3 Ton Overhead Crane Price: Sale Types, Costs & Practical Guide

3 ton overhead crane for sale. Explore pricing, models & smart buying tips to select best 3 ton overhead crane for you.Get 3 ton eot crane for sale price!

Category: Ton & Price

Your Trusted 3 Ton Overhead Crane Manufacturer & Supplier

3 Ton Overhead Crane for Sale

3 Ton Overhead Crane Price – Types, Models, Costs & Buyer's Practical Guide

Introduction

Why 3 Ton Overhead Cranes Remain a Versatile Choice in Industry

A 3 ton overhead crane is kind of a "sweet spot" in many industries. It's heavy enough to handle a wide range of loads, yet not so big that it requires huge infrastructure or big budgets. Because of this, these cranes pop up in all sorts of workplaces, from small workshops to medium-sized factories.

The 3 ton capacity fits well with common lifting needs—think equipment parts, pallets, molds, and medium-sized steel components. It offers enough strength for many daily tasks without the complexity or cost of larger cranes. That's why it's a popular go-to choice for many businesses.

Key Industries and Typical Applications Benefiting from 3 Ton Cranes

You'll find 3 ton overhead cranes all over the place. Here are a few of the main industries and uses where they shine:

- Manufacturing plants: Lifting machine parts, tools, and assemblies during production or maintenance.

- Automotive workshops: Handling molds, engines, and body parts without fuss.

- Warehouses and logistics: Moving pallets, crates, and equipment safely and efficiently.

- Steel mills and metalworking: Transporting medium-sized steel slabs, billets, or coils.

- Food and pharmaceutical facilities: In clean or hygienic environments, with proper crane customization.

Each industry has slightly different demands, but the 3 ton crane often fits just right—balancing lifting power with ease of use and cost.

How Smart Buying Decisions on Price and Quality Impact Long-Term Savings

When it comes to buying a 3 ton overhead crane, it's easy to get caught up in price alone. But the truth is, a cheaper crane isn't always the best deal. Think about it: a crane is an investment you expect to use every day for years.

A well-made crane may cost a bit more upfront, but it pays off by running smoothly, needing fewer repairs, and lasting longer. On the other hand, a bargain crane might mean higher maintenance costs, downtime, and even safety risks.

Here's what smart buyers keep in mind:

- Quality matters: Look for cranes made with reliable materials and proven designs.

- Suitability: Choose a crane that fits your exact needs—not too big, not too small.

- After-sales support: Good suppliers offer service, spare parts, and support over the crane's life.

- Total cost of ownership: Factor in installation, maintenance, and operating costs, not just the sticker price.

Making thoughtful choices means fewer headaches, better productivity, and money saved over the long haul. It's not just buying a crane—it's securing your workflow and safety for years to come.

Hot Sale Types of 3 Ton Overhead Crane

Detailed Pricing Overview of 3 Ton Overhead Crane Models

Common Models and Their Price Ranges

Below is a clear table showing typical 3 ton overhead crane models, their specs, and price ranges. This gives you a practical snapshot to start comparing options:

| Crane Model | Span (m) | Lifting Height (m) | Power Supply | Price Range (USD) |

|---|---|---|---|---|

| 3 Ton Single Girder EOT Crane | 7.5 – 28.5 | 6 – 30 | 220V–660V, 50-60Hz, 3ph AC | $2,130 – $7,680 |

| 3 Ton Low Headroom Single Girder | 7.5 – 28.5 | 6 – 30 | 220V–660V, 50-60Hz, 3ph AC | $2,240 – $8,100 |

| 3 Ton Underslung Single Girder | 7.5 – 31.5 | 6 – 30 | 220V–660V, 50-60Hz, 3ph AC | $2,130 – $7,680 |

| 3 Ton Offset Trolley Single Girder | 7.5 – 31.5 | 6 – 30 | 220V–660V, 50-60Hz, 3ph AC | $3,400 – $13,800 |

| 3 Ton FEM/DIN Single Girder | 7.5 – 28.5 | 6 / 9 / 12/custom | 220V–660V, 50-60Hz, 3ph AC | $4,980 – $11,050 |

| 3 Ton Manual Single Girder | 5 – 14 | 3 – 10 | Manual operation | $1,117 – $1,760 |

Note: Prices can shift based on regional factors and supplier.

Pros and Cons of Each Model Type From a Buyer's Perspective

- Single Girder EOT Crane 3 Ton

Pros: Lower cost, lighter structure, easier installation. Good for moderate use and simpler lifting needs.

Cons: Limited lifting height and span compared to double girder; less suited for heavy-duty or continuous use. - Low Headroom Single Girder Overhead Crane 3 Ton

Pros: Fits tight ceiling spaces; maximizes lifting height.

Cons: Slightly higher price due to compact design; may require specialized installation. - Underslung Single Girder Overhead Crane 3 Ton

Pros: Saves runway height, ideal for facilities with limited overhead clearance.

Cons: Can be more complex to install; generally requires more precise maintenance. - Offset Trolley Single Girder Overhead Crane 3 Ton

Pros: Allows crane hook to travel beyond the girder edge—useful for loading/unloading outside rails.

Cons: Higher cost and mechanical complexity. - FEM/DIN Single Girder Overhead Crane 3 Ton

Pros: Superior quality, durability, and precision; often comes with better warranties and certifications.

Cons: Noticeably higher upfront cost. - Manual Single Girder Overhead Crane 3 Ton

Pros: Lowest cost; simple operation; good for light or infrequent lifting tasks.

Cons: Labor-intensive; not suitable for heavy or frequent loads.

What Influences the Price of a 3 Ton Overhead Crane?

Breakdown of Main Cost Drivers: Design, Materials, Technology, and Labor

When you look at the price tag of a 3 ton overhead crane, several things are at play behind the scenes. First up, the design—a simple, straightforward crane costs less than one with complex engineering. The shape and structure of the crane, including whether it's a single or double girder, impact how much steel and parts are needed.

Then there's the material quality. High-grade steel and durable components push the price up but offer better strength and longer life. Using cheaper materials can lower upfront costs but may lead to more repairs later.

Technology is another factor. Modern cranes may include advanced control systems, variable frequency drives, or energy-saving motors. These features improve operation and safety but add to the cost.

Finally, don't forget labor—skilled craftsmanship and factory standards affect manufacturing expenses. Custom or specialized cranes often require more time and expertise, increasing the price.

Comparing Standard vs Premium European Design Cranes (FEM/DIN)

Not all 3 ton cranes are built the same. The standard designs are usually reliable and meet basic safety and performance requirements. However, the FEM/DIN European standard cranes take things further: they are engineered with tighter tolerances, better materials, and higher quality control.

These premium cranes often last longer and handle more demanding workloads with less wear and tear. Naturally, they come with a higher price. So, if your operation requires consistent precision or heavy use, investing in a FEM/DIN crane could save money and trouble over time.

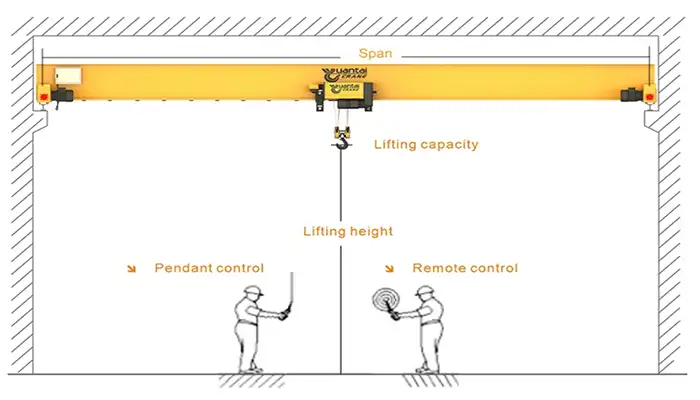

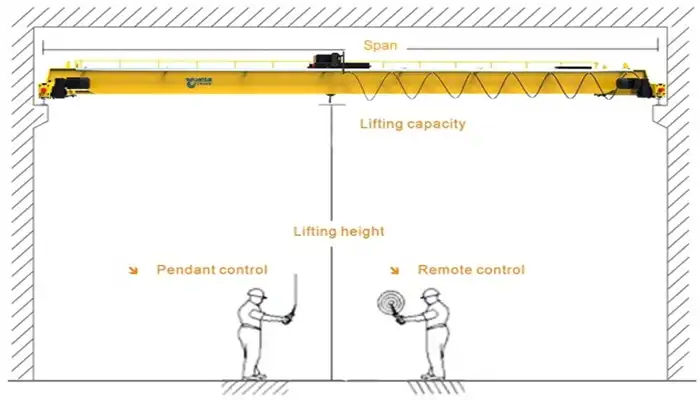

How Span, Lifting Height, and Crane Duty Class Affect Pricing

The crane's span (the distance between the rails it runs on) plays a big role in cost. A longer span means more steel and bigger components to keep the crane stable, which drives prices up.

Lifting height matters too. The higher the crane needs to lift, the taller and sturdier the structure must be, adding to complexity and expense.

Also, cranes are classified by duty class, which basically rates how often and how hard the crane will work. A crane for light-duty use costs less than one designed for heavy-duty or continuous operation. Higher duty classes mean stronger motors, better brakes, and reinforced parts.

Impact of Optional Features: Remote Control, Automation, Safety Systems

Optional extras can significantly change the price:

- Remote control systems let operators run the crane from a distance, improving safety and convenience.

- Automation features, like preset lifting positions or anti-sway control, increase efficiency but add tech costs.

- Safety systems such as overload protection, emergency stop buttons, and warning alarms protect people and equipment but raise the initial price.

While optional, these features often pay off by reducing accidents, improving productivity, and lowering insurance costs.

Environmental Adaptations: Explosion-Proof, Corrosion Resistance, Weatherproofing

If your crane will work in a harsh or hazardous environment, expect to pay more. For example:

- Explosion-proof cranes are specially designed for industries like chemical or mining, with sealed electrical parts and flame-retardant materials.

- Corrosion-resistant coatings or stainless steel parts are essential in salty, humid, or chemical-rich settings to prevent rust and breakdown.

- Weatherproof cranes can handle outdoor use in rain, dust, or extreme temperatures, with protective enclosures and rugged construction.

These adaptations add complexity and cost but are necessary to keep your crane safe and operational in tough conditions.

In summary, many factors shape the price of a 3 ton overhead crane. Knowing these lets you make smarter choices and avoid surprises.

Typical Lead Times and How Customization Influences Delivery Schedules

Standard 3 ton overhead cranes usually ship within 4 to 8 weeks depending on factory workload and order size. Basic models with standard specs tend to be faster since parts and assembly processes are streamlined.

Customization—such as special spans, lifting heights, control options, or environmental adaptations—adds engineering time and can extend lead times by 2 to 6 weeks or more. If you need a crane tailored to a unique site or application, it's smart to plan ahead and allow for extra time.

Also, large orders or seasonal demand surges (like post-holiday periods) may affect delivery timing, so early inquiry and clear communication with your supplier are key to staying on schedule.

Price Comparison: Manual vs Electric Hoists and Single vs Double Girder

- Manual Hoists

Typically the most affordable option, manual hoists are simple and require no power source. They work well for light, occasional loads but can slow down workflow due to manual effort. Prices usually start from around $1,100 and up, depending on features. - Electric Hoists

These provide powered lifting and lowering, boosting productivity and reducing physical strain. They come with various speed options and safety features. Expect prices to start roughly at $2,000 and climb with capacity and tech upgrades. - Single Girder Cranes

Generally less expensive and lighter, single girder cranes fit well for moderate capacity and medium span lengths. Installation is usually simpler and cheaper. - Double Girder Cranes

Double girder cranes are more robust and suited for heavier loads, longer spans, or higher lifting heights. They cost more upfront—often 30-50% higher than single girder cranes—but offer better durability and less maintenance in demanding environments.

Practical Buyer Tips: Getting the Best Value for Your 3 Ton Overhead Crane Budget

How to Specify Your Project Details to Get Accurate Quotes

When asking for quotes on a 3 ton overhead crane, details matter. Don't just say "I need a 3 ton crane." Instead, be clear about:

- Span length: How wide the crane needs to travel along the rails.

- Lifting height: The maximum height the crane should lift loads—this affects hoist selection.

- Duty cycle: How often and how hard the crane will work daily (light, medium, or heavy usage).

- Power supply: Voltage, phase, and frequency available where the crane will operate.

- Working environment: Is it indoors, outdoors, dusty, humid, or hazardous?

- Special features: Do you need low headroom design, remote control, or explosion-proof equipment?

- 3 Ton Overhead Crane kit without Main girder: More economcial crane kit solution for those who will buy the crane girder locally.

Supplying drawings or photos of your workshop or factory helps suppliers give you an accurate, tailored quote. This reduces surprises and extra costs later on.

Evaluating Supplier Certifications, Warranty, and After-Sales Support for 3 Ton Cranes

A 3 ton overhead crane is an important investment. To avoid problems down the line, check:

- Certifications: Look for ISO, CE, or FEM certificates that prove the crane meets international safety and quality standards.

- Warranty: What's covered? How long? Does the supplier provide spare parts or repair service during warranty?

- After-sales support: Can the supplier help with maintenance, provide operator training, or quickly send parts if needed?

Good suppliers don't just sell you a crane; they back it up with reliable support, which keeps your 3 ton crane running smoothly for years.

Tips for Negotiating Price Without Sacrificing Quality on Your 3 Ton Crane

Price talks can be tricky. Here's how to get a fair deal without risking safety or performance:

- Ask for a detailed cost breakdown so you know exactly what you're paying for.

- Check if volume discounts apply if you plan to buy multiple cranes or accessories.

- Discuss payment terms—sometimes spreading payments out helps more than lowering price.

- Request value-added services like free installation or extended warranty.

- Never skip key safety features like brakes and overload protection just to save a few bucks.

Remember, a bargain 3 ton crane that breaks down frequently will cost you more in downtime and repairs.

Hidden Costs to Watch for When Buying a 3 Ton Overhead Crane

Buying the crane is just the start. Watch out for these extra expenses:

- Customizations:Overhead Crane Prices: Guide to EOT Cost, Customization & Savings

- Installation: Professional setup for your 3 ton crane can add 10-20% to the cost. Don't forget to budget for this.

- Commissioning: Testing and fine-tuning after installation is essential and might be extra.

- Maintenance: Regular checkups, lubrication, and repairs keep your crane safe and working but need funds.

- Training: Operators must be trained on your 3 ton crane to prevent accidents and improve efficiency. Some suppliers include this, others don't.

By planning for these costs upfront, you avoid surprises and ensure your 3 ton overhead crane runs safely and reliably from day one.

Financing and Cost Management Strategies for Your 3 Ton Overhead Crane

Leasing vs Buying: What Suits Your Business Needs?

When it comes to acquiring a 3 ton overhead crane, you have two main options: leasing or buying. Each approach has pros and cons depending on your company's financial situation and long-term plans.

Buying:

- Pros: You own the crane outright. No ongoing rental fees. You can customize it fully and claim depreciation on your taxes. It's a good choice if you expect to use the crane for many years.

- Cons: Higher upfront cost. You're responsible for maintenance and repairs. If your needs change, selling the crane later might take time.

Leasing:

- Pros: Lower initial cost and flexible contract terms. Leasing can help manage cash flow better and preserve working capital. Some leases include maintenance and service packages, reducing your hassle.

- Cons: You don't own the crane, so there may be restrictions on modifications. Over the long term, leasing can be more expensive than buying. You need to keep up with lease payments whether or not you use the crane fully.

Think about your budget, how long you'll need the crane, and how stable your workload is. If your business is growing or seasonal, leasing might offer flexibility. If you have steady, long-term lifting needs, buying often makes more financial sense.

How to Calculate Total Cost of Ownership (TCO) Beyond Purchase Price

The sticker price of a 3 ton overhead crane is just the starting point. The total cost of ownership (TCO) includes all costs over the crane's useful life. To get a full picture, add:

- Purchase price: The initial cost of the crane and any customizations.

- Installation and commissioning: Professional setup, testing, and training expenses.

- Maintenance and repairs: Regular inspections, lubrication, parts replacement, and unexpected fixes.

- Energy consumption: Electricity costs to run the crane, especially if used heavily.

- Downtime costs: Lost production when the crane is under repair or maintenance.

- Operator training: Costs to properly train staff to operate the crane safely and efficiently.

- Disposal or resale costs: Expenses involved when upgrading or replacing the crane in the future.

By estimating these factors, you can avoid surprises and choose a crane option that fits your long-term budget, not just your upfront capital.

Understanding Depreciation and Resale Value of Overhead Cranes

Your 3 ton overhead crane is a capital asset that loses value over time—that's depreciation. Understanding this helps in budgeting and tax planning.

- Depreciation: Typically, overhead cranes depreciate over 10 to 15 years depending on usage and maintenance. Heavy use or harsh environments can shorten this. Some tax systems allow you to write off depreciation as an expense, reducing taxable income.

- Resale value: Well-maintained cranes hold better resale value. If you keep the crane clean, perform regular maintenance, and keep documentation, you can recover a good portion of your investment when selling or trading it in.

- Planning upgrades: Knowing when a crane's value and reliability drop helps you decide the right time to upgrade without excessive risk or downtime.

A solid understanding of depreciation and resale keeps your equipment budget realistic and helps you plan equipment replacement smoothly.

Taking time to evaluate financing options, fully understand costs, and plan for depreciation means you can manage your 3 ton overhead crane investment wisely—keeping your business efficient and your budget in check.

Industry-Specific Considerations for 3 Ton Overhead Cranes

Steel Mills and Heavy Manufacturing: Robustness and Durability Needs Steel Mill Cranes

In steel mills and heavy manufacturing plants, 3 ton overhead cranes face tough conditions. These environments are demanding, with high temperatures, heavy dust, and continuous use.

- Cranes need to be built tough, with reinforced steel structures that can handle constant heavy loads.

- Components like hoists and wheels should be wear-resistant and designed for long service life.

- Many steel mills require special coatings to resist heat and corrosion.

- Explosion-proof features may be necessary if the crane works near flammable materials.

- Reliability is key to avoid costly downtime in production lines.

Here, choosing a crane with a proven track record of durability can save time and money over years of heavy operation.

Warehousing and Logistics: Speed, Automation, and Energy Efficiency

Warehouses and distribution centers often move goods quickly, so cranes need to keep up.

- Faster lifting and trolley speeds help improve throughput.

- Many warehouses benefit from automation features, like programmable controls or remote operation, to reduce operator fatigue and improve accuracy.

- Energy-efficient motors and regenerative braking systems lower electricity costs and reduce wear on components.

- Cranes in these settings usually run indoors, so space-saving designs like low headroom cranes maximize vertical space.

- Integration with warehouse management systems (WMS) can streamline material handling.

For warehouses, investing in a smart, efficient 3 ton crane means faster operations and lower running costs.

Automotive and Mold Handling: Precision and Low Headroom Requirements

Automotive factories and mold shops demand precise and nimble lifting.

- Cranes often need to operate in tight spaces with limited ceiling height, making low headroom designs essential.

- Precise control is critical when handling molds or engine parts—smooth trolley and hoist movement prevents damage.

- Cranes may include two-speed hoists and fine positioning controls for delicate work.

- Sometimes, multiple hooks or dual trolleys are used for complex lifting tasks.

- Safety features like overload protection are a must to protect expensive molds and parts.

Here, choosing a 3 ton crane with precision and compact design ensures productivity without risking costly damage.

Food and Pharmaceutical Industries: Hygiene and Cleanroom Considerations

In food processing and pharmaceutical manufacturing, overhead cranes must meet strict hygiene and cleanliness standards.

- Cranes should be made from stainless steel or coated with food-grade paint to prevent contamination and withstand regular cleaning.

- Designs often avoid crevices and flat surfaces where dirt or bacteria can accumulate.

- Explosion-proof cranes might be needed in environments with flammable dust or chemicals.

- Cranes may be installed in cleanrooms or controlled environments requiring special sealing and filters.

- Easy-to-clean controls and smooth surfaces help meet sanitation regulations.

Selecting a 3 ton crane adapted for hygiene-sensitive industries protects product quality and ensures compliance with health standards.

Each industry has unique demands for a 3 ton overhead crane. Matching the crane's features to these needs keeps your operation safe, efficient, and cost-effective.

Installation & Maintenance: Cost Implications and Best Practices for 3 Ton Overhead Cranes

Typical Installation Costs and Timeline for a 3 Ton Overhead Crane

Installing a 3 ton overhead crane isn't just about dropping it into place—it requires careful planning and skilled labor. On average, installation costs can add about 10% to 20% of the crane's purchase price. This includes site preparation, mounting the runway beams, assembling the crane, wiring electrical components, and testing.

The timeline typically ranges from 1 to 3 weeks, depending on:

- Site readiness and complexity

- Crane type and customization

- Availability of installation professionals

If the site requires modifications—like strengthening floors or reinforcing ceilings—this will add time and cost.

Importance of Professional Installation for Safety and Warranty Compliance

It's tempting to save money by handling installation in-house, but professional installation is crucial for several reasons:

- Safety: Overhead cranes carry heavy loads overhead—improper installation risks accidents. Professionals ensure the crane is securely mounted, balanced, and tested to meet safety standards.

- Warranty: Most manufacturers require professional installation for the warranty to remain valid. DIY or unqualified installation can void coverage.

- Performance: Proper setup ensures the crane runs smoothly and lasts longer, preventing costly breakdowns and repairs.

Hiring certified installers or factory-trained technicians protects your investment and your people.

Maintenance Schedules and How Preventive Care Reduces Downtime and Cost

Routine maintenance keeps your 3 ton overhead crane reliable and safe. A typical maintenance schedule includes:

- Daily checks: Inspect hooks, ropes, brakes, and controls before operation.

- Monthly inspections: Check lubrication, wear on parts, and structural integrity.

- Annual comprehensive maintenance: Detailed inspection of mechanical and electrical systems, replacing worn components as needed.

Preventive care catches small issues before they become big problems, minimizing unexpected downtime and expensive repairs. It also helps comply with safety regulations and prolongs the crane's working life.

Training for Operators: A Key Investment in Safety and Productivity

Well-trained operators are essential. Even the best crane won't work safely if mishandled. Training should cover:

- Proper operation procedures specific to your 3 ton crane model

- Emergency stop and safety protocols

- Daily inspection routines to spot potential issues early

- Load handling techniques to avoid accidents or damage

Training reduces accidents, protects equipment, and improves efficiency on the job. Many suppliers offer operator training as part of their package, so be sure to ask.

Investing in professional installation, regular maintenance, and thorough operator training is the smartest way to keep your 3 ton overhead crane running safely and cost-effectively for years to come.

Emerging Trends Impacting 3 Ton Overhead Crane Pricing

Advances in Smart Crane Technology and Remote Monitoring

Today's 3 ton overhead cranes and advanced electric hoist are getting smarter. Manufacturers now offer cranes equipped with sensors and remote monitoring systems. These allow operators and maintenance teams to track crane performance in real time—things like load weight, motor temperature, and operating hours.

- This technology helps catch problems early, preventing breakdowns.

- It also enables remote diagnostics, reducing the need for on-site visits.

- While these smart features add to the initial price, they save money by lowering downtime and repair costs.

Energy-Efficient Motors and Regenerative Braking Systems

Energy efficiency is a big focus in crane design. Newer 3 ton cranes often use high-efficiency motors that consume less electricity without sacrificing power.

- Some models include regenerative braking, which captures energy when slowing down the crane and feeds it back into the power system.

- These innovations reduce energy bills and can sometimes qualify for government incentives.

- Although energy-efficient systems may increase upfront costs, the long-term savings on electricity can be significant.

Growing Demand for Explosion-Proof Cranes in Hazardous Industries

Industries like chemical processing, mining, and oil refining require cranes that can safely operate in explosive or flammable environments.

- Explosion-proof 3 ton overhead cranes have special sealed electrical components and flame-resistant materials.

- These cranes cost more due to additional engineering and certifications but are essential for worker safety and regulatory compliance.

- The demand for explosion-proof cranes is growing, pushing prices upward but also encouraging manufacturers to innovate cost-effective solutions.

Role of IoT and Automation in Reducing Operational Costs

The Internet of Things (IoT) is transforming crane operations. Connected cranes can be integrated into factory automation systems, allowing:

- Automated or semi-automated lifting cycles that improve accuracy and reduce operator fatigue.

- Data collection for preventive maintenance, optimizing service schedules.

- Remote control options that improve safety by distancing operators from hazards.

While adding automation and IoT features increases the initial price of a 3 ton overhead crane, these investments can lower overall operational costs and increase productivity over time.

In short, these trends are shaping not only how 3 ton overhead cranes perform but also how much they cost. Being aware of these innovations helps buyers make informed decisions balancing price and future-proof functionality.

How to Request a Customized Quote: Step-by-Step Guide

Checklist of Key Information to Prepare Before Inquiry

Before reaching out to suppliers for a quote on your 3 ton overhead crane, having all relevant details ready will save time and get you a more accurate offer. Here's what you should gather:

- Required lifting capacity: Confirm 3 ton or specify if slight variation is needed.

- Span length: Distance between runway rails.

- Lifting height: Maximum height the crane needs to lift.

- Duty cycle/class: How often and intensively the crane will be used.

- Power supply details: Voltage, frequency, phase at your site.

- Installation environment: Indoor/outdoor, temperature range, humidity, presence of corrosive or explosive materials.

- Special features: Low headroom design, remote control, explosion-proof, automation needs.

- Site layout: Drawings, photos, or sketches showing available space and mounting conditions.

- Timeline: When you need the crane delivered and installed.

Sample Questionnaire for Suppliers to Ensure Clear Communication

To get the best quote, you can ask suppliers these questions when you inquire:

- What certifications does your 3 ton overhead crane have?

- What is the standard lead time for delivery and installation?

- Can you provide options with different control systems (wired remote, wireless, pendant)?

- Are installation and commissioning included in the quote?

- What warranty period and coverage do you offer?

- Do you provide after-sales support and spare parts?

- Can you customize the crane for special environmental conditions?

- What are payment terms and financing options?

- Do you offer operator training as part of the package?

Understanding Terms and Conditions: Payment, Delivery, Warranty

Before finalizing your purchase, carefully review these terms:

- Payment: Understand if the supplier requires deposits, milestones, or full payment upfront. Confirm accepted payment methods.

- Delivery: Check who is responsible for shipping costs and insurance. Clarify estimated delivery dates and penalties for delays.

- Warranty: Know what is covered (parts, labor), for how long, and what actions might void the warranty.

- Installation: Confirm if installation is included or if it's a separate cost. Ask about responsibilities for site preparation.

- After-sales service: Review the supplier's policy on maintenance, emergency support, and spare parts availability.

Clear understanding of these points helps avoid misunderstandings and ensures a smooth purchasing process.

Common Mistakes Buyers Make and How to Avoid Them

Overlooking Site-Specific Constraints Like Power Supply and Ceiling Height

One of the most frequent mistakes buyers make when purchasing a 3 ton overhead crane is not fully assessing their own site conditions before ordering. For example:

- Power supply mismatch: Assuming any crane will fit without confirming your facility's voltage, phase, and frequency can lead to costly modifications or delays.

- Ceiling height limitations: Not measuring the available headroom might result in ordering a crane that can't physically fit or lift loads to the required height.

- Runway structure and foundation: Ignoring the capacity and condition of your building's beams and supports may cause unsafe installations or extra reinforcement costs later.

How to avoid: Conduct a thorough site survey with detailed measurements and electrical specs before requesting quotes. Share these clearly with suppliers so they can design the crane to fit your exact environment.

Choosing Lowest Price Without Considering Total Cost of Ownership

It's tempting to pick the cheapest 3 ton crane option, but focusing only on upfront price can backfire. Cheaper cranes often use lower quality materials or lack advanced safety and efficiency features, resulting in:

- Higher maintenance and repair costs

- Increased downtime from breakdowns

- Shorter lifespan, leading to early replacement

- Potential safety hazards that could result in accidents or fines

How to avoid: Calculate the total cost of ownership, including installation, maintenance, energy use, and expected lifespan. A slightly higher initial investment can save you money and headaches over the long term.

Neglecting to Verify Supplier's Certifications and Track Record

Not all crane manufacturers are created equal. Buying from an unverified or inexperienced supplier risks poor quality, unreliable delivery, and weak support.

Common issues include:

- Cranes without proper safety certifications (ISO, CE, FEM)

- Limited or no warranty coverage

- Lack of spare parts availability

- Poor after-sales service and slow response times

How to avoid: Research supplier reputation through reviews, ask for certificates, request references, and confirm warranty and support policies before signing a contract.

Ignoring Future Expansion Needs and Crane Adaptability

Sometimes buyers order a crane just to meet current needs, without thinking ahead.

- What if your production grows and requires heavier or more frequent lifting?

- Will the crane system allow for easy upgrades or capacity increases?

- Can control systems be updated or expanded for automation in the future?

Ignoring these questions means you might have to buy a whole new crane sooner than expected, increasing costs and causing downtime.

How to avoid: Discuss your growth plans with suppliers and choose a 3 ton crane system designed with flexibility and scalability in mind. Modular designs or options to upgrade hoists and controls can extend your crane's useful life.

Avoiding these common pitfalls ensures your investment in a 3 ton overhead crane pays off—delivering reliable, safe, and efficient lifting now and down the road.

Contact & Consultation: How We Help You Find the Perfect 3 Ton Crane

Free Expert Consultation and Needs Analysis

We understand that choosing the right 3 ton overhead crane isn't always straightforward. That's why we offer a free, no-obligation consultation where our experienced engineers listen carefully to your needs.

- We analyze your specific lifting requirements, workspace conditions, and budget.

- We help identify the ideal crane type, features, and customization options that fit your operation.

- Whether you're upgrading, replacing, or buying your first crane, we provide honest advice tailored to your goals.

This personalized approach saves you time and ensures you don't overpay or end up with an unsuitable crane.

Flexible Pricing and Tailored Solutions for Unique Industrial Requirements

Every industry and facility has its own challenges. Our solutions adapt to those specifics:

- From low headroom cranes for tight workshops to explosion-proof cranes for hazardous zones, we customize designs to match your environment.

- Our pricing is flexible — we work within your budget to find the best balance of cost, quality, and functionality.

- Large orders, repeat customers, or special project needs? We offer competitive discounts and support to make your investment more affordable.

You get a crane that's just right, not a one-size-fits-all product.

Supporting You Through Selection, Purchase, Installation, and After-Sales

Our service doesn't stop once you get a quote. We guide you through every step:

- Selection: We clarify technical specs and help you compare models.

- Purchase: We handle contracts, financing options, and logistics.

- Installation: Our team coordinates professional installation to guarantee safety and compliance.

- After-sales: Ongoing maintenance support, operator training, and rapid response to any issues keep your crane running smoothly.

We're with you from start to finish, making the whole process easier and more reliable.

Summary and Final Recommendations

- Price Is Important, but Reliability, Service, and Safety Are Paramount -Buying a 3 ton overhead crane isn't just a one-time cost—it's a long-term partnership with your equipment and supplier. The cheapest option upfront may not serve you well in the long run.

- Make Decisions Based on Total Value and Operational Fit -Look beyond the sticker price. Consider how well the crane matches your actual lifting needs, work environment, and future growth. The best value crane balances quality, safety, efficiency, and maintenance costs.

- Invest in Professional Guidance for Long-Term ROI-Don't hesitate to seek expert help. Professional advice helps you avoid costly mistakes, select the right model, and optimize your investment. A well-chosen crane pays for itself through years of safe, dependable operation.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch