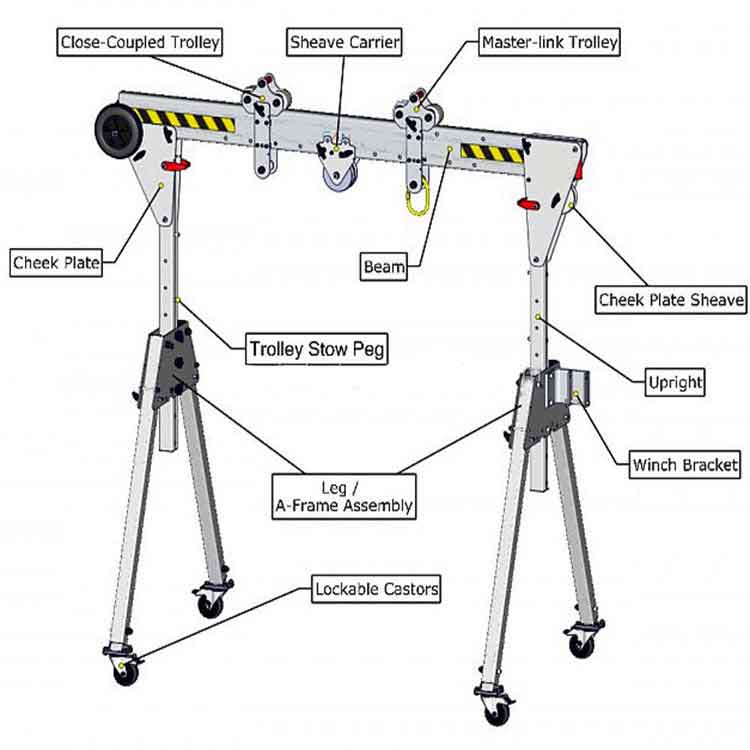

500kg-1 Ton Compact & Light Duty Foldable Aluminum Gantry Crane

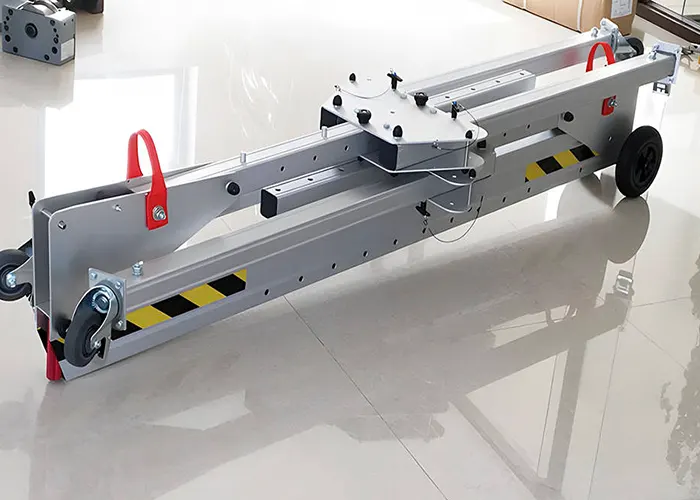

Light duty & lightweight aluminium gantry crane with foldable & compact gantry design, a portable small gantry crane with capacity of 500 kg to 1 ton.

Category: Light Crane & Portable Crane

Your Trusted Portable Aluminum Manufacturer & Supplier

Lightweight, Light Duty, Portable& Foldable

0.5-1 ton Foldable Aluminum Gantry Crane

Light duty & lightweight aluminium gantry crane with foldable & compact gantry design, a portable small gantry crane with capacity of 500 kg to 1 ton. Foldable aluminium gantry crane are designed for transporting and lifting materials. Foldable aluminum gantry crane which is manufactured for the medium and small factory (company) daily production need. It applies to model manufacture and installing situation, automobile factories, producing department and other lifting occasions.

Main Specifications of Foldable Aluminium Gantry Crane

- The foldable aluminium gantry crane can move easily, disassemble and install quickly, cover little area. The structure design reasonably.

- Specifications of foldable aluminium gantry crane

- Load capacity of foldable aluminium gantry crane:0.1 ton - 1 tons

- Crane span of foldable aluminium gantry crane:2m - 8m or customized

- Lifting height of foldable aluminium gantry crane:1m to 8m or customized

- Hoist unit of foldable aluminium gantry crane:Motorized or manual

It has a unique design for light duty load handling with capacities of 100-5000kg and with the features of extremely light deadweight (aluminum alloy material), simple installation, adjustable span, adjustable height, and so on. With unique aluminum gantry crane design, the foldable gantry crane provide an ultra-light and rapid quickly deployment.

Feature of Aluminum Gantry Crane

- Lightweight, portable, transportable, and easy to assemble all-aluminum construction;

- Three-piece design for easy set-up, tear-down, and ground-up assembly;

- Lift height and clear span are fully adjustable with just four bolts;

- Easy-to-clean powder coat finish for usage in clean rooms, labs, and hospitals;

- Locking Casters for independent swivel and roll for complete operator control;

- Our standard models with lift capacity of 5000kg. The foldable gantry crane are widely used for light duty loads handling.

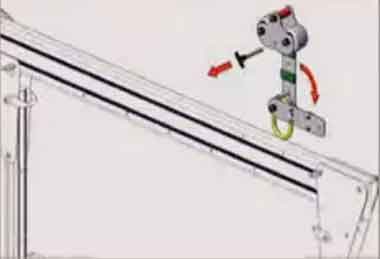

- Locking Surround Beam Trolley including surrounds beam, for prevention of derailment;

- Grade 9 Plated fasteners for corrosion resistance and exceptional strength Padded handles aid in height adjustment, and beams have handles for convenient transport.

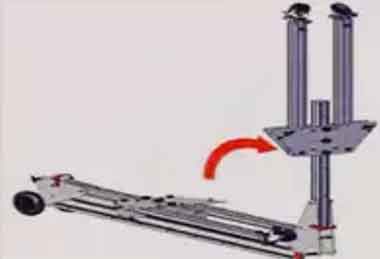

Unfolding of foldable aluminium gantry crane

Folding of foldable aluminium gantry crane

Advantages of Foldable Aluminium Gantry Crane

Welcome to our in-depth exploration of folding gantry cranes—a pivotal solution in the world of industrial material handling. In this comprehensive guide, we delve into the definition, purpose, and advantages of folding gantry cranes, providing practical insights into their typical industrial applications. A folding gantry crane is a versatile and portable lifting solution designed to facilitate material handling in various industrial settings. Unlike traditional gantry cranes, these innovative structures are equipped with a folding mechanism that enhances their mobility and storage capabilities. The primary purpose of a folding gantry crane is to efficiently lift, move, and position heavy loads within confined spaces, offering a dynamic alternative to conventional lifting equipment.- Portability:With self-weigh of only 33kg, the potable aluminium gantry crane can be carried and transported by 1-2 people.

- Load trolley:Easy and quick installation.The gantry wheels are made of high strength nylon

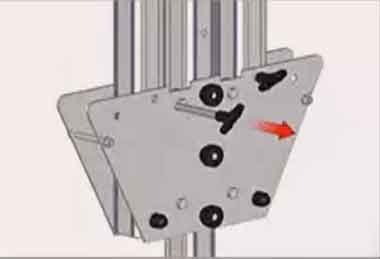

- Quick release latch:Only need to change the quick latch, no need other tools, which only needs 1 minute to plug in and out with 6 pins.

- Compactness-With foldable aluminum alloy structure, the portable gantry cranes can be folded into a compact size to transport and storage.

- Stow ability : All components fold neatly and stone on structure, which can be moved on a wheel

- Rapid attachments :Winch options can be quickly added without the need for tools

- Space Optimization: One of the key advantages of folding gantry cranes lies in their ability to optimize space. The folding mechanism allows the crane to be conveniently stored when not in use, making it an ideal choice for facilities with limited space constraints.

- Quick Setup and Teardown: Efficiency is paramount in industrial operations. Folding gantry cranes boast a quick setup and teardown process, minimizing downtime and enhancing overall productivity.

- Cost-Effective: Compared to fixed gantry cranes, folding gantry cranes are a cost-effective option. Their versatility and adaptability contribute to a higher return on investment for businesses seeking efficient lifting solutions.

Typical Industrial Applications

Folding gantry cranes find applications across a diverse range of industries, proving their adaptability and utility. Some typical industrial applications include:

- Manufacturing and Production: Folding gantry cranes play a crucial role in assembly lines, aiding in the seamless movement of materials and components. Their portability allows for easy integration into various stages of the manufacturing process.

- Warehousing and Logistics: In warehouses, these cranes excel in tasks such as loading and unloading of goods, as well as optimizing storage space. Their quick setup makes them invaluable for handling the dynamic demands of logistics operations.

- Construction Sites: Construction projects benefit from the flexibility of folding gantry cranes, especially in scenarios where heavy loads need to be lifted and positioned precisely. Their adaptability makes them a go-to choice for construction sites with varying requirements.

Unlocking Efficiency Key Features of Folding Gantry Cranes

In this section, we delve into the core features that make folding gantry cranes stand out in the realm of industrial lifting equipment. Understanding the design, construction, load capacity, mobility, and safety features is essential for making informed decisions when considering these versatile cranes for your operations.

Design and Construction

- Materials Used: Folding gantry cranes are engineered with durability and strength in mind. Common materials include high-strength steel for the frame, ensuring a robust structure capable of withstanding heavy loads and repeated use. The choice of materials contributes to the crane's longevity and reliability in diverse working environments.

- Folding Mechanism: The hallmark of folding gantry cranes is their innovative folding mechanism. Typically, these cranes feature a collapsible design that allows for easy setup and disassembly. This mechanism involves precision engineering to maintain structural integrity while enabling quick and efficient folding, ensuring seamless transitions between operation and storage modes.

Load Capacity and Range

Folding gantry cranes are designed to handle a broad spectrum of loads, catering to the diverse needs of industrial applications. Load capacity is a critical factor that varies among different models. Manufacturers provide clear specifications detailing the maximum weight the crane can lift. Additionally, the range of the crane, indicating how far it can extend horizontally and vertically, is crucial for precise material positioning.

Mobility and Portability

The mobility and portability of folding gantry cranes make them invaluable assets in dynamic industrial environments. These cranes often come equipped with wheels or casters, allowing for easy movement across shop floors or construction sites. The ability to relocate the crane swiftly contributes to operational efficiency and adaptability to changing work demands.

Safety Features

- Emergency Stop: Folding gantry cranes prioritize safety with features like an emergency stop button. In the event of an unforeseen circumstance or hazard, operators can immediately halt all crane functions, mitigating potential risks and ensuring the well-being of personnel and assets.

- Overload Protection: To prevent damage to the crane and ensure safe operations, overload protection mechanisms are incorporated. These features monitor the load being lifted, automatically halting the crane if it exceeds the specified capacity. This safeguard not only protects the equipment but also enhances overall workplace safety.

- Locking Mechanisms: The folding gantry crane's stability during operation and storage is reinforced by locking mechanisms. These mechanisms secure the crane in its extended or folded position, preventing unintended movements. Locking features contribute to the structural integrity of the crane and eliminate risks associated with accidental unfolding.

In the subsequent sections of our guide, we will explore the diverse industrial applications of folding gantry cranes and compare them with other portable gantry crane types. Stay tuned for a deeper understanding of how these features translate into practical benefits for your lifting operations.

Where Precision Meets Productivity Industrial Applications of Folding Gantry Cranes

Now that we've explored the foundational features of folding gantry cranes, let's unravel the tapestry of their diverse applications across different industrial sectors.

Manufacturing and Production

- Assembly Lines: Folding gantry cranes play a pivotal role in manufacturing assembly lines, facilitating the seamless movement of components and materials. The cranes' ability to navigate confined spaces and lift heavy loads with precision enhances the efficiency of assembly processes. The quick setup and teardown contribute to minimizing downtime, allowing manufacturers to maintain a smooth and continuous workflow.

- Material Handling: In manufacturing settings, efficient material handling is essential for optimizing production processes. Folding gantry cranes excel in transporting raw materials, sub-assemblies, and finished products within the facility. Their mobility and adaptability make them ideal for various manufacturing layouts, contributing to a streamlined and agile production environment.

Warehousing and Logistics

- Loading and Unloading: Warehouses are dynamic hubs requiring efficient loading and unloading of goods. Folding gantry cranes prove invaluable in these environments, offering quick and precise lifting capabilities. Their portability allows them to be deployed where needed, enhancing the versatility of warehouse operations. The ability to swiftly move from one loading bay to another minimizes downtime, optimizing the throughput of goods.

- Storage: Space optimization is a critical consideration in warehouses, and folding gantry cranes address this challenge effectively. When not in use, these cranes can be easily folded and stored, freeing up valuable floor space. This feature is particularly advantageous for warehouses with varying storage needs, allowing for flexibility in layout and maximizing storage capacity.

Construction Sites

- Building and Infrastructure Projects: Folding gantry cranes are a valuable asset on construction sites, where the lifting and positioning of heavy materials are common requirements. Their portability ensures they can be quickly moved to different locations within the construction site, adapting to the evolving needs of building projects. The ability to navigate tight spaces and provide precise vertical and horizontal movements makes them indispensable in the construction industry.

- Heavy Equipment Installation: When it comes to installing heavy equipment on construction sites, folding gantry cranes shine. Their robust design and lifting capabilities make them suitable for hoisting and placing large machinery with precision. The flexibility to adjust the crane's height and reach ensures that it can meet the specific requirements of different equipment installation scenarios.

Installation of Foldable Aluminum Gantry Crane

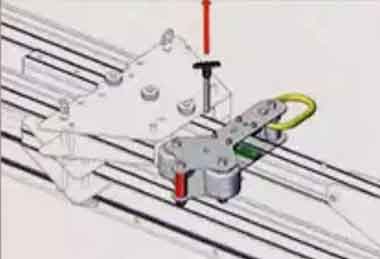

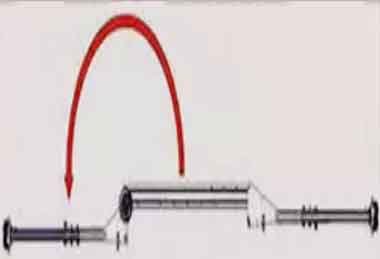

1.Take the pin out of the trolley. Two pins must be removed from the sheaved trolley.

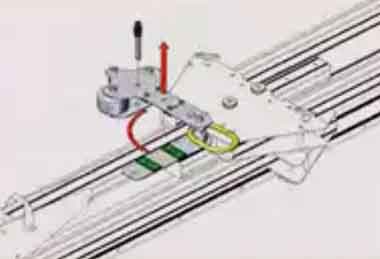

2.Open the trolley by rotating the underneath plate and removing the stone pin.

3.Rotate the first leg assembly so that it is vertical.

4.Remove the ball lock from its storage hole while in this upright position.

5.Open the leg and place the aircraft/ball-lock pin into the second hole to keep it open. Continue with the second leg.

6.Continue to rotate the leg assembly until it lands on the ground.

7. Repeat steps 3-6 to assemble the second leg.

8.Assemble the scissor legs until the aircraft/ball-lock pin is adjacent to the beam. Remove the pin and continue scissoring until the stops engage the beam and the holes line up. Make sure your hands aren't caught between the beam and the cheek plate.

9.Insert the pin into the hole, making sure it is fully engaged. Alignment can be achieved with a gently rocking motion.

10.To assemble the opposite leg, repeat steps 8-9.

11.Take out the pin. Open the trolley and place the plate on the beam, which has been rotated 90 degrees. Allowing the plate to swing open uncontrollably is not a good idea.

12.Insert the aircraft/ball lock pin and close the trolley plate encasing the beam. Make sure the pin is properly engaged in the holes.

Choosing Wisely Comparing Folding Gantry Cranes with Other Portable Options

As we navigate the landscape of small portable gantry cranes, it's essential to understand how folding gantry cranes measure up against their counterparts. In this section, we'll delve into a comparative analysis, starting with fixed gantry cranes.

Fixed Gantry Cranes

Stability and Rigidity:

- Folding Gantry Cranes: While folding gantry cranes offer commendable stability during operation, it's essential to acknowledge that fixed gantry cranes typically surpass them in terms of rigidity. Fixed gantry cranes are anchored to the ground, providing a solid and stable lifting platform. This advantage makes them suitable for applications requiring consistent and heavy lifting without the need for frequent repositioning.

- Fixed Gantry Cranes: These cranes boast a rigid structure, ensuring stability even when lifting substantial loads. Their fixed nature provides a sturdy foundation, making them preferable for applications demanding precision and minimal sway during lifting operations.

Limited Mobility:

- Folding Gantry Cranes: The primary distinction lies in the mobility aspect. Folding gantry cranes, as the name suggests, are designed for easy folding and portability. They excel in scenarios where mobility is a key requirement, allowing for quick relocation between different work areas. This flexibility is a significant advantage in dynamic industrial environments.

- Fixed Gantry Cranes: In contrast, fixed gantry cranes are, as the name implies, stationary structures. Once installed, their location is typically fixed, limiting their adaptability to changing work demands. While this makes them ideal for consistent lifting operations in a dedicated space, it may pose challenges in dynamic work environments or facilities with varied spatial requirements.

These distinctions is crucial when selecting the right gantry crane for your specific needs. In the subsequent sections, we'll explore additional comparisons with adjustable height gantry cranes and telescopic gantry cranes, providing you with a comprehensive understanding to inform your decision-making process. Stay tuned for a deeper dive into the world of portable gantry cranes!

Adjustable Height Gantry Cranes

Versatility in Lifting Heights:

- Folding Gantry Cranes: Folding gantry cranes often come with adjustable height features, providing versatility in lifting operations. The ability to modify the crane's height enhances its adaptability to various tasks and work environments. This flexibility is particularly advantageous when dealing with loads of varying sizes or when precision in lifting height is crucial.

- Adjustable Height Gantry Cranes: These cranes are specifically designed to offer variable lifting heights. They come equipped with mechanisms that allow operators to adjust the crane's height based on the requirements of the task at hand. This adaptability makes them suitable for applications where loads need to be lifted to different elevations within the same workspace.

Trade-offs in Stability:

- Folding Gantry Cranes: The stability of folding gantry cranes is generally well-balanced, especially when designed with a sturdy frame and proper safety features. However, it's essential to note that as the height of the crane increases, there may be some trade-offs in stability. Operators must adhere to load capacity guidelines and recommended usage to maintain a safe working environment.

- Adjustable Height Gantry Cranes: The trade-off in stability for adjustable height gantry cranes primarily occurs at higher elevations. As the crane's height increases, there may be a reduction in overall stability, which could impact the crane's ability to handle heavier loads. It's crucial to consider the specific requirements of your lifting tasks and choose a crane that strikes the right balance between height adjustability and stability.

The trade-offs in stability and the versatility of lifting heights is essential for making informed decisions based on your operational needs. In the next section, we'll explore telescopic gantry cranes, providing a comprehensive comparison to help you choose the optimal portable gantry crane for your specific requirements. Stay tuned for an in-depth analysis of telescopic gantry cranes!

Telescopic and Adjustable Height Gantry Cranes

Extended Reach:

- Folding Gantry Cranes: Folding gantry cranes offer versatility in movement and positioning within a workspace. However, their reach is limited compared to telescopic gantry cranes. While folding cranes provide efficient lifting and maneuverability, telescopic gantry cranes are designed for applications demanding an extended reach. These cranes are ideal for scenarios where materials need to be lifted and placed at greater distances horizontally or vertically.

- Telescopic Gantry Cranes: The defining feature of telescopic gantry cranes is their extended reach. Equipped with telescoping booms, these cranes can reach heights and distances that surpass the capabilities of folding gantry cranes. This makes telescopic gantry cranes well-suited for tasks where a long outreach is essential, such as loading and unloading materials from elevated platforms or reaching over obstacles.

Complexity in Operation:

- Folding Gantry Cranes: The operation of folding gantry cranes is designed to be straightforward, emphasizing user-friendly controls and efficient folding mechanisms. These cranes are known for their ease of use, making them accessible for operators with varying levels of experience. The simplicity in operation contributes to quicker setup and teardown times, enhancing overall productivity.

- Telescopic Gantry Cranes: While telescopic gantry cranes offer unparalleled reach, their operation tends to be more complex compared to folding gantry cranes. The telescoping feature introduces additional controls and adjustments, requiring operators to have a more comprehensive understanding of the crane's capabilities. Proper training is crucial to ensure safe and efficient operation, especially when dealing with extended boom lengths.

The balance between extended reach and the complexity of operation is pivotal when deciding on the right portable gantry crane for your specific requirements. In the following sections, we will explore considerations for purchasing folding gantry cranes, maintenance practices, and delve into case studies to provide real-world insights. Stay tuned for a well-rounded guide to enhance your understanding of the world of gantry cranes!

Choosing Wisely Considerations for Purchasing a Folding Gantry Crane

As you embark on the journey to invest in a folding gantry crane, it's crucial to carefully consider various factors to ensure that the chosen crane aligns seamlessly with your operational needs. Let's delve into the key considerations that should guide your decision-making process.

Load Requirements

- Weight Capacity: Define the maximum weight your folding gantry crane needs to lift regularly. Ensure that the crane's load capacity comfortably accommodates your heaviest loads. It's essential to consider potential future requirements, allowing for scalability and flexibility in your operations.

- Load Size and Dimensions: Consider not only the weight but also the size and dimensions of the loads you'll be handling. Ensure that the crane's design and configuration align with the spatial requirements of your lifting tasks, preventing any operational constraints.

Space Constraints

- Operational Space: Evaluate the available operational space in your facility. Folding gantry cranes are valued for their space-saving design, but it's crucial to confirm that the crane can maneuver effectively within your workspace, especially if it involves tight corners or confined areas.

- Storage Space: Assess the space available for storing the crane when not in use. The folding mechanism is a key feature, but you should ensure that the folded crane can be conveniently stored without causing obstructions or disruptions to other activities in your facility.

Mobility and Transportation

- Ease of Movement: Consider the mobility of the folding gantry crane within your facility. Opt for a crane with sturdy wheels or casters that facilitate smooth movement across different surfaces. The ease of relocation is particularly crucial for operations requiring the crane to be moved frequently between work areas.

- Transportation Between Sites: If your operations involve transporting the crane between different locations, assess the ease of disassembly and transportation. Choose a folding gantry crane that aligns with your transportation logistics, ensuring a seamless transition between sites.

Budgetary Constraints

- Initial Cost: Determine your budget for acquiring a folding gantry crane. Consider the initial cost of the crane itself, along with any additional features or accessories required for your specific applications.

- Total Cost of Ownership: Look beyond the initial purchase price and consider the total cost of ownership. Factor in maintenance costs, potential upgrades, and any operational costs associated with the crane over its lifespan. This holistic approach ensures a comprehensive understanding of the investment.

Safety Standards and Certifications

- Compliance with Regulations: Ensure that the folding gantry crane meets relevant safety standards and regulations in your industry. Compliance with safety guidelines is paramount to creating a secure work environment and preventing accidents or injuries.

- Certifications: Verify that the crane has undergone rigorous testing and holds necessary certifications. Certifications from reputable organizations ensure that the crane meets industry standards for quality, performance, and safety.

By carefully considering these factors, you can make an informed decision when purchasing a folding gantry crane, aligning the equipment with your operational requirements and ensuring a safe and efficient lifting environment. In the next sections, we will explore maintenance practices and share case studies to provide practical insights into the real-world applications of folding gantry cranes. Stay tuned for a comprehensive guide that equips you with the knowledge to make the right choices for your lifting operations!

Nurturing the Lifespan Maintenance and Care for Your Folding Gantry Crane

Ensuring the longevity and optimal performance of your folding gantry crane is not just a matter of investment; it's a commitment to operational efficiency and safety. In this section, we'll explore the essential aspects of maintenance and care, focusing on regular inspection, lubrication of moving parts, repairs and replacements, and operator training.

Regular Inspection:

Regular inspections are the cornerstone of a proactive maintenance strategy. Conduct thorough visual assessments at regular intervals to identify potential issues and ensure the overall health of your folding gantry crane:

- Frame and Structure: Inspect the frame for any signs of corrosion, fractures, or misalignments. Address any structural issues promptly to maintain the crane's stability and load-bearing capacity.

- Lifting Mechanisms: Examine the lifting mechanisms, including hooks, cables, and pulleys. Look for wear, fraying, or deformation. Replace any damaged components to prevent accidents during lifting operations.

- Electrical Components: Check electrical components, such as wiring and control panels, for signs of wear or damage. Ensure that electrical connections are secure and that there are no exposed wires.

- Safety Features: Test and verify the functionality of safety features, including emergency stop buttons, overload protection systems, and locking mechanisms. These features are crucial for preventing accidents and ensuring the well-being of operators and personnel.

Lubrication of Moving Parts:

Proper lubrication is essential for maintaining the smooth operation of your folding gantry crane. Follow these guidelines for effective lubrication:

- Scheduled Lubrication: Adhere to the manufacturer's recommended lubrication schedule. Regularly lubricate moving parts, such as joints, hinges, and pulleys, using the specified lubricants to reduce friction and wear.

- Inspect Lubrication Points: Identify key lubrication points on the crane and inspect them regularly. Ensure that lubrication is applied evenly, and excess lubricant is wiped off to prevent accumulation of dirt and debris.

Repairs and Replacements:

Timely repairs and replacements are critical to preventing further damage and maintaining the crane's operational efficiency:

- Addressing Wear and Tear: Act promptly on identified issues during inspections. Address wear and tear by replacing damaged components with genuine parts to maintain the crane's structural integrity.

- Scheduled Maintenance: Implement a scheduled maintenance program, which includes routine checks, repairs, and proactive replacements. Regularly update and follow the manufacturer's maintenance guidelines to ensure comprehensive care.

Operator Training:

Well-trained operators are essential for safe and efficient crane operation. Ensure your operators are equipped with the knowledge and skills needed to handle the folding gantry crane:

- Comprehensive Training Programs: Invest in comprehensive training programs covering crane functionality, safety protocols, and emergency procedures. Regularly update training to keep operators informed about any changes or advancements in crane technology.

- Operational Awareness: Emphasize the importance of operational awareness, load capacity awareness, and adherence to safety guidelines. Encourage operators to report any issues promptly and to communicate effectively during lifting operations.

By integrating these maintenance and care practices into your operational routine, you contribute to the reliability, safety, and longevity of your folding gantry crane. In the concluding section of our guide, we will explore real-world case studies, showcasing successful implementations of folding gantry cranes across diverse industries. Stay tuned for valuable insights and practical applications!

Insights Studies of Folding Gantry Crane Implementations

In this section, we delve into practical examples of successful folding gantry crane implementations across various industries, examining both triumphs and challenges faced by organizations.

Folded folding gantry crane

Unfolding gantry crane

Case Studies

Successful Implementations in Various Industries:

Automotive Manufacturing:

Challenge: An automotive assembly plant faced the need for a versatile lifting solution to streamline the assembly of vehicle components on the production line.

Solution: The deployment of folding gantry cranes facilitated efficient material handling, ensuring components were lifted and positioned with precision. The cranes' adaptability to changing production demands contributed to improved workflow and reduced assembly times.

Logistics and Distribution Center:

Challenge: A busy logistics and distribution center required a lifting solution that could navigate tight spaces and optimize loading and unloading operations.

Solution: Folding gantry cranes with enhanced mobility were strategically placed throughout the center, providing quick and efficient lifting capabilities. The ability to fold and store the cranes when not in use optimized floor space, contributing to a more organized and productive warehouse.

Construction Site:

Challenge: A construction company engaged in building high-rise structures needed a lifting solution that could handle heavy loads and adapt to different project phases.

Solution: Folding gantry cranes were deployed on the construction site, offering the necessary reach and load capacity. The cranes efficiently lifted and positioned construction materials, contributing to the timely completion of building projects. Their portability facilitated easy relocation as the construction site evolved.

Challenges and Solutions:

Space Constraints in Manufacturing:

Challenge: A manufacturing facility with limited floor space faced challenges in accommodating traditional fixed gantry cranes.

Solution: The implementation of folding gantry cranes addressed the space constraints, as these cranes could be easily folded and stored when not in use. This adaptation allowed the facility to optimize available space while maintaining efficient material handling capabilities.

Mobility Requirements in Infrastructure Projects:

Challenge: Infrastructure projects often involve moving heavy materials across expansive construction sites, requiring a mobile lifting solution.

Solution: Folding gantry cranes with enhanced mobility and a folding mechanism proved to be a suitable solution. The cranes efficiently moved between different project locations, overcoming the challenge of transporting heavy materials across vast construction sites.

Safety Concerns in Warehousing:

Challenge: A warehousing facility needed to address safety concerns related to lifting and positioning heavy loads in confined spaces.

Solution: Folding gantry cranes equipped with advanced safety features, including emergency stops and overload protection, were introduced. These features mitigated safety risks and ensured that lifting operations adhered to industry standards, fostering a secure working environment.

These case studies illustrate the adaptability and effectiveness of folding gantry cranes in addressing diverse challenges across industries. By understanding the successful implementations and overcoming specific challenges, organizations can make informed decisions when integrating folding gantry cranes into their operations. Stay tuned for the concluding section, where we explore future trends and innovations in the realm of gantry cranes!

Embracing the Future Conclusion on Folding Gantry Cranes

In revisiting the journey through folding gantry cranes, we've highlighted the following key benefits and applications:

Space Optimization: Folding gantry cranes efficiently utilize space, both during operation and storage, making them ideal for facilities with limited floor space.

Portability: The ability to move and relocate quickly enhances flexibility in various industrial environments, from manufacturing and warehousing to construction sites.

Versatility: Folding gantry cranes are versatile lifting solutions suitable for a range of applications, including assembly lines, material handling, and heavy equipment installation.

Final Recommendations for Potential Buyers:

For organizations considering the integration of folding gantry cranes into their operations, the following recommendations can guide the decision-making process:

Define Load Requirements: Clearly understand the weight and dimensions of the loads that will be lifted regularly, ensuring the chosen crane meets these requirements.

Assess Space Constraints: Evaluate available space in the facility, considering both the extended and folded states of the crane to ensure seamless integration.

Prioritize Mobility: Determine the mobility requirements based on the need for crane relocation, emphasizing features like wheels or casters for enhanced mobility.

Establish Budget: Set a budget for the crane investment, considering the total cost of ownership, including maintenance and operational expenses.

Prioritize Safety: Select a folding gantry crane that adheres to safety standards and certifications, prioritizing features like emergency stops and overload protection.

Technological Integration: Increased integration with automation and digital technologies to enhance crane control and monitoring capabilities.

Sustainable Features: A focus on incorporating eco-friendly and sustainable features to align with evolving environmental considerations.

Enhanced Safety Measures: Ongoing advancements in safety features and operator-assist technologies to further reduce the risk of accidents and ensure compliance with stringent safety standards.

In conclusion, folding gantry cranes stand as a testament to innovation in industrial material handling. Their space-saving design, portability, and versatility make them indispensable across diverse applications. As industries evolve, folding gantry cranes are poised to play a pivotal role in meeting the dynamic demands of modern workplaces.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch