Choosing Overhead, Gantry & Jib Cranes for Laser Applications

Choosing Overhead, Gantry, and Jib Cranes (0.2–30 t) for Laser Applications: A Buyer’s Guide

Most Important Takeaway:

Selecting the right overhead crane, gantry crane, or jib crane (0.2–30 t) is critical for laser machinery operations. The correct crane type and capacity ensures safety, precision, efficiency, and ROI, while protecting both high-value laser equipment and delicate or heavy workpieces across industries like automotive, EV, electronics, mold repair, and sheet metal fabrication.

- Crane Safety First: Proper cranes reduce operator risk and prevent costly damage to laser-machined components.

- Capacity Matters: Choose cranes based on workpiece weight, attachments, and workflow requirements (0.2–30 t depending on sector).

- Precision & Automation: Cranes with fine positioning, rotation, and automation-ready trolleys integrate seamlessly with laser lines.

- Sector-Specific Selection:

- Jewelry & Micro Electronics: Mini overhead or jib cranes (0.2–2 t)

- Automotive Laser Welding: Overhead bridge cranes (5–20 t)

- EV Battery Assembly: Gantry or overhead cranes (2–15 t)

- Mold & Die Repair: Overhead/jib cranes (5–30 t)

- Sheet Metal / Kitchen & Bath: Overhead/gantry cranes (2–15 t)

- 3C Electronics Assembly: Mini overhead cranes (0.2–1 t)

Why Cranes Are Essential for Laser Applications

When handling laser machinery, from micro-electronics and jewelry repair to automotive and EV assembly, careful material handling is critical. Even small mistakes—such as dropping a workpiece or misaligning a panel—can lead to delays, damage, or serious safety risks. This is why overhead cranes, gantry cranes, and jib cranes are essential tools in modern laser operations.

Protect Operators and Workpieces

Heavy or delicate components present constant handling challenges. Cranes remove the load from human hands, helping to reduce operator injury risk, prevent damage to high-value materials, and ensure fragile or heat-sensitive parts remain intact. Whether lifting a delicate jewelry tray or a large automotive sheet, the right crane minimizes human error and maintains production stability.

Achieve Accurate Positioning

Precision is critical in laser cutting, welding, and micro-assembly. Cranes enable operators to align parts accurately, use rotation arms or fine-position hoists, and integrate seamlessly with multi-axis or automated laser lines. This level of control is impossible with manual handling alone, especially in high-throughput environments.

Improve Workflow and Efficiency

Manual handling is slow, physically demanding, and prone to mistakes. Using cranes allows one operator to manage loads normally requiring multiple people, speeds up material flow along laser lines, and frees staff to focus on laser processes instead of lifting. The result is smoother workflow, higher output, and fewer bottlenecks.

Protect High-Value Laser Machinery

Poorly controlled movement or accidental collisions can damage expensive laser systems. Cranes designed for laser applications provide smooth, stable motion, prevent unintended contact with sensitive machines, and significantly reduce the risk of downtime and costly repairs.

Key Crane Features for Laser Applications

When selecting a crane for laser environments, prioritize electric or manual hoists with precise control, rotation or tilt attachments for complex parts, multi-axis or automation-ready trolleys, and comprehensive safety systems including overload protection, safety interlocks, and emergency stops.

Crane Types and Capacities for Laser Applications

Choosing the right crane for a laser facility goes beyond just lifting weight. The crane must match the type of workpiece, workflow, and precision requirements in your facility. Here's a breakdown of the main crane types, typical capacities, and why they matter.

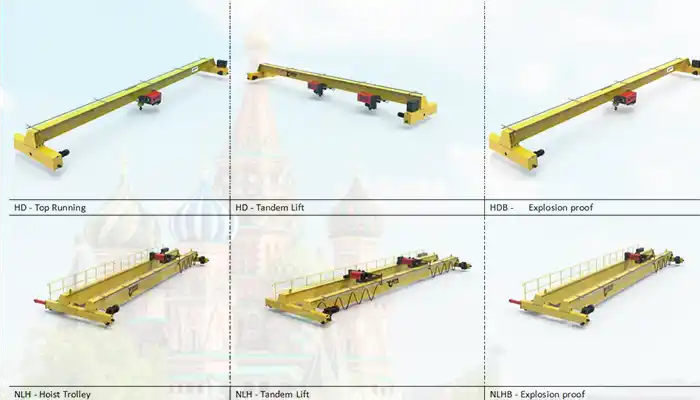

Overhead Bridge Cranes (5–30 t)

Overhead bridge cranes are the backbone of many industrial laser operations, especially where heavy panels or large molds are involved. They provide long-span coverage and consistent movement, making them ideal for automotive lines, sheet metal fabrication, and mold repair.

Best For:

- Automotive laser welding lines

- Large molds and dies

- Sheet metal fabrication and handling

Key Features:

- Double girder design for long spans and multi-station coverage

- Adjustable hoist for precise positioning

- Automation-ready trolley to integrate with production lines

Benefits for Buyers:

- Moves heavy panels safely and efficiently

- Maintains consistent alignment for laser welding or cutting

- Supports multiple stations without needing extra equipment

Practical Tip: These cranes are particularly useful when you need to handle large, heavy materials repeatedly without losing accuracy, protecting both operators and expensive components.

Gantry Cranes (2–15 t)

Gantry cranes are versatile solutions for medium-weight loads and environments where flexibility is key. They are often used in EV battery assembly, solar panel production, or semi-open laser workshops where components need precise positioning but the workspace may change.

Best For:

- EV and new energy battery assembly

- Semi-open or flexible laser workstations

- Temporary or mobile setups

Key Features:

- Multi-axis movement for precise positioning

- Vacuum or gripper attachments for delicate parts

- Safety interlocks to protect operators and materials

Benefits for Buyers:

- Flexible placement for different workstations

- Precise alignment for sensitive components like battery trays

- Safe handling of heat-sensitive or fragile materials

Practical Tip: Gantry cranes are great when mobility and adaptability are important, such as moving battery trays or large modules across multiple stations safely.

Jib Cranes & Mini Overhead Cranes (0.2–2 t)

For small-scale or high-precision laser operations, like jewelry repair or micro-electronics assembly, jib cranes and mini overhead cranes are the go-to choice. They provide precision lifting in a compact footprint, making them ideal for workstations or laser benches.

Best For:

- Jewelry and micro-electronics repair

- 3C electronics micro-welding stations

- Workstation-level laser applications

Key Features:

- Electric hoist for smooth lifting

- Rotation arm for easy access to different angles

- Fine positioning controls and compact footprint

Benefits for Buyers:

- Precise lifting of delicate or small components

- Reduces operator fatigue during repetitive tasks

- Protects delicate materials from damage

Practical Tip: These cranes allow operators to handle tiny or sensitive components safely and quickly, improving productivity while protecting high-value items from damage.

Selecting the Right Capacity for Laser Application Cranes

Choosing the right crane capacity is one of the most important decisions for buyers. A crane that's too small can't safely handle your workpieces, while a crane that's too large may be unnecessarily expensive or take up more space than needed. The goal is to select a capacity that matches your materials, attachments, and workflow requirements, with a healthy safety margin.

How to Calculate Total Load

Before you pick a crane, you need to calculate the total load it will lift. This includes:

- Workpiece weight: The actual weight of the item being lifted, whether it's a jewelry tray, battery module, or large sheet metal panel.

- Lifting attachments: Any clamps, vacuum pads, slings, or grippers used to secure the item. These can add significant weight.

- Safety margin: Always add 20–30% above the maximum expected load to account for dynamic forces during lifting or movement.

Practical Tip: For delicate materials, like micro-electronics or thin sheet metal, even small overloads can cause bending, warping, or damage. Adding a safety margin protects both the component and the crane.

Typical Capacities by Sector

Different laser applications require different crane capacities. Here's a practical guide for buyers:

- Jewelry & Micro Electronics: 0.2–2 t. Lifting trays, small assemblies, and delicate components at laser benches.

- Automotive Laser Welding: 5–20 t. Moving car body panels, molds, or heavy metal sheets across laser welding lines.

- EV Battery Assembly: 2–15 t. Positioning battery modules or trays precisely for laser welding without damaging sensitive cells.

- Mold & Die Repair: 5–30 t. Handling large molds and dies safely for repair and laser modification.

- Sheet Metal / Kitchen & Bath Fabrication: 2–15 t. Lifting and transporting heavy sheets, sinks, and fabricated parts to prevent bending.

- 3C Electronics Assembly: 0.2–1 t. Precise placement of micro-components, laser heads, and shielding materials.

Practical Tip: Always round up the capacity to the next available crane size if your workpieces are close to the upper limit. This ensures safe operation under load swings or unexpected movements.

Key Considerations for Buyers

- Future-proofing: Consider potential production changes or heavier materials in the future.

- Workflow integration: Make sure the selected capacity works with your laser lines, benches, and gantry layouts.

- Attachments and accessories: The weight of lifting tools, grippers, or vacuum lifters must be included in capacity calculations.

- Dynamic vs. static loads: Heavy workpieces in motion exert more force than when stationary; choose cranes rated for dynamic loads if needed.

Practical Reminder: Overestimating capacity is almost always safer than underestimating, especially when handling high-value, fragile, or heat-sensitive laser components. It prevents accidents, material damage, and downtime, which ultimately saves money.

Features Buyers Should Consider for Laser Application Cranes

When choosing a crane for laser machinery, it's not just about lifting capacity. The features of the crane determine how safely, precisely, and efficiently your materials and components are handled. Picking the right combination of features can save time, reduce errors, and protect both your operators and high-value equipment.

Precision & Positioning

For laser applications, even small misalignments can ruin a weld, cut, or assembly. Cranes with fine positioning controls allow operators to place parts exactly where they need to be.

- Enables accurate alignment for laser cutting, welding, and micro-assembly.

- Reduces the need for manual adjustments or repeated handling.

- Keeps fragile or heat-sensitive materials safe during movement.

Practical Tip: Look for cranes with precision trolleys or hoists that can move in very small increments—especially important for micro-electronics and jewelry work.

Rotation / Tilt Attachments

Some components—like molds, dies, or irregularly shaped panels—require rotation or tilt to line up with laser equipment.

- Lets operators adjust the angle without manually repositioning heavy or delicate items.

- Reduces risk of material damage during setup.

- Saves time and effort in multi-step laser processes.

Practical Tip: Even a small rotating or tilting attachment can improve efficiency dramatically for mold repair or automotive laser welding applications.

Vacuum or Clamp Lifters

Thin, delicate, or sensitive materials need extra care during handling. Vacuum or clamp lifters keep parts secure without applying uneven force.

- Protects sheets, trays, and panels from bending or warping.

- Ensures consistent positioning for laser accuracy.

- Reduces operator fatigue and reliance on manual handling.

Practical Tip: For high-precision tasks, like battery tray positioning or sheet metal work, a well-matched vacuum lifter or clamp can prevent costly mistakes.

Automation-Ready Trolleys

High-throughput laser lines often require integration with automated systems. Cranes with automation-ready trolleys make this possible.

- Allows synchronized movement with laser lines or production robots.

- Reduces errors and downtime by automating repetitive lifting tasks.

- Supports long-term upgrades to smart manufacturing or Industry 4.0 setups.

Practical Tip: If your facility is planning to scale or integrate with robotics, choose cranes with ready-to-integrate trolleys and controls.

Safety Features

Operator and material safety should never be an afterthought. Look for cranes with:

- Overload protection to prevent accidents from excessive weight

- Interlocks to stop operation if safety conditions are breached

- Emergency stop functions for instant control in emergencies

Practical Tip: Even when handling small components, safety features are critical. A minor collision or overload can damage high-value laser machinery or sensitive materials.

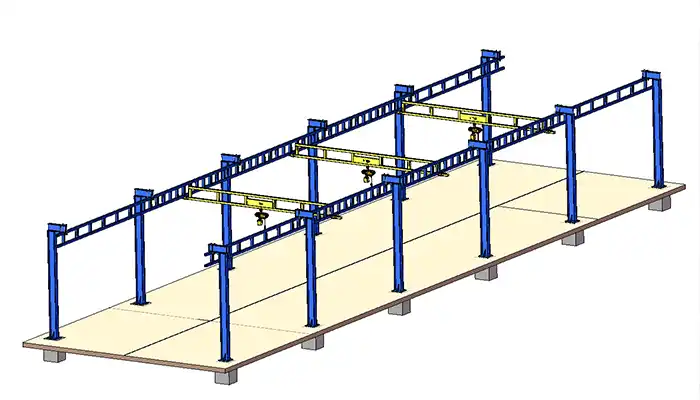

Typical Locations in Laser Facilities

Where you place your cranes in a laser facility can make a big difference in workflow efficiency, safety, and production speed. Different crane types are better suited for specific locations, depending on load size, precision requirements, and accessibility. Understanding this helps buyers choose the right crane for each area.

Workstation Cranes

Workstation Cranes, Mini overhead cranes and jib cranes are ideal for micro-laser tasks where precision and operator access are critical.

- Use Case: Jewelry repair, micro-electronics assembly, or small 3C component workstations.

- Purpose: Enables precise positioning of trays, delicate components, or laser heads at the bench level.

- Benefit: Operators can lift and move parts safely without leaving their workstation, reducing fatigue and improving accuracy.

Practical Note: These cranes usually have a compact footprint and fine positioning controls, making them perfect for tight spaces or densely packed workstations.

Line-Wide Overhead Cranes

Overhead bridge cranes are suited for long production lines where medium to heavy components need to move consistently along the laser line.

- Use Case: Automotive laser welding lines, sheet metal fabrication, and mold repair areas.

- Purpose: Transfers large panels, molds, or sheet metal safely across the production line.

- Benefit: Maintains alignment for laser welding or cutting, supports multi-station workflow, and reduces handling errors.

Practical Note: These cranes often feature double girders, automation-ready trolleys, and adjustable hoists to cover multiple stations efficiently.

Gantry Cranes

Gantry cranes are ideal for large or outdoor operations where loads are heavy or irregular, such as EV battery modules or oversized molds.

- Use Case: EV battery assembly halls, semi-open laser workstations, and heavy mold handling areas.

- Purpose: Provides flexible coverage and precise movement for heavy, sensitive, or bulky items.

- Benefit: Can be positioned or moved as needed, allowing high-precision laser operations while handling heavy loads safely.

Practical Note: Gantry cranes are especially useful when space is limited or when temporary setups are needed for special projects. They can often be reconfigured without major facility changes.

Sector-Specific Crane Applications for Laser Machinery

Different laser sectors have unique lifting and positioning needs. Choosing the right crane type and capacity ensures precision, safety, and efficiency. Here's a practical guide for buyers across industries:

Jewelry & Micro Electronics (0.2–2 t)

Mini overhead cranes or workstation jib cranes are ideal for lifting delicate trays and micro-components to laser benches.

- Use Case: Jewelry repair, micro-electronics assembly, and other small laser operations.

- Purpose: Moves tiny components safely and accurately without operator strain.

- Benefit: Protects delicate parts from damage and improves workflow efficiency at the workstation level.

Practical Note: Compact cranes with fine positioning are essential here. Even slight misalignment can ruin a micro-laser weld or damage fragile materials.

Automotive Laser Welding (5–20 t)

Overhead bridge cranes handle heavy car panels, frames, and molds, integrating seamlessly with automated laser lines.

- Use Case: Automotive assembly lines for laser welding and cutting large components.

- Purpose: Moves large, heavy panels efficiently between stations while maintaining precise alignment.

- Benefit: Supports multi-station operations, reduces manual labor, and ensures consistent laser accuracy.

Practical Tip: Double-girder cranes with automation-ready trolleys are recommended for long spans and high-throughput lines.

EV Battery Assembly (2–15 t)

Gantry cranes are ideal for lifting and positioning sensitive battery modules in laser welding operations.

- Use Case: EV battery production, module assembly, and laser sealing stations.

- Purpose: Provides precise, safe handling of sensitive, high-value components.

- Benefit: Prevents damage to cells and maintains alignment for high-precision laser welding.

Practical Note: Multi-axis movement and gripper attachments improve both speed and safety in battery assembly halls.

Mold & Die Repair (5–30 t)

Overhead or jib cranes handle large molds and dies safely during laser repair and maintenance.

- Use Case: Repairing or modifying molds, dies, and heavy components using laser equipment.

- Purpose: Lifts, rotates, and positions molds accurately without risk of damage.

- Benefit: Keeps expensive molds in production longer and reduces manual handling risks.

Practical Tip: Cranes with rotation or tilt attachments are critical for aligning molds correctly with laser heads.

Sheet Metal Fabrication / Kitchen & Bath (2–15 t)

Bridge or gantry cranes move large sheets, sinks, or fabricated metal parts without deformation.

- Use Case: Laser cutting, welding, and assembly of sheet metal or kitchen/bath components.

- Purpose: Ensures straight, undamaged parts while transferring them between stations.

- Benefit: Improves throughput, reduces waste, and protects high-value materials.

Practical Note: Vacuum lifters or lifting beams help handle wide, flat sheets safely.

3C Electronics Assembly (0.2–1 t)

Mini overhead cranes and jib cranes manage laser heads, shielding, and delicate electronic parts in micro-laser operations.

- Use Case: Assembly of phones, sensors, or other small electronics requiring micro-welding.

- Purpose: Provides precise, repeatable movement for delicate components at the workstation.

- Benefit: Protects sensitive electronics, reduces operator fatigue, and ensures laser accuracy.

Practical Tip: Small cranes with rotation arms and fine positioning are ideal for tight, high-precision workspaces.

Benefits of Proper Crane Selection for Laser Applications

Choosing the right crane for your laser facility is more than a technical decision—it directly impacts safety, efficiency, and long-term operational costs. A well-selected crane not only lifts materials but also improves workflow, protects equipment, and supports precision in laser operations.

Ensures Safety and Reduces Risk

The right crane keeps both operators and materials safe.

- Minimizes the risk of injuries from heavy or awkward loads.

- Protects delicate or heat-sensitive components from drops, collisions, or bending.

- Incorporates safety features like overload protection, interlocks, and emergency stops.

Practical Note: In high-precision laser operations, even small mistakes can damage expensive machinery or workpieces. Safety-focused cranes prevent costly accidents.

Increases Production Throughput and Efficiency

Proper cranes speed up material handling, letting your team focus on laser tasks.

- Moves heavy panels, molds, or micro-components quickly and accurately.

- Reduces time spent on manual adjustments or repositioning.

- Supports multi-station operations without bottlenecks.

Practical Tip: Overhead or gantry cranes can integrate with automated laser lines, further boosting workflow efficiency.

Protects High-Value Laser Machinery and Workpieces

Cranes designed for laser facilities prevent accidental damage.

- Smooth, controlled lifting reduces the chance of collisions with sensitive machines.

- Protects delicate materials like thin sheets, battery cells, or jewelry components.

- Maintains alignment and precision for laser welding, cutting, or micro-assembly.

Practical Note: Investing in the right crane protects not only your components but also your high-value laser equipment.

Supports Automation and Precision Workflows

Modern laser operations often require repeatable and accurate material placement.

- Automation-ready cranes integrate with high-throughput production lines.

- Fine positioning, rotation, and multi-axis movement ensure consistent results.

- Reduces operator fatigue and human error in delicate tasks.

Practical Tip: Precision features are especially important in micro-electronics, EV battery assembly, and mold repair.

Delivers Long-Term ROI and Operational Savings

The right crane pays for itself over time.

- Reduces downtime and material waste caused by handling errors.

- Lowers labor costs by allowing fewer operators to handle heavier loads safely.

- Increases overall facility productivity and throughput.

Practical Note: Buyers often underestimate the value of a properly sized and equipped crane. Long-term savings in materials, labor, and maintenance are significant.

Why Choose Us for Laser Application Cranes

Selecting the right crane supplier is as important as choosing the crane itself. You need a partner who understands laser operations, precision requirements, and material handling challenges across multiple sectors. Here's why our cranes stand out:

Customizable Cranes from 0.2 t to 30 t

We provide solutions for every laser application, whether it's micro-electronics or heavy mold handling.

- Covers small workstation lifts to large automotive or sheet metal lines.

- Allows buyers to select capacities tailored to workpiece weight and workflow.

- Supports scaling operations without frequent equipment upgrades.

Practical Note: From mini overhead cranes at laser benches to large overhead bridge cranes, we can match the right crane to your facility.

Integration-Ready with Automation Systems

Our cranes are designed to work seamlessly with laser production lines, automated trolleys, and lifting attachments.

- Supports synchronized movement with high-throughput laser lines.

- Can integrate with robotics or other industrial automation systems.

- Reduces human error and improves workflow consistency.

Practical Tip: Automation-ready cranes are especially useful for EV battery assembly, automotive laser welding, and sheet metal fabrication, where speed and precision are critical.

Attachments for Delicate or Heavy Loads

We offer a variety of attachments to handle any material safely and efficiently.

- Vacuum or clamp lifters for fragile or thin materials.

- Rotation and tilt attachments for molds, dies, or irregularly shaped components.

- Multi-axis movement for precision alignment of workpieces.

Practical Note: Choosing the right attachment ensures material protection, precision placement, and safer operation for both operators and machinery.

Industrial Safety Compliance and Reliability

Safety and reliability are built into every crane.

- Meets industry standards for overload protection, interlocks, and emergency stops.

- Designed for long-term operation under heavy or repetitive loads.

- Reduces downtime and maintenance costs.

Practical Tip: Safety-compliant cranes not only protect operators but also prevent damage to high-value laser machinery, saving money in the long run.

Proven Experience Across Multiple Sectors

We have hands-on experience supporting laser machinery in diverse industries.

- Jewelry, micro-electronics, and 3C assembly workstations.

- Automotive laser welding lines and sheet metal fabrication.

- EV battery assembly and mold repair workshops.

Practical Note: Our experience means buyers can trust our recommendations, installations, and after-sales support for both standard and complex laser operations.

FAQ: Choosing Overhead, Gantry, and Jib Cranes for Laser Applications (0.2–30 t)

Which crane type is best for laser machinery in different industries?

The best crane depends on your industry, load size, and workflow:

- Mini Overhead or Jib Cranes (0.2–2 t): Ideal for jewelry, micro-electronics, and 3C assembly for precise workstation lifting.

- Overhead Bridge Cranes (5–30 t): Best for automotive laser welding, sheet metal, and mold repair lines for long-span, multi-station operations.

- Gantry Cranes (2–15 t): Suitable for EV battery assembly, large molds, or outdoor/temporary laser setups where flexibility and precise placement are critical.

How do I determine crane capacity for safe and efficient operations?

Calculate the total load for safe and efficient operation:

- Workpiece weight + lifting attachments (clamps, vacuum lifters, etc.) + safety margin (20–30%).

- Match crane capacity to your heaviest expected load, rounding up if necessary.

- Consider dynamic loads and future production changes to prevent overloads and maintain precision.

What crane features are most important for laser applications?

Key features for laser operations include:

- Precision & positioning: Ensures accurate placement for laser welding, cutting, or micro-assembly.

- Rotation and tilt attachments: Needed for molds, dies, or irregular components.

- Vacuum or clamp lifters: Protect thin or delicate materials.

- Automation-ready trolleys: Supports integration with high-throughput laser lines.

- Safety systems: Overload protection, interlocks, and emergency stops.

How do cranes integrate with automated laser workflows?

Modern overhead and gantry cranes can connect with automation systems to:

- Synchronize movement along laser lines for multi-station production.

- Reduce manual handling errors and improve throughput.

- Allow precise, repeatable placement of sensitive or heavy components.

- Support Industry 4.0 initiatives and smart manufacturing setups.

Why does investing in the right crane protect equipment and improve ROI?

Correct crane selection provides:

- Safe handling of high-value laser machinery and delicate workpieces.

- Reduced downtime and material damage, saving labor and replacement costs.

- Increased production efficiency, throughput, and workflow consistency.

- Long-term operational savings and better return on investment for laser operations.

Conclusion: Selecting the Right Crane for Laser Operations (0.2–30 t)

The choice of an overhead, gantry, or jib crane is more than just a lifting decision—it directly impacts safety, productivity, and precision in your laser facility. Using the correct crane ensures that high-value machinery, delicate micro-components, and heavy materials are handled safely and efficiently.

Key Takeaways for Buyers

- Safety First: Proper cranes reduce risk to operators, prevent accidents, and protect sensitive or heavy workpieces.

- Precision Matters: Features like fine positioning, rotation, tilt, and multi-axis movement ensure accurate laser alignment.

- Capacity Counts: Selecting the right load capacity (0.2–30 t) avoids underperformance and prevents overloading.

- Efficiency & Throughput: Automation-ready and line-integrated cranes speed up workflow and reduce handling time.

- Long-Term ROI: Correct crane selection lowers maintenance costs, protects machinery, and improves production efficiency over time.

Investing in the right crane today is an investment in safer, faster, and scalable laser production operations. Buyers who carefully consider crane type, capacity, location, and features can ensure smooth workflow, protect equipment, and achieve measurable long-term savings.