

- Reduces the risk of personal injury or strain.

- Makes it easier to maneuver around tight corners or uneven surfaces.

Move in Small Sections: If possible, separate the folded frame and beam to make handling simpler.

- Smaller sections are easier to lift and fit into transport vehicles.

- Reduces the chance of tipping or scratching aluminum surfaces.

- Allows more control during movement through confined spaces.

Caster Maintenance: Keep wheels clean and lubricated for smooth mobility.

- Remove debris or dirt that can hinder rolling performance.

- Check for wear or damage to prevent uneven movement.

- Properly maintained casters make repositioning faster and safer on all surfaces.

Practical Tips & Safety Considerations

Safety and efficiency go hand in hand when using foldable aluminum gantry cranes. Even though these cranes are lightweight and portable, neglecting proper handling or storage can lead to damage or accidents. Following practical tips and safety guidelines ensures smooth operations and protects both operators and equipment.

Key Safety and Practical Tips:

Verify Load Capacity: Always check the crane's rated load before lifting, especially after transport or storage.

- Prevents overloading that can damage the crane or cause accidents.

- Ensures safe handling of varying load sizes.

- Gives operators confidence in everyday operations.

Use Casters Properly: Avoid dragging the crane across rough surfaces; let heavy-duty swivel or brake casters do the work.

- Minimizes wear and tear on wheels.

- Protects the aluminum frame from scratches or bending.

- Ensures smooth movement even on slightly uneven floors.

Mark and Measure Storage Areas: Plan and label storage locations to avoid blocking emergency exits or workspace.

- Keeps workshops and job sites organized.

- Reduces the risk of accidents during storage or transport.

- Makes it easier to retrieve cranes when needed.

Organize Small Parts: Keep pins, bolts, trolleys, and other removable components in labeled containers.

- Prevents loss of critical parts.

- Speeds up assembly and setup on-site.

- Helps maintain order and reduces downtime.

Conclusion

Foldable aluminum gantry cranes are a practical solution for on-site lifting, combining mobility, compact storage, and adjustable lifting capabilities. When handled correctly, they save time, space, and effort compared to traditional permanent cranes.

Proper transport, careful storage, and thoughtful setup help extend the crane's service life. By taking precautions like protective padding, securing folded legs, and using the right transport vehicle, operators can reduce wear and prevent damage.

Planning ahead, following practical setup sequences, and training operators are essential steps to maximize portability and on-site performance. With these measures, foldable gantry cranes remain reliable, efficient, and ready for diverse lifting tasks whenever they are needed.