Standard vs Custom Cranes: When Customization Saves Costs

Standard Crane Configuration vs Custom Crane Design: When Customization Reduces Total Cost

Key Takeaway:

When choosing between standard crane configurations and custom crane designs, the initial cost is not the only factor to consider. In some cases, custom cranes can actually reduce the total cost of ownership over time through improved efficiency, lower maintenance costs, and longer operational life. Understanding when and why customization is beneficial will help you make the right choice for your project’s specific needs and budget.

Key Takeaways in Bullet Points:

- Customization can lower long-term costs by improving crane efficiency and reducing downtime.

- Total Cost of Ownership (TCO) includes maintenance, repair costs, energy consumption, and operational efficiency, not just the initial purchase price.

- Custom cranes are ideal for heavy-duty applications or industries with specialized needs (e.g., steel mills, hazardous environments).

- Standard cranes are best suited for general-purpose lifting in industries without specialized demands, offering quick delivery and lower initial cost.

- Energy-efficient design, durability, and tailored features in custom cranes can significantly reduce operating costs in the long run.

Introduction: Understanding the Crane Selection Process

Choosing the right crane is a big decision for any business. It’s not just about getting the cheapest option upfront; it’s about looking at the total cost over the crane’s lifetime. For many businesses, this means weighing the pros and cons of standard cranes versus custom-designed cranes.

At first, custom cranes can seem like a more expensive choice. However, when you consider factors like maintenance costs, energy efficiency, and long-term durability, custom designs can often provide greater value over time. While a standard crane may work fine for basic tasks, industries with specific needs—such as steel mills, chemical plants, or ports—might find that custom cranes are a better fit.

This article will explore how custom crane designs can actually lead to cost savings in the long run, especially when considering specialized lifting needs and unique project requirements.

Why Consider Custom Cranes?

- Long-Term Savings: Although custom cranes come with a higher initial price, they can save businesses money in the long run by reducing maintenance and improving energy efficiency.

- Tailored Features: Custom cranes are built to handle specific tasks, whether that’s lifting heavy loads, working in harsh environments, or meeting unique safety standards.

- Efficiency Boost: Custom designs can help optimize operations, increasing productivity and reducing costly downtime.

By thinking beyond the upfront cost, businesses can make a more informed choice, ultimately benefiting from greater efficiency and lower overall operating costs with the right crane design.

Standard Crane Configurations: Cost-Efficiency with Limitations

Standard cranes offer a budget-friendly, quick-deployment option for general-purpose lifting. However, their limited customization and potential for higher maintenance costs make them less suitable for industries with specialized needs. For simple, routine lifting, they are a practical choice, but for more demanding tasks, custom cranes may offer better long-term value.

What Are Standard Cranes?

Standard cranes are pre-designed, mass-produced models that cater to general lifting needs. They are ideal for businesses that require reliable, everyday lifting solutions without the need for specialized features.

Advantages of Standard Cranes

- Lower Initial Cost: Affordable due to mass production, making it a great choice for businesses with budget constraints.

- Faster Delivery: Quick availability and delivery, perfect for projects with tight timelines.

- Easily Accessible Spare Parts: Since standard cranes are widely used, spare parts are readily available, minimizing downtime for repairs.

Limitations of Standard Cranes

- Limited Flexibility: Not suitable for specialized applications like handling hazardous materials or working in extreme conditions.

- Higher Maintenance: May require more frequent repairs and maintenance over time, leading to higher operational costs.

Who Benefits from Standard Cranes?

- Basic Lifting Needs: Ideal for industries like warehouses and light-duty manufacturing where specialized features aren't necessary.

- Tight Budget or Quick Installation: Perfect for projects that need cost-effective solutions and fast turnaround.

Custom Crane Design: Tailored for Efficiency and Longevity

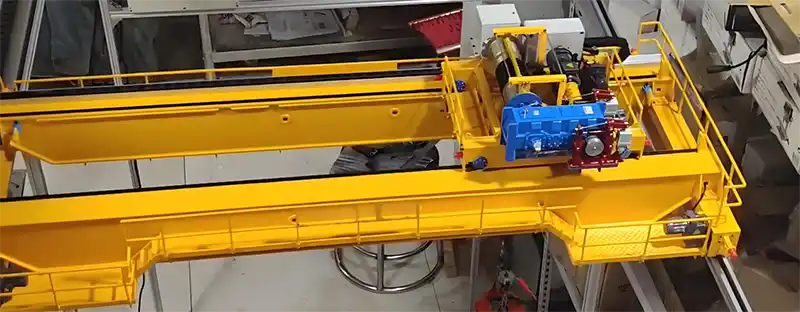

Custom cranes are designed to handle specific, high-demand tasks, offering significant advantages like increased efficiency, enhanced durability, and a lower total cost of ownership in the long term. Although they come with a higher upfront price, industries with unique needs—such as steel manufacturing, chemical processing, or heavy-duty construction—will find that custom cranes offer the best long-term value and performance.

What Makes Custom Cranes Different?

Custom cranes are designed specifically for a project's unique needs. Unlike standard cranes, which are mass-produced for general tasks, custom cranes are built to tackle specialized operations, whether that's lifting heavy materials, working in hazardous environments, or operating at high temperatures.

Advantages of Custom Cranes

- Tailored to Specialized Tasks: Custom cranes are designed to handle specific materials or tasks, like lifting heavy loads in steel mills, working in chemical plants, or handling hazardous materials safely.

- Enhanced Efficiency: These cranes are often equipped with energy-efficient systems, optimized lifting speeds, and better load handling capabilities, which leads to faster cycle times and higher productivity.

- Long-Term Durability: Built to withstand harsh environments and demanding tasks, custom cranes tend to require less frequent repairs, resulting in less downtime and longer operational life.

- Reduced Total Cost of Ownership (TCO): While custom cranes come with a higher initial cost, their reduced maintenance needs, energy efficiency, and extended lifespan often make them more cost-effective in the long run, leading to a lower overall TCO.

Who Benefits from Custom Cranes?

- Industries with Specialized Lifting Needs:

Custom cranes are ideal for industries such as steel mills, chemical plants, ports, and construction projects, where standard cranes just won't cut it. - Projects with Specific Safety or Environmental Requirements:

If your project requires cranes to meet strict safety standards or operational conditions (e.g., explosion-proof features, corrosion resistance, or high-temperature tolerance), custom cranes are the way to go.

Factors That Influence Crane Decision: Standard vs Custom

The decision between standard and custom cranes hinges on several factors: application requirements, total cost of ownership, lead time, and maintenance needs. While standard cranes offer quick delivery and lower upfront costs, custom cranes provide long-term benefits such as higher efficiency, lower operational costs, and extended service life. By carefully considering these factors, businesses can make an informed decision that balances costs with performance needs.

Application Specificity

The type of work you need the crane to perform plays a crucial role in determining whether a standard or custom crane is the best option. If your lifting tasks are routine and don't require specialized equipment, a standard crane might be sufficient. However, if your operations involve heavy-duty lifting, specialized materials, or extreme environments, a custom crane is likely a better fit.

- Standard Cranes:

Standard cranes are typically designed for general-purpose tasks, such as moving light loads, stacking pallets, or handling non-specialized materials. They are ideal for operations that don't have strict requirements and where standard lifting tasks are performed regularly. - Custom Cranes:

Custom cranes are built to address specific challenges, such as handling heavy loads, operating in high-temperature environments, or lifting materials in hazardous or corrosive conditions. They are designed for industries like steel mills, chemical plants, or port operations, where the lifting tasks are more complex and require additional safety or performance features.

Total Cost of Ownership (TCO)

When considering crane options, it's essential to look at the total cost of ownership (TCO), which includes more than just the initial price tag. While custom cranes typically cost more upfront, they can offer significant savings in the long run through energy efficiency, less frequent repairs, and longer service life.

- Reduced Downtime:

Custom cranes are often designed for specific tasks, which means they're better suited for the demands of the job. This results in fewer breakdowns, less downtime, and fewer emergency repairs, ultimately saving you money by keeping operations running smoothly and reducing unplanned maintenance costs. - Energy Savings:

Custom cranes frequently incorporate energy-efficient technologies, such as regenerative braking or variable speed drives. These features can reduce electricity consumption, resulting in lower utility bills. Over time, these savings can help offset the higher initial cost of the crane. - Extended Service Life:

Since custom cranes are designed to operate in harsh or demanding environments, they often have a longer operational lifespan. Built to endure specific conditions, these cranes reduce the need for frequent replacements and repairs, leading to long-term savings and greater return on investment.

Lead Times and Delivery

The speed at which you need your crane delivered can be a deciding factor, especially if your project timeline is tight. Standard cranes offer quick delivery times, making them ideal for businesses that need to get operations up and running quickly. However, for more specialized needs, custom cranes might take longer to manufacture but provide a more tailored solution.

- Standard Cranes:

Standard cranes are available off the shelf and can be delivered quickly, which is perfect for projects that require a fast turnaround. If you don't have time to wait for a custom design and just need something that can handle general lifting tasks, a standard crane is a good option. - Custom Cranes:

Custom cranes, while taking longer to design and manufacture, offer specific features that standard cranes can't provide. While you may experience a longer wait, the crane will be built to match the exact needs of your project, ensuring optimal performance and efficiency once it's up and running.

Maintenance and Spare Parts

The availability of spare parts and the ease of maintenance are critical factors in crane decision-making. Standard cranes tend to have a large service network and readily available spare parts, making maintenance easier and cheaper. In contrast, custom cranes may require specialized parts but can also be designed with maintenance in mind to reduce downtime and optimize long-term reliability.

- Standard Cranes:

Since standard cranes are used in a wide variety of industries, spare parts are widely available, and service technicians are more common. This makes repairs quicker and often cheaper, reducing the risk of long periods of downtime and keeping costs low for general repairs. - Custom Cranes:

Custom cranes may need specialized parts that are less readily available, which can increase maintenance costs. However, they can also be built with maintenance in mind, including easier-to-repair designs and durable components that require less frequent attention, ultimately leading to fewer repairs over time.

When Custom Cranes Reduce Total Cost

Custom cranes bring significant long-term cost savings by improving efficiency, reducing energy consumption, and enhancing durability. While they require a higher initial investment, these cranes are often the more cost-effective choice in the long run for industries with specialized needs. Whether through boosting productivity, lowering utility costs, or offering longer service life, the benefits of custom crane designs go far beyond just meeting basic lifting requirements.

Efficiency Improvements

Custom cranes are designed with specific tasks in mind. This means they are optimized to handle specialized lifting operations more efficiently, improving cycle times and material handling. Whether you're lifting steel beams in a mill or containers at a port, a crane built for your exact needs can boost productivity and minimize downtime.

- Example:

A custom crane designed for a steel mill can increase throughput by efficiently handling larger loads, reducing bottlenecks in the production process, and improving overall operational speed. The result is a more streamlined process, saving both time and money.

Energy Efficiency

One of the key benefits of custom cranes is the ability to integrate energy-saving features. By incorporating elements such as variable frequency drives or optimized hoist speeds, custom cranes can help businesses reduce electricity consumption and lower energy costs over time.

- Example:

A custom crane with regenerative braking technology can drastically reduce energy consumption. When the crane lowers heavy loads, the energy generated is fed back into the system, reducing the amount of electricity used during operation. Over time, this energy-saving feature can result in substantial cost savings, making it a smart investment for energy-conscious businesses.

Longevity and Durability

Custom cranes are built for high-demand environments, which makes them less likely to experience frequent breakdowns. When built to withstand harsh conditions, such as high heat, corrosion, or heavy usage, custom cranes tend to have a longer operational life and require fewer repairs.

- Example:

A custom crane built for a chemical plant, designed to resist corrosion from harsh chemicals, will require fewer repairs compared to a standard crane exposed to the same conditions. This longevity reduces maintenance costs and prolongs the crane's useful life, ultimately lowering the total cost of ownership (TCO).

Case Studies

These case studies demonstrate how custom cranes can address specific operational challenges, leading to increased productivity, lower maintenance costs, and improved efficiency. Whether in a steel mill, port operations, or a chemical plant, custom cranes offer tailored solutions that standard models simply can't match, making them a more cost-effective option in the long run for industries with unique needs.

Steel Mill Application

- Problem:

A standard crane was struggling to handle heavy steel beams efficiently, leading to frequent maintenance and slow processing times. The crane couldn't meet the demands of the steel mill's high-volume operations, which impacted productivity. - Solution:

A custom crane was designed specifically for the steel mill environment, equipped with the necessary features for heavy-duty lifting. This included stronger lifting capacities and optimized speed settings for handling larger loads without compromising on safety. - Result:

The custom crane significantly increased productivity, allowing for faster processing times. With fewer breakdowns and maintenance needs, the mill also saw reduced maintenance costs, improving the overall efficiency of operations.

Port Operations

- Problem:

Standard cranes were struggling to handle large containers efficiently at the port, leading to delays in unloading and loading ships. This bottleneck slowed down the entire port operation, leading to increased costs and delayed deliveries. - Solution:

A custom crane was designed with faster hoisting speeds and larger lifting capacities tailored to the specific demands of port operations. The crane was built for handling larger containers and higher throughput. - Result:

The custom crane led to faster unloading times, improving overall operational efficiency. The port experienced reduced operational costs in the long run, thanks to quicker turnaround times and less need for maintenance.

Chemical Plant

- Problem:

In the chemical plant, a standard crane exposed to highly corrosive environments was constantly breaking down due to rust and wear, leading to frequent repairs and increased downtime. - Solution:

A custom crane was built using corrosion-resistant materials and tailored features to withstand the harsh conditions in the chemical plant. The crane was designed specifically for the plant's unique environment and lifting needs. - Result:

The custom crane required fewer repairs, resulting in lower maintenance costs. With a longer equipment lifespan, the plant experienced reduced downtime and greater reliability in operations, ultimately reducing the overall cost of ownership.

Conclusion

Standard cranes may offer an immediate solution with lower initial costs and faster delivery, but custom cranes provide substantial long-term savings. By enhancing efficiency, reducing maintenance, and improving durability, custom cranes offer more value over time, especially for industries with specific or demanding lifting needs. The right decision depends on your project's unique application requirements, maintenance considerations, and performance expectations.

Final Recommendation

If your industry requires specialized lifting solutions, the higher upfront cost of a custom crane is often justified. Over time, the reduced operational costs, lower maintenance requirements, and increased efficiency make custom cranes the best investment. By focusing on the total cost of ownership and long-term savings, businesses can secure substantial financial benefits with a custom-designed crane.