Explosion-Proof Hoists for Gas and Dusty Explosive Environments

Comparison of explosion proof hoists in explosive gas & dusty environments. Check key design & certification distinctions to get ur explosion proof hoist!

Category: Featured

Your Trusted Explosion Proof Hoist Crane Manufacturer & Supplier

Differences Between Gas Explosion-Proof and Dust Explosion-Proof Hoists

Key Design and Certification Distinctions

Introduction of Explosion Proof Hoists

Explosion-proof hoists are made for dangerous work areas where there's a risk of fire or explosion. These risks often come from flammable gases or combustible dust in the air. A normal hoist can't handle this safely. That's why explosion-proof types exist—to reduce the chance of sparks, heat, or short circuits causing a disaster.

Why Do We Need Explosion-Proof Hoists?

These hoists are used in places like oil refineries, grain processing plants, chemical factories, and coal storage sites. These are all areas where even a small spark can cause a serious accident.

- Designed to prevent ignition

Explosion-proof hoists are built to avoid setting off any explosion, even if flammable materials are around. - Meant for constant exposure

They're made for long-term use in areas where the risk is always there, not just during certain tasks.

Why It Matters to Know the Difference

Not all explosion risks are the same. Gas and dust behave differently. They need different designs to stay safe. You can't just use one hoist for all types of hazards.

- Gas and dust need different protections

Gas can slip into tiny gaps. Dust can build up, trap heat, and catch fire. So the hoist needs to be built for the right type of threat. - Using the wrong type can be dangerous

A hoist designed for gas might not protect against dust, and vice versa. Picking the wrong one could lead to a fire, explosion, or equipment failure.

What This Article Will Cover

This guide will explain how gas explosion-proof hoists differ from dust explosion-proof hoists. It focuses on both design features and certification marks. These are the details buyers, safety managers, and maintenance teams need to know when selecting the right hoist for a hazardous area.

- Clear design differences

You'll learn what makes each type safe and how their parts are built differently. - Understanding the markings

We'll also go over the international safety labels and what each code means, so you can be confident in your purchase.

Hazardous Environments

Explosion-proof hoists are designed for use in areas where a fire or explosion might occur due to the presence of flammable gases or combustible dust. But the type of danger matters. Gases and dusts behave differently, and that's why hoists used in these environments must also be different in design and protection level.

What is a Gas Hazardous Area?

A gas hazardous area is any space where explosive gas or vapor can be present in the air, either during normal operations or due to accidental leaks. These gases mix with air and, if ignited by heat, a spark, or a short circuit, can cause a fire or explosion.

Gas doesn't always hang around for long, but it can spread fast. That makes it especially dangerous in enclosed or poorly ventilated places.

Common locations where gas hazards exist

These are industries where gas leaks or emissions are a regular part of the operation:

- Oil and gas refineries

- Petrochemical plants

- LPG bottling stations

- Fuel depots and tank farms

- Paint and solvent storage areas

- Chemical mixing or processing plants

Typical explosive gases to watch out for

Some gases are more flammable or explosive than others. These are among the most common:

- Methane (CH₄) – found in natural gas pipelines and coal mines

- Propane (C₃H₈) – used in heating systems and gas cylinders

- Butane (C₄H₁₀) – used in portable stoves and lighters

- Hydrogen (H₂) – highly explosive, used in batteries and chemical plants

- Acetylene (C₂H₂) – extremely reactive, common in welding operations

- Ethanol or other solvents – present in pharmaceuticals and coatings

Why gases are dangerous

Gases can seep into tiny openings. You may not see or smell them. If they find an ignition source—like an electric motor or hot surface—they can explode within seconds. That's why gas explosion-proof hoists must have sealed components, spark-proof motors, and special wiring.

What is a Dust Hazardous Area?

A dust hazardous area is a space where fine dust particles—whether in the air or settled on surfaces—can ignite or explode under the right conditions. It's not just the dust you see in the air. Layers of settled dust can become explosive if disturbed and turned into a cloud.

Many people underestimate how dangerous dust can be. But in fact, dust explosions have caused major industrial accidents.

Typical sites where dust hazards exist

Industries with bulk material handling, grinding, drying, or cutting are usually at risk:

- Flour mills and food processing plants

- Grain elevators and storage silos

- Sugar and starch handling facilities

- Wood product factories (sawing, sanding, cutting)

- Metal polishing and machining shops

- Pharmaceutical powder filling lines

- Coal storage and transfer stations

Common types of combustible dusts

Not all dust is dangerous. But when it's dry, fine, and easily airborne, it can explode:

- Flour, starch, and sugar dust – found in baking and food industries

- Wood dust – from sawmills, furniture plants, and carpentry shops

- Coal dust – in mining and thermal power stations

- Aluminum or magnesium dust – very explosive, found in metal polishing

- Plastic or resin dust – used in molding and injection plants

- Pharmaceutical powders – active ingredients in tablet production

Why dust is dangerous

Dust can settle on high surfaces and inside machines. If it builds up and later becomes airborne, a single spark from a motor or static discharge can ignite the entire cloud. This leads to a flash fire or an explosion. That's why dust explosion-proof hoists need dust-tight casings, temperature control features, and smooth surfaces to prevent accumulation.

Why Understanding the Environment is So Important

Each hazardous area is unique. A hoist that's built for gas protection won't automatically be safe in a dusty area, and vice versa. That's why the first step before choosing an explosion-proof hoist is identifying the exact type of hazard at your site.

- Gas needs sealed enclosures

You need flameproof or pressurized enclosures to stop internal sparks from reaching the gas. - Dust needs dust-tight casings and cool surfaces

The focus is on preventing hot spots and dust accumulation on equipment surfaces.

Comparison Table: Gas Explosion-Proof Hoists vs. Dust Explosion-Proof Hoists

| Item | Gas Explosion-Proof Hoist | Dust Explosion-Proof Hoist |

|---|---|---|

| Type of Hazard | Flammable gases or vapors in the air | Combustible dust in the air or on surfaces |

| Where It's Used | Oil refineries, gas plants, paint factories, chemical storage areas | Flour mills, grain storage, coal handling, woodworking, powder processing |

| Common Hazardous Materials | Methane, propane, hydrogen, acetylene, solvents like ethanol | Flour dust, coal dust, wood dust, metal powder, starch, plastic powder |

| How Explosions Happen | Gas mixes with air and ignites from sparks, heat, or short circuits | Dust forms a cloud and explodes if ignited by sparks or heat |

| Main Safety Concern | Stopping gas from getting into the hoist and containing any sparks inside | Keeping dust out of the hoist and avoiding high surface temperatures |

| Enclosure Design | Flameproof or pressurized casing to block gas and trap sparks | Dust-tight enclosure with smooth surface to prevent dust buildup |

| Protection Level (IP Rating) | Usually IP65 to IP68 with gas-tight sealing | Usually IP65 or IP66 with dust-sealed housing |

| Temperature Safety | Must stay below the ignition point of the gas in use | Must avoid heat buildup that can ignite settled or airborne dust |

| Certification Example | Marked as: Ex d IIB T4 Gb (gas group and temperature class) | Marked as: Ex t IIIC T135°C Db (dust group and max surface temperature) |

| Explosion Group | Group IIA, IIB, or IIC depending on gas type | Group IIIA, IIIB, or IIIC depending on dust type |

| Hazard Zone | Zone 1 (gas present often) or Zone 2 (gas present occasionally) | Zone 21 (dust present often) or Zone 22 (dust present occasionally) |

Important Tip for Buyers:

Before choosing an explosion-proof hoist, make sure you know:

- What kind of hazard is present — gas or dust?

- How often it appears — frequent or occasional?

- Which zone and group applies to your work area?

This will help you select the correct hoist model that meets local safety standards.

Explosion Protection Principles

Explosion-proof hoists are made to reduce the chance of fire or explosion in hazardous areas. Some designs stop explosions from starting. Others are built to contain an explosion if it happens inside the equipment.

To choose the right hoist, it's important to understand how explosion protection works and what the markings mean.

Two Core Safety Strategies

Explosion protection generally follows two design methods:

Prevention

The goal is to stop the conditions that lead to explosions.

- Spark-free components are used.

- All electrical parts are tightly sealed.

- Motors and enclosures are designed to keep surface temperatures low.

- Grounding and anti-static materials are used to prevent static discharge.

Containment

If an explosion starts inside the equipment, it stays there and doesn't spread.

- Thick-walled, flameproof enclosures are used.

- Gases inside are cooled and filtered before release.

- This design method is often labeled as "Ex d".

Both methods are often used together, especially in high-risk zones.

Key Terms You Need to Know

Explosion-proof hoists are marked and certified based on safety standards. These markings help match the hoist to the right work environment.

Ex Marking (Explosion-Proof Code)

This is the official code that shows the hoist is explosion-proof.

"Ex" means the hoist follows explosion protection standards.

Different letters show how the hoist is protected:

- Ex d = flameproof enclosure

- Ex e = increased safety

- Ex t = dust-tight or protected against dust ignition

Zoning (Hazardous Area Classification)

Hazardous areas are divided into zones depending on how often gas or dust is present.

For gas environments:

- Zone 0 – Gas is always or almost always present.

- Zone 1 – Gas is present during normal operation.

- Zone 2 – Gas is only present during leaks or failures.

For dust environments:

- Zone 20 – Dust is always or frequently present.

- Zone 21 – Dust may appear during normal use.

- Zone 22 – Dust is rare and usually only after faults.

Choosing the right hoist depends on the zone your site falls into.

Equipment Groups and Categories

These groups show the kind of industry and protection level the hoist is designed for.

Equipment groups:

- Group I – For underground mining (e.g., methane, coal dust).

- Group II – For surface industries (e.g., chemical plants, food factories).

Categories for Group II:

- Category 1 – Very high protection (for Zone 0 or Zone 20).

- Category 2 – High protection (for Zone 1 or Zone 21).

- Category 3 – Normal protection (for Zone 2 or Zone 22).

You should select the hoist based on both the zone and the category.

Application Example

If your facility handles grain or coal and dust is often in the air:

- You are likely in Zone 21.

- You need a Group II, Category 2 dust explosion-proof hoist.

- The correct model might be marked Ex tD A21 IP65 T130°C.

Explosion protection starts with understanding the risk level in your work area. Prevention and containment are two ways to manage that risk. The terms like "Ex marking", "zone", and "equipment group" are not just technical labels — they guide you to the safest hoist for your environment.

Design Differences Between Gas and Dust Explosion-Proof Hoists

Gas explosion-proof and dust explosion-proof hoists both aim to prevent accidents in hazardous environments. However, the risks they face are quite different, so the hoists have distinct design features. Understanding these differences is important for selecting the right hoist and ensuring safety.

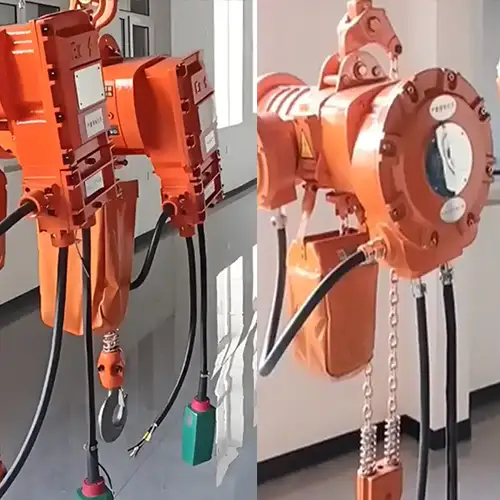

Explosion proof electric chain hoists for dusty working environments

Explosion proof electric chain hoist for explosive gas working environments

Enclosure Design

The enclosure is the main barrier between the hoist's internal parts and the hazardous environment. It must stop gases or dust from entering or escaping, depending on the type of hazard.

Gas Explosion-Proof Hoists:

- Use flameproof or hermetically sealed enclosures, typically marked as Ex d.

- These enclosures are made from thick, strong materials like cast steel or aluminum alloys.

- The joints and seams are precision-machined to fit tightly and prevent any flame or hot gases from leaking out if an internal explosion occurs.

- The design must withstand the pressure of a possible internal explosion without deforming or breaking.

- Air-tightness is critical to avoid any flammable gases from entering the hoist housing where sparks or hot parts could ignite them.

Dust Explosion-Proof Hoists:

- Use dust-tight enclosures, classified as Ex t, designed to prevent fine dust particles from entering the hoist.

- Dust can accumulate inside if the enclosure isn't sealed properly, creating a fire or explosion risk.

- The enclosure materials can vary, but surfaces must be smooth to reduce dust buildup on the outside.

- Seals and gaskets are designed to block dust ingress while allowing necessary ventilation or cooling without letting dust settle inside.

- Unlike gas-proof enclosures, these don't need to contain internal explosions but must prevent dust layers that could smolder or ignite.

Surface Temperature Control

Both gases and dust can ignite from heat alone, but dust is especially sensitive to heat buildup due to its insulating properties. Managing surface temperature is therefore a key safety measure.

Gas Explosion-Proof Hoists:

- The hoist must be designed so that no surface exceeds the auto-ignition temperature of any flammable gas expected in the environment.

- Different gases have different ignition temperatures — for example, methane ignites at about 537°C, propane at 470°C, and hydrogen even lower at 560°C.

- To stay below these temperatures, hoists may use motors designed to run cool, heat-resistant materials, or external cooling systems.

- Temperature sensors may be included to monitor heat and trigger alarms or shutdowns if limits are approached.

- Proper ventilation inside the hoist enclosure also helps dissipate heat.

Dust Explosion-Proof Hoists:

- Dust can form insulating layers on surfaces, trapping heat and increasing ignition risk even if the ambient temperature is safe.

- Surface temperatures must be kept below the lowest ignition point of the specific dust involved, which can be as low as 150°C for some dusts like flour or coal.

- Hoists are often coated with heat-resistant paint or have special thermal insulation.

- Designs may include temperature monitoring on critical parts such as brakes, motors, and gears, where heat can build up.

- Regular cleaning is also critical to prevent dust accumulation and smoldering.

Cable and Conduit Protection

Electrical cables and conduits are potential weak points where hazardous gases or dust could enter the hoist or cause ignition.

Gas Explosion-Proof Hoists:

- Cables enter the enclosure through sealed glands and flameproof barriers that prevent gas migration.

- These seals must withstand pressure and temperature in case of an internal explosion.

- Cable entries are often located inside flameproof junction boxes or flameproof compartments for added safety.

- All wiring and conduits are designed to prevent sparks and are often protected by special insulating materials.

- Installation must follow strict guidelines to ensure no gas leaks along cable runs.

Dust Explosion-Proof Hoists:

- The goal is to avoid dust settling in gaps or crevices around cable entries where ignition might start.

- Cable glands and conduit openings are designed with smooth surfaces to minimize dust traps.

- Seals and gaskets are used to maintain dust tightness but also allow for easy cleaning during maintenance.

- Cable routing avoids sharp bends or hidden cavities where dust can accumulate.

- The hoist design often includes easy access points for cleaning and inspection of cable areas.

| Design Aspect | Gas Explosion-Proof Hoists | Dust Explosion-Proof Hoists |

|---|---|---|

| Enclosure Design | - Flameproof, sealed to stop gas in or out (Ex d). | - Dust-tight to keep dust out (Ex t). |

| - Made from thick metal, strong enough to contain explosions. | - Smooth surfaces to avoid dust buildup. | |

| - Joints are tightly fitted to prevent flame escape. | - Seals block dust but allow some ventilation. | |

| - Must withstand pressure if explosion happens inside. | - Does not need to contain explosions, only prevent dust. | |

| Surface Temperature Control | - Must stay below ignition temp of gases (e.g., propane ~470°C). | - Must stay below ignition temp of dust (can be as low as 150°C). |

| - Uses cooling systems and temperature sensors. | - Uses heat-resistant coatings and regular cleaning. | |

| - Ventilation helps keep it cool inside. | - Dust can trap heat, so temperature control is critical. | |

| Cable and Conduit Protection | - Sealed glands and flameproof barriers stop gas leaks. | - Cable entries are sealed and easy to clean. |

| - Wiring is insulated and protected from sparks. | - Avoids crevices where dust can collect. | |

| - Cable joints inside flameproof boxes for extra safety. | - Designed for easy inspection and dust removal. |

The design of explosion-proof hoists varies significantly based on the type of hazard they face.

- Gas explosion-proof hoists focus on tightly sealed, flameproof enclosures that can contain internal explosions and prevent gas ingress. They require precise machining, strong materials, and effective temperature control to avoid igniting flammable gases.

- Dust explosion-proof hoists prioritize dust-tight enclosures that prevent dust entry and buildup. Since dust can trap heat and smolder, surface temperature control and easy cleaning are essential. Cable and conduit designs minimize dust accumulation and maintain sealing.

5. Certification and Standards Comparison

Explosion-proof hoists need proper certifications to prove they are safe for use in hazardous environments. The rules and tests are different for gas and dust explosion risks. Let's break it down.

International Standards Overview

There are two main certification systems you'll see worldwide:

- IECEx: This is an international standard that covers equipment for explosive atmospheres. It applies to both gas and dust hazards and is accepted in many countries.

- ATEX: This is a European Union directive focusing on safety in explosive environments. Like IECEx, it applies to gas and dust and sets clear safety requirements for equipment design, testing, and maintenance.

Both systems make sure equipment meets strict safety rules before it can be used in dangerous places.

Markings and Codes

When you look at an explosion-proof hoist, the certification marks tell you a lot about where and how it can be safely used.

For Gas Explosion-Proof Hoists:

Marked as Equipment Group II – meaning they're for general industrial use (not mining).

Category 2G means they can be used in Zone 1 or Zone 2 gas hazardous areas.

- Zone 1: Explosive gases are likely during normal work.

- Zone 2: Explosive gases are not likely but possible.

Gas groups (IIA, IIB, IIC) show what type of gas the hoist can handle. For example, IIC is for very explosive gases like hydrogen.

For Dust Explosion-Proof Hoists:

Also in Equipment Group II for industrial areas.

Category 2D means they are fit for Zone 21 or Zone 22 dust hazardous zones.

- Zone 21: Dust is likely during normal work.

- Zone 22: Dust might appear sometimes.

Dust groups (IIIA, IIIB, IIIC) indicate the type of dust — from non-conductive dust to metal dust.

These codes help you pick the right hoist for your work environment.

Test Requirements

Gas and dust hoists face different testing challenges because of their different hazards.

Gas Explosion-Proof Hoists:

- Tested to make sure they can safely contain an internal explosion without flames or hot gases escaping.

- Must prevent any gas from leaking into the hoist's enclosure.

- Surface temperatures are carefully checked to stay below the ignition point of gases (for example, propane ignites around 470°C).

- Electrical parts are tested to avoid sparks or arcs inside the hoist.

Dust Explosion-Proof Hoists:

- Tested mainly to keep dust from entering the hoist enclosure. Dust inside can cause fires or explosions.

- Surface temperature limits are stricter because dust layers can trap heat and cause smoldering even at lower temperatures (sometimes around 150°C).

- Enclosures are tested for smoothness and seal tightness to avoid dust buildup.

- Also tested under vibration and cleaning conditions to make sure they stay dust-tight during real working conditions.

Application Suitability and Selection Guidelines

Choosing the right explosion-proof hoist is crucial. It starts with knowing the specific hazards of your working environment. This section will help you match the right hoist type to your conditions and avoid costly mistakes.

Matching Hoist Type to Environment

The first step is to determine whether your hazard is related to gas or dust. This isn't always obvious, so a careful site assessment is key.

Identify the hazard type:

- Look at the materials handled and the environment.

- Gas hazards often occur in places like petrochemical plants, oil refineries, or gas processing facilities.

- Dust hazards appear in industries like flour milling, grain storage, coal handling, or metal powder manufacturing.

Conduct a site hazard classification:

- A professional safety assessment will classify your area into zones (Zone 0, 1, 2 for gases; Zone 20, 21, 22 for dust).

- This classification determines the level of risk and the category of explosion-proof equipment needed.

Use the correct explosion-proof hoist accordingly:

- Gas explosion-proof hoists are built to handle gases, with enclosures designed to contain explosions and prevent gas ingress.

- Dust explosion-proof hoists focus on stopping dust entry and controlling surface temperature to avoid ignition.

Proper matching ensures safety and compliance with standards.

Misapplication Risks

Using the wrong type of explosion-proof hoist can cause serious problems:

Safety hazards:

- A gas explosion-proof hoist used in a dusty environment might allow dust to enter, leading to hidden fires or explosions.

- A dust explosion-proof hoist used where explosive gases exist might not contain a gas explosion properly, putting people and property at risk.

Performance issues:

- Dust hoists in gas areas may fail to prevent gas leaks and spark risks.

- Gas hoists in dusty areas might overheat, as dust can trap heat and cause smoldering.

- Both cases may lead to frequent downtime and costly repairs.

Regulatory non-compliance:

- Using the wrong equipment can violate safety laws and lead to fines or shutdowns.

Taking the time to understand your site's hazard and choosing the right hoist type will protect your workers, your assets, and your business.

Practical Buying Tips for Crane and Hoist Buyers

Buying an explosion-proof hoist isn't just about picking the right model. You also need to ask the right questions and make sure you get the proper certifications and support. Here are some key tips to help you make a smart purchase.

Questions to Ask When Specifying Explosion-Proof Hoists

Before you buy, clarify important details with your supplier:

- What hazard type is the hoist certified for?

Make sure it matches your site's classification — gas or dust. - What is the explosion-proof certification?

Ask for IECEx, ATEX, or other relevant certificates. - What are the exact zoning and category ratings?

Confirm the equipment group, zone (e.g., Zone 1 or Zone 21), and gas or dust group. - What is the maximum surface temperature?

Check it's safe for your specific gas or dust ignition temperature. - How is the hoist sealed and protected?

Understand the enclosure design and materials to ensure durability. - What are the maintenance and inspection requirements?

Know how often it needs checking and servicing.

Importance of Third-Party Certification and Documentation

Third-party certifications are your proof that the hoist meets international safety standards. Don't settle for equipment without these:

- Certified hoists are independently tested for safety and performance.

- Proper documentation ensures traceability and helps with regulatory inspections.

- Certificates also show the hoist was made under strict quality control.

Always ask for copies of the certifications before finalizing your purchase.

Considerations for Maintenance and Inspection

Regular maintenance is crucial for explosion-proof equipment:

- Plan periodic inspections to check seals, electrical components, and temperature controls.

- Use trained technicians familiar with explosion-proof standards.

- Keep detailed records of maintenance and repairs.

- Replace worn parts promptly to avoid safety risks or downtime.

A good supplier will also provide clear maintenance guidelines and support after the sale.

Conclusion

Choosing the right explosion-proof hoist starts with understanding the key differences between gas and dust hazards. Their designs and certifications are tailored to handle very different risks.

- Gas explosion-proof hoists use sealed, flameproof enclosures to contain gases and prevent ignition.

- Dust explosion-proof hoists focus on keeping dust out and controlling surface temperatures to avoid smoldering.

Certification marks like IECEx and ATEX provide clear guidance on where each hoist can be safely used, based on zones and hazard groups.

Why It Matters

- Proper hoist selection ensures safety for workers and equipment.

- It keeps your operations compliant with regulations.

- Avoids costly mistakes, downtime, and potential accidents.

Take time to assess your site's hazards carefully and choose a hoist that matches your environment perfectly. This will protect your investment and your team.

Appendix (Optional)

This appendix provides helpful tools and references to support your understanding and decision-making when selecting explosion-proof hoists. It includes a comparison table, sample markings explanations, and a handy site survey checklist.

Comparison Table: Gas vs. Dust Explosion-Proof Hoist Features

To quickly see the main differences, here's a side-by-side overview:

| Feature | Gas Explosion-Proof Hoists | Dust Explosion-Proof Hoists |

|---|---|---|

| Enclosure Type | Hermetically sealed or flameproof (Ex d) | Dust-tight enclosures (Ex t) |

| Hazard Focus | Prevent gas ingress, contain internal explosion | Prevent dust accumulation and ignition |

| Surface Temperature Control | Avoid auto-ignition temperature of gases | Control lower temperatures due to dust insulation |

| Certification Zones | Zone 1 or 2 (gas zones) | Zone 21 or 22 (dust zones) |

| Equipment Groups | IIA, IIB, IIC (gas groups) | IIIA, IIIB, IIIC (dust groups) |

| Testing Focus | Explosion containment, gas tightness | Dust ingress prevention, surface temperature |

| Typical Applications | Petrochemical plants, oil & gas facilities | Flour mills, grain silos, coal handling |

Sample Markings and Labels Explained

Explosion-proof hoists come with markings that indicate their suitability. Here's what to look for:

- Ex: Indicates explosion-proof equipment.

- Equipment Group II: For use in industrial, non-mining areas.

- Category 2G or 2D: Category 2 means high safety, with 'G' for gas hazards and 'D' for dust hazards.

- Zone 1, 2 (Gas) / Zone 21, 22 (Dust): Defines the hazardous area classification where the hoist can be safely used.

- Gas Group (IIA, IIB, IIC): Specifies which gases the equipment is designed to handle.

- Dust Group (IIIA, IIIB, IIIC): Specifies which dust types the equipment can handle, from non-conductive dust to metal dust.

- Temperature Class (e.g., T4, T6): Shows the maximum surface temperature allowed on the equipment, important for avoiding ignition.

Always check these labels carefully to confirm the hoist fits your environment.

Checklist: Site Survey Information Needed for Hoist Quotation

To get an accurate quote, your supplier will need detailed info about your site and requirements. Here's a checklist to prepare:

- Hazard Type: Is the risk gas, dust, or both?

- Zone Classification: What zone is your work area classified as? (Zone 1, 2, 21, 22, etc.)

- Material Handled: Type of gas or dust involved (e.g., methane, coal dust).

- Lifting Capacity: Maximum load the hoist must handle.

- Lifting Height and Span: Distance hoist needs to cover vertically and horizontally.

- Power Supply Details: Voltage, phase, frequency, and availability of explosion-proof power supply.

- Environmental Conditions: Temperature range, humidity, presence of corrosive substances.

- Maintenance Access: Is there easy access for inspections and repairs?

- Special Requirements: Any unique needs like low temperature operation, outdoor use, or remote controls.

- Certification Requirements: Which standards and certifications are mandatory for your region or industry?

Providing these details upfront speeds up the quotation process and ensures you get the right hoist for your needs

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch