Overhead Crane Prices: Guide to EOT Cost, Customization & Savings

A practical guide covering overhead crane prices, key cost factors, customization options & tips to save on your investment. Get cost-effetice eot crane!

Category: Ton & Price

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Crane Prices: Complete Guide to Cost, Customization & Savings

Introduction: Why Overhead Crane Price Matters Most to Buyers

When you're shopping for an overhead crane, the first question almost everyone asks is simple: "How much does it cost?" Whether it's a 5-ton overhead crane for a small workshop or a heavy-duty 10-ton double girder bridge crane for a factory, price often becomes the deciding factor. But it's not just about the number on the price tag — it's about understanding what affects that price and how to get the best value for your money.

This guide is designed to give you a clear picture of overhead crane prices today, what influences those costs, and how to avoid surprises when you get your quote. We'll also look at how crane customization is evolving in 2025 and why getting a detailed, tailored quote is the smartest way to buy.

You'll find practical, technical information here — nothing vague or salesy. This is for buyers who want to make informed decisions.

What This Guide Covers

To help you get the full picture, we cover:

- Typical price ranges for various overhead crane types and capacities

- Key factors that influence crane prices, from design to features

- Current trends in customization and why they matter in 2025

- Tips on how to prepare for and get accurate price quotes from suppliers

Why Price Is So Important

Price is often the first filter for buyers, but it's also one of the most misunderstood parts of crane purchasing. Many buyers assume cranes with the same tonnage cost about the same, but that's rarely true. Several hidden details like span length, lifting height, and special features can push costs up or down quite a bit.

To save you time and avoid costly mistakes, this guide focuses on helping you understand what really goes into an overhead crane price, so you can:

- Know what to expect when you ask for a quote

- Ask the right questions of your supplier

- Match your budget with your actual needs, avoiding unnecessary extras

Key Factors Affecting Overhead Crane Prices

When it comes to overhead crane prices, there's no one-size-fits-all. A lot depends on the specifics of your operation and the technical features you need. Understanding what drives the cost from both an engineer's and a buyer's point of view will help you make smarter choices — and get better value.

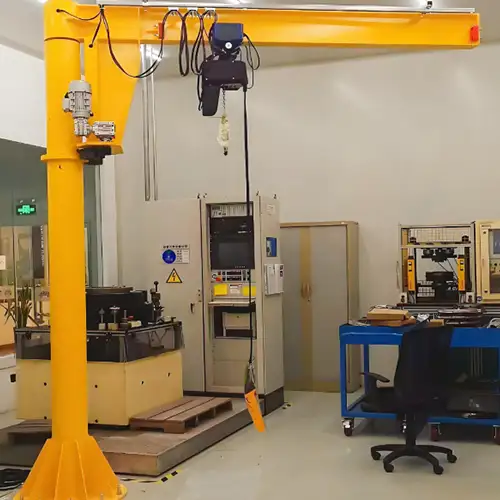

single girder overhead crane

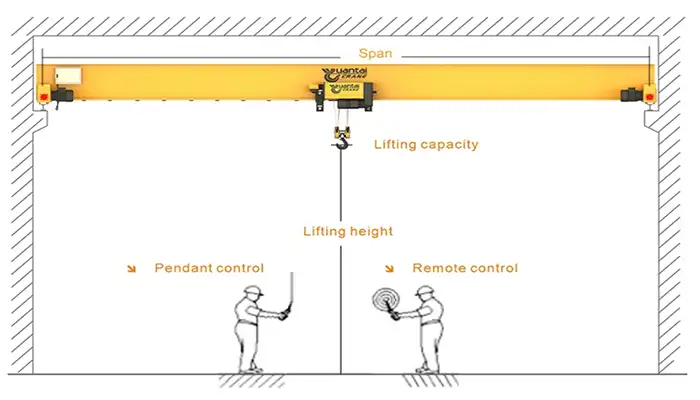

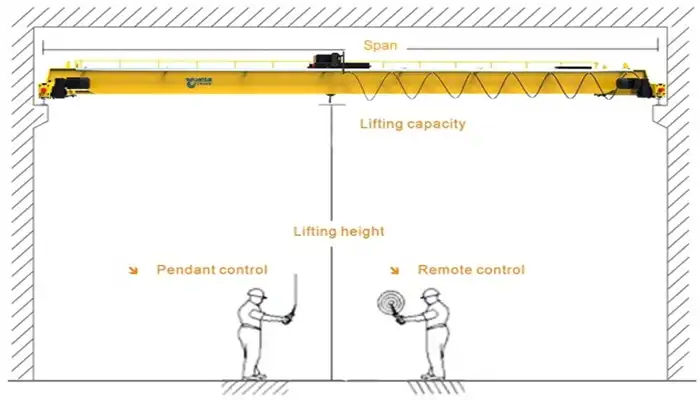

double girder overhead crane

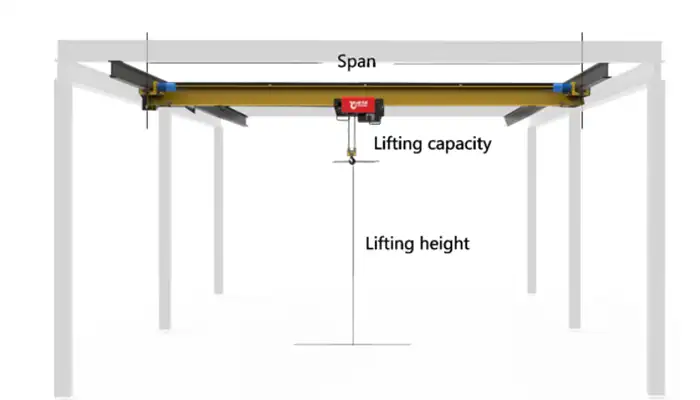

underhung bridge crane

Technical Perspective: What Engineers Consider

Engineers look closely at the crane's design and technical specs because these directly affect materials, manufacturing complexity, and performance.

Crane Configuration:

- Single girder vs. double girder: Single girder cranes are lighter, simpler, and usually less expensive. They're great for light to medium loads (up to about 20 tons). Double girder cranes support heavier loads and longer spans, but require more steel and a stronger structure, so they cost more.

- Top running vs. under running: Top running cranes run on rails mounted above the runway beams and generally allow longer spans and heavier loads but need stronger supporting structures. Under running cranes hang from the rails and are usually easier and cheaper to install but have lower load and span limits.

Customization Options:

- Lifting height and span: The higher and wider the crane needs to reach, the more materials and design work go into it. Larger spans require stronger girders and more powerful motors, which increase cost.

- Hoist type: Choosing between wire rope hoists and chain hoists affects price. Wire rope hoists handle heavier loads and longer lifts but are pricier.

- Explosion-proofing: If your environment is hazardous (chemical plants, dusty or flammable atmospheres), cranes must meet strict safety standards, adding to the cost.

- Control systems: Basic pendant control is cheaper. Radio remote controls, variable frequency drives (VFDs), and anti-sway technology add to price but improve safety and precision.

Buyer Perspective: How These Factors Impact Your Budget

From a buyer's standpoint, these technical details translate into clear cost differences. Here's what you can expect:

Standard Configurations vs. Custom Builds:

- Standard cranes with common lifting capacities (like 5 or 10 tons), typical spans, and simple controls are generally the most affordable. Suppliers often have these ready to go or easy to assemble.

- Custom cranes — for example, with unusual spans, high lifting heights, special hoists, or explosion-proof features — will cost more because they require additional engineering, materials, and sometimes special certifications.

Examples:

- A 5-ton single girder crane with a 10-meter span and basic hoist might cost around $4,000 to $7,000.

- A 10-ton double girder crane with a 20-meter span, advanced control system, and explosion-proof hoist can push toward $60,000 or more.

- Adding features like a load weighing system or anti-sway can add 10-20% to the base cost but greatly improve operation safety and efficiency.

Summary: What Drives Overhead Crane Prices?

Understanding what affects the price of an overhead crane can help you make smarter buying decisions. Crane pricing isn't just about the lifting capacity — it's a combination of many technical and practical factors that all add up to the final cost.

- Crane Type and Girder Design: The basic design of the crane, such as whether it's a single girder or double girder model, plays a big role in price. Double girder cranes use more steel and heavier components, so they usually cost more but handle heavier loads and longer spans better. Underhung or low headroom cranes have special designs that can increase costs as well.

- Lifting Capacity and Span Requirements: How much weight you need to lift and how far the crane must span across your workspace are crucial factors. Larger capacities and longer spans require stronger girders, more powerful hoists, and sturdier wheels — all of which raise the price. Even a small increase in span length can add significantly to steel and fabrication costs.

- Specialized Hoists and Controls: Not all hoists are created equal. Standard electric hoists are more affordable, while explosion-proof, variable frequency drive (VFD) controlled, or remote-controlled hoists add complexity and cost. Advanced control systems that improve safety and precision also affect the price.

- Environmental and Safety Requirements: If your crane operates in harsh conditions — like outdoors, in dusty or corrosive environments, or in hazardous/explosive areas — it needs special coatings, weatherproofing, or explosion-proof features. These modifications increase manufacturing and maintenance expenses.

- Degree of Customization vs. Standard Models: Off-the-shelf, standard cranes are generally more affordable because they use common components and designs. But custom cranes built to fit unusual workshop layouts, specific lifting tasks, or unique safety requirements will cost more due to additional engineering, special parts, and testing.

Price Ranges by Crane Type — Quick Buyer Reference

For crane buyers, knowing the baseline prices for standard models is a good starting point. From there, it's easier to see how custom features or special crane types can raise the price. Here's a clear overview based on typical capacities and common crane types, followed by key reasons why some overhead cranes cost more.

Standard Overhead Crane Prices: Quick Reference Table

| Crane Type | Typical Capacity Range | Price Range (USD) | Typical Applications |

|---|---|---|---|

| Single Girder Overhead Crane | 1 to 20 tons | $3,000 – $15,000 | Light to medium loads, small workshops |

| Double Girder Overhead Crane | 5 to 50 tons | $8,000 – $75,000+ | Heavy-duty use, long spans, factories |

| Underhung (Underrunning) Crane | 1 to 20 tons | $5,000 – $25,000 | Light work, limited floor space |

| Low Headroom Overhead Crane | 1 to 20 tons | $10,000 – $40,000 | Facilities with low ceilings |

| Explosion-Proof Overhead Crane | 1 to 30 tons | $15,000 – $80,000+ | Hazardous environments |

Single Girder Overhead Crane Price

Single girder overhead cranes are a popular choice for light to medium loads — usually up to 20 tons. They're simpler in design, lighter, and generally the most cost-effective option for many workshops and factories.

- Price Range: $3,000 to $15,000

- Capacity Range: 1 to 20 tons

- Typical Uses: Small fabrication shops, maintenance bays, light assembly lines

- Hot sale- European style single girder overhead crane -HD series, and types of single girder overhead cranes for your selections.

- More details on Single Girder Bridge Crane Prices: From Selection to Pricing Strategiese Economical Single Girder Bridge Crane Price 1, 2, 3, 5, 10, 15, 20 Ton

Why This Price?

- Fewer materials compared to double girder cranes

- Easier to install and maintain

- Suitable for lower lifting heights and moderate spans

Double Girder Overhead Crane Price

Double girder cranes are built for heavier loads and longer spans. Because they use two girders to support the hoist and trolley, they are stronger, more stable, and better for continuous heavy-duty use.

- Price Range: $8,000 to $75,000+

- Capacity Range: 5 to 50 tons and beyond

- Typical Uses: Large manufacturing plants, steel mills, heavy assembly

- Hot Sale- NLH European style double girder overhead crane with low headroom hoist trolley, and types of double girder overhead cranes for your selections.

Cost Factors:

- More steel and structural work

- Higher capacity motors and hoists

- Advanced control systems often included

Underhung (Underrunning) Bridge Crane Price

Underhung cranes run on rails suspended from the building's ceiling or support beams, rather than on top of runway beams. They're great for workshops with limited floor space or lighter loads.

- Price Range: $5,000 to $25,000

- Capacity Range: 1 to 20 tons

- Typical Uses: Light manufacturing, storage areas, automotive shops

- Hot sale - European style underhung bridge crane - and types of under running overhead cranes for your selections.

Pricing Notes:

- Lower structural support needed, reducing building modification costs

- Limited span and lifting height compared to top-running cranes

- Simpler installation but usually for lighter duty

Low Headroom Overhead Crane Price

Low headroom cranes are designed to maximize lifting height in facilities where ceiling clearance is tight. This special design can come at a premium because of the compact trolley and optimized girder structure.

- Price Range: $10,000 to $40,000

- Capacity Range: 1 to 20 tons

- Typical Uses: Workshops or plants with low ceilings, retrofit projects

- Economical low headroom overhead crane LDP series and types of low headroom overhead cranes for low built workshops and facilities.

Why It Costs More:

- Special trolley designs to fit tight spaces

- Custom engineering to maintain lifting capacity without raising the overall height

- Often double girder for higher capacity low headroom needs

Explosion-Proof Overhead Crane Price

For industries like chemical processing, oil & gas, or coal mining, explosion-proof cranes are a must. These cranes meet strict safety standards and use special electrical components and materials that can withstand hazardous environments.

- Price Range: $15,000 to $80,000+

- Capacity Range: 1 to 30 tons (typical)

- Typical Uses: Hazardous environments where sparks or heat could ignite gases or dust

- Hot Sale - single girder explosion proof crane & double girder explosion proof cranes, and types of explosion proof cranes for your selections.

Key Cost Drivers:

- Explosion-proof motors and hoists

- Sealed electrical controls and wiring

- Specialized paint and corrosion resistance

- Certification and testing requirements

What Drives Prices Up Beyond the Standard Models?

Standard cranes come with basic features and typical specs. But many factors can increase your crane cost significantly:

- Higher Lifting Capacity: Bigger cranes with capacities above 20 tons require heavier girders, stronger motors, and more durable components — all of which add to the price.

- Longer Span and Lifting Height: A crane spanning a larger workshop or lifting to higher ceilings needs a stronger structure and more powerful hoists. The bigger the span or height, the higher the price.

- Specialized Hoists: Using European or branded hoists, variable frequency drives (VFD), or anti-sway systems improves performance but raises cost.

- Explosion-Proof and Hazardous Location Requirements: Cranes designed for flammable or dusty environments require sealed electrical parts, special paint, and certifications — these safety features are costly.

- Low Headroom Designs: When ceiling clearance is limited, cranes must be custom-engineered with compact trolleys and optimized girder profiles — increasing manufacturing and design costs.

- Underhung vs. Top-Running: Underhung cranes save floor space but have limits on capacity and span. They can cost less initially but might not suit heavy or complex applications.

- Installation and Site Preparation: Civil work, power supply adjustments, runway beam installation, and load testing all add to the overall investment.

- Control Systems and Automation: Adding remote control, automated functions, or integration with factory systems increases cost but improves safety and productivity.

Summary for Buyers

Start by looking at standard single or double girder cranes to get a sense of pricing for your capacity needs. Then consider:

- Will your workshop require a low headroom or explosion-proof crane?

- How long is the span and what's the lifting height?

- Do you want premium hoists or special control systems?

- What about installation and ongoing maintenance?

Price Breakdown by Capacity: Standard Overhead Cranes (1 Ton to 40 Ton)

When you start planning your overhead crane purchase, capacity is one of the first things to consider. Different lifting capacities mean different structural needs, cost ranges, and typical uses. Here's a practical breakdown by capacity, including what engineers and buyers should know. Each capacity will eventually link to a detailed article for those who want to dive deeper.

Engineer Notes: What Capacity Means for Crane Design

- Structural Demands:: Higher capacities need stronger girders and support beams to handle heavier loads without bending or warping. The crane's framework must be engineered precisely to ensure safety.

- Wheel Loads:: As capacity increases, so does the load on wheels and runway rails. This affects wheel size, material choice, and rail specifications.

- Technical Limits:: Some capacities push the limits of standard designs, requiring custom components, specialized hoists, and advanced controls.

Buyer Notes: Typical Uses and Cost Expectations

- Standard vs. Custom:: Lower capacities (1–5 tons) are often available as standard models, ready to ship. Higher capacities or specialized requirements usually mean custom-built cranes.

- Cost Expectations:: Prices rise sharply with capacity, but the jump isn't linear — doubling the capacity often more than doubles the price due to engineering complexity.

- Common Applications:: Smaller cranes fit light workshops; mid-range cranes serve medium factories, while large capacities are for heavy manufacturing or steel mills.

Popular Capacities Overview

- 5 Ton – The Versatile Workhorse:

Most popular and flexible for a wide range of light to medium tasks. Ideal for small to medium workshops and fabrication shops.

Price range (single girder): $3,000 – $4,150

Price range (double girder): $5,800 – $72,000 (depends on specs) - 10 Ton – Mid-Range Power:

Great for medium factories handling larger parts or heavier materials. Often used in fabrication and maintenance.

Price range (single girder): $4,000 – $4,500

Price range (double girder): $6,500 – $79,000 - 20 Ton – Heavy-Duty Capability:

For large-scale production requiring strong support and durable components. Usually double girder design for stability and safety.

Price range (single girder): $6,000 – $50,000

Price range (double girder): $8,600 – $95,000 - 40 Ton – High Investment, Heavy Lifting:

Reserved for heavy industries like steel manufacturing or large construction. Custom-engineered double girder cranes are standard here.

Price on request; always tailored to project specifics

Quick Price Tables for Reference

Single Girder Overhead Crane Price Overview

| Capacity | Price Range (USD) | Notes |

|---|---|---|

| 1 ton | $2,200 – $4,000 | Entry-level, compact workshops |

| 3 ton | $2,600 – $4,100 | Light-duty handling |

| 5 ton | $3,000 – $4,150 | Most popular model |

| 10 ton | $4,000 – $4,500 | For medium factories |

| 20 ton | $6,000 – $50,000 | Requires stronger structure |

Double Girder Overhead Crane Price Overview

| Capacity | Price Range (USD) | Notes |

|---|---|---|

| 5 ton | $5,800 – $72,000 | Higher duty or lifting height |

| 10 ton | $6,500 – $79,000 | Large-scale fabrication |

| 15 ton | Contact us | Custom-configured, varies by design |

| 20 ton | $8,600 – $95,000 | Heavy-duty continuous lifting |

| 30 ton | Contact us | Tailored based on layout |

Customization Options and How They Affect Crane Costs

When you're shopping for an overhead crane, the base price is just the starting point. Most buyers need cranes tailored to their specific needs — and those custom options can add up. Understanding what customization means for your budget helps you make informed choices and avoid surprises.

Why Customize Your Overhead Crane?

Every factory or workshop has unique requirements. Maybe your space has a low ceiling, or you need a crane that can work in a hazardous environment. Sometimes it's about fitting the crane to unusual load sizes or improving safety and efficiency with advanced controls.

Customizations make your crane safer, easier to use, and better suited for your work—but they do increase the cost.

Common Customization Options and Their Cost Impact

- Hoist Type and Brand: Choosing a premium European or American hoist over a standard Chinese model can improve reliability and service life. Expect a price increase of 10% to 30%.

- Explosion-Proof Features: Cranes for hazardous zones require sealed motors, special enclosures, and certifications. These safety upgrades can add 50% or more to the standard price.

- Low Headroom Design: For workshops with limited ceiling space, cranes need compact trolleys and optimized girder designs. Custom engineering and production raise costs by 20% to 40%.

- Advanced Control Systems: Options like variable frequency drives (VFD), remote controls, anti-sway devices, or load monitoring improve performance but can add 15% to 35%.

- Increased Span and Lifting Height: Longer spans or higher lifts require stronger steel and more powerful motors, increasing cost by 10% to 50% depending on the scale.

- Special Paint and Corrosion Protection: Outdoor or corrosive environments call for weather-resistant paints and coatings, typically adding 5% to 15%.

- Multiple Hoists or Hooks: Some cranes need two hoists or twin hooks for lifting very large or awkward loads. This often doubles the cost compared to a single hoist.

- Rails and Runway Installation: If you require the supplier to provide runway rails or installation services, expect additional charges. Installation costs vary widely based on site conditions.

Practical Tips for Managing Customization Costs

- Prioritize Needs: Focus on must-have features for safety and compliance before adding "nice-to-have" options.

- Get Detailed Quotes: Ask suppliers for itemized pricing on each customization to compare costs clearly.

- Plan for the Future: If you expect growth, consider options that allow easy upgrades later.

- Local Regulations: Check if your industry or region requires explosion-proof cranes or other specific certifications to avoid costly retrofits.

How Customization Affects Final Pricing

| Custom Feature | Typical Cost Increase vs. Base Price |

|---|---|

| Premium Hoist | +10% to +30% |

| Explosion-Proof | +50% or more |

| Low Headroom Design | +20% to +40% |

| Advanced Controls | +15% to +35% |

| Larger Span / Height | +10% to +50% |

| Special Paint | +5% to +15% |

| Multiple Hoists / Hooks | 2x or more (depends on number of hoists) |

| Rails and Installation | Varies widely, 10% to 30% typical |

Customizing your overhead crane ensures it fits your unique needs, improving safety, productivity, and longevity. However, it's important to understand that customization comes with added costs. Balancing your budget with must-have features will get you the best value.

Installation, Commissioning & Hidden Costs

When buying an overhead crane, the sticker price is just part of the total investment. Installation, testing, and sometimes unexpected expenses add to the final cost. Knowing what to expect can help you budget better and avoid surprises.

Engineer Notes: What Installation Really Involves

Installing an overhead crane is more than just putting the crane in place. Here are the key engineering steps that affect cost and timeline:

- Power Supply Requirements: Cranes usually need a three-phase power supply, often 380V or 415V, with stable voltage and proper grounding. If your site lacks this, you might need electrical upgrades or dedicated transformers, which increase costs.

- Civil Works: Foundations and Runway Rails: Before the crane can operate safely, you need a strong foundation for the runway rails. This involves concrete footings or steel columns that meet engineering specs for load and vibration resistance. Poor existing structures might require reinforcement or complete rebuilds, adding substantial expenses.

- Load Testing and Commissioning: After installation, the crane must be load tested to ensure safety and compliance. This includes lifting weights near the maximum capacity and testing limit switches, brakes, and controls. Commissioning also involves calibrating all systems and training operators.

- Safety and Compliance Checks: Depending on your region, installation must meet local safety codes, which may require inspections from third parties or government agencies.

Buyer Notes: What's Usually Included or Excluded in Installation Quotes

Quotes from crane suppliers often differ on what they cover, so be clear upfront:

Included in most quotes:

- Delivery of crane components to site

- Assembly of the crane on the runway rails

- Basic functional testing

Often excluded or extra:

- Runway rail supply and installation (sometimes your responsibility)

- Electrical wiring and power supply preparation

- Civil works like foundation construction

- Load testing with certified weights

- Operator training and detailed commissioning

- Travel and accommodation for installation technicians (for remote sites)

Installation Cost Variations by Site and Country

Installation costs can vary a lot depending on where and how the crane is installed:

- Site Conditions:: Difficult access, limited workspace, or hazardous environments (hot, dusty, corrosive) increase labor time and equipment needs.

- Country and Local Labor Rates:: Labor and material costs differ widely by region. For example, installation in developed countries can cost 2-3 times more than in parts of Asia.

- Existing Infrastructure:: If your factory's structure or electrical system needs upgrades, expect additional expenses beyond the crane vendor's scope.

- Permitting and Regulations:: Some places require special permits, inspections, or certifications, which can add time and money.

Practical Tips for Buyers

- Get a Detailed Installation Quote: Ask suppliers to clearly list what is included and excluded.

- Plan for Site Prep: Factor in runway rail and foundation costs early in your budget.

- Consult Local Experts: Hiring local engineers or contractors familiar with regulations can prevent costly rework.

- Consider Full-Service Packages: Some vendors offer "turnkey" installation that handles everything, often at a higher but predictable cost.

- Schedule Load Testing Properly: Confirm who provides the test weights and certification—sometimes it's your responsibility.

Summary Table: Installation and Hidden Costs Overview

| Cost Factor | Typical Considerations | Estimated Cost Impact |

|---|---|---|

| Power Supply Upgrade | Electrical work, transformers | Varies, moderate to high |

| Civil Works (Foundations) | Concrete footings, steel supports | Moderate to high |

| Runway Rails Installation | Rail supply, precise alignment | Moderate |

| Load Testing & Commissioning | Test weights, certifications, operator training | Low to moderate |

| Travel & Accommodation | For vendor technicians (remote sites) | Variable |

| Permitting and Inspections | Local authority approvals | Low to moderate |

Buyer FAQ — Real Questions from Crane Buyers

When you're in the market for an overhead crane, questions come fast and often. Below are some of the most common questions buyers ask — with straightforward answers to help you make sense of pricing, options, and installation.

How Much Does an Overhead Crane Cost Per Ton?

There's no one-size-fits-all answer here because costs depend on several factors:

- Basic Price Range: Generally, overhead cranes cost between $1,000 to $5,000 per ton of lifting capacity for standard single girder models.

- Double Girder Models: These are stronger and usually more expensive, often $2,000 to $7,000+ per ton depending on specs.

- Customization: Features like explosion-proofing, low headroom designs, or special hoists add to the price per ton.

- Example: A 5-ton single girder crane might cost around $4,000–$7,000, while a 10-ton double girder crane could range from $15,000 to $50,000 or more.

Tip: Always get detailed quotes based on your exact requirements, not just "per ton" estimates.

Is a Single Girder Crane Always Cheaper?

Usually, yes — but not always.

- Why Single Girder Is Cheaper: It uses less steel and simpler design, so the material and manufacturing costs are lower.

- Limitations: Single girder cranes have lower lifting heights and shorter spans. They're best for lighter loads (typically under 20 tons).

- When Double Girder Is Worth It: For heavy loads, longer spans, or more frequent use, double girder cranes offer better stability and durability — but at a higher price.

Bottom line: If your application fits within single girder limits, it's a budget-friendly choice. Otherwise, investing more in a double girder crane pays off in performance.

Should I Buy a Crane Kit or a Full System?

Both options have pros and cons depending on your capabilities and needs.

Crane Kit: Includes main components like girders, hoist, trolley, and controls — but excludes steel structure or runway rails.

- Pros: Lower upfront cost; flexibility to fabricate steel locally; suitable for companies with technical teams.

- Cons: Requires local fabrication and engineering expertise; longer assembly time.

Full System: Supplier provides the complete crane, including structure, rails, and installation services.

- Pros: Turnkey solution with quality control; faster installation; good for buyers without fabrication resources.

- Cons: Higher initial cost; less flexibility for local customization.

Consider: Your in-house skills, timeline, and budget when choosing between kits or full systems.

What Is the Installation Cost of a 10-Ton Crane?

Installation costs vary widely based on site conditions, location, and scope of work.

- Typical Range: For a 10-ton overhead crane, installation usually adds 10% to 30% of the crane's purchase price.

Factors Influencing Cost:

- Need for foundation or runway rail construction

- Electrical system setup and power supply upgrades

- Labor rates and site accessibility

- Load testing and certification requirements

Example: If your crane costs $30,000, installation might be $3,000 to $9,000, but this can increase if site prep is complicated.

Tip: Ask your supplier for a detailed installation quote including all related work.

How to Get an Accurate Quote for Your Overhead Crane

When you're ready to ask suppliers for a price, providing the right information upfront makes all the difference. The more detailed and precise your data, the more accurate and relevant your quotes will be. This saves time and avoids back-and-forth that slows down your project.

Why Detailed Information Matters

Overhead cranes are highly customizable machines. Two cranes with the same lifting capacity can vary greatly in price depending on how they are designed, the environment they operate in, and additional features.

Suppliers rely on your specifications to select the correct components — such as hoists, motors, electrical controls, and steel structures — to meet your needs safely and efficiently.

Essential Information to Provide

Here are the key details you should prepare before requesting a quote:

- Lifting Capacity (tons): The maximum weight your crane needs to lift. This is the single most important factor and affects almost every part of the crane design and cost.

- Span (meters): The distance between the crane's runway rails. The longer the span, the stronger (and pricier) the main girders and structure must be.

- Lifting Height (meters): How high the crane needs to lift the load. This affects the hoist specification and sometimes the overall crane height and workshop clearance.

- Power Supply Specifications: Include voltage, frequency, and phase (e.g., 380V, 50Hz, 3-phase). If your site's power differs or is unstable, special electrical equipment or converters may be necessary.

- Crane Traveling Length: The distance the crane needs to move along the runway rails. Longer travel requires more precise rail installation and possibly additional safety features.

- Working Conditions: Describe the environment where the crane will operate: indoor or outdoor, temperature range, dust, moisture, corrosive atmosphere, explosive zones, etc. These affect material choices and safety requirements.

- Duty Cycle / Daily Working Hours: How often and how long the crane will be used each day. Heavy or continuous use demands higher-grade components, impacting price and maintenance schedules.

- Rails Required?: Confirm if you need the supplier to provide and install runway rails or if you will handle that separately.

- Special Features or Customization: Mention any special needs such as: explosion-proof hoists, low headroom designs, remote controls, additional safety devices, special paint or coatings, multiple lifting hooks, or integrated automation.

Bonus Tips for Getting a Good Quote

- Send Photos or Drawings: Visual references of your workshop or site layout help suppliers understand your space constraints and installation challenges.

- Be Clear About Your Budget and Timeline: This helps suppliers propose solutions within your financial and time limits.

- Ask for Detailed Breakdowns: Request quotes to list costs for main components, installation, shipping, and extras separately. This helps you compare suppliers better.

- Check Supplier Credentials: Confirm certifications (ISO, CE) and after-sale support policies to avoid surprises later.

Summary Table: What to Include in Your Quote Request

| Detail | Why It Matters |

|---|---|

| Lifting Capacity (tons) | Determines crane size and strength |

| Span (meters) | Influences girder design and cost |

| Lifting Height (meters) | Affects hoist and clearance |

| Power Supply Specs | Ensures electrical compatibility |

| Traveling Length | Affects rail and travel system |

| Working Conditions | Determines materials and safety |

| Duty Cycle / Working Hours | Impacts durability and pricing |

| Rails Required? | Clarifies scope of supply |

| Special Features or Customization | Tailors crane to your needs |

Request Your Customized Crane Price Today

When you're ready to move forward, getting a tailored quote is the best next step. Every crane project is unique, so generic prices rarely tell the full story. That's why we encourage you to share your exact needs — the specs, site conditions, and any special requests — to receive an accurate and fair price.

Why You Should Submit Your Specs

- Get a Quote That Fits Your Needs: Off-the-shelf prices are a starting point, but only a custom quote considers your workshop layout, load requirements, and working environment. This helps avoid surprises and ensures your crane performs exactly as expected.

- Save Time and Money: By providing details upfront, you avoid vague offers or back-and-forth emails. The supplier can quickly recommend the right crane model, options, and pricing that match your budget and schedule.

- Access Expert Advice: Experienced suppliers often include suggestions for improving safety, efficiency, or cost-effectiveness based on your specs — insights you might not get otherwise.

How to Request Your Customized Quote

It's easy to get started. Simply send the following details (or fill out the online inquiry form) to receive your free, no-obligation quote:

- Lifting capacity (tons)

- Span (meters)

- Lifting height (meters)

- Power supply details

- Crane travel length

- Site conditions and environment

- Daily working hours and duty cycle

- Rails needed or already installed

- Any special features or requirements

Useful Tools to Help You Estimate

If you want to do some preliminary calculations or get a rough price estimate before reaching out, check if there's a downloadable price guide or crane price calculator available. These tools let you enter your specs and see ballpark numbers instantly. While they don't replace a custom quote, they're handy for quick budgeting or comparisons.

What to Expect After You Submit Your Request

- Fast Response: Most suppliers commit to providing a detailed quote within 24 hours, so you're not left waiting.

- Detailed Breakdown: You'll receive a clear proposal including equipment specs, pricing, optional features, and installation costs if requested.

- Personalized Follow-up: The supplier may contact you to clarify details or suggest optimizations tailored to your needs.

Ready to Get Started? Don't wait—send your specs today and take the next step toward finding the perfect overhead crane for your operation.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch