Your Trusted Overhead Gantry Crane Manufacturer & Supplier

3 Ton Gantry Crane for Sale, Portable & A-Frame Gantry,

Non Rail vs Rail Travelling Gantry Crane 3 Ton

3 Ton Gantry Crane Buying Guide: Models, Prices, and Key Factors for Smart Buyers

Introduction: Why Choose a 3 Ton Gantry Crane

What Is a 3 Ton Gantry Crane?

A 3-ton gantry crane is a versatile lifting system designed to handle loads up to 3,000 kilograms (6,600 lbs) safely and efficiently. It typically consists of a steel or aluminum frame, cross beam (girder), supporting legs, and a hoist and trolley for lifting and moving heavy equipment or materials. This crane type can be portable, adjustable, or fixed, depending on your workspace and operation needs. It is often used as an alternative to permanent overhead cranes because it's easier to install, more flexible, and cost-effective.

- Common lifting capacity: 3 tons (ideal for medium-duty tasks)

- Working height: 3–6 meters (adjustable in most models)

- Beam span: 3–8 meters (customizable for larger workshops)

- Material: steel for strength or aluminum for lightweight mobility

Ideal Applications and Work Environments

The 3-ton gantry crane is widely used in light industrial, maintenance, and production environments, providing an excellent balance of lifting capacity and flexibility.

Typical applications include:

- Workshops and garages: Moving engines, molds, or mechanical parts.

- Warehouses: Loading and unloading pallets, machines, and components.

- Shipyards and docks: Repairing boats, handling marine equipment.

- Construction sites: Lifting materials where overhead cranes are not available.

- Maintenance departments: Relocating heavy tools or performing machinery servicing.

Tip: A 3-ton gantry crane is often the best solution when your load requirements are beyond what manual hoists can handle but don't justify installing a permanent overhead crane system.

Advantages Over 2-Ton and 5-Ton Models

Choosing the right capacity depends on your operational needs. A 3-ton gantry crane strikes a balance between flexibility, cost, and lifting power.

Compared to a 2-ton gantry crane:

- Handles heavier loads safely without requiring significant structural changes.

- Better suited for industrial or production environments rather than just light maintenance.

- Offers future-proof capacity if your load requirements increase.

Compared to a 5-ton gantry crane:

- Lighter and easier to move, especially if you need a portable setup.

- Lower cost of purchase, maintenance, and transportation.

- Ideal for facilities with limited floor strength or restricted ceiling height.

In short: A 3-ton model gives you the perfect mix of lifting strength and mobility—powerful enough for industrial jobs, yet practical for smaller spaces.

Your Trusted Overhead Gantry Crane Manufacturer & Supplier

Main Types of 3 Ton Gantry Cranes

Hot Sale 3 Ton Gantry Cranes for Your Selection

Choosing the right 3-ton gantry crane type is key to maximizing efficiency, safety, and cost-effectiveness. Depending on your workspace, material handling frequency, and mobility requirements, you can select from several models—each with distinct features and advantages.

Below are the four most common types of 3-ton gantry cranes, used across workshops, factories, and outdoor job sites.

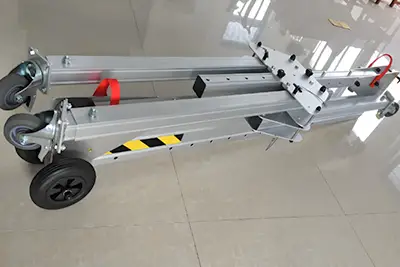

Portable Aluminum Gantry Cranes

Lightweight and corrosion-resistant, aluminum gantry cranes are ideal for users who need a crane that can be easily moved, assembled, and stored.

These cranes are often used for light industrial maintenance, HVAC installation, and machine repair, where flexibility and portability matter more than heavy-duty lifting.

Practical Tip: Portable aluminum gantry cranes are perfect for technicians who move between sites. Look for models with lockable casters and easy pin height adjustments for faster deployment.

Key Features:

- Made from high-strength aluminum, reducing overall weight by 30–40% compared to steel.

- Corrosion-resistant surface—suitable for both indoor and outdoor use.

- Adjustable height and span, allowing adaptation to various load sizes and workspace constraints.

- Collapsible frame design for quick setup and convenient storage or transport in service vehicles.

Typical Applications:

- On-site maintenance and installation jobs.

- Workshops without a fixed crane structure.

- Temporary lifting setups in construction or marine repair areas.

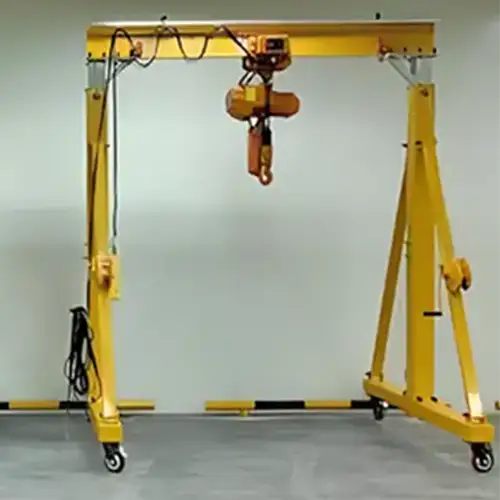

Steel A-Frame Gantry Cranes

The steel A-frame gantry crane is the most popular option for medium-duty industrial use.

It provides superior stability, load capacity, and long-term durability, making it suitable for repetitive lifting tasks in factories and repair shops.

Buyer Insight: A steel A-frame model is a cost-effective solution for buyers who need strength and mobility combined. It's heavier than aluminum but can handle more frequent use in demanding environments.

motorized a frame gantry crane 3 ton for sale, in the picture is a case of 3 ton gantry crane for honduras

Key Features:

- Constructed from high-grade carbon steel, ensuring excellent strength and rigidity.

- A-frame design delivers structural stability even under maximum 3-ton load conditions.

- Equipped with locking swivel casters for easy mobility and positioning.

- Bolt-together design enables quick assembly and disassembly for relocation.

Typical Applications:

- Small factories handling molds, dies, or engines.

- Warehouse loading/unloading areas.

- Machine assembly and repair lines.

Fixed or Stationary Gantry Cranes

When operations require repetitive lifting in a fixed location, a stationary gantry crane offers unmatched stability and precision.

These cranes are permanently installed and often customized for specific industrial processes or warehouse layouts.

Maintenance Note: While fixed cranes require professional installation, they offer long-term durability and low operational cost—ideal for facilities with consistent workflows.

Key Features:

- Rigid structure ensures minimal movement during lifting operations.

- Customizable spans and heights to match building or production line requirements.

- Compatible with manual chain hoists, electric wire rope hoists, or air-powered systems.

- Anchored base design improves safety and load stability.

Typical Applications:

- Assembly lines or production areas where materials are handled repeatedly.

- Warehouses with designated lifting zones.

- Heavy equipment or tool storage areas.

Motorized or Electric Gantry Cranes

For operations that demand frequent lifting, higher productivity, and reduced manual effort, a motorized or electric gantry crane is the top-tier option.

These cranes integrate electric motors for hoisting and travel, significantly improving speed, precision, and operator safety.

Efficiency Tip: Although electric models cost more upfront, they save on labor time and reduce fatigue-related accidents, making them ideal for high-frequency operations.

motorized portable gantry crane 3 ton, tailored solution for your needs

motorized gantry crane 3 ton rail travelling

motorized gantry crane 3 ton low headroom design

Key Features:

- Powered hoisting and traveling systems reduce manual handling.

- Remote control operation allows precise movement from a safe distance.

- Safety limit switches prevent over-travel and over-lifting.

- Available in single-speed or variable-speed options depending on lifting precision needs.

Typical Applications:

- Production facilities with continuous lifting tasks.

- Shipyards and logistics centers requiring fast material transfer.

- Workshops upgrading from manual to semi-automated handling systems.

Your Trusted 3 Ton Gantry Crane Manufacturer & Supplier

3 Ton Gantry Cranes for Sale, Various Types and Cost-effective Price

Featured Gantry Crane Projects and Tailored Solution for Your Reference

Our range of 1-10 ton portable gantry cranes is engineered for versatile load handling across major industrial economies and emerging markets worldwide. From automotive and precision manufacturing in Japan and Germany, to warehouse logistics and workshop lifting in the United States and India, and construction, maintenance, and equipment assembly in China and Brazil, our cranes deliver reliability, mobility, and efficiency. Whether aluminum, steel, or motorized configurations, each system adapts seamlessly to local worksite needs — providing safe, flexible lifting solutions trusted by industries across Asia, Europe, and the Americas. Contact us to get your solution.