Electric Explosion-Proof Chain Hoist vs. Ex-Proof Wire Rope Hoist

Electric explosion proof chain hoists suit light loads; Explosion proof wire rope hoists excel in heavy lifting with higher capacity & durability. Click!

Category: Featured

Your Trusted Explosion Proof Hoists Manufacturer & Supplier

Comparison of Explosion-Proof Electric Chain Hoists vs. Wire Rope Explosion Proof Hoists

Introduction

In many industries, especially those dealing with flammable gases, dust, or chemicals, safety is a top priority. Explosion-proof hoists are essential tools in these hazardous environments. They are specially designed to prevent sparks or heat from causing explosions. This makes them a reliable choice where safety cannot be compromised.

Why Explosion-Proof Certification Matters

Explosion-proof certification is not just a label — it means the hoist has passed strict tests. These tests prove that the equipment can work safely in dangerous conditions without triggering a fire or explosion. Certifications like ATEX, IECEx, or others show that the hoist meets international safety standards.

Using certified explosion-proof hoists helps companies:

- Protect workers and facilities

- Follow legal and industry regulations

- Reduce the risk of costly accidents and downtime

Why Compare Electric Chain Hoists and Wire Rope Hoists?

Both electric chain hoists and wire rope hoists are popular in hazardous areas. But they are quite different in design, use, and capabilities. Understanding these differences can help buyers choose the right hoist for their specific needs.

This comparison aims to:

- Highlight how each type works in explosion-proof versions

- Show strengths and weaknesses for different applications

- Help buyers pick the safest and most efficient hoist for their job

Choosing the right explosion-proof hoist is not just about price. It's about matching the hoist to the task, the environment, and safety rules. This guide will help you do just that.

Basic Definitions and Operating Principles

In hazardous environments where flammable gases, vapors, or dust are present, the right lifting equipment must not only handle the load but also prevent ignition. Explosion-proof hoists are built specifically for this purpose. In this section, we explain how explosion-proof electric chain hoists and explosion-proof wire rope hoists work, and where each is typically used.

Explosion-Proof Wire Rope Hoists

An explosion-proof wire rope hoist uses a steel rope wound around a drum to handle heavier loads and longer lifting distances. It is equipped with explosion-proof components to safely operate in hazardous industrial environments.

Working mechanism:

- The hoist is powered by an explosion-proof motor with a flameproof enclosure.

- The motor drives a gearbox connected to a drum.

- As the drum rotates, it winds or unwinds the wire rope, raising or lowering the attached load.

- The rope may pass through pulleys (sheaves) for multi-reeving to balance the load and reduce stress.

- A braking system and upper/lower limit switches control safe operation.

- Control stations, pendant buttons, and cables are designed to be spark-free and sealed against dust or gas.

Typical applications:

- Medium to heavy-duty lifting, from 5 tons to 100 tons or more.

- High-lift situations requiring extended vertical travel.

- Continuous or fast-paced operations in hazardous zones.

- Heavy lifting in chemical plants, oil and gas facilities, refineries, and offshore rigs.

- Indoor or outdoor fixed installations in explosion-risk zones.

Explosion-proof wire rope hoists are selected for their lifting power, durability, and performance in demanding industrial environments where safety is critical.

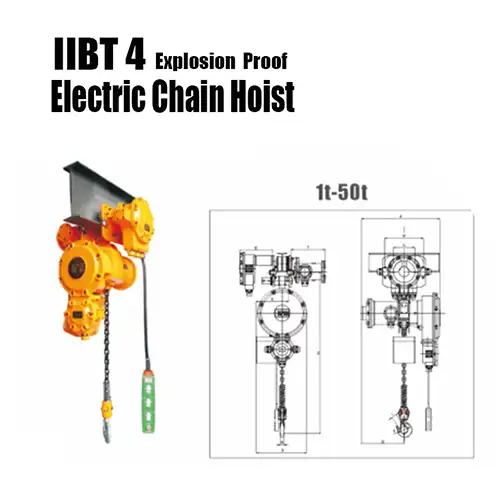

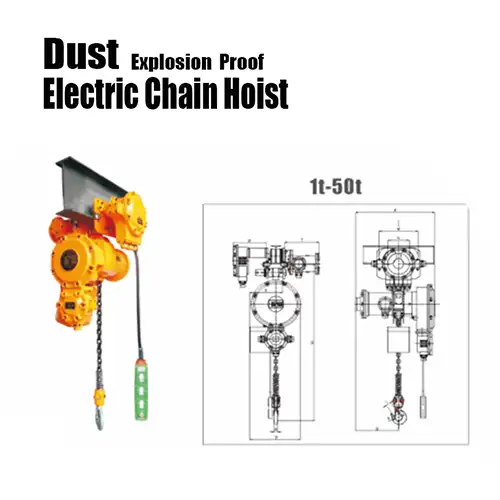

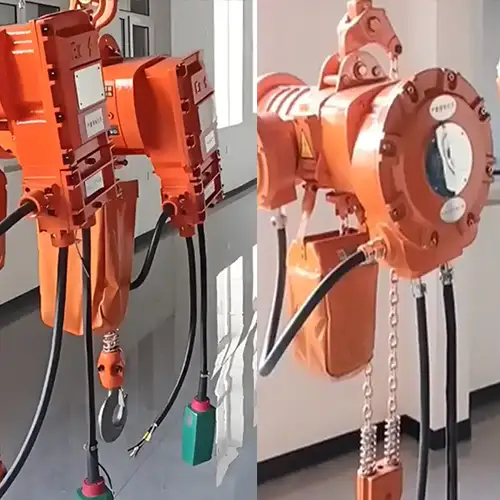

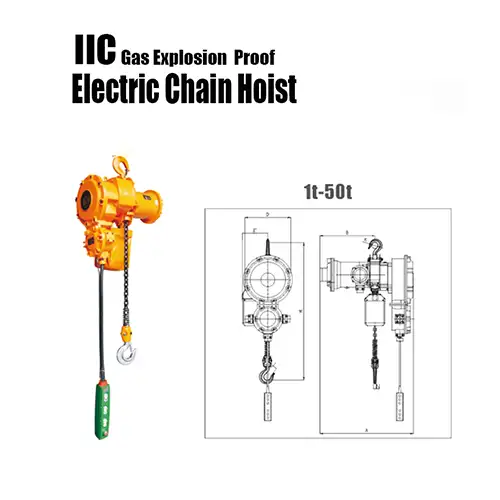

Explosion-Proof Electric Chain Hoists

An explosion-proof electric chain hoist is a compact lifting device that uses a high-strength chain and a sealed electric motor to lift loads vertically. It is designed to operate safely in hazardous areas where flammable substances may be present.

Working mechanism:

- The hoist includes an explosion-proof motor enclosed in a flameproof casing to prevent ignition.

- The motor drives a gearbox that turns a sprocket.

- The sprocket engages the load chain, lifting or lowering the load attached to the hook.

- The chain moves through a chain guide to ensure smooth operation.

- A mechanical or electromagnetic brake holds the load when the motor stops.

- All wiring, controls, and terminals are sealed or made spark-resistant for safe use in explosive atmospheres.

Typical applications:

- Light to medium lifting tasks, generally up to 5 or 10 tons.

- Sites with limited headroom or space constraints.

- Repetitive lifting operations in hazardous workshops or processing facilities.

- Service and maintenance tasks in explosive gas or dust zones.

- Skid-mounted units, mobile equipment, or containerized systems.

Explosion-proof electric chain hoists are chosen for their compact size, ease of installation, and reliability in frequent-use scenarios within explosive areas.

Hook mounted electric chain hois for material handling in explosive working environment

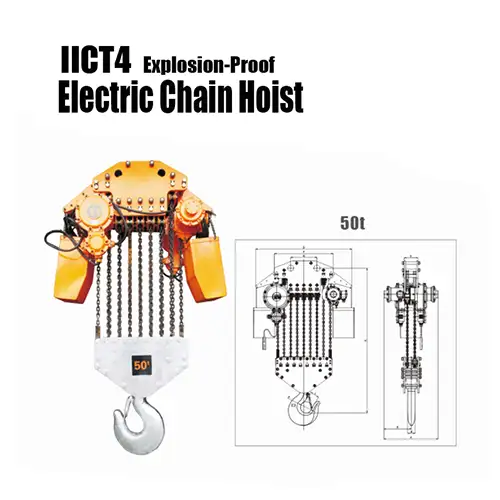

Heavy lifting llct4 explosion proof electric chain hoist

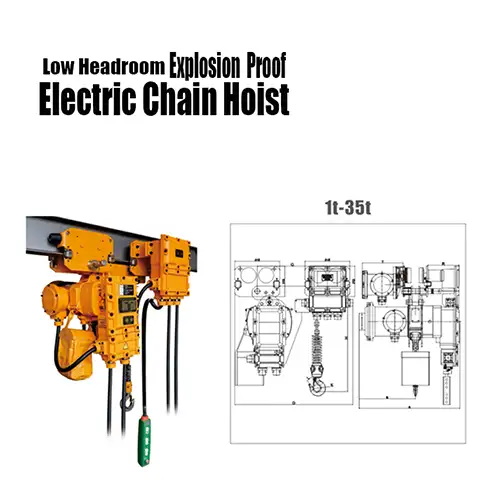

1 ton to 35 ton low headroom explosion proof electric chain hoist

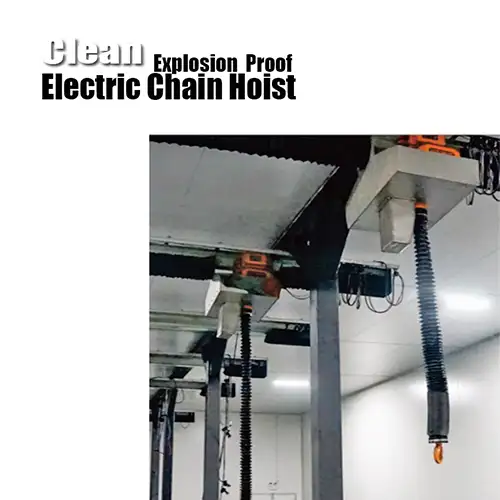

Explosion proof electric chain hoist for clean working environments

Explosion-Proof Features

Choosing the right explosion-proof hoist is not just about load capacity—it's about safety in dangerous environments. In hazardous areas, equipment must be built to prevent any spark, heat, or electrical failure that could cause an explosion. Let's break down what makes a hoist explosion-proof and what features you should look for.

What Makes a Hoist Explosion-Proof?

An explosion-proof hoist is designed so it will not ignite the surrounding atmosphere, even if flammable gas, vapor, or dust is present. This is done by carefully sealing electrical parts, using non-sparking materials, and designing all components to meet strict international safety standards.

Enclosure Types

The enclosures around motors, controls, and other electrical components are critical.

- Flameproof (Ex d) enclosures: These can contain an internal explosion without letting it escape into the external environment.

- Increased safety (Ex e): These enclosures reduce the risk of sparks and excessive heat.

- Dust-ignition proof (Ex t): For areas with explosive dust, these keep particles from entering and causing combustion.

- Enclosures are typically made from cast iron, aluminum alloy, or stainless steel, depending on the environment.

Certification Standards

Explosion-proof hoists must be certified to meet recognized standards for hazardous locations.

- ATEX (EU standard) – Based on zones and gas/dust classification. Required in Europe.

- IECEx (International) – Similar to ATEX, accepted in many countries outside the EU.

- NEC Class/Division (USA) – Used in North America; defines equipment by class, division, and group.

- GB3836 (China) – National standard for explosion-proof equipment in China.

Each certified hoist will be marked with the relevant zone or class, along with temperature rating and protection type. Always match the certification to your work area's classification.

| Feature | Explosion-Proof Electric Chain Hoist | Explosion-Proof Wire Rope Hoist |

|---|---|---|

| Lifting Medium | Alloy steel chain | Steel wire rope |

| Drive Mechanism | Motor-driven sprocket | Motor-driven drum |

| Typical Load Capacity | Up to 5–10 tons | 5 tons to 100+ tons |

| Lifting Speed | Moderate | Moderate to high |

| Suitable for | Short lifts, tight spaces, repetitive use | Long lifts, heavy loads, continuous use |

| Common Applications | Workshops, skids, maintenance | Plants, refineries, offshore platforms |

| Explosion Protection | Flameproof motor, sealed control parts | Flameproof motor, sealed control parts |

Key Explosion-Proof Components

Both explosion-proof electric chain hoists and explosion-proof wire rope hoists share several critical safety features:

Explosion-proof motors

- Enclosed in flameproof housings

- Designed to prevent ignition from internal sparks or overheating

- Often equipped with thermal protection

Explosion-proof control panels and pendants

- Use sealed or encapsulated switches and wiring

- Housed in cast metal boxes rated for hazardous zones

- Include emergency stop functions

Spark-resistant brakes

- Non-sparking friction materials

- Enclosed braking systems that prevent dust or gas intrusion

- Electromagnetic or mechanical brakes rated for explosive environments

Sealed cable glands and conduits

- Prevent flammable gases or dust from entering the control circuit

- Cable entries are rated to the same explosion-proof level as the housing

Limit switches and sensors

- Explosion-proof or intrinsically safe versions to prevent ignition during operation

- Protect against over-travel or overload

Similarities in Explosion-Proof Features

While the lifting mechanisms differ, the explosion-proof safety designs for both hoist types are very similar.

- Both types must follow the same zone or class certification for the site.

- Both have enclosed motors, sealed controls, and spark-resistant brakes.

- Both use similar materials for enclosures and components (like copper-free aluminum or stainless steel).

- Both can be fitted with flameproof limit switches and anti-condensation heaters.

Comparison Criteria: Explosion-Proof Electric Chain Hoists vs. Explosion-Proof Wire Rope Hoists

Choosing the right explosion-proof hoist depends on several factors, especially when safety and efficiency are critical in hazardous environments. This section breaks down the major comparison points to help buyers and engineers make informed decisions.

Lifting Capacity & Load Range

Selecting a hoist starts with understanding the weight and type of loads it must handle. The load range also influences the system's durability, structure, and long-term reliability.

Explosion-Proof Electric Chain Hoists:

- Typically designed for light to moderate lifting tasks.

- Common capacity ranges from 0.5 tons up to 5 tons, with some models extending to 10 tons.

- Ideal for lifting small machinery parts, barrels, gas cylinders, or process equipment within hazardous zones.

Explosion-Proof Wire Rope Hoists:

- Built for medium to heavy-duty lifting applications.

- Standard models support loads from 3 tons to 50 tons or more.

- Frequently used in oil refineries, steel mills, mining operations, and other industrial plants requiring constant heavy lifting.

| Criteria | Chain Hoist (Explosion-Proof) | Wire Rope Hoist (Explosion-Proof) |

|---|---|---|

| Typical Capacity | 0.5 – 5 tons (up to 10 tons) | 3 – 50+ tons |

| Application Scale | Light to medium loads | Medium to heavy loads |

| Common Use Cases | Maintenance tools, drums, valves | Industrial machinery, steel coils |

Lifting Speed and Precision

Lifting speed and control precision are key when planning repetitive handling tasks, especially where alignment and time matter.

Explosion-Proof Electric Chain Hoists:

- Slower lifting speed, typically ranging from 2 to 8 meters per minute.

- Standard controls often include single-speed or dual-speed operation.

- Not ideal for operations requiring fine load positioning.

Explosion-Proof Wire Rope Hoists:

- Faster speeds—often 6 to 20 meters per minute or more.

- Advanced models come with variable frequency drives (VFDs) for smooth acceleration and deceleration.

- Excellent for operations that demand precise control and load alignment.

| Criteria | Chain Hoist (Explosion-Proof) | Wire Rope Hoist (Explosion-Proof) |

|---|---|---|

| Lifting Speed | 2 – 8 m/min | 6 – 20+ m/min |

| Control Options | 1 or 2 speeds | VFD control for variable speeds |

| Precision Placement | Moderate | High |

Durability and Maintenance

The expected usage frequency and operational stress determine how durable the hoist needs to be and what type of maintenance is involved.

Explosion-Proof Electric Chain Hoists:

- Simple construction with a chain drive system and fewer moving parts.

- Lower maintenance requirements in low-frequency applications.

- Chain stretch and sprocket wear require occasional inspection.

Explosion-Proof Wire Rope Hoists:

- More robust and designed for high-duty cycles.

- Require regular inspections of wire rope, drums, and lubrication systems.

- More suitable for continuous, rugged use in challenging environments.

| Criteria | Chain Hoist (Explosion-Proof) | Wire Rope Hoist (Explosion-Proof) |

|---|---|---|

| Maintenance Frequency | Low to moderate | Moderate to high |

| Durability (Heavy Use) | Limited | Excellent |

| Typical Service Life | Moderate | Long (with maintenance) |

Size and Weight of Hoists

Space constraints and ease of installation play a major role in choosing between chain and wire rope hoists.

Explosion-Proof Electric Chain Hoists:

- Compact and lightweight.

- Easier to install in small workshops or areas with limited headroom.

- Useful in maintenance bays, test labs, and confined process zones.

Explosion-Proof Wire Rope Hoists:

- Larger and heavier because of the drum and motor arrangement.

- Need more structural support and vertical clearance.

- Usually installed on overhead bridge cranes or custom gantry systems.

| Criteria | Chain Hoist (Explosion-Proof) | Wire Rope Hoist (Explosion-Proof) |

|---|---|---|

| Physical Size | Compact and space-saving | Large and requires space |

| Installation Flexibility | High | Limited |

| Headroom Requirement | Low | Higher |

Cost Considerations

Budget planning involves not just the upfront price, but also maintenance, lifespan, and repair costs over time.

Explosion-Proof Electric Chain Hoists:

- Cost-effective for lighter applications.

- Lower purchase price and reduced installation complexity.

- Less costly spare parts and simpler servicing.

Explosion-Proof Wire Rope Hoists:

- Higher initial investment.

- Designed for long-term operation with a higher load capacity.

- Maintenance costs vary depending on usage and environmental exposure.

| Criteria | Chain Hoist (Explosion-Proof) | Wire Rope Hoist (Explosion-Proof) |

|---|---|---|

| Initial Cost | Low | High |

| Long-Term Value | Good for small jobs | Better for heavy-duty operations |

| Spare Parts Availability | Easy and low-cost | Moderate to high cost |

Operational Environment Suitability

Where you install the hoist matters—especially in environments with corrosive air, moisture, or outdoor exposure.

Explosion-Proof Electric Chain Hoists:

- Suitable for indoor hazardous zones like paint booths, gas plants, or confined service rooms.

- Limited corrosion protection unless upgraded.

Explosion-Proof Wire Rope Hoists:

- Designed for harsher environments such as chemical plants, outdoor platforms, marine docks.

- Can be equipped with heaters, IP66 enclosures, anti-corrosion treatments.

| Criteria | Chain Hoist (Explosion-Proof) | Wire Rope Hoist (Explosion-Proof) |

|---|---|---|

| Environmental Suitability | Mild to moderate | Harsh and extreme |

| Corrosion Resistance | Basic (can be upgraded) | Advanced coatings available |

| Usage Zones | Indoor / semi-protected | Outdoor / offshore / heavy plants |

Safety Features

Both types include critical safety mechanisms, but the design and complexity may differ slightly based on the load type and environment.

Shared Explosion-Proof Safety Features:

- Flameproof enclosures for motors and switches

- Explosion-proof pendant or remote control stations

- Spark-resistant materials for lifting chains, hooks, or rope drums

Additional Safety Systems:

- Upper and lower limit switches

- Thermal protection in motors

- Mechanical overload protection

- Emergency stop systems

| Criteria | Chain Hoist (Explosion-Proof) | Wire Rope Hoist (Explosion-Proof) |

|---|---|---|

| Flameproof Components | Yes | Yes |

| Overload Protection | Standard | Standard / Advanced Options |

| Emergency Stop Systems | Yes | Yes |

Advantages of Explosion-Proof Electric Chain Hoists

- Compact and Easy to Install

Their small size and light weight make them perfect for tight spaces or areas with low headroom. Installation is straightforward and usually requires minimal structural support. - Ideal for Light Loads and Frequent Use

Designed to handle lower capacity loads efficiently. They perform well in jobs involving frequent starts and stops, such as maintenance or light manufacturing. - Simplified Maintenance

Fewer parts mean simpler upkeep. Routine checks and repairs, like chain replacement, are quick and less costly. - Cost-Effective for Light to Medium Loads

Generally more affordable upfront and cheaper to install compared to wire rope hoists, making them a budget-friendly option for lighter lifting needs.

Advantages of Explosion-Proof Wire Rope Hoists

- High Lifting Capacity

Suitable for heavier loads, typically ranging from 3 tons to 50+ tons. Perfect for demanding industrial sectors like mining, steel production, and oil refining. - Longer Lifting Heights and Faster Speeds

Designed to lift loads over greater heights and at higher speeds, which increases overall productivity in large-scale operations. - Built for Tough Environments

Robust construction and protective features make these hoists reliable in harsh conditions such as outdoor settings, chemical plants, or offshore facilities. - Smooth and Stable Operation

Offers less vibration and noise during lifting, ensuring precise positioning and safer handling of sensitive or heavy equipment.

Disadvantages and Limitations

Explosion-Proof Electric Chain Hoists

- Limited Maximum Load Capacity

Chain hoists are typically designed for lighter loads—usually up to 5 or 10 tons. This limitation makes them unsuitable for heavy industrial lifting tasks, where higher capacity is mandatory. - Chain Wear and Fatigue

The lifting chain is exposed to constant stress and friction. Over time, this leads to stretching, wear, or corrosion, especially in harsh environments. Regular inspection and timely replacement are essential to maintain safety and performance. - Lower Lifting Speed and Precision

Chain hoists generally operate at slower speeds and offer less precise load positioning. This can be a drawback in operations requiring quick cycles or fine control. - Sensitivity to Contamination

Dirt, dust, or moisture can cause chain corrosion or jamming, especially if the chain or housing is not properly sealed. This requires careful maintenance and sometimes additional protective features.

Explosion-Proof Wire Rope Hoists

- Heavier and Larger Size

Wire rope hoists are bulkier due to the drum, motor, and rope assembly. They require more installation space and stronger structural support, which can complicate retrofitting or installations in confined areas. - More Complex Maintenance

Maintenance tasks are more involved, including regular lubrication of the wire rope and drum, inspection for rope wear or damage, and occasional motor servicing. This can increase downtime and maintenance costs. - Higher Initial Cost

Wire rope hoists are more expensive to purchase and install compared to chain hoists. The upfront investment is higher, reflecting their greater capacity and robust design. - Potential for Rope Failure

While wire ropes are strong, they are susceptible to fatigue, corrosion, and broken strands if not properly maintained. Failure can lead to serious safety risks, so inspections must be thorough and frequent.

Typical Use Cases and Industry Applications

Explosion-Proof Electric Chain Hoists

Explosion-proof electric chain hoists are best suited for applications where loads are relatively light to moderate and where space or headroom is limited. Their compact size, combined with explosion-proof features, makes them ideal for indoor or semi-enclosed hazardous areas where safety and precision matter but heavy lifting is not the main requirement.

Industries & Environments:

- Chemical Plants:

Frequently used to lift chemical containers, drums, and smaller equipment in processing areas classified as hazardous due to flammable vapors or gases. The chain hoist's ability to operate safely without sparking is critical here. Their size also allows use in confined process rooms or maintenance workshops. - Oil & Gas Facilities:

Ideal for routine maintenance tasks such as lifting gas cylinders, tools, or small equipment inside controlled hazardous zones like gas processing units or pipeline stations. The chain hoist's frequent start-stop capability supports maintenance schedules. - Pharmaceutical Manufacturing:

In production areas requiring strict cleanliness and explosion protection, chain hoists help move sensitive components or small machinery parts without contaminating the environment or risking sparks. - Food and Beverage Plants:

Certain processing areas involve dust or gas risks (e.g., flour mills or alcohol production). Chain hoists are used for lifting containers, valves, or light machinery while complying with explosion-proof safety regulations.

Common Applications:

- Lifting and positioning drums, barrels, and chemical containers during filling or transport.

- Moving small process equipment or tools in hazardous workshops.

- Handling gas cylinders or compressed air tanks in confined hazardous zones.

- Supporting routine maintenance and repair activities where light load lifting is frequent.

Explosion-Proof Wire Rope Hoists

Explosion-proof wire rope hoists are designed for demanding environments where heavy loads, long lifting heights, and continuous operation are the norm. Their robust design and larger capacity make them indispensable in heavy industry sectors with extreme safety and durability requirements.

Industries & Environments:

- Oil Refineries and Petrochemical Plants:

Wire rope hoists manage heavy valves, large pipe sections, and heavy machinery. These plants often have outdoor or semi-outdoor lifting areas exposed to corrosive gases and chemicals, requiring durable, explosion-proof lifting equipment. - Mining and Mineral Processing:

Mining operations require rugged equipment capable of lifting heavy ore containers, machinery parts, and bulk materials. Wire rope hoists handle rough environments with dust, moisture, and high usage rates. - Steel Mills and Foundries:

The intense heat, heavy weights (steel slabs, coils), and dusty atmospheres demand hoists that can withstand tough conditions and operate safely. Wire rope hoists are commonly integrated into bridge cranes for moving large steel products. - Marine, Offshore, and Chemical Storage:

Offshore platforms and dockyards face corrosive saltwater air and heavy lifting needs. Explosion-proof wire rope hoists provide reliable, heavy-duty lifting with coatings and heaters to resist corrosion and maintain performance in extreme climates.

Common Applications:

- Lifting steel coils and slabs in steel manufacturing plants.

- Handling large industrial pumps, compressors, or refinery equipment.

- Transporting heavy mining machinery parts or bulk mineral loads.

- Loading and unloading cargo on marine vessels or offshore rigs.

Both hoist types are vital in hazardous environments, but their suitability depends largely on the specific industrial demands:

| Aspect | Explosion-Proof Electric Chain Hoist | Explosion-Proof Wire Rope Hoist |

|---|---|---|

| Load Capacity | Light to medium loads (up to 10 tons) | Medium to heavy loads (3 to 50+ tons) |

| Typical Environment | Indoor, confined hazardous zones | Outdoor, heavy industrial and harsh hazardous zones |

| Common Industries | Chemical, pharmaceutical, food processing, light maintenance | Oil & gas, mining, steel mills, offshore, petrochemical |

| Operation | Frequent start-stop, short lifting heights | Continuous use, long lifting heights, high speed |

| Maintenance | Simpler, lower cost | More complex, higher cost but robust |

Decision-Making Factors for Buyers

Choosing the right explosion-proof hoist is critical for safety, productivity, and long-term cost-effectiveness. Buyers need to carefully weigh multiple factors to ensure the hoist meets operational demands while complying with strict safety standards in hazardous environments.

Matching Hoist Type to Operational Needs and Safety Requirements

Start by clearly defining your lifting tasks:

- Load capacity: Identify the maximum and average weights you need to lift. Chain hoists are best for lighter loads (usually under 10 tons), while wire rope hoists handle medium to very heavy loads (up to 50 tons or more).

- Frequency and duration of use: Frequent, short lifts favor electric chain hoists due to simpler design and easier handling. Continuous heavy-duty lifting requires the durability and power of wire rope hoists.

- Lifting height and precision: Wire rope hoists typically offer longer lift heights and better speed control for precise positioning. For shorter lifts, chain hoists can be more than adequate.

- Environmental conditions: Consider temperature extremes, presence of dust, moisture, corrosive chemicals, or confined spaces. Each hoist type may offer different protective options suitable for your environment.

- Safety regulations: Always ensure that the hoist meets recognized explosion-proof certifications (ATEX, IECEx, or other local standards). This is vital to protect workers and avoid legal penalties.

Consideration of Budget, Maintenance Capabilities, and Space Constraints

- Budget constraints: Chain hoists generally cost less upfront and have lower installation expenses. They also require simpler maintenance, which helps reduce ongoing costs. Wire rope hoists have a higher initial price but may offer better value for heavy or continuous use by minimizing downtime and repairs.

- Maintenance resources: Assess your team's ability to perform regular inspections and maintenance. Wire rope hoists need more frequent and technical upkeep, including wire rope inspection, lubrication, and brake checks. Chain hoists are simpler to maintain but still require routine checks to prevent chain wear or sprocket damage.

- Space and installation conditions: Chain hoists are compact and ideal for low headroom or tight areas. Wire rope hoists are bulkier and require sufficient overhead clearance and a structurally strong mounting system. Choose according to your facility's spatial limits.

Importance of Certified Explosion-Proof Ratings and After-Sales Support

Certified explosion-proof ratings: Always verify the hoist's compliance with internationally accepted safety standards such as ATEX (Europe), IECEx (international), or country-specific certifications. These certifications confirm that the hoist is designed and tested to prevent ignition in explosive atmospheres.

After-sales support and service: Reliable supplier support is essential. Look for manufacturers or distributors who offer:

- Technical advice on installation and operation.

- Access to genuine spare parts.

- Responsive maintenance and repair services.

- Training programs for your operators and maintenance staff.

Good after-sales service reduces downtime and extends your hoist's lifespan, ensuring consistent safety and performance.

Summary Table: Key Buyer Considerations

| Decision Factor | Key Points to Evaluate |

|---|---|

| Operational Needs | Load size, frequency, lift height, environment |

| Safety Compliance | Explosion-proof certification, compliance with local laws |

| Budget | Initial cost, installation, maintenance, long-term value |

| Maintenance Capability | Staff expertise, inspection schedules, spare parts access |

| Space Constraints | Headroom availability, structural support |

| Supplier Support | Warranty, service, training, spare parts availability |

Conclusion

Choosing between explosion-proof electric chain hoists and wire rope hoists depends largely on your specific lifting needs and the working environment.

Key Differences and Suitability

- Explosion-proof electric chain hoists are compact, easier to install, and best suited for light to medium loads with frequent start-stop cycles. They work well in confined spaces and simpler hazardous zones. Maintenance is straightforward, and initial costs are generally lower.

- Explosion-proof wire rope hoists offer higher lifting capacities, longer lifting heights, and faster speeds. They are designed for heavy-duty, continuous use in harsher environments such as oil refineries, chemical plants, and steel mills. These hoists require more space and maintenance but deliver superior durability and precision.

Recommendations for Selecting the Right Hoist

- For light to medium loads, especially where space is limited and budget is a concern, explosion-proof electric chain hoists are often the better choice. They provide safe, reliable lifting with simpler operation.

- For heavy lifting tasks that demand durability, higher speed, and precision, explosion-proof wire rope hoists are recommended. They are ideal for tough industrial conditions and long-term continuous operations.

- Always prioritize hoists with certified explosion-proof ratings that comply with your region's safety standards.

- Factor in maintenance capabilities, installation space, and supplier support to ensure smooth operation and longevity.

Making an informed decision helps maintain safety, improves productivity, and optimizes your investment in hazardous-area lifting equipment.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch