From Light to Heavy Loads: Laser Crane Selection Guide

From Light to Heavy Loads: Choosing Cranes for Laser Applications (0.2–30 t)

Introduction

Laser operations require more than just lifting and moving materials. Precision is critical—slight shifts in position can affect cut quality, weld alignment, or even damage delicate components. At the same time, safety cannot be ignored. Heavy or sharp sheets handled carelessly can pose serious risks to operators and equipment. Efficiency is another key factor. Slow, awkward material handling can disrupt the entire production line, increasing downtime and reducing throughput.

Understanding Laser Material Handling Needs

- Precision is essential for cutting, welding, or additive manufacturing.

- Safety is crucial when handling heavy or sharp materials.

- Efficient workflows reduce production delays and improve overall output.

Why Choosing the Right Crane Type and Capacity Matters

Not all cranes are built for laser applications. Picking the wrong type or size can lead to accidents, production delays, or even costly equipment damage. For example, a small jib crane works well for light components on a workstation, but it can't safely lift thick steel plates. Conversely, a large overhead crane can handle heavy plates, but it may be unnecessary for a small lab or assembly area.

Selecting the right crane ensures:

- Smooth and accurate movement of materials.

- Reduced risk of accidents and equipment damage.

- Faster, more reliable operations across multiple laser workstations.

Hot Sale Crane Capacities for Laser Applications

Through practical experience and market trends, certain crane capacities are the most commonly used and purchased for laser tasks. These capacities cover everything from tiny electronics parts to heavy steel plates.

- 0.5 t – Perfect for small, precise components in labs or electronics assembly.

- 1 t – The most widely used capacity for general light-load laser tasks.

- 2 t – Suitable for medium-sized laser parts, bundled sheets, or mid-range fabrication.

- 3–5 t – Versatile mid-range capacity for laser workshops covering multiple stations.

- 10 t – Handles larger or heavier laser-cut sheets, common in automotive or aerospace workshops.

- 15–20 t – For heavy industrial laser lines with thick steel plates or high-volume production.

Matching your crane capacity to the actual workflow makes a big difference. It's not just about lifting—it's about lifting safely, efficiently, and reliably every time.

Sector Landscape

Each industry has unique laser material handling needs. Cranes must be selected to match load sizes, precision requirements, and workflow demands.

Metal Fabrication & Cutting Facilities

Metal fabrication shops are some of the most common users of cranes in laser operations. They work with steel, aluminum, and other metals in various forms—sheets, plates, tubes, and profiles. Material handling here can involve light aluminum sheets or heavy steel plates, depending on the job. Precision is important to make sure laser cuts are accurate and edges remain clean.

- Typical Loads: 0.5–10 t, depending on sheet thickness and size.

- Handling Needs: Smooth lifting, minimal vibration, repeatable positioning.

- Challenges: Large sheets can be unwieldy; improper handling may cause scratches, warping, or cutting misalignment.

- Typical Crane Types: Overhead bridge cranes for heavy sheets, mid-range gantry cranes for flexible handling, jib cranes for small workstations.

Cranes in these facilities often need a combination of mid-range and heavy capacities to accommodate different job sizes. Efficiency and safety are top priorities, as multiple workstations may operate simultaneously.

Automotive & Aerospace Workshops

Automotive and aerospace sectors require high precision and reliability. Laser applications here are used for cutting, welding, and surface modifications of components that must meet strict tolerances. The loads can vary from medium-sized parts like car panels to large aircraft components or structural elements.

- Typical Loads: 2–20 t for heavy parts, 0.5–5 t for smaller components.

- Handling Needs: Accurate positioning, repeatable motion, high load stability.

- Challenges: Irregular shapes and large sizes make manual handling difficult. Cranes must reduce risk of damage while maintaining precise movement.

- Typical Crane Types: Overhead bridge cranes for large assemblies, gantry cranes for flexible mid-size parts, jib cranes for small workstation lifts.

Cranes often integrate with automated or semi-automated production lines, ensuring consistent throughput and reducing manual labor.

Electronics Assembly & R&D Labs

In electronics labs and research facilities, laser applications are often for precision cutting, microfabrication, or prototype development. The parts handled are usually small but delicate. Even light loads require careful positioning, and equipment must avoid vibrations that could damage components or affect accuracy.

- Typical Loads: 0.2–2 t for small components or light assemblies.

- Handling Needs: Extremely precise movement, flexibility in confined spaces.

- Challenges: Limited space, need for adjustable crane reach, and smooth, controlled lifting.

- Typical Crane Types: Jib cranes for individual workstations, small gantry cranes for moving parts between labs or stations.

These cranes are compact, precise, and cost-effective, making them ideal for small-scale or prototype work.

Heavy Machinery & Shipbuilding

Heavy machinery and shipbuilding workshops handle the largest loads in laser applications. Steel plates, thick tubes, and structural components can weigh several tons. Lasers are used for cutting large sections, marking, or welding, and cranes must safely handle these loads while allowing precise alignment.

- Typical Loads: 10–30 t for plates and assemblies.

- Handling Needs: Maximum stability, long spans, heavy-duty hoists, and high load capacity.

- Challenges: Large parts are awkward to maneuver; precision is harder to maintain over long distances.

- Typical Crane Types: Heavy-duty overhead bridge cranes with double girder design, large gantry cranes for movable setups, rarely high-capacity jib cranes for localized tasks.

Overhead bridge cranes dominate this sector due to their ability to cover large areas and move extremely heavy materials reliably.

Load Handling Requirements Vary by Sector

Each sector has its own specific handling demands. Some require extreme precision and light handling, while others focus on moving very heavy, bulk materials. Selecting the correct crane type and capacity is therefore not a one-size-fits-all decision.

- Light precision parts: Jib or small gantry cranes.

- Medium loads across multiple stations: Mid-range gantry or overhead cranes.

- Heavy laser-processed structures: Large overhead cranes with high-capacity hoists.

Matching crane specifications to sector-specific needs ensures safety, improves workflow, and reduces downtime in laser operations.

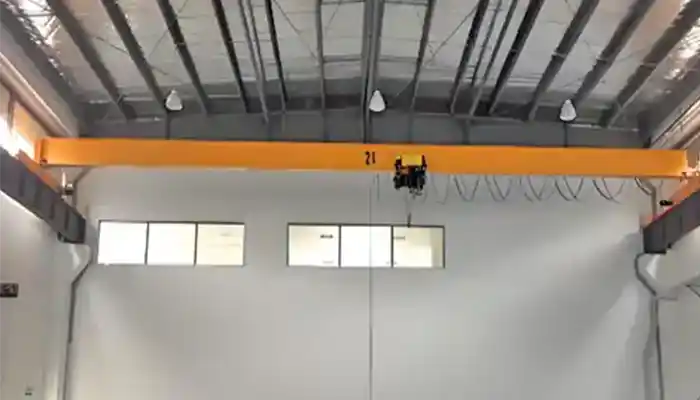

Overhead (Bridge) Cranes

Overhead bridge cranes are the backbone of many laser fabrication facilities. They are designed to lift heavy loads smoothly across large areas, making them ideal for handling thick metal sheets, tubes, and large assemblies. These cranes are particularly valuable in operations where precision and repeatability are essential.

Ideal Hot-Sale Capacities

Choosing the right capacity depends on the size and weight of your laser materials. The most commonly used capacities in industrial laser operations are:

- 3 ton–5 ton — The most versatile and widely used. Handles mid-range loads like medium steel sheets or bundled parts efficiently.

- 10 ton — For heavier laser-cut plates or tubes, common in automotive or aerospace workshops.

- 15 ton–20 ton — Suited for large fabrication lines, shipbuilding, or heavy machinery production where massive parts need careful handling.

Best Locations for Use

Overhead cranes are perfect for areas that require full coverage of production floors or multiple laser stations. Typical installation points include:

- Laser cutting halls and large fabrication bays.

- Central material flow corridors where multiple workstations need access.

- Assembly areas for heavy or large-scale components.

Key Features

The strength of overhead cranes comes not just from lifting capacity, but from precision and reliability:

- Long spans covering wide work areas without obstruction.

- Precise travel control to ensure smooth movement and minimal vibration.

- High-duty cycle hoists that can handle frequent lifting throughout production shifts.

- Optional automation or remote operation for integration with laser production lines or robotic systems.

Main Benefits

Using overhead cranes in laser operations provides several practical advantages:

- Handles mid to heavy loads safely and efficiently, reducing damage risks.

- Speeds up production by reducing manual handling and cycle times.

- Minimizes operator strain, especially when moving bulky or awkward parts.

- Scales with your production needs—whether adding more stations or increasing part sizes, overhead cranes adapt easily.

Gantry Cranes

Portable Gantry Cranes are the flexible solution for many laser operations, especially when mobility or temporary setups are needed. Unlike overhead cranes, gantry cranes don't require a permanent runway, which makes them ideal for workshops with changing layouts or outdoor laser prep yards. They are particularly useful when materials need to move between different stations or areas without being tied to a fixed ceiling structure.

Ideal Hot-Sale Capacities

The most practical and commonly used capacities for gantry cranes in laser applications are:

- 1 t — Perfect for light to medium tasks, such as moving small sheets, prototypes, or delicate components between workstations.

- 2 t — A popular choice for general fabrication support, capable of handling mid-size laser-cut parts efficiently.

- 5 t — Strong mid-range demand; suitable for workshops that handle multiple stations or slightly heavier steel components.

These capacities balance cost, flexibility, and workflow needs, making them the go-to choice for many small to mid-sized laser operations.

Best Locations for Use

Gantry cranes are versatile because they don't require permanent installation, and they can serve multiple functions across a workshop. Typical locations include:

- Flexible workshop layouts where workstations are rearranged frequently.

- Outdoor laser prep areas or storage yards for bulky materials.

- Temporary laser cell setups, especially in production expansions or project-based operations.

Key Features

Gantry cranes are designed to adapt to changing production needs while still providing reliable material handling:

- Adjustable span and height to fit various workshop layouts or part sizes.

- Mobile or fixed configurations depending on whether the crane needs to move or stay in one place.

- Coverage across multiple stations, allowing parts to be lifted and moved efficiently without extra equipment.

Main Benefits

Using gantry cranes provides practical advantages for laser operations:

- Ideal for mid-sized laser operations or production lines with multiple stations.

- Cost-effective alternative to full overhead crane installations, requiring less infrastructure.

- Easy to relocate when production needs change, allowing flexibility as workflow or laser setups evolve.

- Reduces dependency on manual handling, which helps improve safety and efficiency.

Jib Cranes

Jib cranes are the go-to solution for localized laser operations where precision and convenience are critical. They are compact, easy to install, and perfect for moving light parts quickly without interfering with other workflow areas. For labs, small assembly lines, or electronics fabrication benches, jib cranes provide fast, repetitive lifts with minimal effort.

Ideal Hot-Sale Capacities

Jib cranes are typically used for lighter loads, and certain capacities are most in demand in laser applications:

- 0.5 t — Ideal for small, precise components in electronics labs or light fabrication tasks.

- 1 t — The best-selling capacity for general workstation handling; can lift small sheets or assemblies with ease.

- 2 ton–3 ton — Extended range for handling small bundles or mid-size parts without requiring a larger crane.

These capacities strike the right balance between precision, efficiency, and safety for smaller laser setups.

Best Locations for Use

Jib cranes work best where space is limited, and material needs to move within a specific area:

- Laser workstations requiring precise, short-distance lifts.

- Small assembly areas where larger cranes would be impractical.

- Electronics fabrication benches or prototype labs with delicate components.

Key Features

The design of jib cranes allows for flexibility and simplicity in small-scale operations:

- 180–360° rotation to reach multiple points around a workstation.

- Wall-mounted or floor-mounted options depending on available space.

- Compact footprint that doesn't obstruct other operations.

Main Benefits

Using jib cranes in laser operations provides practical and measurable advantages:

- Perfect for quick, repetitive lifts in a confined workspace.

- Improves throughput in localized areas without major infrastructure.

- Minimal installation and maintenance costs compared to larger cranes.

- Reduces manual handling, improving safety and consistency for small or delicate parts.

Hot‑Sale Capacities: Quick Reference

When it comes to laser operations, knowing the right crane capacity at a glance can save a lot of time and prevent costly mistakes. The following quick reference table shows the most commonly used (hot-sale) capacities, their typical applications, and the best crane types for each scenario.

This helps buyers immediately identify which crane fits their workflow, whether it’s a small electronics bench or a large fabrication line.

Hot-Sale Capacity Overview

| Capacity Bracket | Primary Use in Laser Applications | Best Crane Type(s) |

|---|---|---|

| 0.5 t | Precision small parts, lightweight sheets or assemblies | Jib Crane |

| 1 t | Light to mid workstation handling, small batches | Jib / Gantry |

| 2 t | General fabrication and laser part handling, medium sheets or bundles | Jib / Gantry |

| 3–5 t | Mid-range laser workflow, multi-station operations | Overhead / Gantry |

| 10 t | Heavy laser elements, large sheets, or batch lifting | Overhead |

| 15–20 t | Heavy industrial laser production lines, thick steel plates, large assemblies | Overhead |

Practical Notes for Buyers

- 0.5–2 t capacities are ideal for precision work and flexible setups; commonly found in labs, small workshops, or electronics fabrication.

- 3–5 t capacities handle mid-sized laser operations where multiple stations are involved or bundled sheets need moving.

- 10–20 t capacities are best for heavy production floors, automotive, aerospace, or shipbuilding workshops.

- Choosing the right crane type for each capacity ensures safe handling, consistent positioning, and smooth workflow.

- Always consider future growth, production layout, and potential expansions when selecting crane capacity.

Key Features to Evaluate

Choosing the right crane for laser applications isn't just about lifting capacity. Several critical features determine whether a crane will be safe, precise, and efficient in your workflow. Paying attention to these factors can prevent costly mistakes, reduce downtime, and ensure your laser operations run smoothly.

Precision Travel & Minimal Vibration

Laser work demands accuracy. Even small vibrations or uneven movement can affect cutting, welding, or marking quality. Cranes should move materials smoothly and consistently across the workspace.

- Smooth horizontal and vertical travel to prevent material shifts.

- Precise stopping and positioning for repetitive laser operations.

- Reduced vibration for sensitive components or delicate materials.

Duty Cycle & Hoist Speed

Your crane needs to keep up with production. Choosing a crane with the right duty cycle and hoist speed ensures it can handle frequent lifts without overheating or excessive wear.

- Match hoist speed to production throughput to avoid bottlenecks.

- High-duty cycle for continuous operations, especially in industrial laser setups.

- Adjustable speed settings for different materials or load sizes.

Safety Systems

Safety should never be overlooked. Overload protection and limit switches protect both the crane and the operators. These systems also reduce the risk of damage to expensive laser machinery or workpieces.

- Overload detection prevents lifting beyond the rated capacity.

- Upper and lower limit switches stop the hoist automatically at maximum range.

- Emergency stop buttons and safety interlocks for operator protection.

Automation Compatibility

Modern laser production lines often integrate with automated systems. Cranes that support remote control, PLC, or MES integration can streamline material flow and reduce manual handling.

- Remote operation for precise positioning without manual strain.

- PLC or MES connectivity for integration into automated production workflows.

- Option for semi- or fully automated movement to improve efficiency.

Environmental Protection

Laser zones can have dust, smoke, or debris that may affect crane operation. Choosing cranes with environmental protection ensures long-term reliability.

- Dust-proof and smoke-resistant components to reduce maintenance.

- Enclosed or coated hoists for protection against debris.

- Suitable for both indoor and partially covered outdoor setups.

Benefits for You

Investing in the right crane for laser applications isn't just about lifting materials—it directly impacts how smoothly your operation runs. The benefits go beyond just moving parts from one station to another; they touch productivity, safety, precision, and long-term planning.

Higher Productivity

A well-chosen crane keeps material moving efficiently. Faster cycle times mean less waiting for parts, fewer interruptions, and smoother workflows. Overhead, gantry, or jib cranes that match the load and layout allow operators to focus on production instead of struggling with manual handling.

- Reduces downtime caused by manual lifting or inefficient equipment.

- Supports continuous operations across multiple laser stations.

- Speeds up part transfers, allowing more work to be completed in less time.

Improved Safety

Laser workshops often involve sharp, heavy, or hot materials. Cranes reduce the need for manual handling, lowering the risk of injury. Overload protection, limit switches, and proper hoist design make daily operations safer for your team.

- Less risk of cuts, burns, or strain injuries.

- Consistent handling reduces accidents caused by human error.

- Safer movement of heavy or awkwardly shaped parts across workspaces.

Precision Handling

Accuracy is critical in laser operations. The right crane ensures materials are positioned exactly where they need to be, every time. This reliability is essential for repeatable laser cuts, precise welding, or delicate assembly tasks.

- Smooth travel and minimal vibration maintain material alignment.

- Repeatable positioning reduces mistakes and scrap.

- Supports delicate or high-precision components without damage.

Scalability

Operations grow, and your crane should be ready for it. Choosing the right capacity and type now can save costs later. Whether you plan to expand production, increase load sizes, or add more laser stations, a scalable crane solution ensures you won't outgrow your equipment.

- Handles larger loads or multiple workstations as production grows.

- Allows for future automation or integration with new processes.

- Minimizes downtime and cost when upgrading operations.

Location & Layout Considerations

Before choosing and installing a crane for laser operations, it's important to carefully evaluate the space where it will operate. Even the best crane can underperform if the location isn't suitable. Planning ahead prevents safety issues, workflow bottlenecks, and costly adjustments later.

Ceiling Height, Bay Width, and Runway Capability (for Overhead Cranes)

Overhead cranes require a stable runway and enough vertical clearance to move loads safely. The ceiling height, bay width, and runway strength all affect crane performance. Without proper clearance, the crane may be unable to lift loads to the required height or could interfere with other equipment.

- Measure ceiling height to ensure full hoist lift range is achievable.

- Verify bay width and crane span to cover all necessary workstations.

- Check runway rails for strength and alignment to support crane weight and dynamic loads.

Floor Strength and Ground Clearance (for Gantry and Jib Cranes)

Gantry and jib cranes rely on floor support rather than ceiling-mounted runways. The floor must be strong enough to handle both the crane and its maximum load. Ground clearance and unobstructed pathways ensure safe, smooth operation.

- Ensure the floor can handle the crane's maximum load plus dynamic forces.

- Maintain sufficient clearance for travel, rotation, and hoist operation.

- Avoid obstacles like ducting, storage racks, or uneven surfaces that could interfere with movement.

Travel Paths and Workflow Integration

Even a properly sized crane can create bottlenecks if its travel path is poorly planned. Consider the full workflow of your laser operations to ensure material moves efficiently between stations.

- Plan crane travel routes to minimize crossing active laser zones.

- Avoid placing cranes where they could block access to workstations or emergency exits.

- Ensure smooth, direct paths for both small and heavy loads to reduce handling time.

Conclusion

Selecting the right crane for laser applications is more than just matching weight to hoist. It’s about understanding your workflow, the size and type of materials, and how your production layout operates. Choosing the proper crane ensures safety, precision, and efficiency across your laser operations.

Practical Crane Selection Guidelines

- 0.5–1 t Jib Cranes – Ideal for localized, light-load tasks. Perfect for small workstations, electronics fabrication benches, or prototype setups where precision is critical.

- 1–5 t Gantry Cranes – Best when flexibility and mobility are required. Great for workshops with multiple stations, temporary laser cells, or layouts that may change over time.

- 3–20 t Overhead Cranes – Suited for heavy laser loads and high-throughput workflows. Ideal for fabrication halls, automotive, aerospace, and shipbuilding operations handling large plates or assemblies.

Key Takeaways

- Always align crane capacity with hot-sale ranges to ensure reliable performance and ease of sourcing.

- Consider not only the weight but also the material size, travel paths, and production layout.

- Investing in the right crane type and capacity reduces downtime, improves safety, and boosts overall productivity.

- Properly selected cranes provide long-term ROI and proven performance in real-world laser applications.