Modernize 30 Ton Slipway Gantry Crane Safely, 30 Ton Gantry Crane

Modernizing a 30 Ton Slipway Gantry Crane: How Upgrades Extend Service Life by 30+ Years

Slipway Gantry Cranes Still Working After Decades

Many shipyards are still operating slipway gantry cranes built back in the 1950s and 60s. Some of these machines, often rated as a 30 ton gantry crane, have been doing the heavy lifting for more than 70 years. That's a long service life, but time eventually takes its toll.

The Challenge of Old Equipment

As these cranes age, several problems start to appear that owners can't ignore.

- Spare parts are obsolete and hard to source.

- Maintenance takes longer and costs more.

- Safety risks increase with worn-out structures and wiring.

- Outdated motors waste energy and reduce precision.

These issues make daily operations harder, less predictable, and more expensive over time.

Why Modernization Makes Sense

Buying a brand-new crane is always an option, but it requires a big investment and long lead times. Modernization provides a more practical solution by extending the life of existing equipment.

- Hoists, winches, and controls can be upgraded with modern technology.

- Steel structures can be reinforced and protected.

- Service life can be extended by another 30–50 years.

- Operating costs drop thanks to more efficient motors and systems.

With this approach, a 30 ton gantry crane can keep working safely and reliably while saving both time and money compared to full replacement.

Why Modernize a Slipway Gantry Crane?

A slipway gantry crane built decades ago may still be running, but the cost of keeping it in service keeps climbing. What once was routine maintenance can turn into lengthy downtime and higher repair bills.

- Repairing old equipment is expensive, and frequent breakdowns add to overall operating costs.

- Mechanical and electrical spare parts are often out of production and hard to source.

- Older cranes consume more energy and lack the precision of modern controls.

These challenges make it harder to rely on an aging crane for daily slipway operations.

Modernization offers a practical middle ground. Instead of replacing a trusted 30 ton gantry crane with a brand-new one, upgrading the core systems extends its life, improves safety, and keeps operations running smoothly. For many owners, it's a smart way to balance cost and performance without losing valuable lifting capacity.

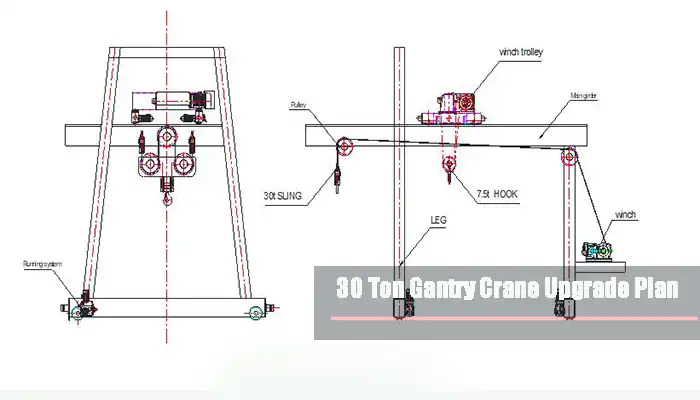

Key Areas of the Modernization Plan – A Case

When an old slipway gantry crane reaches the end of its service life, modernization focuses on the most critical systems. Each upgrade is designed to improve safety, efficiency, and reliability while keeping the existing structure in service.

a) 7.5t Hoist Trolley Replacement

The auxiliary trolley was replaced with a modern, compact unit.

- Compact design and VFD-controlled motors

- Smooth, vibration-free lifting operations

This ensures safer handling of lighter loads and reduces wear on the crane.

b) Hoisting Winch Upgrade

The main winch received a complete overhaul.

- New VFD motor, drum, brake, and gearbox

- Reliable and energy-efficient lifting performance

This upgrade improves heavy-lift control and reduces mechanical stress.

c) Travel Mechanism Renewal

The travel system was modernized for smoother movement.

- Integrated 3-in-1 motor, gearbox, and brake

- Compact, efficient, and low-maintenance design

It allows the 30 ton gantry crane to move steadily with less downtime.

d) Electrical System Overhaul

All outdated wiring and control equipment were replaced.

- Full wiring and cable replacement

- PLC and VFD controls for speed, acceleration, and braking

- Remote control operation for safer handling

This step improves precision, reduces power waste, and enhances operator safety.

e) Pulley and Wire Rope Improvements

The lifting mechanism was reinforced for durability.

- New bearings with lubrication

- Complete wire rope replacement for reliability

This minimizes risk during high-capacity lifts.

f) Steel Structure Treatment

The gantry structure was repaired and protected.

- Rust removal and reinforcement

- Protective primer and topcoat application

This ensures the steel frame remains strong for decades of continued use.

Together, these upgrades breathe new life into an aging slipway gantry crane. Instead of struggling with constant repairs, owners get a crane that operates like new, with the capacity and reliability of a freshly built machine.

Benefits of Modernization

Modernizing a slipway gantry crane is not just about replacing old parts. It creates a stronger, safer, and more efficient machine that can keep working for decades.

- Service life extended by 30–50 years

- Safer, more efficient, and more reliable operation

- Reduced maintenance and downtime costs

- Faster project timeline: only 40–45 days

These benefits make modernization an attractive option for shipyards and workshops where a 30 ton gantry crane is central to daily operations. Instead of investing in a brand-new crane, owners gain long-term value from equipment they already trust.

Practical Considerations for Crane Owners

Not every crane needs a full rebuild, so it's important to know when modernization is the right choice. If repairs are constant, parts are hard to find, or safety is becoming a concern, an upgrade is usually more cost-effective than continuing patchwork fixes.

- Modernization is often the better choice when a crane structure is still sound but core systems are outdated.

- Slipway operations, ship repair yards, and heavy lifting workshops rely heavily on Slipway Gantry Cranes, making downtime costly.

- Upgraded cranes support long-term productivity by reducing unexpected stoppages and improving load handling efficiency.

For many operators, modernization offers the balance between cost savings and dependable performance. It keeps a 30 ton gantry crane in service while preparing it for another generation of work.

Conclusion

Modernization gives an old slipway gantry crane a new lease on life. By upgrading key systems, an aging crane can operate safely, efficiently, and reliably for decades to come.For companies running 30 ton gantry cranes in shipyards or slipways, it's a practical and cost-effective alternative to buying a brand-new machine.Investing in a well-planned upgrade not only reduces downtime and maintenance costs but also ensures your crane is ready to handle future workloads with confidence.