Electric winch

Electric winches of various industrial winch designs, small & heavy duty electric power winch & electric motor winch for hoist, lift & pull.Electric winch for sale.

| Model | JM, JK, JMM, JK-D, JKL, JT |

| Loading Capacity | 0.5 ton to 80 ton |

| Rope Capacity | 20m to 5000m |

| Working speed of electric winch | 5~35m/min |

| Power Supply | 220-690V,50/60HZ,3Phase |

Category: Winch

Your Trusted Electric Motor Winch Manufacturer & Supplier

Safe & Efficient Hoist & Pull Cable Winch

Electric Winches& Electric Power Winch

Electric winch is a type of industrial equipment for small and heavy duty loads or objects hoisting and pulling which are equipped with one or two winch drum and the winch rope is arranged orderly and neatly around the winch drum. The electric cable winch or wire rope winch not only can work independently, but also can be used as a part or component of large scale and complex machine for safe, efficient and stable hoisting, pulling and other handling operations,etc.

Main Specifications & Parameters of Electric Winches

As a manufacturer and supplier, we can offer you types of electric winches with process features to meet your particular applications, including JM Series electric controlling slow speed winch, JK series electric control high speed winch, JMM series friction winches, JK-D series winch and JKL series hand control high speed free rolling winch etc. The main specifications of our electric winches are presented for your reference.

- Winch Model: JM, JK, JMM, JK-D, JKL, JT

- Loading capacity of electric winch: 0.5t to 80t

- Rope capacity of electric winch: 20m to 5000m

- Working speed of electric winch: 5~35m/min

- Power supply of electric winch:220-690V,50/60HZ,3Phase or tailored

Electric winches of process winch designs and configurations, free consultation on electric winch design and electric winch price are available. Contact us to see what we can do for you.

Chinese crane open winch

Loading Capacity: 0.5~200 t ;

Rope Capacity: 20~3600 m;

Working Speed: 5~20 m/min;

Power Supply: 220-690V,50/60HZ,3Phase;

Ask for electric winch price

European style crane open winch

Loading Capacity: 0.5~60 t

Rope Capacity: 20~500 m

Working Speed: 20~35 m/min

Power Supply: 220-690V,50/60HZ,3Phase

Ask for electric winch price

JM Low Speed Electric Winch

Loading Capacity: 0.5~200 t ;

Rope Capacity: 20~3600 m;

Working Speed: 5~20 m/min;

Power Supply: 220-690V,50/60HZ,3Phase;

Ask for electric winch price

JK Fast Speed Electric Winch

Loading Capacity: 0.5~60 t

Rope Capacity: 20~500 m

Working Speed: 20~35 m/min

Power Supply: 220-690V,50/60HZ,3Phase

Loading Capacity: 0.5~60 t

Rope Capacity: 20~500 m

Working Speed: 20~35 m/min

Power Supply: 220-690V,50/60HZ,3Phase

2JKL Double Drum Piling ElectricWinch

Loading Capacity: 1~20 t;

Rope Capacity: 20~500 m

Working Speed: 20~36 m/min

Power Supply: 220-690V,50/60HZ,3Phase

JMM Friction Type Electric Winch

Loading Capacity: 0.5~80 t

Wire Rope Capacity:20~5000 m

Working Speed:5~20 m/min

Power Supply: 220-690V,50/60HZ,3Phase

JKL Piling Electric Winch

Loading Capacity: 1~10 t;

Rope Capacity: 20~500 m

Working Speed: 20~36 m/min

Power Supply: 220-690V,50/60HZ,3Phase

JKD Planetary Electric Winch

Loading Capacity: 0.75-3 t

Wire rope Capacity:20~200 m

Working Speed:20~35 m/min

Power Supply: 220-690V,50/60HZ,3Phase

Ask for electric winch price

JT Variable Speed Electric Winch

Loading Capacity: 3-20 t

Rope Capacity:20~500 m

Working Speed:0~30 m/min

Power Supply: 220-690V,50/60HZ,3Phase

Ask for electric winch price

Electric Winch Design, Process Electric Winch for Specific Applications

When it comes to winch design, there are several factors you need to consider, including rated capacity, speed, rope capacity and environmental conditions.

Main components and structures of electric winch

Generally, the electric winch is mainly consisted of electric driven motor, coupling, brake, gear box and winch drum, installed on the winch trolley frame, etc. Simply, the electric winch converts electrical power into mechanical power and winch drum rolling the wire rope on and off for the loading and unloading of heavy objects or materials.

For large lifting heights and heavy loading and unloading conditions, the electric pulling winch and hoist winch are required to have good performance of speed regulation to meet various lifting requirements. The heavy load can be hoisted to a higher position at a relatively high speed, and the empty hook can be lowered at fast speed, and for the sensitive load, the operation speed of electric winch is relatively slow. Customized electric winch are available to meet your application conditions and handling requirements. Contact us to get more information.

Factors define your winch design

- Working load limit - The maximum load capacity or pulling force , and working length of the wire rope on the winch drum should be designed and fabrications according to your requirements.

- Winch drum- The size of the winch drum is largely determined by the winch capacity requested.

- Rope speed - The speed of the electric winch are defined by the usage of your cable winch, which are optional with single speed, two speed motor and variable speed, etc.

- Braking system-The process electric winch can be configured with motor brake, transmission brake and band brake to ensure the operation safety with a fail-safe braking system.Motor brake is re-commanded for accurate positioning with high safety and the band brake is an extra brake equipped on winch drum, which can be operated manually or hydraulically as your requirements.

- Winch controls- A push-button control and remote control are optional for electric winch. The push-button winch control box in installed on or near the electric winch to control the rotation of winch drum and the remote control either by a control pendant or wireless remote control to enable the long distance control of electric winch possible and improve operator safety. For hydraulic winch, hydraulic power units (HPU) of tailored design is required to operate the hydraulic winch.

- Winch options - Additional features can be added to meet particular requirements by adopting various options and accessories such as, pressure roller, spindle limit switch, winch drum guard, wire rope guide, winch band brake, clutch, additional wire rope anchor and manual emergency crank,etc.

Classifications of Electric Winches

Electric winches of various types and configurations are available to meet the diverse applications and industrial requirements. Our electric winch shop are available with various types of electric winches including:

- Electric industrial winch for different applications and functions such as construction winch, mine winch, hoisting winch, pulling winch, crane winch, etc.

- Electric power winch and motor winch of different power supplies such as, the 110 v winch, 120 v winch, or electric winches with the power supply of 220-690V,50/60HZ,3Phase,

- Electric winch for different working duties such as the small winch and heavy duty winch, etc.

- Electric winch of different rope speed such as fast speed winch, medium speed winch, slow speed winch and variable speed winch,etc.

- Customized electric power winch and motor winch are available. Contact us to get free consultation on electric winch design and electric winch price.

Advantages and benefits of electric winches

Why to use an electric power winch? An electric winch or motor winch provides many advantages over hydraulic winch or air powered winch. An electric winch can provide you the a lots of benefits:

- A motor winch are available with a wide range of designs and large capacity to fit your specific needs with reliable and safe operations.

- Electric winch is powered by electricity which has relative low operational cost.

- The structure of electric power winch is simple and the maintenance of electric motor winch is minimal.

- The transportation and installation of motor winch are very simple and convenient.

- The motor winch can be controlled remotely to ensure safety.

Generally speaking, the electric winch is always the first choice when hoisting winch or pulling winch is needed. When the electric motor winch is not practical to your applications, the hydraulic winch and pneumatic winch will be come into consideration. If you do not know how to select, please feel free to contact us to get professional suggestions.

Your Trusted Electric Winceh Manufacturer & Supplier

Electric Winch for Sale, Your Electric Winch Shop on Line

As a manufacturer and supplier, we can offer you types of electric winches with process features to meet your particular applications, including JM Series slow speed winch, JK series high speed winch, JMM series friction winches, JK-D series electric power winch and JKL series hand control electric winch etc. Base on their features and advantages, you can select the suitable motor winch for your application or contact us to get customized electric winch for your application.

Slow Speed Winch of JM Series Wlectric Winches

JM series slow speed electric winch is a type of wire rope winch with the structural characteristic of wire rope orderly arranged around the winch drum, with the features of simple and convenient operation, large rope capacity, easy relocation, high safety, reliable, durable, and low noise,etc. The slow speed electric winch can be used widely for vertical hoisting , horizontal or slop pulling or towing heavy cargos, such as large concrete, steel structure, mechanical equipment in various industries such as, ports, docks and other road and bridge construction projects and large-scale factories and mines, etc.

- Loading Capacity: 0.5~200 ton

- Rope capacity of electric winch: 20~3600 m;

- Working speed of electric winch: 5~20 m/min;

- Power supply of electric winch: 220-690V,50/60HZ,3Phase;

- Ask for electric power winch price

Features of Slow Speed Electric Winch:

Slow-speed winches are designed for precision and controlled movements. They provide a gradual and steady winding or unwinding of the cable, allowing for careful handling of loads.

Features:

- Precise control over lifting or pulling operations.

- Ideal for applications where speed needs to be carefully managed.

- Reduced risk of sudden movements.

Applications:

- Construction sites for controlled material handling.

- Tasks requiring careful positioning of loads.

- Applications where safety is a primary concern.

High Speed Winch of JK Series Electric Power Winch

JK series fast speed electric winch with high speed of 20~35 m/min and 1ton -80 ton load lifting capacity can be used for large and heavy sized loads handling such as large and medium concrete, steel structure and machinery equipment installation and dismantling, etc. The high speed electric winch can be processed with various industrial features to meet diverse industrial applications such as factory workshops, warehouses,construction site, mines,, harbors, cargo storage areas and others, to improve your working efficiency and safety.

- Loading capacity of electric winch: 0.5~60 t

- Rope capacity of electric winch: 20~500 m

- Working speed of electric winch: 20~35 m/min

- Power supply of electric winch: 220-690V,50/60HZ,3Phase

- Ask for electric power winch price

Features of High Speed Electric Winch:

High-speed electric winches are engineered for rapid cable deployment and retrieval. They offer quick response times, making them suitable for scenarios where speed is of the essence. Features:

- Swift and efficient cable movement.

- Ideal for tasks that require a quick response.

- Increased productivity in certain applications.

Applications:

- Emergency response scenarios.

- Rapid deployment of equipment.

- Situations where time is a critical factor.

JT Variable Speed Winch

Variable speed electric winch of JT series electric winch is a type of electric winch with the features of variable speed winch controller, high speed and low speed's brake, easy usage and operation, high efficient and safe, etc. The JT series of various speed electric winch are usually adopted for vertically hoisting or horizontally pulling heavy and large loads or objects, such as, steel structure, mechanical equipment, concrete and prefabricated parts and components, and others, etc.

- Model: JT electric winch

- Loading capacity of electric winch: 3-20 t

- Rope capacity of electric winch :20~500 m

- Working speed of electric winch: 0~30 m/min

- Power supply of electric winch: 220-690V,50/60HZ,3Phase

- Ask for electric power winch price

Features of Variable Speed Winch:

Variable speed winches provide the flexibility of adjusting the speed according to specific tasks. Users can vary the winch's speed to accommodate different load requirements and operational conditions.

Features:

- Versatility in adapting to various tasks.

- Ability to control speed based on load and application.

- Enhanced flexibility for diverse operations.

Applications:

- Tasks with varying load capacities.

- Applications where different speeds are required for different phases of the operation.

- Versatile usage across a range of scenarios.

Slow Speed Winch, High Speed Electric Winch & Variable Speed Winch:

Electric winches come with different speed configurations, catering to a wide range of applications. Understanding the distinctions between slow speed, high-speed electric winches, and those with variable speed capabilities is crucial for selecting the most suitable option for your specific tasks.

How to Choose the Right Speed Configuration:

Selecting the appropriate speed configuration depends on the nature of your tasks and specific requirements:

- Precision Tasks:Slow Speed Winch: Optimal for tasks that demand careful and precise movements.

- Time-Sensitive Operations:High Speed Electric Winch: Ideal for scenarios where quick response times are crucial.

- Versatility and Flexibility:Variable Speed Winch: Offers adaptability for diverse applications and load requirements.

Consider the specific demands of your projects, the nature of the loads you'll be handling, and the level of control required. Choosing the right speed configuration ensures efficient and safe operation in various scenarios.

Friction Winches of JMM Series Motor Winches

The friction type motor driven winches are frequently adopted for long-distance towing and long stroke handling of large and heavy loads such as concrete structures, steel structures, steel cables and other objects and items in various industrial sectors, especially in infrastructure of road and bridge, building construction, and other industrial sectors to ensure material handling safety and efficiency.

JMM Friction Type Electric Winch

- Model: JMM electric winch

- Loading capacity of electric winch: 0.5~80 t

- Wire Rope Capacity:20~5000 m

- Working speed of electric winch: 5~20 m/min

- Power supply of electric winch: 220-690V,50/60HZ,3Phase

- Ask for electric power winch price

Features of Electric Friction Winches

Friction winches stand out in the realm of winching solutions due to their distinctive operating principle, relying on the creation of friction between the winch drum and the load. This unique approach opens up possibilities for scenarios where conventional winching methods may pose challenges, making friction winches a valuable alternative for specific lifting or pulling tasks.

- Description:Friction Winch: Unlike traditional winches that rely on direct cable winding, a friction winch operates by generating friction between the winch drum and the load. This frictional force facilitates the lifting or pulling of the load.

- Features:Variable Friction Control: Friction winches often come equipped with mechanisms to adjust the level of friction. This provides operators with control over the lifting or pulling force applied to the load. Adaptability: The frictional approach allows for adaptability to different shapes and sizes of loads, making friction winches suitable for tasks where the load characteristics may vary. Alternative Lifting Method: Friction winches provide an alternative lifting method, offering solutions in scenarios where traditional winching setups are impractical.

- Applications:Challenging Terrain: Friction winches excel in situations where the terrain is challenging, such as steep inclines or uneven surfaces, where a direct pull may be difficult to achieve. Irregularly Shaped Loads: The adaptability of friction winches makes them well-suited for lifting irregularly shaped or uneven loads that may pose challenges for conventional winches. Limited Anchor Points: In scenarios where anchor points are limited or unconventional, friction winches offer flexibility in creating suitable anchor surfaces.

Considerations for Friction Winch Usage:

Integrating a friction winch into your operations requires careful consideration of specific factors related to its unique operating principle:

- Friction Adjustment:Understand and experiment with the friction adjustment mechanisms to achieve the desired lifting or pulling force while preventing excessive strain on the system.

- Load Characteristics:Assess the characteristics of the loads to be lifted or pulled. Friction winches are versatile, but understanding load shapes, sizes, and weights is crucial for effective operation.

- Terrain and Conditions:Consider the terrain and environmental conditions where the friction winch will be utilized. Its adaptability is advantageous in challenging conditions.

- Operator Training:Provide training to operators on the specific nuances of operating a friction winch, emphasizing the control of friction and ensuring safe usage.

- Maintenance and Inspection:Regularly inspect and maintain the friction winch to ensure optimal performance. Pay attention to components that contribute to friction and make necessary adjustments.

Friction winches present a unique and versatile solution in the world of winching technology, offering an alternative approach to lifting and pulling tasks. Understanding their features, applications, and considerations allows industries to leverage the benefits of friction winches in situations where traditional winches may fall short.

Planetary Winch of JK-D Series Electric Winch

Planetary winch of JKD electric winch series is a type of small cable winch, a new type of pulling and hoisting winch with a planetary drive with small teeth difference, featured as compact winch structure, stable running speed, convenient operation,convenient maintenance, low noise and durable working life. This planetary small electric winch is applicable for heavy duty application of various industries, including the construction, mining, piers, and metallic industries and general manufacturing, etc.

- Model: JKD electric winch

- Loading Capacity of electric winch: 0.75-3 t

- Wire rope capacity of electric winch:20~200 m

- Working speed of electric winch: 20~35 m/min

- Power supply of electric winch: 220-690V,50/60HZ,3Phase

- Ask for electric power winch price

Features of Planetary Winch:

Planetary winches represent a specialized category known for their distinctive design, incorporating a planetary gear system. These winches are engineered to deliver high efficiency, compact form factors, and substantial torque. Understanding the features and applications of planetary winches is crucial for industries and activities requiring robust pulling power in a compact package.

- Description:Planetary Winch: Characterized by a planetary gear system, consisting of multiple gears that revolve around a central gear (sun gear). This design enhances the winch's overall efficiency and torque output while maintaining a compact and lightweight structure.

- Features:Efficient Power Transmission: The planetary gear system allows for efficient power transmission, ensuring that a significant amount of input power is converted into pulling force. Compact Design: Planetary winches are known for their compact and space-efficient design, making them suitable for installations where space constraints are a consideration. High Torque Output: The planetary gear configuration provides increased torque, making these winches ideal for applications demanding substantial pulling power.

- Applications:Off-Road Recovery: Planetary winches find extensive use in off-road vehicles for recovery purposes. Their high torque output is valuable when pulling vehicles out of challenging terrains. Industrial Tasks: Industries requiring powerful winches in confined spaces benefit from the compact design and robust torque capabilities of planetary winches. Construction and Rigging: Planetary winches are employed in construction and rigging applications where the combination of power and size is crucial for efficient material handling and positioning.

Considerations for Planetary Winch Selection:

Selecting a planetary winch involves considering specific factors aligned with the intended applications:

- Torque Requirements:Assess the torque requirements of the intended task to ensure that the selected planetary winch can deliver the necessary pulling power.

- Space Constraints:If space is limited, a planetary winch's compact design makes it a suitable choice for installations where traditional winches may not fit.

- Weight Considerations:Planetary winches are generally lighter than their counterparts with similar power outputs. Evaluate weight constraints, especially in mobile applications.

- Environmental Conditions:Consider the environmental conditions where the winch will operate. Planetary winches are versatile, but ensuring compatibility with the operating environment is essential.

- Task Specifics:Match the winch specifications with the specific requirements of the task, whether it involves off-road recovery, industrial pulling, or construction applications.

The unique advantages of planetary winches, along with thoughtful consideration of the application's requirements, allows industries and enthusiasts to make informed choices when incorporating these high-performance winches into their operations.

Piling Winch of JKL Series Electric Winch

Piling winch of JKL electric winch series is a specialized manual control piling winch ,hoisting winch and pulling winch, with high operation speed hand control brake , and the structural characteristic of rotating shaft, etc. The piling type electric winch can be used independently or worked as a hoisting equipment of a process crane, mining hoist machine or other equipment, etc.

- Model: JKL electric winch

- Loading capacity of electric winch: 1~10 t;

- Rope capacity of electric winch: 20~500 m

- Working speed of electric winch: 20~36 m/min

- Power supply of electric winch: 220-690V,50/60HZ,3Phase

- Ask for electric power winch price

Featues of Electric Piling Winches

Piling winches play a crucial role in construction and civil engineering projects, specifically designed for driving piles into the ground efficiently. These winches are essential in tasks where the installation of structural foundations, such as piles or posts, is required. Understanding the features and applications of piling winches is key to their successful integration into construction operations.

- Description:Piling Winch: A specialized winch designed for the purpose of driving piles into the ground during construction and foundation work. Piling winches are engineered to provide the force and control necessary for efficient pile installation.

- Features:Robust Power: Piling winches are equipped with robust motors capable of delivering high torque and force required for driving piles into various types of soil and ground conditions. Controlled Operation: Precision and control are essential in piling operations. These winches are designed to offer precise control over the piling process to ensure accurate and stable pile placement. Durable Construction: Piling winches are built with durability in mind, considering the challenging conditions often encountered in construction sites. Sturdy construction materials and components contribute to their reliability.

- Applications:Foundation Construction: Piling winches are extensively used in the construction of foundations for buildings, bridges, and other structures. They are employed to drive piles into the ground to provide structural support. Retaining Walls: Piling winches play a vital role in the construction of retaining walls, where the driving of piles is necessary to create a stable structure capable of resisting soil pressure. Infrastructure Projects: These winches are utilized in various infrastructure projects, including the installation of support structures for highways, railways, and other transportation networks. Deep Foundations: Piling winches are employed in deep foundation projects, ensuring the stability and integrity of structures in challenging soil conditions.

Considerations for Piling Winch Selection:

Selecting the right piling winch involves considering specific factors related to the project requirements:

- Pile Size and Type:The winch should be capable of accommodating the size and type of piles used in the construction project.

- Soil Conditions:Different soil conditions require varying levels of force. The winch should be chosen based on the soil characteristics to ensure efficient pile driving.

- Control and Precision:Precision is critical in piling operations. Choose a winch that offers precise control over the piling process to achieve accurate and stable pile placement.

- Durability and Reliability:Given the challenging conditions of construction sites, durability and reliability are paramount. Opt for a piling winch with robust construction to withstand the rigors of the job.

- Project Scale:Consider the scale of the construction project, as larger projects may require more powerful and high-capacity piling winches.

The specific requirements of the construction project and the soil conditions is essential for selecting the right piling winch. By considering these factors, construction professionals can ensure the efficiency and success of piling operations in building stable and resilient structures.

Double Drum Winch of 2JKL Series Electric Winch

Double drum electric winch also called double drum winch is a type of fast speed electric winch equipped with double wire rope drums with large rope capacity up to 500 meters. With double drum design, one of the wire rope drum is for wire rope or cable storing and the other is for piling. The double drum electric winch is the most frequently used piling winch.

- Model: 2JKL electric winch

- Loading capacity of electric winch: 1~20 t;

- Rope capacity of electric winch: 20~500 m

- Working speed of electric winch: 20~36 m/min

- Power supply of electric winch: 220-690V,50/60HZ,3Phase

- Ask for electric power winch price

Drum Winch: Single Drum Winch & Double Drum Winch:

The distinction between single drum winches and double drum winches lies in their drum configuration, impacting their functionality and suitability for various applications. Understanding the characteristics and applications of each type is essential for selecting the right winch based on specific project requirements.

Single Drum Winch:

- Description: A single drum winch is equipped with one drum for winding the cable or rope. It is a straightforward and efficient design suitable for applications where a single cable is sufficient for the intended tasks. Features:

- Simplicity in design and operation. Compact and lightweight compared to double drum winches. Ideal for tasks that do not require independent cable winding or simultaneous operation. Applications:

- Light to moderate lifting and pulling tasks. Situations where a single cable is adequate for the application. Commonly used in general material handling and towing scenarios.

Double Drum Winch:

- Description: A double drum winch is designed with two independent drums, allowing for the winding or unwinding of two separate cables simultaneously. This configuration provides versatility for handling multiple loads or executing different tasks at the same time. Features:

- Independent cable operation for increased flexibility. Capable of handling more complex lifting and pulling scenarios. Enhanced efficiency in certain applications requiring dual cable functionality. Applications:

- Construction sites with varied lifting requirements. Marine applications where multiple cables are utilized. Tasks demanding simultaneous and independent cable operations.

Choosing Between Single Drum and Double Drum Winches:

Selecting the appropriate winch configuration depends on the nature of your tasks and the complexity of the lifting or pulling requirements:

- Simplicity and Efficiency:Single Drum Winch: Optimal for straightforward tasks where a single cable suffices.

- Versatility and Complexity:Double Drum Winch: Ideal for applications requiring simultaneous and independent cable operations.

- Consider Load Variety:Single Drum Winch: Suited for tasks with consistent load requirements. Double Drum Winch: Versatile for handling diverse loads simultaneously.

- Space and Weight Considerations:Single Drum Winch: Compact and lightweight design. Double Drum Winch: Suitable for applications where the benefits of dual cable operation outweigh the added weight and complexity.

The specific demands of your projects and the need for single or dual cable functionality allows you to choose between single drum and double drum winches effectively, ensuring optimal performance and efficiency in your applications.

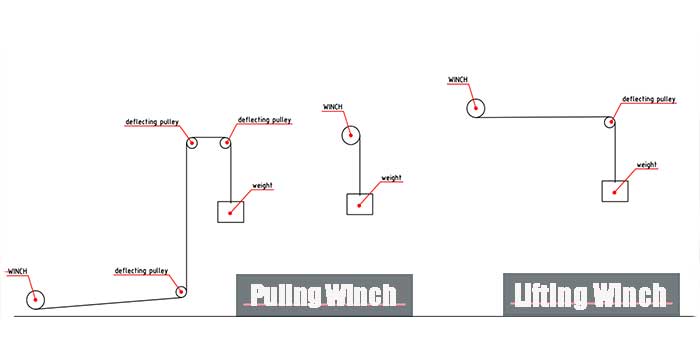

Electric Lifting Winch & Electric Pulling Winch:

Electric winches serve distinct purposes based on whether they are designed for lifting or pulling tasks. Understanding the differences between electric lifting winches and electric pulling winches is essential for selecting the right tool to meet your specific requirements.

Electric Lifting Winch:

Electric lifting winches are engineered for vertical lifting applications. They are designed to elevate loads vertically with precision and control, making them suitable for tasks where materials or equipment need to be raised to a higher position. Features:

- Vertical lifting capabilities.

- Enhanced control for precise positioning.

- Designed with safety features for lifting applications.

Applications:

- Construction sites for lifting building materials.

- Warehouses for vertical material handling.

- Tasks requiring controlled lifting in industrial settings.

Electric Pulling Winch:

Electric pulling winches are designed for horizontal pulling or dragging applications. They are well-suited for tasks where loads need to be moved horizontally, providing the necessary pulling force to tow or drag objects. Features:

- Horizontal pulling capabilities.

- Robust pulling force for dragging loads.

- Versatile for a range of pulling applications.

Applications:

- Off-road recovery for pulling vehicles.

- Moving heavy equipment horizontally.

- Tasks requiring controlled pulling force.

Light Duty Electric Winch & Heavy Duty Electric Winch

Light Duty Electric Winch & Heavy Duty Electric Winch: How to Confirm Winch Duty:

Electric winches come in various capacities, and understanding the distinction between light-duty and heavy-duty options is pivotal for selecting the right tool for your specific needs.

Light Duty Electric Winch:

Light-duty electric winches are designed for occasional or light use. They are characterized by their compact size, lower load capacities, and simplified construction. Features:

- Suitable for intermittent tasks.

- Compact and portable design.

- Economical choice for lighter loads.

Applications:

- DIY projects and home use.

- Recreational activities like ATV recovery.

- Occasional lifting or pulling tasks.

Heavy Duty Electric Winch:

Heavy-duty electric winches are robust and built to handle frequent and demanding applications. They are designed with reinforced components to withstand continuous use and tackle higher load capacities. Features:

- Sturdy construction for durability.

- Higher load capacities.

- Suitable for frequent and challenging tasks.

Applications:

- Construction sites for material handling.

- Industrial settings with regular lifting requirements.

- Off-road recovery for larger vehicles.

How to Confirm Winch Duty:

Determining whether you need a light-duty or heavy-duty electric winch depends on several factors. Consider the following guidelines:

- Frequency of Use:Light Duty: If you plan to use the winch occasionally for light tasks. Heavy Duty: For frequent and demanding applications where the winch will be in regular use.

- Load Requirements:Light Duty: Suitable for tasks with lighter loads. Heavy Duty: Choose if you anticipate dealing with heavier materials or equipment.

- Construction and Durability:Light Duty: Compact and designed for occasional use. Heavy Duty: Built with reinforced components to endure continuous usage.

- Budget Considerations:Light Duty: Generally more budget-friendly. Heavy Duty: May require a higher initial investment but offers durability and performance for heavy tasks.

By carefully assessing your specific requirements and understanding the nature of your tasks, you can confidently choose between a light-duty and heavy-duty electric winch. Whether you're a DIY enthusiast, off-road adventurer, or involved in industrial applications, selecting the appropriate winch duty ensures optimal performance and longevity.

Hot Sale Capacities of Electric Winches: Choosing the Right Ton for Your Task

Small Capacity Winch: Designed for lighter loads, offering a compact and efficient solution for tasks with lower weight requirements. Ideal for applications where the load is relatively light, providing an economical and practical solution.

Medium Capacity Winch:Suitable for moderate loads, striking a balance between versatility and capacity. Well-suited for tasks where a moderate amount of lifting or pulling power is required, providing flexibility across various scenarios.

Large Capacity Winch:Built for heavy-duty tasks, featuring robust construction and higher load capacities. Tailored for applications demanding substantial lifting or pulling power, handling heavy loads in demanding industrial or construction environments.

When it comes to electric winches, one size certainly does not fit all. The capacity of an electric winch is a critical factor, determining its ability to handle various loads effectively. To assist you in making an informed decision, let's explore the hot sale capacities of electric winches, ranging from 10 to 50 tons.

- 10 Ton Electric Winch: Designed for lifting and pulling tasks requiring a moderate capacity. Applications: Ideal for scenarios where a robust yet moderately powered winch is sufficient, such as material handling in construction or light industrial applications.

- 12 Ton Electric Winch: Offers a slightly higher capacity than the 10-ton model, providing increased lifting and pulling power. Applications: Well-suited for tasks demanding a bit more strength, such as lifting heavier equipment or handling larger loads in construction and manufacturing.

- 15 Ton Electric Winch: Stepping up in capacity, the 15-ton electric winch brings more substantial lifting and pulling capabilities. Applications: Suitable for tasks requiring a higher level of strength, including heavier material handling in construction and industrial settings.

- 20 Ton Electric Winch: Considered a heavy-duty winch, the 20-ton capacity ensures robust performance for demanding applications. Applications: Ideal for lifting and pulling heavy loads in industries like mining, where the demands on equipment are significant.

- 25 Ton Electric Winch: A powerhouse in the electric winch lineup, the 25-ton capacity provides exceptional strength for challenging tasks. Applications: Well-suited for heavy-duty lifting and pulling requirements, especially in industries with substantial loads such as mining and offshore operations.

- 30 Ton Electric Winch: Designed for extremely heavy loads, the 30-ton electric winch is built to handle the most demanding tasks. Applications: Commonly used in industries where the weight of materials or equipment requires a robust and high-capacity winching solution.

- 50 Ton Electric Winch: The pinnacle of capacity, the 50-ton electric winch is a heavyweight performer for the toughest lifting and pulling challenges. Applications: Reserved for the most demanding tasks, such as large-scale construction projects or heavy material handling in industrial settings.

When selecting an electric winch, it's crucial to match the winch's capacity to the specific requirements of your task. Consider factors such as the weight of the loads, the frequency of use, and the conditions in which the winch will operate. Opting for a capacity that aligns with your needs ensures optimal performance, longevity, and safety in your operations.

In conclusion, the hot sale capacities of electric winches cater to a diverse range of applications, providing solutions for tasks of varying magnitudes. Whether you're lifting moderate loads in construction or tackling heavy-duty challenges in mining, there's a capacity that suits your specific requirements. Make the right choice, and empower your operations with the strength and reliability of an electric winch tailored to your needs.

The line pull capacity of electric winches is crucial in ensuring the tool's capability aligns with the specific demands of the intended application. As we progress through this guide, we will explore safety features, power sources, control systems, and other essential aspects, providing a comprehensive overview of electric winch specifications. Stay engaged as we uncover more insights into these powerful tools and their diverse applications.

Your Trusted Electric Winch Manufacturer & Supplier

Main Applications of Electric Winches

Electric winches are indispensable tools in various industries, offering efficient and reliable solutions for lifting, pulling, and positioning heavy loads. In this comprehensive guide, we will delve into the diverse world of electric winches, exploring their types, applications, and key considerations to empower you with the knowledge needed to make informed decisions.

Custom Electric Winches for Every Industrial Uses

In the following the main industrial applications of electric winches are presented for your reference. For different applications or particular applications, the custom electric winches are provided. If you have any need, please feel free to contact us.

Electric Winches Powering the Construction Industry

The construction industry is a dynamic and demanding field where efficiency, precision, and safety are paramount. Electric winches play a pivotal role in enhancing various aspects of construction operations, offering versatile solutions for material handling and heavy equipment positioning.

Applications:

- Material Handling on Construction Sites:

Challenge: Construction sites are bustling hubs of activity, with materials arriving and needing to be precisely positioned.

Solution: Electric winches excel in lifting and moving construction materials, providing a controlled and efficient method for transporting items to different levels or specific locations on the site. - Lifting and Positioning Heavy Equipment:

Challenge: Construction projects often involve the use of heavy machinery and equipment that requires precise positioning.

Solution: Electric winches with varying capacities are employed to lift and position heavy equipment, ensuring accurate placement and efficient workflow. This is especially crucial when working on structures with multiple levels. - Foundation Work:

Challenge: Foundation work involves intricate processes that require the precise placement of materials like steel and concrete.

Solution: Electric winches aid in the controlled lowering of materials, ensuring they reach the intended location without compromising the structural integrity of the foundation. - Tensioning and Alignment:

Challenge: Achieving proper tension and alignment in construction elements is crucial for the stability and longevity of structures.

Solution: Electric winches with variable speed control and precise line pull capacities are utilized to apply controlled tension and alignment, contributing to the overall stability of the construction project. - Roofing and Façade Installation:

Challenge: Installing roofing materials and façade elements requires careful handling and positioning.

Solution: Electric winches, especially those with remote control capabilities, assist in the controlled placement of roofing materials and architectural features, ensuring a seamless and efficient installation process. - Tower Crane Assistance:

Challenge: Tower cranes play a pivotal role in vertical construction but may require additional assistance for certain tasks.

Solution: Electric winches, whether stationary or portable, are employed to support tower crane operations, providing additional lifting and positioning capabilities when needed.

Benefits of Electric Winches in Construction:

- Precision and Control: Electric winches offer precise control over lifting and positioning, allowing construction professionals to execute tasks with accuracy.

- Safety: Features such as load sensing and automatic braking contribute to enhanced safety, preventing overloading and ensuring secure operations.

- Versatility: Electric winches come in various capacities and configurations, making them adaptable to different construction scenarios and project scales.

- Efficiency: The efficiency of electric winches contributes to streamlined construction processes, reducing manual labor requirements and optimizing time management.

In conclusion, electric winches serve as indispensable tools in the construction industry, addressing diverse challenges and contributing to the overall success and efficiency of construction projects. Whether it's lifting materials, positioning heavy equipment, or ensuring precise alignments, electric winches play a pivotal role in shaping the landscapes of our built environment.

Electric Winches for Mining Industry?

The mining industry, characterized by its rugged terrains and heavy-duty operations, relies on robust equipment to extract valuable resources from the earth. Electric winches, designed to withstand challenging conditions, find crucial applications in hauling materials and handling heavy mining equipment, contributing to the efficiency and safety of mining operations.

Applications:

- Hauling Materials in Mining Operations:

Challenge: Mining operations involve the extraction of vast amounts of materials, requiring efficient hauling mechanisms.

Solution: Electric winches, known for their high line pull capacities, are employed in hauling materials from mines, ensuring a reliable and controlled process even in harsh terrains. - Lifting and Lowering Heavy Mining Equipment:

Challenge: Heavy mining equipment, such as excavators and drills, needs to be precisely positioned for optimal functionality.

Solution: Electric winches play a pivotal role in lifting and lowering heavy mining equipment during assembly, maintenance, and relocation, contributing to operational flexibility and efficiency. - Conveyor System Assistance:

Challenge: Conveyor systems are integral in the transportation of mined materials within the mining facility.

Solution: Electric winches are utilized to assist conveyor systems by providing additional pulling force, ensuring a continuous and reliable flow of materials throughout the mining process. - Tailing Dam Maintenance:

Challenge: Tailing dams, used to store waste materials from mining operations, require regular maintenance.

Solution: Electric winches are employed in tasks such as dredging and repositioning pipes for tailing dam maintenance, contributing to the overall integrity and safety of these structures. - Shaft Operations:

Challenge: Mines often have vertical shafts that require equipment and materials to be transported to different levels.

Solution: Electric winches, especially those with variable speed control and precise load sensing, are utilized for controlled lifting and lowering operations in mining shafts. - Equipment Retrieval in Challenging Terrain:

Challenge: Mining sites can have challenging terrains, and equipment may become stuck or require retrieval.

Solution: Electric winches, often mounted on specialized vehicles, assist in the recovery and retrieval of mining equipment from difficult terrains, ensuring minimal downtime.

Benefits of Electric Winches in Mining:

- Durability: Electric winches are built to withstand harsh environmental conditions prevalent in mining operations, ensuring longevity and reliability.

- High Load Capacities: The high line pull capacities of electric winches make them suitable for handling heavy loads commonly encountered in mining activities.

- Precision and Safety: Electric winches provide precise control and safety features, essential for delicate operations such as positioning heavy equipment and maintaining tailing dams. Adaptability: The versatility of electric winches allows for their use in various mining applications, contributing to the adaptability of mining operations.

In summary, electric winches are indispensable assets in the mining industry, where the demands for durability, precision, and safety are paramount. From hauling materials to assisting conveyor systems and maintaining critical infrastructure, electric winches play a crucial role in ensuring the efficiency and reliability of mining operations.

Marine and Offshore Industry

The vast expanse of the open sea and the unique challenges posed by offshore environments necessitate specialized equipment in the marine and offshore industry. Electric winches, with their precision and reliability, play a pivotal role in critical tasks such as anchoring, mooring, and lifting on ships and offshore platforms.

Applications:

- Anchoring and Mooring on Ships:

Challenge: Anchoring and mooring are fundamental aspects of ship navigation, demanding reliable and controlled operations.

Solution: Electric winches are integral to the anchoring systems of ships, providing the necessary pulling force to secure the vessel in place. Additionally, they play a crucial role in mooring activities, contributing to the stability of ships during docking. - Lifting and Positioning on Offshore Platforms:

Challenge: Offshore platforms require precise lifting and positioning of heavy loads in dynamic sea conditions.

Solution: Electric winches, known for their accuracy and load control, are employed in lifting operations on offshore platforms. Whether it's positioning equipment or handling materials, electric winches ensure stability and safety in offshore environments. - Cargo Handling on Vessels:

Challenge: Cargo handling on ships demands efficient and controlled mechanisms for loading and unloading.

Solution: Electric winches are utilized in cargo handling systems on vessels, facilitating the smooth and controlled movement of goods. Their variable speed capabilities contribute to adapting to different cargo weights and handling requirements. - Personnel Transfer and Rescue:

Challenge: Offshore platforms may require personnel transfer or emergency rescue operations.

Solution: Electric winches, equipped with safety features and precise control, are employed in personnel transfer systems between vessels and offshore structures. In emergency scenarios, they play a crucial role in the controlled retrieval of personnel. - Towing and Salvage Operations:

Challenge: Towing and salvage operations in the open sea or near offshore structures require powerful and reliable winching systems.

Solution: Electric winches, often mounted on towing vessels, contribute to towing and salvage activities by providing the necessary pulling force for controlled operations, ensuring the safety of both vessels and structures.

Benefits of Electric Winches in Marine and Offshore Applications:

- Precision Control: Electric winches offer precise control over load movements, crucial for delicate operations in marine environments.

- Corrosion Resistance: Many electric winches designed for marine use are built with corrosion-resistant materials, ensuring durability in saltwater environments.

- Emergency Response: The rapid and controlled deployment of electric winches makes them valuable in emergency response situations, contributing to swift and safe operations.

- Adaptability: Electric winches can be adapted to various marine and offshore applications, providing versatile solutions for different tasks.

In conclusion, electric winches stand as indispensable components in the maritime and offshore industry, where precision, reliability, and adaptability are paramount. Whether anchoring a ship, lifting loads on an offshore platform, or facilitating emergency rescue operations, electric winches contribute to the efficiency and safety of marine and offshore activities.

Manufacturing and Industrial Facilities

The bustling environments of manufacturing and industrial facilities require seamless material handling and the precise positioning of heavy equipment. Electric winches, known for their reliability and controlled operation, find extensive applications in these settings, contributing to the efficiency of various processes.

Applications:

- Material Handling in Manufacturing:

Challenge: Manufacturing processes involve the constant movement of raw materials, semi-finished goods, and final products.

Solution: Electric winches play a crucial role in material handling within manufacturing facilities. Whether it's lifting materials onto production lines or moving goods between different stages of the manufacturing process, electric winches provide controlled and efficient solutions. - Lifting and Moving Equipment in Industrial Settings:

Challenge: Industrial facilities often house heavy machinery and equipment that require precise lifting and positioning.

Solution: Electric winches are employed in lifting and moving industrial equipment, ensuring controlled and accurate operations. From positioning heavy machinery for maintenance to facilitating the movement of equipment within the facility, electric winches contribute to streamlined processes. - Conveyor System Integration:

Challenge: Conveyor systems are integral to many manufacturing setups, demanding efficient loading and unloading mechanisms.

Solution: Electric winches are integrated into conveyor systems to facilitate the smooth loading and unloading of materials. Their variable speed and load control capabilities ensure that materials move seamlessly along the production line. - Automated Production Processes:

Challenge: Automation is a key aspect of modern industrial facilities, requiring precise control over various processes.

Solution: Electric winches play a role in automated production processes, providing the necessary control for tasks such as the precise positioning of components, lifting materials onto assembly lines, or moving products along automated pathways. - Overhead Crane Operations:

Challenge: Overhead cranes are commonly used in industrial settings for heavy lifting and material movement.

Solution: Electric winches are a vital component of overhead crane systems, contributing to the lifting and movement of heavy loads with precision and reliability. Their variable speed control is particularly beneficial in scenarios where different lifting speeds are required.

Benefits of Electric Winches in Manufacturing and Industrial Settings:

- Precision and Control: Electric winches offer precise control over lifting and movement, crucial for delicate manufacturing processes.

- Efficiency: The efficient material handling facilitated by electric winches contributes to streamlined production processes, reducing downtime and enhancing overall efficiency.

- Adaptability: Electric winches can be integrated into various manufacturing setups, adapting to different material handling and lifting requirements.

- Safety: Controlled operations provided by electric winches enhance safety in industrial environments, preventing accidents and ensuring the well-being of workers.

In conclusion, electric winches play a pivotal role in the dynamic and demanding environments of manufacturing and industrial facilities. Whether it's lifting materials, moving equipment, or contributing to automated production processes, electric winches bring precision and efficiency to the heart of industrial operations.

Agricultural Sector

In the vast landscapes of the agricultural sector, where the demands of lifting heavy equipment and efficiently pulling loads are constant, electric winches emerge as reliable workhorses. Their versatility and precision make them invaluable tools in addressing the unique challenges presented by agricultural operations.

Applications:

- Lifting Heavy Agricultural Equipment:

Challenge: Agricultural machinery, such as plows, cultivators, and seeders, often requires lifting for maintenance, transportation, or storage.

Solution: Electric winches play a pivotal role in lifting heavy agricultural equipment. Whether it's elevating machinery for maintenance tasks or loading equipment onto trailers for transport, electric winches provide the necessary lifting power with control. - Pulling Loads in Field Operations:

Challenge: Agricultural field operations involve various tasks that require pulling loads, such as dragging heavy logs, moving equipment, or repositioning obstacles.

Solution: Electric winches become indispensable in pulling loads during field operations. Their ability to provide a controlled and steady pull ensures that tasks like clearing land, repositioning equipment, or managing heavy loads are accomplished efficiently. - Towing Implements and Trailers:

Challenge: Agricultural activities often involve towing implements, trailers, or other heavy loads across fields.

Solution: Electric winches, when integrated into tractors or other agricultural vehicles, enhance towing capabilities. Whether it's pulling a loaded trailer through the fields or recovering a stuck implement, electric winches contribute to smooth and controlled towing operations. - Livestock Handling:

Challenge: Livestock handling may require moving heavy gates, lifting feeding equipment, or assisting in veterinary procedures.

Solution: Electric winches find applications in tasks related to livestock management. Whether it's lifting gates for penning, pulling heavy loads associated with feeding systems, or assisting in veterinary procedures, electric winches offer versatile solutions. - Field Infrastructure Setup:

Challenge: Setting up field infrastructure, such as irrigation systems, may involve moving heavy components into position.

Solution: Electric winches contribute to the efficient setup of field infrastructure. From positioning irrigation pipes to lifting components into place, the controlled power of electric winches ensures precise and hassle-free installations.

Benefits of Electric Winches in Agriculture:

- Versatility: Electric winches adapt to various agricultural tasks, from lifting and towing to field infrastructure setup.

- Controlled Operations: The ability to control the speed and power of electric winches ensures precision in lifting and pulling tasks.

- Time Efficiency: Electric winches contribute to time-efficient operations, reducing manual effort and enhancing overall productivity.

- Equipment Maintenance: Facilitating the lifting of heavy agricultural equipment aids in routine maintenance, contributing to the longevity of machinery.

In conclusion, the agricultural sector leverages the adaptability and controlled power of electric winches to overcome the lifting and pulling challenges inherent in field operations. From maintaining equipment to efficiently managing field tasks, electric winches stand as reliable allies in the pursuit of agricultural efficiency.

Utility Sector

The utility sector, encompassing services vital for our daily lives, relies on efficient and robust equipment to maintain and expand essential infrastructure. Electric winches prove to be indispensable in utility operations, contributing to tasks that demand precision, strength, and reliability.

Applications:

- Setting Poles and Pulling Cables:

Challenge: The installation and maintenance of utility poles and cables require precise control and power.

Solution: Electric winches are employed to set utility poles securely in place, ensuring stability and reliability. Additionally, they play a crucial role in pulling cables, facilitating the expansion and maintenance of power and communication networks. - Lifting Equipment for Utility Maintenance:

Challenge: Utility maintenance often involves the lifting of heavy equipment and components, demanding robust and controlled lifting solutions.

Solution: Electric winches are utilized for lifting equipment during maintenance operations. Whether it's raising transformers for inspection or positioning heavy components for repairs, electric winches provide the necessary power and control. - Emergency Response Scenarios:

Challenge: In emergency situations, quick and efficient response is crucial for utility operations.

Solution: Electric winches with high-speed capabilities find applications in emergency scenarios. Rapid cable deployment or retrieval is essential for quick response, making electric winches valuable assets in critical situations. - Adaptable to Challenging Terrains:

Challenge: Utility operations often take place in diverse and challenging terrains.

Solution: Electric winches, especially those designed for off-road applications, are adaptable to challenging terrains. They assist utility vehicles in navigating through rough landscapes, ensuring that equipment reaches remote locations with ease. - Supporting Renewable Energy Infrastructure:

Challenge: The integration and maintenance of renewable energy infrastructure, such as wind turbines, demand specialized lifting solutions.

Solution: Electric winches are utilized in supporting renewable energy initiatives. Whether it's positioning components during installation or facilitating maintenance tasks, electric winches contribute to the growth of sustainable energy sources.

Benefits of Electric Winches in the Utility Sector:

- Precision in Pole Installation: Electric winches ensure precise and stable pole installation, contributing to the reliability of utility networks.

- Efficient Cable Pulling: The controlled pulling of cables using electric winches enhances the efficiency of network expansion and maintenance.

- Quick Response in Emergencies: High-speed electric winches enable rapid response in emergency situations, minimizing downtime and ensuring timely interventions.

- Versatility in Challenging Environments: Electric winches, designed for off-road applications, provide utility vehicles with the adaptability to navigate through challenging terrains.

In conclusion, electric winches are indispensable tools in the utility sector, supporting the installation, maintenance, and expansion of essential infrastructure. Their precision, strength, and adaptability make them valuable assets in ensuring the reliability of utility networks and responding effectively to the dynamic challenges of the sector.

Entertainment Industry

The use of electric winches plays a crucial role in creating captivating performances and ensuring smooth operations in the entertainment sector.

Applications

- Lifting and Moving Stage Elements in Theaters:Electric winches are integral in theater productions where elaborate stage designs and set changes are common. These winches facilitate the seamless movement of stage elements, such as backdrops, curtains, and props. The precision and control offered by electric winches contribute to the flawless execution of scene transitions, enhancing the overall theatrical experience. Handling Props and Lighting in Film

- Productions:In film and television production, electric winches are employed to handle various tasks related to props and lighting. Whether it's raising and lowering set pieces for a specific scene or positioning lighting equipment for optimal illumination, electric winches provide the necessary lifting and control mechanisms. Their versatility and reliability contribute to the efficiency of film productions, allowing directors and cinematographers to achieve their creative vision with ease.

The entertainment industry demands precision, safety, and efficiency, and electric winches deliver on these requirements, making them indispensable tools in the dynamic world of live performances and cinematic productions.

In the Automotive Industry

Electric winches are instrumental in various applications within the automotive sector, providing solutions for both vehicle recovery and handling heavy automotive components. Here's an in-depth look at their applications:

- Vehicle Recovery and Towing:Electric winches are commonly utilized in off-road vehicles, tow trucks, and recovery vehicles for vehicle recovery and towing operations. When a vehicle gets stuck in challenging terrains such as mud, sand, or snow, an electric winch mounted on the vehicle's front or rear can be used to pull it out safely. This capability is particularly valuable for off-road enthusiasts, adventure seekers, and professional recovery services.

- Handling Heavy Automotive Components:In automotive workshops and manufacturing facilities, electric winches play a crucial role in handling heavy components. Whether it's lifting and positioning large engine blocks, chassis, or other substantial parts, electric winches provide the necessary lifting power and control. This enhances efficiency in the assembly, repair, and maintenance processes within the automotive industry, contributing to a smoother workflow.

The automotive sector relies on the robust capabilities of electric winches to address challenges related to vehicle recovery and the handling of substantial automotive components. Their versatility and reliability make them essential tools in ensuring the seamless operation of various automotive applications.

Rail Industry

Electric winches serve critical roles in the rail sector, offering solutions for tasks involving the movement and positioning of railcars, as well as the handling of various rail components. Here's a detailed exploration of their applications in the rail industry:

- Moving Railcars in Rail Yards:Electric winches are commonly employed in rail yards for the movement of railcars. Whether it's repositioning railcars for maintenance, assembling trains, or managing the layout of the rail yard, electric winches provide the necessary pulling power. Their ability to handle substantial loads makes them essential for the efficient and controlled movement of railcars within the yard.

- Positioning and Handling Rail Components:The rail industry involves the handling of various components, including rail segments, switches, and signaling equipment. Electric winches are utilized to position and maneuver these components with precision. This is crucial for the maintenance and construction of rail infrastructure, ensuring that each element is accurately placed and securely anchored.

Electric winches contribute significantly to the operational efficiency and safety of rail-related activities. Their ability to provide controlled movement and precise positioning makes them indispensable tools in the rail industry for tasks ranging from the manipulation of railcars to the handling of critical rail components.

Your Trusted Electric Winch Manufacturer & Supplier

Electric Winch Selection

Select Right Electric Winch for Your Applications

Factors to Consider: When it comes to selecting the right electric winch, several factors play a crucial role in ensuring optimal performance and safety. Here's an in-depth exploration of key considerations:

Load Capacity, Speed, and Features:Guidelines for Determining Load Capacity:

- The weight of the intended load is the foundational step in selecting an electric winch. Consider factors such as the maximum weight the winch will need to pull or lift in your specific application. It's essential to choose a winch with a load capacity that comfortably exceeds the anticipated load, ensuring safety and efficiency. Importance of Speed Control and Additional Features:

- Speed control is a critical aspect, especially in applications where precision and controlled movement are essential. Variable speed winches offer flexibility in adjusting the pulling or lifting speed according to the task at hand. Additionally, consider features such as automatic braking systems and load sensing capabilities. These features enhance safety by preventing overloading and ensuring the winch operates within its designed limits.

Selecting an electric winch that aligns with the specific load requirements and provides essential safety features is paramount. Careful consideration of these factors ensures that the chosen winch not only meets but exceeds the demands of the intended application, guaranteeing reliable and efficient operation.

Safety Considerations: Ensuring the safety of both personnel and equipment is paramount when selecting an electric winch. Here's an in-depth exploration of crucial safety considerations:

Safety Features in Electric Winches

Electric winches are equipped with various safety features designed to prevent accidents and ensure smooth operation. One key safety element is the braking system. Modern electric winches often come with automatic braking mechanisms that engage when the winch is not actively pulling or lifting a load

This feature enhances stability and prevents unintended movements. Load sensing is another critical safety feature. Winches with load sensing capabilities can adjust their speed and power output based on the load being handled. This prevents overloading, a common cause of accidents in winch operations. Load sensing technology adds a layer of intelligence to the winch, making it responsive to the dynamic conditions of different loads.

Importance of Automatic Braking and Load Sensing:

Automatic braking is crucial for holding the load securely in place when the winch is not actively in use. This feature prevents the load from slipping or drifting, enhancing overall safety on the worksite. Load sensing, on the other hand, adds a proactive safety measure by preventing the winch from attempting to lift or pull a load beyond its capacity. This not only protects the winch from potential damage but, more importantly, ensures the safety of personnel and surrounding structures.

In conclusion, prioritizing winches with advanced safety features, including automatic braking and load sensing, is essential for creating a secure working environment. These features contribute to accident prevention and the longevity of the equipment, aligning with the highest safety standards in various industries.

Installation and Maintenance:

Proper installation and regular maintenance are critical aspects of ensuring the longevity and reliable performance of electric winches. Here's a detailed exploration of these crucial considerations:

Proper Installation,Tips for Installing Electric Winches:

Electric winches must be installed correctly to operate safely and efficiently. Here are key installation tips:

- Secure Mounting: Ensure the winch is securely mounted to a stable and robust structure, whether it's a vehicle, stationary platform, or portable frame. Proper mounting is essential to withstand the forces exerted during pulling or lifting operations.

- Alignment: Align the winch properly to prevent issues with cable spooling and ensure smooth operation. Misalignment can lead to uneven stress on the winch components and compromise performance.

- Electrical Connections: Pay careful attention to electrical connections, ensuring they are secure and appropriately insulated. Follow the manufacturer's guidelines for wiring and connection specifications.

- Ventilation: Provide adequate ventilation around the winch, especially if it's in a confined space. This helps prevent overheating during extended or heavy-duty operations.

Importance of Regular Maintenance:Tips for Maintenance:

Regular maintenance is crucial for preserving the performance and reliability of electric winches. Here are key maintenance tips:

- Inspect Cable or Rope: Regularly inspect the cable or rope for signs of wear, fraying, or damage. Replace any damaged components promptly to prevent accidents.

- Check Fasteners: Inspect and tighten all bolts, nuts, and fasteners to ensure the winch remains securely mounted. Loose fasteners can lead to instability and compromised safety.

- Lubrication: Apply lubrication to moving parts, such as the drum and gears, according to the manufacturer's recommendations. Proper lubrication minimizes friction, reducing wear and extending the lifespan of components.

- Electrical Components: Inspect electrical connections for signs of corrosion or damage. Clean connections and replace any faulty wiring or components.

- Test Functionality: Regularly test the winch under controlled conditions to ensure all functions, including braking systems and load sensing, are working correctly.

By following these installation and maintenance guidelines, users can maximize the efficiency, safety, and durability of their electric winches. Regular inspections and proactive measures contribute to a reliable and high-performing winching system across various applications.

Electric Winch Buying Guide

Selecting the right electric winch involves careful consideration of various factors to ensure optimal performance and value for money. Here, we delve into the key considerations guiding your purchasing decision:

Budget:Factors to Consider When Budgeting for an Electric Winch:

Determining your budget is the initial step in the electric winch buying process. Consider the following factors when establishing your budget:

- Load Capacity Requirements: The winch's load capacity is a significant determinant of its price. Assess your specific needs and choose a winch with an appropriate load capacity, balancing the cost with your budget constraints.

- Features and Technology: Advanced features, such as variable speed control, automated systems, and enhanced safety mechanisms, may contribute to a higher price. Evaluate the necessity of these features based on your application requirements.

- Brand Reputation: Established and reputable brands often offer higher-quality products but may come at a premium. Research various brands, read reviews, and weigh the cost against the brand's reputation for durability and performance.

Application:Matching the Winch to the Specific Application and Environment:

- Understanding the intended application is crucial for choosing the right electric winch. Consider the following application-specific factors:

- Terrain and Environmental Conditions: If your application involves challenging terrains or harsh environmental conditions, opt for a winch with features like weather-resistant construction and robust materials to withstand these challenges.

- Frequency of Use: Assess how frequently the winch will be used. For occasional or light use, a lighter-duty winch may suffice, while heavy-duty applications demand a more robust and durable solution.

- Specialized Requirements: Some applications, such as marine, construction, or off-road recovery, may have specialized requirements. Choose a winch that is specifically designed to meet the demands of your unique application.

Environment:Considering the Operating Environment:

The operating environment plays a crucial role in determining the longevity and performance of the electric winch. Take the following environmental factors into account:

- Corrosion Resistance: In marine or corrosive environments, prioritize winches with corrosion-resistant materials to prevent deterioration over time.

- Temperature Extremes: For applications in extreme temperatures, choose a winch with features that ensure optimal performance in both hot and cold conditions.

- Dust and Debris Resistance: In dusty or debris-laden environments, select a winch with effective seals and protection to prevent the ingress of contaminants.

By carefully considering your budget, application requirements, and the operating environment, you can make an informed decision when purchasing an electric winch. This ensures that the chosen winch not only meets your immediate needs but also provides long-term reliability and durability.

Popular Brands and Models:

When it comes to electric winches, choosing a reputable brand is paramount for ensuring reliability, durability, and performance. Here, we provide an overview of well-known brands in the industry, along with some popular models that have garnered positive reviews:

Reputable Electric Winch Brands:

- Warn Industries:Overview: Warn is a globally recognized brand renowned for producing high-quality winches. They offer a diverse range of winches catering to various applications, from off-road adventures to industrial use.

- Smittybilt:Overview: Smittybilt is synonymous with rugged off-road equipment, and their electric winches are no exception. Known for their durability and innovation, Smittybilt winches are popular among off-road enthusiasts.

- Superwinch:Overview: Superwinch has a long-standing reputation for manufacturing reliable and robust winches. Their products are widely used in off-road recovery, utility, and industrial applications.

- Engo Industries:Overview: Engo is a trusted brand in the winch market, offering a range of electric winches known for their performance and durability. They cater to various applications, including off-road and industrial use.

Popular Models with Positive Reviews:

- Warn Zeon Series:Overview: The Warn Zeon series is highly regarded for its advanced features, including wireless remote control, durable construction, and efficient performance. Models like the Warn Zeon 10 and Zeon 12 have received positive reviews for their reliability.

- Smittybilt XRC Gen3:Overview: The Smittybilt XRC Gen3 series is known for its heavy-duty design and innovative features. With powerful motors and synthetic rope options, models like the XRC Gen3 9.5 and XRC Gen3 12,500 have gained popularity.

- Superwinch Tiger Shark Series:Overview: The Tiger Shark series by Superwinch is appreciated for its versatility and durability. With features like weather-sealed solenoids and efficient motors, models like the Tiger Shark 9500 and Tiger Shark 15 have received positive user feedback.

- Engo E Series:Overview: Engo's E Series is known for providing reliable and cost-effective winching solutions. Models like the E9000 and E12000 are popular choices for various applications, including off-road adventures and utility tasks.

Before making a purchase, it's advisable to read user reviews and consider the specific requirements of your application. Each brand and model may have unique features, and selecting the one that aligns with your needs ensures a satisfying winching experience.

Where to Buy:

Choosing the right source for purchasing your electric winch is as crucial as selecting the winch itself. To ensure a smooth buying experience and obtain a genuine product, consider the following guidance on where to buy your electric winch:

Authorized Dealers:

- Directly from the Manufacturer:Purchasing directly from the manufacturer is often a reliable option, ensuring that you receive a genuine product with full warranty coverage. Visit the official websites of the winch brands you are interested in to explore direct purchasing options.

- Authorized Physical Stores:Many reputable electric winch manufacturers have authorized physical stores or dealerships. Buying from these authorized brick-and-mortar outlets ensures that you are getting a legitimate product, and you can seek expert advice from trained staff.

- Automotive and Off-Road Retailers:Specialized automotive and off-road retailers often carry a selection of electric winches. Ensure that the retailer is an authorized dealer for the specific brand you are interested in to guarantee the authenticity of the product.

Online Retailers:

- Manufacturer's Official Website:Some manufacturers sell their products directly through their official websites. Purchasing from the official site provides assurance in terms of product authenticity and access to customer support.

- Reputable Online Marketplaces:If you choose to buy online, opt for well-known and reputable online marketplaces. Platforms like Amazon, eBay, and others may have authorized sellers offering genuine products. Check for seller ratings and reviews for added confidence.