Complete Buyer’s Guide to Wire Rope Explosion-Proof Hoists

Master safety and lifting power with essential tips for selecting reliable, durable wire rope explosion-proof hoists.Get right explosion proof rope hoist!

Category: Featured

Your Trusted Explosion Proof Hoist and Crane Manufacturer & Supplier

Complete Buyer's Guide to Wire Rope Explosion-Proof Hoists

Mastering Safety and Lifting Power

Introduction: What Is Explosion-Proof Lifting Equipment?

In many industrial settings, safety isn't just important—it's critical. Especially in places where flammable gases, dust, or vapors are present. One small spark could cause a disaster.

That's where explosion-proof lifting equipment comes in. These are special hoists, cranes, and trolleys built to prevent sparks, heat, or flames during operation. Every part that could create ignition—like motors or switches—is sealed, shielded, or specially designed.

They're made to do the job safely, even in the most dangerous conditions.

Why Wire Rope Explosion-Proof Hoists Matter

Wire rope explosion-proof hoists are a smart choice when you need reliable lifting in hazardous zones. Why? Because they combine strength, durability, and safety all in one.

- Smooth and steady lifting – Ideal for heavy or sensitive loads.

- Long service life – Wire ropes last longer in tough environments.

- More lifting height options – Better than chain hoists when you need high vertical movement.

- Built for safety – Every component is explosion-proof: motor, control system, rope drum, and more.

In short, they're strong and safe. That's exactly what's needed when the risk is high.

Who Uses Explosion-Proof Hoists?

These hoists are not for ordinary places. They're used in industries where fire or explosion risks are part of daily life.

- Oil & Gas – Offshore platforms, refineries, tank farms

- Chemical Plants – Areas with flammable liquids or vapors

- Mining – Underground areas with explosive gases or dust

- Paint Shops & Coating Plants – Where solvents and fine particles mix

- Grain Processing & Storage – Dust explosion risk is real

- Pharmaceutical – Clean rooms and hazardous mixing zones

If you're working in any of these places, you likely need an explosion-proof hoist. And if heavy lifting is involved, a wire rope type is usually the better fit.

What Makes a Hoist Explosion-Proof?

What "Explosion-Proof" Really Means

In industrial safety, explosion-proof doesn't mean a hoist can survive an explosion. It means the hoist is designed not to cause one.

This type of equipment is built so that, even if it sparks or heats up inside, no flame or spark can escape the enclosure. It prevents fire or explosion in dangerous work areas.

Explosion-proof hoists are used in classified zones—places where gas, vapor, or dust could ignite. In these areas, safety rules are strict. One wrong move could cause a serious accident.

Key Certifications and What They Mean

If you're buying for a hazardous site, you'll need to check certifications. These standards prove the hoist meets global or regional safety rules.

Here are the most common ones:

ATEX – Used in the European Union. It defines equipment safety for explosive atmospheres.

IECEx – A global standard that ensures explosion protection.

EX d IIB T4 / EX d IIC T4 – These mark the gas group and temperature class.

- "IIB" and "IIC" refer to the type of gases present (IIC is more dangerous).

- "T4" means the hoist's surface will never get hotter than 135°C. This prevents ignition.

Tip: Always ask your supplier for the EX marking. It tells you exactly what protection the hoist offers.

Parts That Must Be Explosion-Proof

A proper explosion-proof wire rope hoist has several protected components. It's not just about the motor.

Here's what usually needs to be explosion-proof:

- Motor – Fully sealed to stop internal sparks from escaping

- Control box – Enclosed and sealed, often with copper or aluminum parts

- Push button pendant or remote – Spark-proof switches

- Limit switches and sensors – Certified to prevent ignition

- Wiring and cable glands – Sealed and tested against gas entry

- Gears and brake system – Often enclosed and made with non-sparking materials

- Hooks and trolleys – Coated or made with bronze to reduce spark risk

If any of these parts aren't protected, the system isn't fully explosion-proof.

Wire Rope vs. Chain: Why Choose Wire Rope for Explosion-Proof Hoists?

Strength That Lasts

Wire rope is often stronger than chain in the same size class. It's better for medium to heavy loads and performs well over time, especially when lifting is frequent.

Why wire rope?

- Higher lifting capacity – It handles more weight without deforming.

- Tougher under stress – Stands up to shock loads and harsh conditions.

- Better for longer distances – Especially useful if your hoist moves across wide spans.

Smooth, Controlled Lifting

Wire rope hoists offer steady and precise lifting. This is important in hazardous zones where sudden drops or jerks can damage sensitive materials—or worse, cause sparks.

- Smoother start and stop

- Less swinging under load

- Good for handling drums, tanks, or bulk bags

They're especially useful in explosive gas zones where stable control is a must.

Ideal for High Lifting Heights

If you're working in a tall facility or need to lift items from deep pits or tanks, wire rope hoists are the better option.

- Can reach higher lift heights than chain hoists

- No buildup of slack like with chain storage

- Less chance of chain jamming or binding

That's why many oil refineries, chemical plants, and gas facilities choose wire rope explosion-proof hoists for overhead lifting.

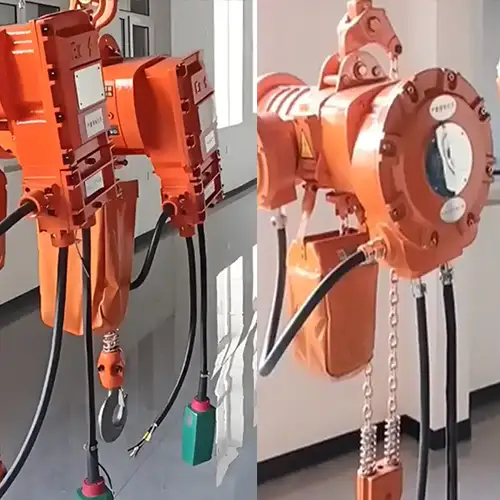

Wire rope explosion proof hoist

Core Components of a Wire Rope Explosion-Proof Hoist

Every part of a wire rope explosion-proof hoist is designed with one goal: prevent sparks and operate safely in hazardous environments. Let's break down the key components and what to look for when selecting the right hoist.

Explosion-Proof Motor

The motor is one of the most critical parts. It powers the hoist and must be tightly sealed.

- Explosion-proof grade: Look for markings like EX d IIB T4 or EX d IIC T4, depending on your site's gas classification.

- Cooling system: Often includes a flameproof fan cover and motor fins to reduce temperature buildup.

- Spark suppression: Motors are designed so internal sparks can't escape. The casing is thick and sealed with flame paths to control any ignition inside.

Tip: Make sure the motor has passed explosion-proof testing and comes with a certified label.

Wire Rope

The wire rope does the lifting. Its quality directly affects safety and performance.

- Material: Typically made of high-strength steel. Stainless options are available for corrosive areas.

- Diameter and strength: Depends on the hoist's rated load. Common sizes range from 6 mm to 24 mm.

- Copper core (optional): In some explosion-proof designs, a copper-clad core is used to reduce friction and static buildup.

- Twist-resistant: Prevents rotation of the load while lifting.

Always check the rope's wear resistance and lubrication condition before use.

Explosion-Proof Gearbox

The gearbox transfers power from the motor to the lifting mechanism. In explosive zones, the design must be sealed and durable.

- Integrated explosion-proof housing: No gaps, bolts are tightly fitted.

- Oil-sealed design: Prevents oil leaks and keeps dust or gas from getting in.

- Low-noise, high-torque: Reduces vibration and the risk of heat buildup.

Explosion-Proof Control Box

The control system must be fully enclosed and isolated from external gas or dust.

- Sealed enclosures: Often made of aluminum or copper alloy. Fully gasketed to prevent gas entry.

- Certified wiring glands: Prevent leaks at cable entry points.

- Circuit protection: Built-in fuses, contactors, and spark-proof relays.

Look for ATEX or IECEx certification labels on the control box.

Limit Devices

Limit switches and levers are used to stop the hoist when it reaches the top or bottom of its range. These are key safety items.

- EX-rated limit switches: Designed to operate without causing sparks.

- Limit levers: Often mechanical with copper or brass contact points.

- Backup systems: Some hoists include secondary cutoffs for extra safety.

Make sure these are well-calibrated during installation.

Trolley Mechanism

If your hoist moves horizontally on a beam, the trolley also needs explosion protection.

- Spark-resistant wheels: Usually bronze-coated or nylon-covered.

- Shielded bearings: Lubricated and sealed to avoid friction sparks.

- Travel motor: Uses the same explosion-proof standards as the main lifting motor.

The trolley should roll smoothly and avoid hard stops.

Hooks and Safety Features

The hook carries the load—so it must be tough, safe, and spark-free.

- Material: Often forged steel with bronze coating.

- Safety latch: A spring-loaded tongue to prevent slipping.

- Swivel base: Allows 360° rotation without twisting the rope.

Double-check the load rating engraved on the hook.

Wire Rope Drum and Rope Guide

This is where the rope winds and unwinds. A poor design can cause tangling, jamming, or uneven wear.

- Drum design: Grooved to guide the rope evenly.

- Anti-jam system: Rope guide device keeps the rope in place.

- Anti-twist features: Important for heavy or fragile loads.

Tip: Some drums have a copper or aluminum cover to prevent sparks during contact.

Classification and Explosion-Proof Grades

Explosion-proof hoists must match the danger level of the environment. Not all hazardous areas are the same, so it's important to understand how they're classified.

Understanding Hazardous Zones

Hazardous areas are divided into zones. These zones describe how often explosive gases or vapors may be present.

- Zone 0 – Gas or vapor is present all the time or for long periods.

- Zone 1 – Gas is likely to appear during normal operation.

- Zone 2 – Gas is not likely to appear, but if it does, it won't stay long.

Most wire rope explosion-proof hoists are used in Zone 1 and Zone 2. For Zone 0, special custom-built equipment is usually required.

Tip: Before buying, ask your site safety team which zone the hoist will operate in.

Gas Groups and Temperature Classes

Different gases have different explosion risks. These are grouped by how easily they ignite.

Gas Groups:

- Group IIA – Less dangerous gases (e.g., propane)

- Group IIB – Medium-risk gases (e.g., ethylene)

- Group IIC – High-risk gases (e.g., hydrogen, acetylene)

Temperature Classes:

- Marked as T1 to T6, depending on the hoist's maximum surface temperature

- T4 is common for explosion-proof hoists – it means the surface will not exceed 135°C

If a gas can ignite at 135°C, the hoist must stay cooler than that. That's why T4-rated equipment is often used—it covers many gases safely.

Choosing the Right Explosion-Proof Grade

You might see labels like EX d IIB T4 or EX d IIC T4. Here's what they mean:

- EX d – "Flameproof enclosure" design. Any internal explosion is contained.

- IIB / IIC – The gas group. IIC is more demanding (for higher-risk gases).

- T4 – Temperature class. Max surface temp: 135°C.

EX d IIB T4:

- Suitable for Zone 1 and 2

- Safe for ethylene-type gases

- Standard for oil, gas, and chemical industries

EX d IIC T4:

- Also for Zone 1 and 2

- Can handle hydrogen or acetylene risks

- Required for high-risk gas zones

Rule of thumb:

If you're unsure, go one level higher in protection. It adds safety and may prevent rework if your zone classification ever changes.

Key Technical Parameters to Specify

Before you order a wire rope explosion-proof hoist, make sure you know the key technical specs. These details help you get the right hoist for your job—and avoid costly mistakes.

Lifting Capacity

This is the maximum weight your hoist can safely lift.

- Common ranges: 1 ton to 50 tons

- Always add a safety margin (especially if lifting irregular loads)

- For explosion-proof applications, oversized motors are sometimes used for extra safety

Tip: Never guess the load. Know the heaviest item your hoist will handle.

Lifting Height

How high do you need to lift?

- Measured from the ground to the hook's highest point

- Standard heights range from 6 to 30 meters or more

- Longer heights require longer wire ropes, which affect hoist size and cost

Note: Always confirm clearance space above the hoist, especially in low-headroom areas.

Lifting Speed and Travel Speed

Speed affects both safety and efficiency.

Lifting speed: How fast the hook moves up/down

- Common: 4 to 8 meters/minute

- Slower speed = more control

Travel speed: How fast the hoist or trolley moves along the beam

- Typically: 10 to 20 meters/minute

You can choose single speed or dual speed options, depending on how precise your work needs to be.

Power Supply

Explosion-proof hoists require stable and compatible power.

- Common voltages: 380V / 400V / 415V, 3-phase

- Frequency: 50 Hz or 60 Hz, depending on country

- Always check your local grid specs before ordering

Tip: Let your supplier know early if you need custom voltage (e.g., 440V 60Hz in some countries).

Control Method

How will the operator control the hoist?

- Pendant control: Wired remote hanging from the hoist (most common)

- Wireless remote: No cables; better flexibility and safety

- Control panel: Fixed control box, used for stationary or semi-automated systems

Some explosion-proof hoists can support multiple control methods.

Duty Class / Working Frequency

This tells you how often and how hard the hoist can work.

- Based on FEM / ISO or Chinese JB standards

- Light duty: for occasional use

- Medium duty: regular daily use

- Heavy duty: frequent and continuous use (e.g., shift work)

For example:

- FEM 2m / ISO M5 = medium-heavy use

- FEM 3m / ISO M6 = frequent use under full load

Important: Choosing the right duty class helps avoid overheating or motor failure.

Wire rope explosion proof hoist customized with large lifting height 40 meters and up to 70 meters

Heavy lifting explosion proof wire rope electric hoist with capacity of 40 ton, 25 ton for your referfence

Special Customizations for Hazardous Environments

In explosive or corrosive environments, standard equipment isn't enough. Small upgrades can make a big difference in both safety and long-term durability. These customizations are often requested for wire rope explosion-proof hoists working in harsh conditions.

Full Copper Wire Ropes and Limit Rods

- Why it matters: Steel rubbing on steel can create sparks.

- Copper-coated or full copper wire ropes reduce that risk.

- Limit rods (used in upper/lower limit switches) are often made of pure copper or brass for the same reason.

This is a simple, low-cost upgrade that adds real value in Zone 1 or Zone 2 applications.

Non-Sparking Materials

- Bronze-coated wheels

- Brass travel rollers

- Aluminum bronze or stainless steel hooks

These parts reduce the risk of impact sparks when the hoist is moving or lifting. It's especially useful in dusty or gas-filled environments.

Tip: Ask if all moving parts in the trolley or hook assembly are spark-resistant.

Anti-Condensation Heaters for Motors

In humid or coastal areas, condensation can form inside the motor.

- This causes internal rust, short circuits, and insulation breakdown.

- Anti-condensation heaters keep the motor dry and safe, even when not in use.

- Usually low-wattage and automatically controlled.

Good to know: These are standard for many explosion-proof hoists in Southeast Asia or offshore use.

Stainless Steel Control Enclosures

Standard control boxes may rust or corrode over time.

- 304 or 316 stainless steel enclosures resist corrosion and are easier to clean.

- Required in chemical plants, marine platforms, and food-grade facilities.

- Still built to EX d or EX e standards, with full explosion-proof certification.

Also protects sensitive electronics from chemical fumes or salty air.

Explosion-Proof Painting and Corrosion Protection

Protecting the outside is just as important as protecting the inside.

- Epoxy zinc-rich primers help block corrosion.

- Thick topcoats are applied to resist acid, oil, and salt spray.

- Coatings are usually rated to ISO 12944 or other marine-grade standards.

Best practice: Always request the dry film thickness (DFT) and paint spec sheet from the supplier.

Inspection and Maintenance Guidelines

Explosion-proof wire rope hoists are built for safety, but they still need proper care. Regular inspection and maintenance keep the equipment reliable and prevent dangerous failures in hazardous environments. This section helps you understand what to check, how often, and what records to keep.

Routine Inspection Checklist

These checks should be done daily or weekly depending on how often the hoist is used and the severity of the working environment:

- Visual check of the wire rope for wear, kinks, or broken strands

- Inspect motor housing and seals for cracks, oil leakage, or overheating signs

- Check that the control box is tightly sealed with no visible damage or moisture

- Confirm the limit switches and rods are working and trigger at the correct height

- Inspect travel wheels and rollers for abnormal noise, looseness, or visible wear

- Check that the hooks and safety latches are secure and not deformed

- Look at grounding and bonding connections to ensure they are not corroded or loose

In explosive zones, some of these may be required before each shift by safety rules or company policy.

Preventive Maintenance Schedule

Preventive maintenance helps avoid unexpected breakdowns. Follow a consistent schedule:

Every 1 to 3 Months:

- Lubricate the wire rope using flame-resistant, approved grease

- Tighten bolts and electrical terminals throughout the hoist

- Clean motor cooling vents and remove dust or debris

Every 6 Months:

- Test the emergency stop and both upper and lower limit switches

- Measure insulation resistance on motors to catch early faults

- Check and re-align hoist travel path if movement is irregular

Every 12 Months:

- Perform a full inspection of internal components if in heavy-duty use

- Replace any filters or breathers on sealed explosion-proof enclosures

- Re-apply or touch up anti-corrosion paint on any worn surfaces

Always refer to the specific maintenance manual provided by the hoist manufacturer for exact requirements, especially for explosion-proof components.

Replacement Intervals for Wire Ropes and Spark-Proof Components

Critical components need replacing on time to avoid risks. Don't wait for failure.

- Wire rope should be replaced if it loses 10% of its diameter or if you find broken wires

- Spark-resistant wheels (bronze or brass) should be changed if grooves wear out or sharp edges develop

- Hooks must be replaced if bent, cracked, or if the opening has widened

- Limit rods should be changed if they become bent, damaged, or loose

It's smart to keep a few spare parts on hand. Certified components for explosion-proof hoists can take time to ship.

Documentation and Compliance Logging

Keeping records is more than a good habit—it's a safety requirement in many industries.

- Inspection logs should include the inspection date, who performed it, and what was found

- Record any part replacements, including type, model, and serial numbers

- Store test or calibration results for electrical safety devices and motors

- Take photos if necessary, especially before and after repairs

- Maintain an explosion-proof compliance checklist signed by a qualified technician

Whether you use paper logs or digital tools, make sure records are complete and easy to access. Good documentation can also protect you during audits or after an incident.

Frequently Asked Questions (FAQ)

When it comes to explosion-proof wire rope hoists, many buyers have similar questions. Below are straightforward answers to some of the most common concerns.

Can I use a standard hoist with an explosion-proof motor?

No, that's not recommended.

An explosion-proof motor alone doesn't make the whole hoist safe for hazardous areas. Every component—control box, wiring, limit switches, and trolley—must also be explosion-proof and certified. Using a standard hoist with just an EX-rated motor creates a false sense of security and violates most safety codes.

If you're working in a Zone 1 or Zone 2 area, you need a fully explosion-proof hoist, not a partial one.

What is the difference between EX d and EX e motors?

These refer to different explosion protection methods:

- EX d means "flameproof enclosure." The motor is built to contain any internal explosion, so it won't ignite the external atmosphere. It's common in high-risk areas (Zone 1).

- EX e stands for "increased safety." It doesn't contain explosions but is designed to reduce the chance of sparks or high temperatures. Usually used in Zone 2 areas.

EX d offers higher protection but is heavier and more expensive. In many explosion-proof hoists, EX d motors are the standard choice.

How do I verify certification compliance?

Start by checking the labels on the hoist and key components. You should find:

- A clear EX marking, such as EX d IIB T4 Gb

- Certification numbers for ATEX, IECEx, or other relevant standards

- Name of the certifying body (like TÜV, CNEX, or SGS)

Also ask the supplier for:

- Full certificates of conformity

- Test reports from a third-party lab

- A declaration of explosion protection for the complete hoist system

Don't rely on verbal claims or vague paperwork. In hazardous environments, proper certification is not optional—it's critical for legal and operational safety.

Requesting a Quotation: What Information Should You Provide?

Getting the right explosion-proof wire rope hoist starts with giving the right information. If your request is too vague, you may get the wrong offer—or worse, a hoist that doesn't meet safety standards. This section outlines what you need to prepare to ensure fast, accurate, and reliable quotations.

A Checklist of Technical Specs to Prepare

When reaching out to suppliers, have the following specs ready:

- Lifting capacity (in tons or kilograms): How much weight the hoist needs to lift at once.

- Lifting height (in meters): The vertical distance the hook must travel.

- Lifting speed and travel speed (in m/min): Affects productivity and motor selection.

- Duty class or working frequency: How often the hoist will run (e.g., light, medium, or heavy-duty usage).

- Hoist type: Fixed, monorail, or double girder trolley.

- Mounting type: Top-running or underrunning.

- Power supply: Voltage, frequency, and phase (e.g., 380V/50Hz/3Ph).

- Control method: Pendant control, remote control, or local panel.

- Explosion-proof grade: For example, EX d IIB T4 or EX d IIC T4, depending on your hazardous zone.

- Certifications needed: Specify ATEX, IECEx, CNEX, or any local requirement.

These are the key specs most manufacturers need to start designing or selecting the correct model. The more complete your info, the faster the quote process.

Environment and Application Details

Explosion-proof hoists must match the working environment. Here's what else you should tell the supplier:

- Hazardous zone classification: Zone 1, Zone 2, etc.

- Type of hazardous material present: Gas, vapor, dust, or mixed.

- Gas group and temperature class: (e.g., IIB T4 or IIC T4).

- Indoor or outdoor installation: Affects protection level, painting, and covers.

- Ambient temperature range: Especially if it's extremely hot or cold.

- Installation height: If it's very high, transport and assembly method may need to be considered.

- Usage application: Tell the supplier if it's for oil refineries, chemical loading bays, paint shops, or fuel depots, etc.

- Humidity or moisture concerns: Useful for deciding if anti-condensation heaters or stainless steel enclosures are needed.

Giving this information up front helps the supplier suggest special materials, protection systems, or hoist configurations suited for your actual conditions.

Expected Lead Time and Documentation Requirements

Before placing an order, it helps to align expectations:

- Expected delivery date or project timeline: Some explosion-proof hoists are custom-built, and lead times can range from 4 to 12 weeks.

- Shipping preferences: Sea freight, air freight, or FOB/CIF terms.

- Destination port or country: Helps prepare export documents.

Required documents:

- Full explosion-proof certification documents (ATEX/IECEx/CNEX)

- Factory test reports (load testing, insulation testing, etc.)

- User manual and maintenance instructions

- Spare parts list

- Declaration of conformity

- Customs clearance documents, if needed

If your project requires third-party inspection (e.g., from SGS, BV, or TUV), mention this early so the supplier can schedule it in advance.

Conclusion

Choosing a wire rope explosion-proof hoist isn't just a technical decision—it's a critical part of keeping your site safe and your operations running smoothly.

These hoists are designed specifically for hazardous areas where gas, vapor, or dust can create explosion risks. With the right design, certified components, and proper installation, they help prevent dangerous accidents and ensure compliance with international safety standards.

Why It Matters

- Safety: Explosion-proof features protect both people and property.

- Performance: Wire rope models offer smoother, stronger lifting for heavy-duty jobs.

- Reliability: Certified systems are built to last, even in harsh environments.

The upfront investment in a well-designed explosion-proof hoist may be higher—but the long-term value in safety, uptime, and compliance is well worth it.

When safety is on the line, don't compromise. Work with trusted manufacturers, provide complete technical details, and always check for proper certifications.

If you're unsure where to start, feel free to reach out. A well-prepared inquiry can save you time and avoid costly mistakes down the road.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch