Industrial Overhead Crane for Hazardous Environment– Buyer Guide

Learn how to choose safe, compliant overhead cranes for hazardous environments. A step-by-step buyer’s guide for steel mills, chemical plants & workshops.

| Crane type | Hazardouse Environment Cranes |

| Crane Capacity | 3 ton to 320 ton |

| Lifting Height | 7.5-31.5 m |

| Crane Span | Customized. |

| Noted | Tailored industrail cranes are available for your needs. |

Category: Featured

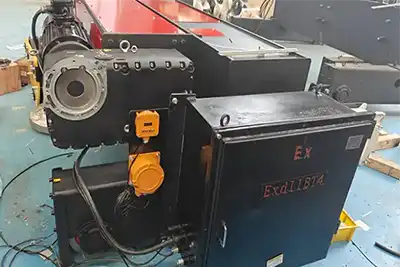

Your Trusted Overhead Crane Manufacturer & Supplier Not every crane can handle extreme conditions. In workshops, steel mills, chemical plants, or any environment where fire, chemicals, explosions, or high-voltage equipment are present, standard cranes simply aren't enough. Choosing a crane built for hazardous environments ensures that lifting operations are both safe and reliable. Using the wrong crane in hazardous environments isn't just risky—it can be costly, slow production, or even result in serious accidents. Hazardous environment cranes are designed to handle sparks, chemical fumes, flammable materials, and electrical hazards without compromising performance. Key benefits include: Investing in a crane suitable for hazardous environments protects your team, your equipment, and your production workflow. It's a practical decision that pays off in safety, efficiency, and compliance. Industrial sites are full of potential risks. Knowing what you're dealing with is the first step toward selecting the right crane and keeping everyone safe. Common hazards include: When working in hazardous environments, the right crane isn't just about lifting capacity—it's about protecting people, equipment, and the facility. Essential safety features include: Choosing cranes with these features isn't optional—it's a practical necessity. They reduce accidents, protect your workforce, and keep operations running smoothly in tough industrial environments. Hazardous environment cranes are designed for workplaces where fire, chemical, explosive, or electrical risks exist. The type of crane you select depends on the specific hazards, material types, and operational requirements. European style explosion proof hoist cranes These explosion proof cranes are built for environments with flammable gases, vapors, or dust—common in chemical plants, petrochemical facilities, or steel mills. Key Features: Ideal Applications: Tailoring Options: Used in industries where corrosive chemicals, paints, or acids are handled. These cranes are designed to withstand long-term exposure to harsh substances. Key Features: Ideal Applications: Tailoring Options: These cranes are designed for steel mills, foundries, or any facility with molten metals, sparks, or open flames. Key Features: Ideal Applications: Tailoring Options: In extreme hazard areas, removing the operator from the immediate danger zone is often the safest choice. Key Features: Ideal Applications: Tailoring Options: Some facilities require cranes that handle multiple risks simultaneously, like a steel mill with molten metal, chemical exposure, and high voltage. Key Features: Tailoring Options: When choosing a hazardous environment crane, buyers should assess: Hazardous environments require more than just strong lifting equipment—they demand strict safety practices, trained operators, and the right type of crane for the job. The following guide outlines essential operational standards, PPE requirements, and crane selection tips to help you maintain a safe, compliant, and efficient workplace.本 Even with the right crane and safety features, how you operate equipment in hazardous environments makes a huge difference. Following proven practices reduces accidents, protects your team, and keeps workflow efficient. These operational practices, combined with properly designed cranes and safety features, create a layered approach to risk management. In hazardous environments, attention to detail in everyday operations is just as important as the equipment itself. Operator & Maintenance Requirements Even the safest, most advanced crane won't perform well without trained operators and regular maintenance. Hazardous environments demand extra attention because mistakes or neglect can have serious consequences. Personal Protective Equipment (PPE) Working with cranes in hazardous environments isn't just about the machinery—it's about protecting the people operating and working around it. Proper PPE is essential to prevent injuries from falls, flying debris, chemical exposure, and electrical hazards. Consistent use of PPE, combined with training and regular checks, creates a safer working environment where crane operations in hazardous conditions are much less risky. Choosing the Right Crane for Hazardous Environments When working in areas with fire, chemical, or explosive risks, the choice of crane can make all the difference. It's not just about lifting heavy loads—safety, reliability, and compatibility with site hazards are crucial. Types of Cranes for High-Risk Sites Factors to Consider When Choosing a Crane Practical Tip: Don't just pick a crane off the shelf. Assess the specific hazards of your facility, the materials handled, and workflow patterns. A crane matched to your environment improves safety, efficiency, and regulatory compliance. When purchasing a crane for high-risk sites, safety is the first priority. Use this checklist to make sure your equipment meets both regulatory and operational requirements. Check that the crane design is appropriate for your facility's specific risks: A crane that looks good on paper may still be unsafe if it's not matched to your site's conditions. Use this checklist as a guide before making any purchase—it saves time, cost, and prevents accidents. Answers to the most common questions about selecting, operating, and maintaining hazardous environment overhead cranes. The key is in the certifications and construction. Explosion-proof cranes are designed with motors, electricals, and controls that won't spark, and materials that resist flames or chemicals. Always check for official compliance certificates and ensure the crane's design matches the specific risks in your workshop, such as gas, dust, or molten metal exposure. In some cases, yes, but modifications must meet strict safety standards. Adding chemical-resistant coatings or grounding equipment can help, but you should never compromise the crane's electrical or mechanical integrity. Often, it's safer and more reliable to select a crane already built for hazardous environments. Look for cranes with anti-sparking hooks and chains, overload detection, secure lifting devices, and protective coatings against fire or chemicals. Some sites also benefit from remote or automated operation to keep personnel at a safe distance from potential hazards. Only trained and certified operators should run hazardous environment cranes. They need to understand the specific risks of fire, chemicals, or high-voltage areas and be familiar with proper PPE use, inspection routines, and emergency procedures. Daily inspections are essential. Check all mechanical and electrical systems, record observations, and follow the manufacturer's duty charts. Proper maintenance includes monitoring coatings, ensuring grounded components are intact, and reviewing documented inspection reports regularly. Establish clear work zones below lifts, post warning signs, and ensure tools or materials at height are secured. Automation features such as anti-sway control, obstacle detection, and hook alignment systems can significantly reduce human error in busy or complex environments. Absolutely. Operators must wear full-body harnesses, helmets, gloves, and eye protection, and it's critical they are trained in using it properly. Compliance with recognized safety standards ensures that PPE provides the protection it's designed for. Start with a detailed risk assessment of your workplace. Consider the type of materials handled, presence of flammable gases or chemicals, electrical hazards, and overhead operations. Match these risks to crane features such as explosion-proof motors, chemical coatings, remote operation options, and customizable safety systems. On the contrary. While safety features add complexity, modern cranes are designed to operate efficiently even under strict safety constraints. Automated systems for hook alignment, anti-sway, and obstacle detection not only reduce accidents but can speed up repetitive lifting tasks. Keep thorough records of inspections, maintenance, operator training, and any modifications. Schedule regular audits of your crane's performance and update procedures as regulations or site conditions change. This approach protects both personnel and equipment over the long term.Overhead Cranes for Hazardous Environments:

Hazardouse Environment Crane Safety, Compliance & Buyer's GuideWhy Hazardous Environment Cranes Matter

Common Hazards in Industrial Sites

Safety Features to Look for in Cranes

Types of Hazardous Environment Overhead Cranes

Explosion-Proof Overhead Cranes

Chemical-Resistant or Coated Cranes

High-Temperature or Fire-Resistant Cranes

Remote-Controlled or Automated Cranes

Multi-Hazard Cranes

Selection Considerations

Hazardous Environment Overhead Crane Operational Best Practices

Operational Best Practices

Store cylinders upright and make sure they are properly secured and clearly labeled. For flammable gases like acetylene, keep them at least 6 meters away from oxygen cylinders—or use fireproof barriers if spacing is limited. Proper storage prevents tipping, leaks, and dangerous chemical reactions.

When lifting or moving loads above ground, restrict access to the area underneath. Post clear warning signs like "Danger – Work Overhead" to alert personnel. Never allow anyone to pass under suspended loads, and make sure tools and materials at height are secured to prevent accidental drops.

Always maintain accessible firefighting equipment and ensure staff are trained to use it. Follow Material Safety Data Sheet (MSDS) instructions for handling chemicals, and wear the proper personal protective equipment (PPE) at all times. Quick response and proper protection can prevent small incidents from becoming serious accidents.Operator & Maintenance Requirements

Only certified operators should be allowed to operate cranes in hazardous zones. Training should cover not just crane operation but also specific risks in your environment—flammable materials, chemicals, electrical hazards, and proper emergency response. Knowledge and experience reduce the chance of accidents.

Conduct daily checks of the crane before every shift. Look for signs of wear on hooks, chains, hoists, and electrical systems. Make sure explosion-proof components, grounding, and safety interlocks are functional. Record all inspections in a logbook to maintain accountability and traceability.

Keep operator manuals, duty charts, certificates, and maintenance records readily available. Operators should know load limits, operational restrictions, and emergency procedures. Clear documentation ensures consistent safety practices and simplifies audits or regulatory inspections.Personal Protective Equipment (PPE)

Operators and nearby personnel should always wear full-body harnesses when working at heights, safety helmets to protect from falling objects, gloves for handling materials, and eye protection to prevent contact with sparks, dust, or chemical splashes.

All PPE should meet recognized safety standards, such as ANSI or BS EN. This ensures equipment is tested for durability, impact resistance, and overall safety performance.

PPE is only effective if used correctly. Workers must receive training on how to wear, adjust, and inspect equipment before each shift. Improperly fitted or damaged gear can be worse than no protection at all.Choosing the Right Crane for Hazardous Environments

Types of Cranes for High-Risk Sites

Factors to Consider When Choosing a Crane

Practical Tip for Crane Selection

Buyer's Safety Checklist for Hazardous Environment Cranes

Certification & Compliance

Operator Training & Procedures

Inspections & Maintenance Records

Hazard-Specific Suitability

Practical Advice

Frequently Asked Questions (FAQ)

Q1: How do I know if a crane is truly safe for explosive or flammable environments?

Q2: Can standard cranes be adapted for hazardous areas?

Q3: What safety features are most important for everyday operations?

Q4: How should operators be prepared to work with these cranes?

Q5: What maintenance routines are required to keep the crane safe?

Q6: How can I minimize the risk of accidents during overhead operations?

Q7: Is PPE really necessary for crane operators in these areas?

Q8: How do I decide which type of hazardous environment crane is best for my site?

Q9: Will investing in a hazardous environment crane slow down production?

Q10: How do I ensure long-term compliance and safety?

Conclusion: Making the Right Choice for Safety and Efficiency

Choosing the right crane for hazardous environments isn't just about lifting heavy loads—it's about protecting your people, your facility, and your workflow.

A properly selected hazardous environment crane ensures that:

- Workers remain safe from fire, chemical, electrical, and overhead risks.

- Operations stay compliant with local and international safety regulations.

- Productivity is maintained or even improved because equipment operates reliably in challenging conditions.

In short, the right crane is an investment that pays off every day—minimizing accidents, reducing downtime, and keeping your industrial site running smoothly. Always match crane features, certifications, and safety systems to your specific hazards to get the full benefit.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch