Explosion-Proof Electric Chain Hoist for Explosive Gas Zones

Certified explosion-proof electric chain hoist, 1 to 50 ton, designed for safe lifting in IIC & IIB gas hazardous areas.Get custom explosion proof hoist !

Category: Explosion Proof Cranes

Your Trusted Overhead Crane Manufacturer & Supplier

Explosion-Proof Electric Chain Hoist 1 Ton to 50 Ton

for Gas Hazardous Environments(IIC, IIC T4, IIB T4 Ratings)

Introduction

When working in hazardous gas environments, safety is the top priority. That's where explosion-proof electric chain hoists come in. These hoists are specially designed to prevent sparks or heat that could ignite flammable gases. They help keep your workplace safe while handling heavy loads.

Why Gas Group Ratings Matter

Not all explosion-proof equipment is the same. Gas group ratings like IIC, IIC T4, and IIB T4 tell you what types of gases the hoist is safe to work around. For example:

- IIC covers the most dangerous gases, like hydrogen and acetylene.

- IIC T4 means the hoist can handle gases in this group and its surface won't get hotter than 135°C.

- IIB T4 is for slightly less volatile gases, but still very flammable.

Choosing the right rating is crucial. Using a hoist not rated for your gas type can be risky. So, always match the hoist rating to the gas hazards in your area.

Benefits of Certified Explosion-Proof Hoists

- Safety First: They prevent sparks or heat that might cause explosions.

- Durability: Built tough with strong materials for long life in tough environments.

- Reliable Operation: Designed to work smoothly even in hazardous areas.

- Compliance: Meets international safety standards, so you know it's tested and approved.

In short, explosion-proof electric chain hoists give you peace of mind while lifting heavy loads where flammable gases are present. They combine safety, strength, and reliable performance to protect both people and property.

Gas Group Ratings and Their Significance

When it comes to explosion-proof equipment, understanding gas group ratings is key. These ratings tell you which kinds of gases the equipment can safely handle without causing a spark or fire.

What Do IIC, IIC T4, and IIB T4 Mean?

- IIC is the highest gas group rating. It covers the most dangerous gases like hydrogen and acetylene. These gases ignite easily and burn fast, so equipment must be very well protected.

- IIC T4 means the equipment meets IIC gas group standards and the maximum surface temperature of the hoist won't exceed 135°C. This is important because hot surfaces can ignite gas.

- IIB T4 applies to gases that are less explosive than IIC gases but still flammable, such as ethylene. Equipment with this rating is still highly protected but for slightly less risky environments.

Examples of Gases in Each Group

- IIC: Hydrogen, Acetylene

- IIB: Ethylene, Propane

Using a hoist rated for a lower gas group in a high-risk gas environment is dangerous. It could cause sparks or overheating, leading to explosions. On the other hand, using a higher-rated hoist than necessary might increase cost but improves safety.

Always choose a hoist with the right gas group rating for your specific hazardous area. This keeps your operation safe and compliant with regulations.

Application for Explosion-Proof Hoists

Explosion-proof electric chain hoists are essential tools in industries where flammable gases or vapors pose safety risks. These hoists help ensure safe lifting and handling without causing sparks or heat that could ignite hazardous atmospheres.

Key Industries Using Explosion-Proof Hoists

Many industries face the challenge of working in environments with explosive gases. These hoists are widely used to meet strict safety requirements:

- Petrochemical plants: Handling heavy equipment and materials where explosive gases are common.

- Oil & Gas facilities: Including drilling sites, production plants, and pipelines where safety is critical.

- Refineries: Processing crude oil involves many flammable substances needing careful handling.

- Gas storage facilities: Tanks and storage areas where gas leaks could cause fires or explosions.

- Chemical processing plants: Where volatile chemicals are processed or transferred.

Suitable Hazardous Zones

Understanding where explosion-proof hoists can be safely operated is crucial. These hazardous zones are classified based on how often flammable gases might be present:

- Zone 1: Areas where explosive gases are likely to be present during normal operation. This is a higher-risk zone, so equipment must meet strict explosion-proof standards.

- Zone 2: Areas where explosive gases may be present only occasionally or for short periods. Equipment still needs to be explosion-proof but the risk level is lower than Zone 1.

Environmental Factors and Safety Requirements

The specific gases and conditions in your work environment determine the hoist features needed to ensure safety:

- In these zones, gases like hydrogen or ethylene might be present. These gases are highly flammable and can ignite if the hoist sparks or overheats.

- Equipment rated for IIC gas groups (like hydrogen and acetylene) must have extra protection because these gases ignite easily and burn fast.

- Equipment rated IIB is used in areas with less volatile gases, but it still needs to prevent sparks and hot surfaces.

- The hoist must also have corrosion-resistant parts and sealed electrical components to prevent sparks from dust or moisture.

- Safety features such as overload protection, mechanical limits, and flameproof housings are essential to prevent accidents.

In summary, explosion-proof hoists are carefully designed to meet the safety demands of hazardous gas environments, ensuring reliable and safe lifting operations.

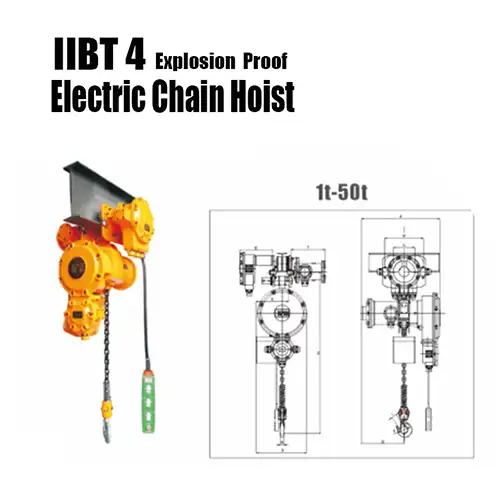

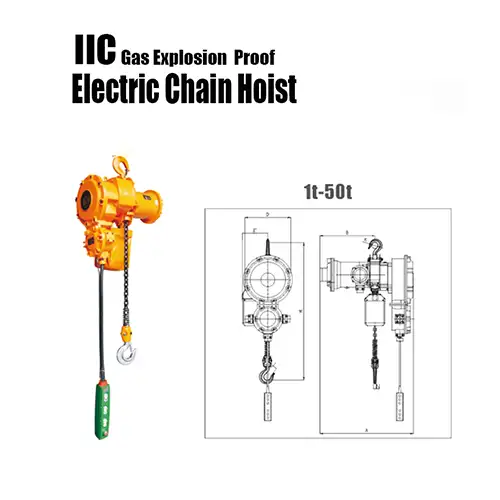

Types of Explosion-Proof Electric Chain Hoists

Explosion-proof electric chain hoists come in different types to suit various lifting needs and workspace conditions. Choosing the right type helps improve efficiency and safety on site.

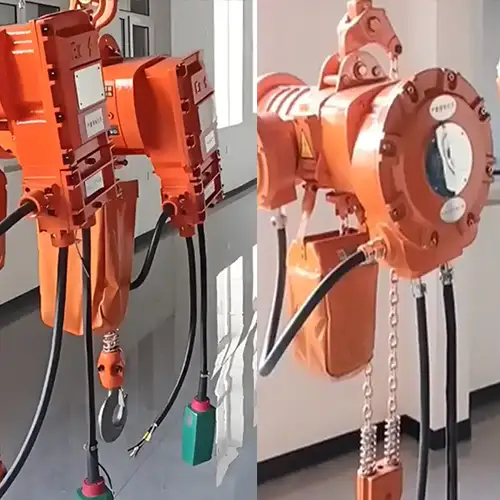

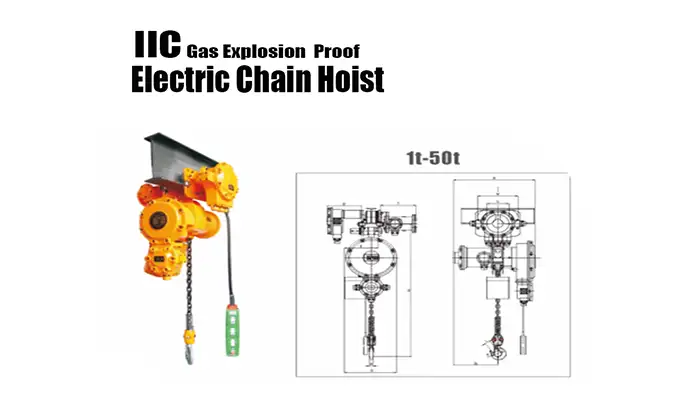

Motorized Trolley Travelling Exlosion proof electric chain hoist 1 ton to 50 ton for IIC explosive environments

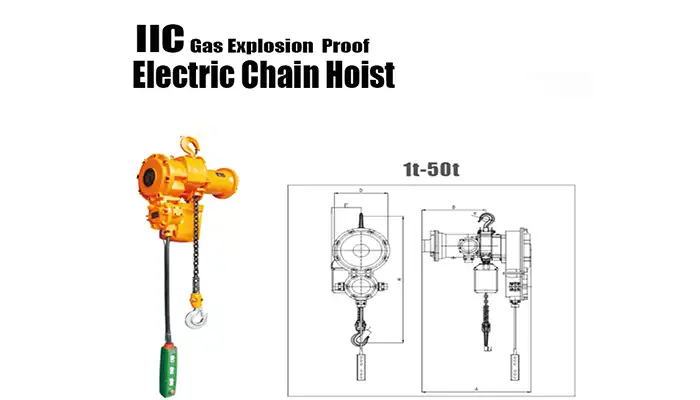

Hook mounted explosion proof electric chain hoist 1 ton to 50 ton for IIC explosive environments

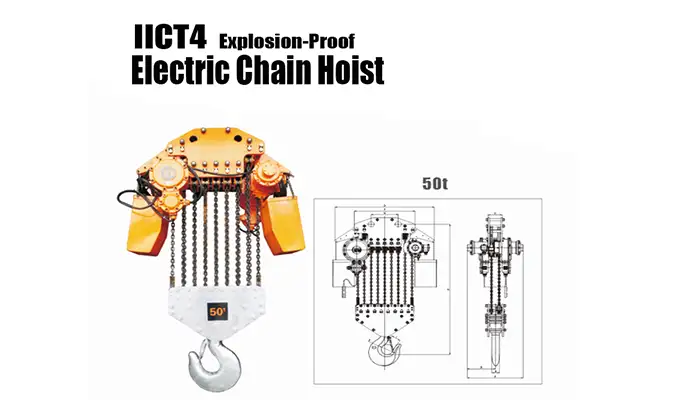

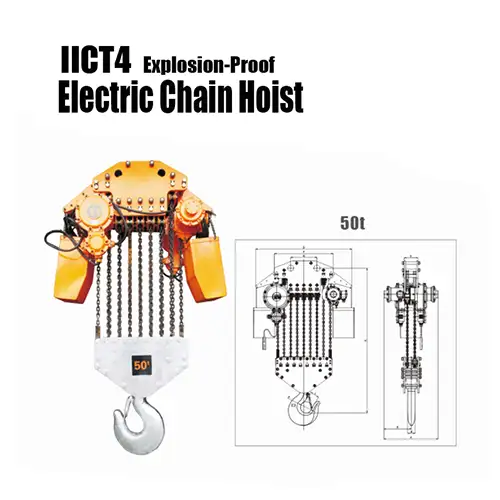

Exlosion proof electric chain hoist 50 ton for IICT 4explosive environments

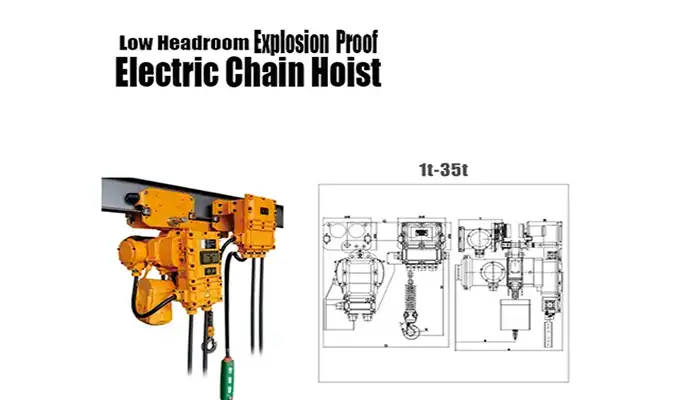

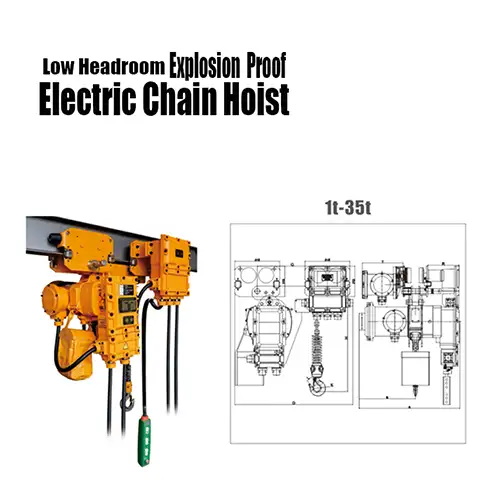

Low headroom explosion proof electric chain hoist 1 ton to 35 ton for hazardrouse explosive environments

Hook Mounted Hoist

This type is very simple and easy to install. You can move it around or fix it in one spot, making it flexible for different tasks.

- Best for lighter loads and quick setup.

- Great when you need a hoist that's easy to relocate.

Electric Trolley Mounted Hoist

This hoist comes with a powered trolley that runs smoothly along runway beams. It moves the load horizontally with ease.

- Perfect for medium to heavy loads.

- Commonly used in fixed lifting stations where regular movement is needed.

Manual Trolley Mounted Hoist

Instead of powered movement, this trolley is moved by hand, giving you precise control over positioning.

- Ideal for smaller operations or places where power isn't available.

- Allows careful load placement without relying on electricity.

Low Headroom Hoist

When overhead space is tight, this hoist is designed to give you maximum lifting height without needing extra clearance.

- Compact but still strong enough for heavy loads.

- Perfect for workshops or factories with limited ceiling height.

Each type offers specific benefits depending on your work environment and lifting needs. Selecting the right explosion-proof hoist type ensures safer and smoother operations in hazardous gas areas.

Explosion-Proof Electric Chain Hoist – Specification Table

| Item | Specification |

|---|---|

| Rated Lifting Capacity | 1 ton to 50 tons (customizable) |

| Lifting Height | custom heights available |

| Lifting Speed | Single or dual speed (typically 2.7–6.8 m/min) |

| Traveling Speed | Electric trolley: 11–22 m/min; Manual trolley: manual |

| Explosion-Proof Classification | Ex d IIC T4 Gb / Ex d IIB T4 Gb |

| Applicable Hazardous Zones | Zone 1 and Zone 2 (Gas environments) |

| Motor Type | Explosion-proof squirrel cage motor, IP65 protection |

| Motor Insulation Class | F or H class, heat-resistant |

| Electrical Control | Explosion-proof control box with stainless steel fasteners |

| Control Mode | Pendant control (standard), explosion-proof wireless remote (optional) |

| Power Supply | 380V/3Ph/50Hz (custom voltages available) |

| Duty Cycle | M3–M5 (ISO/FEM standards) |

| Load Chain | G80 alloy steel, copper-plated, corrosion-resistant |

| Hook | Stainless steel with safety latch and swivel |

| Mounting Options | Hook mounted, electric trolley mounted, manual trolley mounted, low headroom type |

| Ambient Temperature | -20°C to +40°C |

| Optional Features | VFD for smooth speed control, anti-condensation heater |

Explosion-Proof Hoist Components

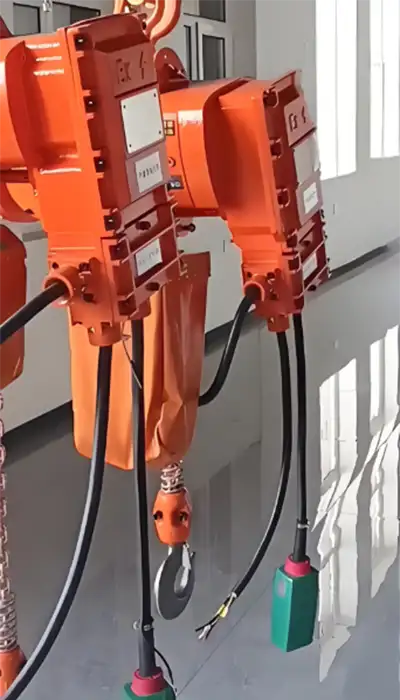

The key to safety in hazardous environments lies in the quality and design of each component in the explosion-proof hoist. Let's look closer at the main parts that make these hoists safe and reliable.

Explosion-Proof Motor

The motor is the heart of the hoist. It's fully enclosed in a thick cast iron housing.

- This housing prevents any sparks or heat inside the motor from reaching the outside atmosphere.

- It's built to stop ignition of flammable gases around the hoist.

- Durable and designed to handle tough working conditions without failing.

Electrical Enclosure and Control Box

All the electrical parts are safely housed in flameproof, sealed boxes.

- Made from cast iron or stainless steel for strength and corrosion resistance.

- These enclosures meet strict IIC and IIB T4 standards to ensure safety in explosive gas zones.

- Sealing prevents dust, moisture, or gas from entering and causing hazards.

Control Pendant

The control pendant lets the operator control the hoist safely.

- It's explosion-proof certified to keep dust and gas out.

- Designed ergonomically for easy handling during operation.

- Includes an emergency stop button for quick shutdown if needed.

Load Chain

The load chain is a critical lifting component.

- Made from high-strength G80 steel, which is copper-plated to reduce the chance of sparks.

- It's durable and corrosion-resistant, ideal for harsh environments with dust or chemicals.

Hook Assembly

The hook must be strong and safe during lifting.

- Made from stainless steel to prevent rust and withstand heavy use.

- Comes with a safety latch to keep the load secure.

- Swiveling design allows easy positioning without twisting the chain.

Fasteners and Connectors

Every bolt and connection matters for safety.

- Made from stainless steel to resist corrosion and avoid spark risks.

- All connections are sealed and explosion-proof to maintain the hoist's integrity.

Each of these components works together to create a hoist that can safely operate in explosive gas environments without risk of ignition or failure. This careful design protects workers, equipment, and facilities.

Explosion proof electric chain hoist body

Chain fall of electric chain hoist with explosion proof hoist design

Hook of explosion proof chain hoist

Explosion proof pendant control

Technical Specifications and Capacity Range

Explosion-proof electric chain hoists come with a wide range of technical options to meet different lifting demands. Here's what you need to know about their specs and capacities.

Lifting Capacity

- The hoists handle loads starting from 1 ton all the way up to 50 tons.

- Capacity can be customized based on your specific project or operation needs.

- This flexibility ensures you get the right hoist for light to very heavy lifting tasks.

Lifting Heights and Speeds

- Lifting height options vary to suit different workspace sizes and requirements.

- Speeds can be adjusted to match the task — slower for delicate loads or faster when speed is essential.

- Variable speeds help protect the load and improve handling precision.

Control Systems

- Standard control is through a wired pendant, allowing simple and direct operation.

- Wireless remote control is available as an option for more flexibility and safer distance operation.

- Variable Frequency Drive (VFD) can be added to provide smooth start/stop and speed control, reducing mechanical stress.

Safety and Reliability

Safety and reliability are crucial for equipment working in hazardous, explosive gas environments. These hoists come equipped with multiple features to protect operators and assets.

Overload Protection

- Built-in systems prevent the hoist from lifting beyond its safe capacity.

- Protects the hoist from damage and reduces risk of accidents caused by overload.

Mechanical and Electrical Limit Switches

- Limit switches stop the hoist automatically when it reaches the upper or lower travel limits.

- Prevents the chain from over-traveling and damaging the hoist or load.

Heat-Resistant Insulation and Flameproof Wiring

- Wiring and insulation materials are designed to withstand high temperatures.

- Flameproof cabling prevents sparks or electrical faults that could ignite gases.

Durability and Performance

- The entire hoist system is made to operate reliably under tough, explosive gas conditions.

- Designed for long service life with minimal maintenance.

- Ensures continuous safe operation in hazardous environments.

Together, these technical features and safety measures make explosion-proof electric chain hoists a trusted choice for lifting in flammable gas zones.

Installation and Maintenance Considerations

Proper installation and upkeep are essential to ensure safety and performance in explosive gas environments. Explosion-proof electric chain hoists must be handled with extra care due to their sensitive working conditions.

Installation Guidelines

Before installing an explosion-proof hoist, make sure the area is classified correctly (Zone 1 or Zone 2, IIB or IIC).

- Only install hoists certified for that zone's specific gas group and temperature class (e.g., IIC T4).

- Ensure all power supply systems, suspension structures, and supporting beams meet safety codes.

- Use flameproof junction boxes and seal all cable entries to prevent gas ingress.

- Grounding is essential — make sure the hoist and trolley are properly earthed to avoid static discharge.

Routine Inspection and Maintenance

Regular inspection is not just good practice — it's a safety requirement.

- Inspect the load chain for wear, corrosion, and deformation.

- Check the motor casing and electrical enclosures for signs of damage or cracks.

- Clean the hoist and pendant regularly to prevent dust buildup, which could become an ignition source.

- Test emergency stops, limit switches, and overload devices weekly.

- Lubricate moving parts with explosion-safe lubricants as needed.

Operator Training

Anyone using explosion-proof hoists should be trained on both usage and safety protocols.

- Teach operators how to identify signs of malfunction early.

- Emphasize the importance of never bypassing safety devices.

- Include emergency procedures specific to explosive gas environments in training sessions.

Advantages of Using Certified Explosion-Proof Electric Chain Hoists

Choosing a certified explosion-proof hoist is not just about compliance — it's about protecting people, equipment, and operations.

Certified to International Standards

- These hoists comply with globally recognized standards such as ATEX and IECEx.

- Certification ensures the design has passed strict tests for use in hazardous gas environments.

Enhanced Safety in Hazardous Zones

- Properly rated equipment reduces the risk of sparks, overheating, or other ignition sources.

- Helps companies meet legal safety obligations and avoid costly accidents or shutdowns.

Flexible Mounting and Control Options

- Available as hook-mounted, electric trolley-mounted, manual trolley-mounted, or low headroom designs.

- Choose from pendant control, remote control, or VFD systems depending on your application.

- Can be adapted to tight spaces or complex layout requirements.

Long-Term Reliability

- Built with heavy-duty materials like cast iron and stainless steel to withstand harsh environments.

- Designed for long service life with minimal downtime.

- Reliable operation even under continuous or high-load conditions.

Conclusion: Send us an Inquiry to Get Electric Chain Hoist Price

Explosion-proof electric chain hoists rated for IIC and IIB gases play a critical role in keeping operations safe and compliant in hazardous environments.

- These hoists are specifically designed to handle explosive gases like hydrogen, acetylene, and ethylene — common in oil & gas, chemical, and refining industries.

- Certified equipment ensures your lifting operations meet international safety standards like ATEX and IECEx.

- Whether you're lifting 1 ton or 50 tons, these hoists offer the performance, protection, and reliability needed in gas-prone areas.

- With a variety of mounting types and control options, they can be adapted to fit your site's exact needs.

By choosing the right explosion-proof hoist, you improve safety, reduce risk, and keep your operation running smoothly.

trolley mounted explosion proof electric chain hoist

Hook mounted electric chain hois for material handling in explosive working environment

Heavy lifting llct4 explosion proof electric chain hoist

1 ton to 35 ton low headroom explosion proof electric chain hoist

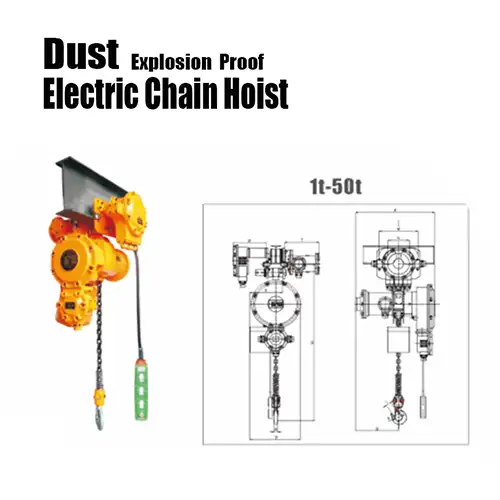

Explosion proof electric chain hoist 1 ton 50 ton for explosive dusty working environments

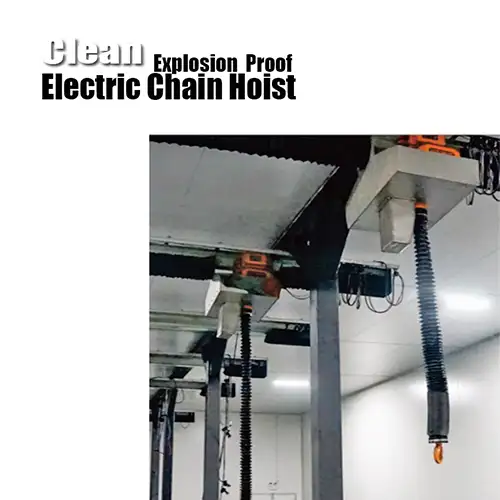

Explosion proof electric chain hoist for clean working environments

Looking for expert help with explosion-proof lifting equipment?

- Contact us today for a free technical consultation or a custom quotation.

- Our team is ready to help you choose the right explosion-proof hoist — based on your lifting needs, gas classification, and worksite conditions.

- Need something special? We also offer customized designs to suit your unique environment and requirements.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch