Double Hoist Overhead Cranes for Sale, 5+5T, 10+10T, 12.5+12.5T

Six sets of double hoist overhead cranes, with capacities of 5+5T, 10+10T, and 12.5+12.5T, for heavy-duty lifting.Get your double hoist crane, good price.

Category: Poland

Your Trusted Overhead Crane Manufacturer & Supplier

Double Hoists Overhead Cranes for Sale in Poland

Overhead Double Hoist Cranes – 6 Sets, 5+5 Ton, 10+10 Ton, 12.5+12.5 Ton

Six sets of double hoist overhead cranes, with capacities of 5+5T, 10+10T, and 12.5+12.5T, for heavy-duty lifting.

Overview of the Case Study

This case study focuses on the sale and installation of six double hoist overhead cranes at a manufacturing facility in Poland. These cranes—designed with European-style top-running double girders and open winch trolleys—are tailored to meet the client's specific material handling needs. The study highlights the technical specifications of the cranes, including their lifting capacities (5+5T, 10+10T, and 12.5+12.5T), span sizes, and lifting heights, as well as their operational benefits. It also examines how these cranes have enhanced the client's production efficiency, safety, and overall workflow in a busy industrial environment.

Project Background

Client Industry: The client operates in the automotive and industrial manufacturing sector in Poland, specializing in heavy-duty components and machinery. Their production facility handles large, heavy parts such as automotive sub-assemblies, steel components, and heavy machinery, all of which require efficient material handling systems to ensure smooth workflows and high productivity.

Challenges Faced: As the company's production scale grew, the limitations of their existing lifting systems became evident. The need for a crane system that could handle heavier, more varied loads simultaneously and operate efficiently within the facility's available space became a priority. The company sought a solution to:

- similiar double girder overhead crane with 20 ton + 20 ton double hoists for reference

- Increase material handling capacity for larger and heavier components.

- Reduce cycle times by optimizing the lifting process.

- Improve operational efficiency while ensuring safety and reducing downtime.

Crane Selection Rationale

Why Double Hoist Overhead Cranes?

- Higher Lifting Capacity: Double hoist cranes provide two independent hoists per unit, which significantly increases the total lifting capacity without needing additional cranes. This is crucial for handling heavy loads that exceed the capabilities of single hoist systems. For example, the 12.5+12.5T cranes can lift up to 25 tons combined, while the 10+10T cranes manage up to 20 tons, making them ideal for lifting large, heavy components with ease.

- Simultaneous Lifting: The ability to lift two loads simultaneously with each crane enhances operational efficiency. This feature reduces cycle times and allows for more tasks to be completed in less time. For instance, in one lift, the client can move a heavy steel part with one hoist while using the other hoist to handle a smaller load, streamlining production and minimizing delays.

- Improved Precision and Flexibility: The open winch trolley design offers smoother, more precise lifting and positioning. This ensures that even large or complex components are moved accurately to their desired locations. The double hoist system also allows for greater flexibility, enabling the client to adjust to varying load sizes and types without requiring different crane setups.

- Space Optimization: The facility had specific spatial limitations, so selecting double hoist cranes helped make the most efficient use of the available headroom and span. The top-running double girder design ensures the cranes are able to cover large distances with minimal space usage, increasing the facility's storage and production capacity without significant facility modifications.

- Enhanced Safety and Durability: Double hoist cranes are equipped with safety features like overload protection and limit switches, which prevent accidents and enhance the reliability of the system. These features are especially important in environments where heavy loads are frequently moved. Additionally, the cranes are built for long-term durability, minimizing maintenance needs and reducing the risk of downtime.

- Cost-Effectiveness in the Long Run: While the initial investment for double hoist cranes is higher than that for simpler lifting systems, the increased efficiency, reduced maintenance costs, and greater load-handling capabilities make them a cost-effective option over time. The cranes' ability to handle larger loads and more varied tasks without needing additional equipment translates to significant savings in both operational costs and time.

In summary, double hoist overhead cranes were selected due to their ability to handle heavy loads, improve productivity, and offer flexibility in a space-constrained environment. Their precise lifting capabilities and safety features also aligned with the client's needs for a durable and efficient solution to meet their growing operational demands.

Crane Specifications and Key Features

Crane Type: European-Style Top-Running Double Girder Overhead Cranes

The cranes in this case study feature a European-style top-running double girder design, known for its durability and heavy-duty performance. The double girder configuration provides superior strength and stability, allowing the cranes to handle large, heavy loads with ease. This design is particularly beneficial for industries that require reliable lifting systems for complex or oversized materials.

In addition, the top-running design ensures that the cranes operate on rails mounted at the top of the structure. This not only maximizes headroom and lifting height but also optimizes the span between the girders, giving the crane the ability to cover a wider working area. This is ideal for large facilities with space constraints or those requiring high lifting capacities and large span coverage.

Low Headroom Electric Hoist Design

Low headroom electric hoists are designed to fit into facilities where vertical space is limited. Compared to standard hoists, these take up less height, allowing cranes to be installed in workshops or factories with lower ceilings without sacrificing lifting height.

Benefits include:

- Compact size: Fits tight spaces without major structural changes.

- Maximized lifting height: You get more lifting range even in low-clearance environments.

- Energy-efficient operation: Modern electric hoists are designed to consume less power.

- Smooth and quiet operation: This improves operator comfort and reduces wear on equipment.

Double Hoist System: Enhanced Flexibility and Load Handling

One of the standout features of these cranes is the double hoist system. Each crane is equipped with two independent hoists, allowing for simultaneous lifting of two loads. This capability provides greater flexibility in lifting various types of materials and components without the need for additional equipment.

The double hoist system is particularly beneficial for operations that involve:

- Lifting and positioning different components at the same time.

- Moving large, heavy, or oversized materials more efficiently.

- Reducing the time needed for lifting tasks by using both hoists in parallel.

This system enhances overall operational productivity, especially in environments where fast and reliable material handling is essential.

Crane Specifications by Set

| Capacity (Ton + Ton) | Span (meters) | Lifting Height (meters) | Quantity (Sets) |

|---|---|---|---|

| 5 + 5 T | 15.19 | 11.74 | 2 |

| 10 + 10 T | 23.68 | 16.56 | 2 |

| 12.5 + 12.5 T | 15.07 | 16.735 | 2 |

Set 1: 5+5T Cranes

- Capacity: 5 tons per hoist

- Span: 15.19 meters

- Lifting Height: 174 meters

- Quantity: 2 sets

- Applications: These cranes are designed for light to medium-duty tasks, such as moving smaller components on an assembly line or handling materials that are not extremely heavy. The moderate lifting capacity and height make them ideal for industries with less demanding lifting requirements.

Set 2: 12.5+12.5T Cranes

- Capacity: 12.5 tons per hoist

- Span: 15.07 meters

- Lifting Height: 16.735 meters

- Quantity: 2 sets

- Applications: The 12.5+12.5T cranes are built for heavier applications, such as lifting large parts in steel fabrication or heavy manufacturing environments. Their higher lifting capacity and greater lifting height make them perfect for handling heavy-duty components that require more precise lifting.

Set 3: 10+10T Cranes

- Capacity: 10 tons per hoist

- Span: 23.68 meters

- Lifting Height: 16.56 meters

- Quantity: 2 sets

- Applications: The 10+10T cranes are best suited for large-scale material handling tasks. Their wider span and substantial lifting capacity allow for the movement of larger equipment, machinery parts, and industrial components. These cranes are designed to handle the demands of large production facilities with heavy-duty lifting requirements.

Crane Power Supply

All six crane sets are powered by a 380V, 50Hz, 3-phase power supply, ensuring reliable and efficient operation across the facility. The 3-phase power system provides consistent energy distribution, supporting heavy lifting operations without the risk of overloads. This type of power supply is ideal for industrial applications where high-performance and reliability are critical.

The 380V, 50Hz electrical standard is widely used in industrial settings and ensures compatibility with most machinery and systems, making these cranes easy to integrate into existing infrastructure. The power system also contributes to energy efficiency, reducing operational costs while maintaining smooth and continuous crane performance.

In conclusion, the cranes specified in this case study provide flexible, efficient, and reliable solutions for a variety of lifting applications. With their European-style top-running double girder design, open winch trolley system, and double hoist configurations, these cranes are well-suited for industries that require high capacity, precision, and continuous operation. The cranes' power supply system and the robust construction of their key components further ensure that they deliver long-term performance and value to the client in Poland.

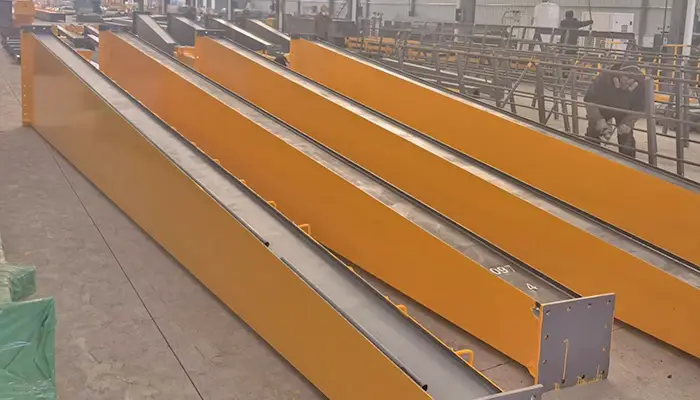

Main girder of double hoist cranes for sale Poland

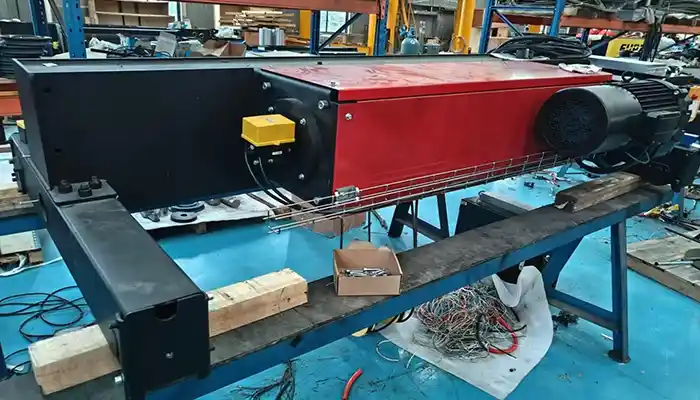

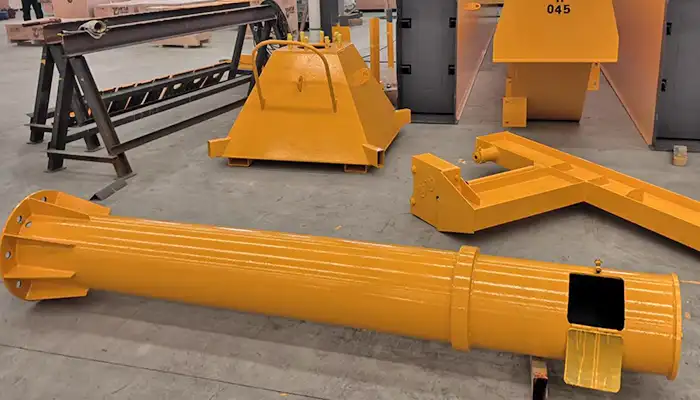

Main parts and components of double girder double hoist overhead crane

End carriages for the overhead bridge cranes for sale Poland

Double girder crane hoist trolley

Design and Engineering Advantages

Top-Running Double Girder Design

The top-running double girder design is a robust structure ideal for handling heavy-duty applications. This design ensures that the crane maintains maximum stability while lifting large loads, thanks to its dual-girder system that evenly distributes weight across both girders.

Load Distribution: The double girder system helps distribute the weight efficiently, which allows the crane to handle heavier loads without stressing individual components.

- Balanced load-sharing reduces the risk of overloading.

- The system supports higher lifting capacities without compromising safety.

Structural Integrity: The rigid frame of the double girder system ensures minimal deflection during operation. This is crucial when lifting heavy or oversized materials, as even minor frame distortions can affect load positioning.

- Prevents deflection under maximum load.

- Enhances precise positioning and operational safety.

- Reduces the risk of component damage, extending crane life.

Double Hoist System

The double hoist system allows for simultaneous lifting of different loads, offering increased flexibility and operational efficiency. This system is especially useful for handling multiple materials or components at once, significantly improving productivity in busy industrial settings.

Increased Capacity and Flexibility: By utilizing two hoists per crane, the system allows for simultaneous handling of multiple loads. This is particularly advantageous for complex lifting tasks or when handling oversized components.

- Reduces cycle time by allowing concurrent lifting tasks.

- Enables handling of different loads independently.

- Ideal for moving large and heavy materials with precise control.

Operational Efficiency: The double hoist setup enhances the overall efficiency of crane operations. It allows a single crane to perform tasks that would otherwise require multiple cranes, optimizing space and reducing equipment requirements.

- Reduces the number of cranes needed in the facility.

- Optimizes space and increases crane utilization.

- Speeds up the lifting process by reducing the time per task.

Installation Details of 6 Sets of Double Hoist Cranes

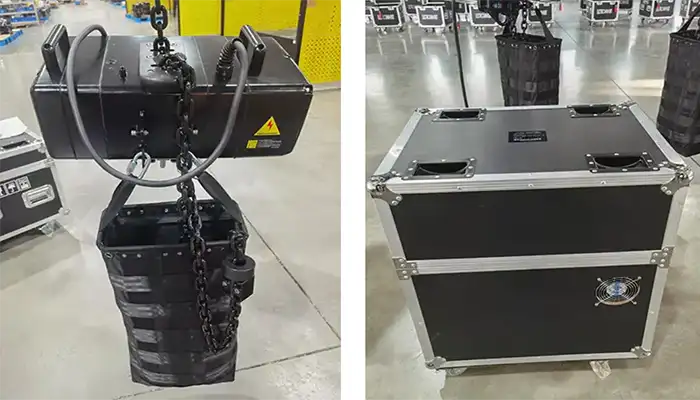

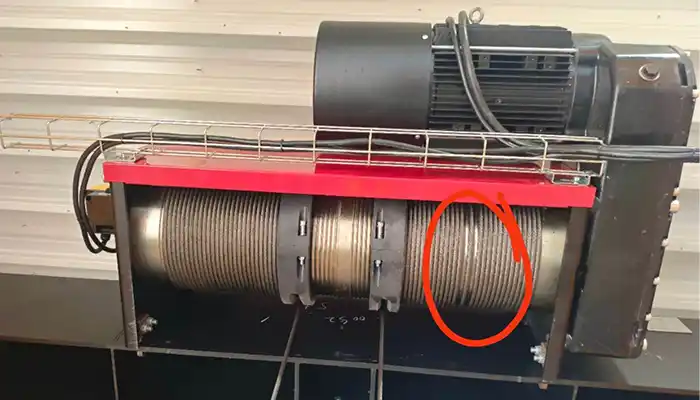

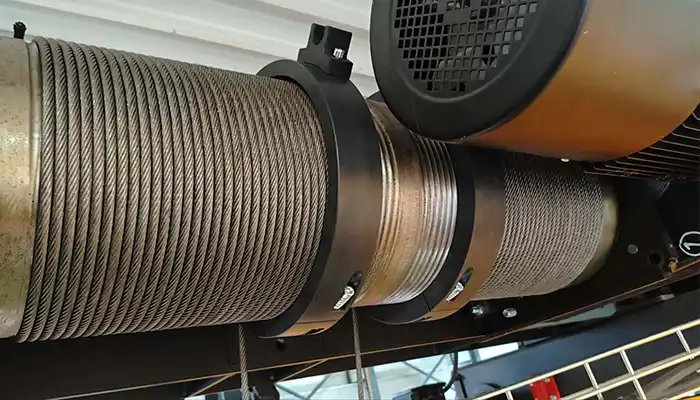

Upon the arrival of the electric hoist at the assembly site, the wire rope of the electri choist may get loosended which need to be rearranged the wire rope in order

Wire rope of the electric hoist have to be arranged in order and neatly.

overhead crane cross limit installation

crane lubircation

double hoists of the overhead crane installed

Overhead travelling crane driving motor

Electrical box of the overhead bridge cranes with double hoist trolley

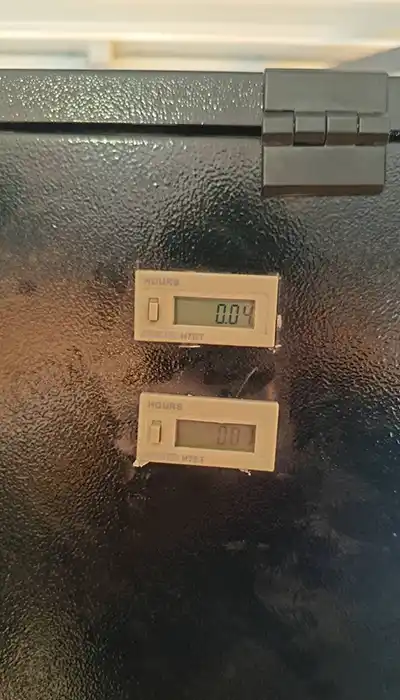

Running time meter

Ladder

Sound and light safety device assembly

Installation specifics by crane capacity:

5+5 Ton Overhead Crane Double Girder Design, 2 Sets:

- Installation typically completed within a shorter timeframe due to smaller size and simpler structure.

- Runway beams are mounted and aligned with precision to ensure smooth crane travel.

- Hoists and trolleys are installed and calibrated for independent or coordinated lifting.

- Electrical systems, including power supply and control panels, are connected and tested.

- Initial trial runs verify the basic functionality of all crane movements.

10+10 Ton Double Hoist Ovehead Crane 2 Sets:

- Larger span and higher capacity require additional structural support, including reinforcement of runway beams and foundations.

- The two hoists undergo synchronization testing for combined lifts to handle heavy or awkward loads safely.

- Installation involves detailed checks on wire ropes, brakes, limit switches, and emergency stops to comply with safety regulations.

- Electrical systems include more advanced control options, sometimes with remote or pendant controls.

12.5+12.5 Ton Overhead Crane with two Hoist Trolley, 2 Sets:

- Due to the heavy-duty nature and high lifting height, installation requires heavy lifting equipment like mobile cranes to position large components.

- Precision alignment of the double girders is critical to avoid structural stress and ensure smooth operation.

- Commissioning tests include full-load lifting trials to confirm crane stability and safety under maximum operating conditions.

- The installation team coordinates with facility engineers to ensure the crane integrates seamlessly with existing infrastructure.

Commissioning and Testing

Once installed, the cranes undergo a thorough commissioning process to guarantee they meet all operational and safety requirements before being handed over to the customer.

Commissioning steps:

- Functional Tests:

All crane movements—bridge travel, trolley travel, and hoist lifting/lowering—are checked for smoothness, accuracy, and responsiveness. - Load Testing:

Each hoist is tested with weights matching or exceeding its rated capacity (5, 10, or 12.5 tons per hoist). This confirms the mechanical integrity and safety of the lifting mechanisms. - Safety Checks:

Safety devices like overload protection, emergency stops, limit switches, and brake systems are inspected and tested. Ensuring these components work correctly is crucial for operator safety. - Operator Training:

Experienced technicians provide hands-on training to crane operators and maintenance staff, covering safe operation, emergency procedures, and basic troubleshooting. - Documentation and Handover:

Detailed reports on testing results, maintenance schedules, and operational manuals are provided to the client for future reference.

The entire process—from production to commissioning—is designed to deliver reliable, efficient, and safe double hoist overhead cranes tailored for your facility's needs in Poland. Whether you choose the 5+5 ton, 10+10 ton, or 12.5+12.5 ton sets, you can expect:

- High-quality manufacturing backed by rigorous testing.

- Professional installation adapted to your site's requirements.

- Comprehensive commissioning ensuring safety and performance.

- Training and documentation to support smooth operation.

This approach minimizes downtime and maximizes the return on your investment in overhead crane equipment.

10 +10 ton double hoist overhead crane testing

12.5 +12.5 ton double hoist overhead crane testinng

Performance and Efficiency Outcomes

Increased Productivity

Time Savings: The implementation of double hoist overhead cranes significantly enhances operational efficiency. By using two hoists on each crane, the system allows for simultaneous lifting of different loads, which reduces the cycle time for each lifting task. This faster processing of materials leads to higher throughput and enables the client to complete more tasks within a given time frame.

- Simultaneous lifting reduces the number of lifting cycles.

- Faster cycle times improve overall production capacity.

- Higher throughput in busy environments, contributing to meeting deadlines and demand.

Enhanced Workflow: The large span and high lifting capacity of the cranes provide workers with the flexibility to handle a wide range of materials, from lighter components to heavier machinery parts. This enhanced capability allows for optimized workflow, as the cranes can efficiently accommodate different sizes and weights of materials without requiring multiple cranes.

- Large span (up to 23.68 meters) facilitates handling large loads.

- High lifting heights (up to 16.735 meters) allow for handling bulky materials.

- Flexible lifting configurations reduce the need for specialized cranes for different tasks.

Energy Efficiency

Lower Operating Costs: The cranes' design incorporates energy-efficient technologies that reduce power consumption. With the 380V, 50Hz, 3-phase power supply, the cranes operate efficiently, minimizing energy use and reducing overall operating costs over the long term. This energy-saving feature supports the client's goal of achieving cost-effective operations.

- 380V, 50Hz, 3-phase power supply ensures efficient energy use.

- Reduced power consumption lowers electricity bills and operating costs.

- Long-term energy savings contribute to a favorable return on investment (ROI).

Longer Lifespan: The cranes' robust engineering, combined with the open winch trolley system, results in minimal wear and tear. The reduced friction and smooth operation help to extend the lifespan of key components, such as the winches, motors, and hoists. As a result, the client experiences fewer maintenance interventions and a reduced total cost of ownership.

- Reduced maintenance needs due to smoother operation.

- Fewer replacements of parts due to minimal wear and tear.

- Longer crane lifespan, leading to reduced capital expenditure over time.

Safety Improvements

Overload Protection and Safety Features: The cranes are equipped with a range of safety features, such as overload protection, limit switches, and emergency stop functions. These systems help to prevent accidents, such as overloading the crane or mishandling heavy loads, ensuring a safe working environment for operators and staff.

- Overload protection prevents damage to the crane and materials.

- Limit switches ensure safe movement limits.

- Emergency stop functions provide immediate control in hazardous situations.

Anti-Sway Technology: The cranes also include anti-sway technology, which reduces the risk of load swinging. This technology is essential for lifting heavy or oversized loads, ensuring that the materials are handled safely and accurately, even in challenging conditions.

- Anti-sway technology minimizes load instability.

- Reduces risk of accidents caused by swinging loads.

- Ensures precise load placement during complex lifting tasks.

Customer Feedback and Satisfaction

Client's Experience with the Cranes

The client has expressed satisfaction with the performance of the six double hoist overhead cranes. They highlighted the ease of operation and seamless integration of the cranes into their daily operations. The cranes have proven to be reliable, contributing significantly to operational efficiency.

- The cranes are easy to operate, with user-friendly controls.

- The integration into existing workflows has been smooth and efficient.

- The client has reported consistent performance with minimal downtime.

Operational Efficiency Gains

Since the cranes were installed, the client has observed significant operational improvements. Key performance metrics, such as cycle times and throughput, have improved dramatically.

- Cycle times have been reduced by up to 30%, leading to faster task completion.

- Throughput has increased, allowing the company to meet higher production demands.

- The cranes' ability to handle multiple loads simultaneously has increased production efficiency.

Overall Satisfaction

The client is highly satisfied with the quality and customization options of the cranes. The flexibility in crane configurations, including the different load capacities and spans, has allowed them to meet their specific material handling needs.

- The client praised the long-term reliability of the cranes.

- Customization options allowed for tailored solutions for their specific needs.

- Challenges during installation were quickly addressed, ensuring minimal disruption to operations.

The Use of Double Hoist Overhead Cranes: Key Benefits to the Client in Poland

The introduction of double hoist overhead cranes has significantly impacted the client's operations in Poland, providing a wide range of operational and financial advantages. These cranes are equipped with two hoists per crane, allowing for increased lifting capacity and greater flexibility in material handling. The dual hoists enable simultaneous lifting of two loads or a single load in two stages, providing enhanced versatility for various applications, from heavy-duty tasks to more delicate operations.

Increased Lifting Capacity and Flexibility

By integrating two hoists on each crane, the client can now handle a broader range of materials and load types without needing additional equipment. This setup allows for:

- Simultaneous lifting of multiple loads: For example, lifting a large machinery component and a smaller part at the same time.

- Improved flexibility: Cranes can lift and move loads of varying sizes and weights more efficiently, which is especially important in industries with diverse material handling needs, like automotive manufacturing or steel production.

- Efficient handling of oversized loads: When combined, the two hoists offer greater lifting power for larger or heavier components that were previously more difficult to handle with a single hoist.

Enhanced Energy Efficiency

Double hoist cranes are engineered to reduce energy consumption by optimizing lifting operations. This results in several benefits:

- Energy-efficient lifting: The cranes are designed to distribute load demands across two hoists, reducing the strain on each hoist, which leads to lower power consumption.

- Reduced operating costs: As energy consumption decreases, the client's overall energy costs are reduced, making these cranes more cost-effective in the long term.

- Lower environmental impact: The efficiency of the cranes aligns with sustainability goals, contributing to a reduced carbon footprint for the client's operations.

Improved Safety Features

The double hoist cranes offer advanced safety features that improve both worker protection and equipment reliability. These features include:

- Overload protection: The cranes are equipped with safety systems to prevent overloading, which helps to avoid equipment damage, reduce maintenance costs, and ensure safe operations.

- Anti-sway technology: The inclusion of anti-sway systems minimizes load swinging during transportation, providing greater stability when moving large or heavy loads, which enhances precision and safety during operations.

- Emergency features: In the event of a system failure or overload, emergency stops and backup systems automatically engage to protect workers and equipment, significantly reducing the risk of accidents.

These safety features ensure that the cranes can be operated confidently by workers, knowing that operational risks are minimized.

Long-Term Cost Savings

The long-term cost savings generated by the use of double hoist cranes are substantial:

- Reduced maintenance costs: The efficiency of the cranes results in less wear and tear, reducing the frequency and cost of repairs or part replacements.

- Extended crane lifespan: The design and technological features of the double hoist cranes contribute to a longer operational lifespan, minimizing the need for costly upgrades or replacements.

- Lower downtime: With reliable performance and fewer breakdowns, the client experiences fewer operational disruptions, leading to higher uptime and greater overall productivity.

These factors combine to create a highly cost-effective solution for material handling, making the double hoist cranes a smart investment for the client in the long run.

Lessons Learned from the Project

The successful implementation of these double hoist cranes has provided several valuable insights for both the client and the project team:

Importance of Selecting the Right Crane Configuration

Choosing the right crane configuration—specifically, cranes with double hoists and high lifting heights—was essential for optimizing material handling efficiency. Key takeaways include:

- Understanding the workload requirements: Ensuring that cranes are appropriately matched to the client's lifting capacity, load types, and working environment is critical for maximizing operational performance.

- Flexibility and versatility: A double hoist system allows for greater operational flexibility, enabling the client to handle different types of materials, from small components to oversized machinery.

Customization to Meet Specific Needs

One of the most important lessons learned from this project was the value of customizing the crane system to fit the client's specific requirements:

- Load capacity: The 25-ton and 12.5-ton capacities were chosen to match the client's material handling needs, allowing the cranes to operate effectively without being over- or under-capacity.

- Crane span and lifting height: Customizing the crane span to 9.16 m for the 12.5-ton cranes and 19.16 m for the 25-ton cranes ensured that the cranes could cover the necessary work area and handle the required lifting heights.

- Adaptability: Customization ensured the cranes could seamlessly integrate into the client's existing operations, improving efficiency and safety.

Efficient Installation Processes and Quick Issue Resolution

The installation phase of the project underscored the importance of planning and coordination:

- Minimizing operational disruptions: The project team was able to install the cranes with minimal disruption to ongoing operations. Pre-installation planning and sequenced deployment helped keep downtime to a minimum.

- Quick issue resolution: During installation, any issues that arose were quickly addressed, ensuring that the cranes were fully operational within the expected timeline.

These efficient installation practices are a model for future projects, ensuring that the client's operations remain as uninterrupted as possible during future upgrades or expansions.

Conclusion: Send Us An Inquiry on the Double Hoist Cranes

The operation of double hoist overhead cranes with advanced features like energy efficiency, safety enhancements, and cost savings has dramatically improved the client's material handling processes in Poland. By choosing the right configuration and customizing the cranes to their specific needs, the client has optimized their operations, ensuring increased productivity, safety, and long-term cost efficiency. This case highlights the importance of thorough planning and customized solutions in achieving operational excellence.

Main Projects

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch