Explosion-Proof Electric Chain Hoists for Combustible Dust Zones

Safe, compliant lifting solutions customized for hazardous dust zones—ideal for industries requiring certified explosion-proof electric chain hoists.

Category: Explosion Proof Cranes

Your Trusted Explosion Proof Hoist Manufacturer & Supplier

Explosion-Proof Electric Chain Hoists for Combustible Dust Zones

Your Practical Guide to Safe, Compliant, and Customized Lifting Solutions

Explosion-proof chain hoists for dust explosive working environments are essential for safely handling loads in places where combustible dust is present. These hoists are specially designed to prevent sparks and overheating that could ignite dust clouds and cause serious accidents.

This guide explains what makes an electric chain hoist safe for dusty hazardous zones like Zone 21 and Zone 22. It covers how to select the right hoist, customize it for your unique needs, install it properly, and keep it well maintained.

The focus is on practical information that helps you meet safety regulations while improving the efficiency and reliability of your lifting operations. Whether you work in grain processing, chemical plants, wood mills, or pharmaceuticals, this guide provides clear steps to choose and use explosion-proof hoists safely.

Intended Audience

This guide is written for the key people involved in selecting, using, and caring for explosion-proof chain hoists in dusty, hazardous workplaces. Understanding who this guide helps can make it easier to apply the information correctly.

It is especially useful for:

- Procurement engineers who buy hoists for hazardous environments

- Safety managers who oversee workplace safety and compliance

- Maintenance teams responsible for upkeep and inspections

- Plant operators who use the hoists every day and need to understand safe operation

Key Insights You'll Gain

Knowing what to look for in an explosion-proof chain hoist and how to handle it on site is vital. This guide provides practical insights to help you make smart choices and keep your equipment running safely.

Here's what you'll learn:

- How to match the hoist to your dust zone and load requirements

- Which customization options fit specific challenges like low headroom or cleanroom use

- Safe installation practices that comply with industry standards

- Maintenance tips to keep hoists working reliably over time

- Understanding certifications that prove the hoist meets strict safety rules

Combustible Dust Hazards in Industrial Environments

In many industrial workplaces, combustible dust poses a hidden but serious threat. This dust can come from everyday materials—like grain, wood, or chemicals—but when it becomes airborne and meets a spark or heat source, it can lead to devastating fires or explosions. Understanding the nature of combustible dust, the risks involved, and how safety zones and regulations apply is key to choosing the right explosion-proof equipment.

Nature of Combustible Dust and Explosion Risks

Combustible dust consists of fine particles small enough to float in the air and mix with oxygen. When this dust cloud reaches a certain concentration and encounters an ignition source, the result can be a rapid combustion known as a dust explosion.

Key points about dust explosion hazards:

- Dust size matters: Particles smaller than 500 microns can ignite more easily because of their large surface area relative to volume.

- Dust layering: Dust can settle on surfaces, building up thick layers that may ignite later from a small spark.

- Ignition sources: Common ignition causes include static electricity, friction from moving machinery, hot surfaces, or electrical sparks.

- Explosion propagation: A small initial ignition can disturb more dust, causing secondary, often more destructive explosions.

- Pressure and damage: Dust explosions generate high pressure waves that can cause structural damage, fires, and serious injuries or fatalities.

Because of these dangers, industries handling combustible dust must take strict precautions to prevent dust cloud formation and control ignition sources.

Common Industries Impacted by Combustible Dust

Dust hazards are widespread across many sectors. The risk and dust characteristics vary by material and process:

- Grain and agriculture: Flour mills, feed plants, and grain elevators generate large amounts of organic dust. Dust can be airborne during unloading, grinding, or storage.

- Wood processing: Sawmills and furniture factories produce wood dust and sawdust, which is highly combustible and can easily accumulate.

- Pharmaceuticals: Manufacturing of powders and tablets creates fine dust particles, often in cleanroom environments requiring special equipment.

- Chemicals: Powdered chemicals, pigments, and resins can be combustible. Their dust may also be toxic or reactive.

- Cement and minerals: Grinding and mixing operations produce mineral dust that can be explosive and abrasive.

- Food processing: Sugar, starch, spices, and other powdered foods create dust that can ignite, especially in enclosed areas.

Each industry needs equipment specifically designed to handle dust safely, such as explosion-proof chain hoists that meet strict standards for these environments.

Zone Classifications Relevant to Dust: Zone 21 and Zone 22 Explained

Classifying areas by dust hazard helps determine what equipment can be safely used.

- Zone 21: This zone covers areas where combustible dust clouds are likely to be present during regular operations. Examples include inside processing equipment, near dust collectors, or in dust storage silos.

- Zone 22: This zone includes locations where combustible dust is not normally present but may appear occasionally or for short periods, such as near open containers or cleaning stations.

Equipment used in these zones must be designed to avoid creating any sparks, hot surfaces, or other ignition risks. The higher risk Zone 21 requires stricter protection measures than Zone 22.

Regulatory Frameworks: ATEX, IECEx, and GB Standards Overview

Various international and national standards set strict safety rules for equipment in dust hazardous zones:

- ATEX (Europe): This directive defines essential safety requirements for equipment and protective systems in explosive atmospheres. It categorizes equipment into groups and categories based on the type and frequency of explosion risk, including dust zones. Equipment must carry ATEX certification to be legally used in EU hazardous areas.

- IECEx (International): The IECEx system offers globally recognized certification for explosion protection. It ensures equipment meets international testing standards for dust and gas explosion risks, facilitating trade and compliance worldwide.

- GB Standards (China): China's national standards set technical requirements for explosion-proof equipment. These are mandatory for equipment used in Chinese hazardous zones and align closely with IEC standards.

Ignoring combustible dust risks can lead to costly accidents, plant shutdowns, and even loss of life. Using the right explosion-proof chain hoist for dusty environments reduces ignition sources and complies with safety rules. It also helps protect your investment by ensuring reliable operation in tough conditions.

What Makes an Electric Chain Hoist Explosion-Proof?

Explosion-proof electric chain hoists are designed to prevent sparks, hot spots, and dust from causing explosions. They have sealed motors and strong housings to keep sparks or flames inside.

Key Explosion-Proof Features

- Dust Ignition-Proof (tD): Blocks dust from entering and traps sparks inside.

- Flameproof Enclosure (d): Strong case that contains any explosion inside the hoist.

- Dust-Tight Design (IP65+): Keeps dust and water out of important parts.

Many hoists use a combination of these features for safety in dusty hazardous zones like Zone 21 and 22.

Core Components and Engineering Features

Explosion-proof electric chain hoists are designed with specialized components to ensure safety and reliable operation in dusty, hazardous environments. Let's break down the key parts that make these hoists safe and efficient.

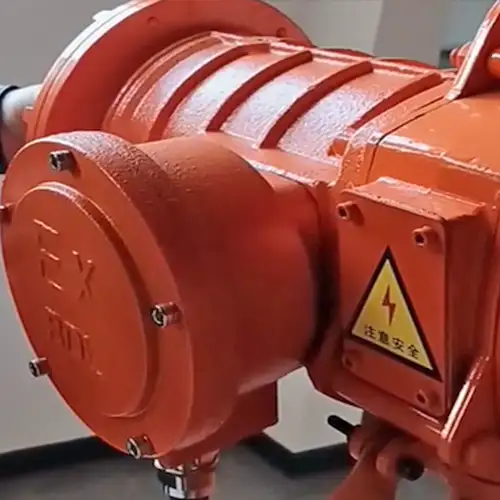

Explosion-Proof Motor

The motor is the heart of the hoist and must be protected carefully:

- Heavy-duty cast iron casing: Provides strong protection against impacts and contains any sparks inside the motor.

- Surface temperature limits: Typically rated at T135°C or lower to prevent igniting dust in the environment.

- Dust-proof sealed bearings and fans: These prevent dust ingress while allowing heat to dissipate, ensuring the motor runs cool and safely.

Explosion-Proof Electrical Enclosure

The electrical box houses vital controls and wiring. It's built tough to prevent any ignition risks:

- Flameproof and dust-tight design: The enclosure is sealed tightly and tested to contain any internal sparks or flames.

- Stainless steel fasteners: Corrosion-resistant screws and bolts improve durability and prevent rust that could weaken the enclosure.

- IP65 or higher rating: Ensures full protection against dust and water jets, keeping internal components safe.

- Integrated grounding and anti-corrosion coatings: These features enhance safety and extend equipment life in harsh factory conditions.

Explosion-Proof Pendant Control

Controls must also meet explosion-proof standards and be easy to use:

- Certified explosion-proof controls: The pendant switches are designed to prevent sparks and meet safety regulations.

- Ergonomic design: Buttons are sized and spaced for easy use, even while wearing work gloves.

- Wireless remote control options: Available for environments where pendant cables could collect dust or limit movement, adding convenience and safety.

Load Chain and Lifting Mechanism

The lifting parts are carefully engineered to reduce risks and improve performance:

- Nickel-plated or stainless steel chains: These materials resist corrosion and reduce static electricity buildup that could cause sparks.

- Dust-proof chain bags: Cover the load chain to keep dust away and minimize ignition hazards.

- Reliable mechanical brakes and load limiters: Ensure safe lifting and prevent overloads that could cause accidents or damage.

Every component is chosen and engineered to handle dusty, explosive environments safely while providing smooth, reliable operation. When selecting a hoist, check these features to match your plant's safety needs.

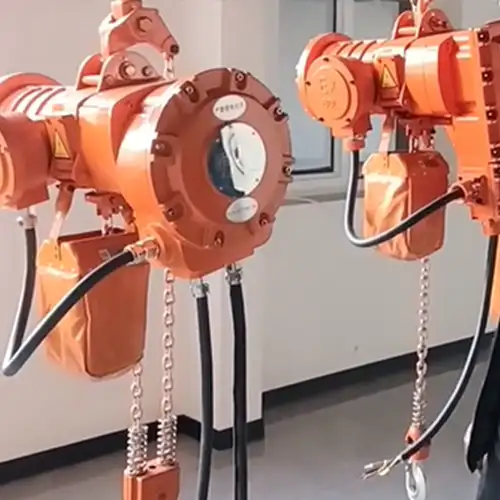

Explosion-proof electrical enclosure

explosion proof electrical cable connector

explosion proof pendant controller

Explosion proof chain fall

Material and Environmental Adaptations

To perform safely and reliably in harsh conditions, explosion-proof electric chain hoists must be built with suitable materials and protective features.

Housing Materials:

- Cast iron: Strong, durable, and excellent at containing explosions. Ideal for heavy industrial use.

- Copper-free aluminum: Lightweight and corrosion-resistant. Good choice where weight matters or easier handling is needed.

Ingress Protection (IP) Rating:

- High IP ratings (usually IP65 or above) guarantee the hoist is fully dust-tight and protected from water jets.

- This prevents dust and moisture from damaging internal components.

Corrosion Resistance:

- Protective coatings (such as powder coating or special paints) shield the hoist against rust and chemical corrosion.

- Essential for humid, marine, or chemically aggressive environments.

Anti-Condensation Heaters (Optional):

- Prevent moisture buildup inside the hoist caused by temperature changes.

- Help maintain dry internals, reduce corrosion risk, and improve electrical reliability.

Selecting proper materials and protections ensures your hoist stays safe and durable in tough industrial environments.

Customized Options for Specialized Applications

Explosion-proof chain hoists can be specially adapted to suit various unique industrial needs. These customized solutions help improve safety, efficiency, and fit within your specific environment.

Cleanroom Explosion-Proof Chain Hoists

For industries requiring extremely low contamination levels, such as pharmaceuticals and electronics, cleanroom explosion-proof hoists are essential.

- Features: Made from ultra-low contamination materials with smooth surfaces and minimal dust traps. Uses special cleanroom-grade lubricants to avoid particle pollution.

- Typical Applications: Clean manufacturing environments, pharmaceutical plants, semiconductor production, and laboratories where dust control is critical.

Low Headroom Explosion-Proof Hoists

When vertical space is limited, such as in older plants or compact facilities, low headroom hoists offer a practical solution.

- Features: Compact, space-saving design with customized trolley options to fit narrow crane beams and tight overhead spaces. Retains full explosion-proof certification despite reduced size.

- Typical Applications: Workshops with low ceilings, confined factory areas, retrofitting existing crane runways, and industrial plants with limited vertical clearance.

Heavy-Duty & High-Capacity Models

Heavy industries need hoists that can handle very large loads while maintaining explosion-proof safety.

- Features: Reinforced motors and mechanical components designed for lifting capacities up to 32 tons or more. Built to endure demanding industrial environments.

- Typical Applications: Steel mills, cement plants, petrochemical facilities, and other heavy industry sectors working in hazardous dust zones.

Wireless Remote Control Systems

Safety and convenience improve dramatically when operators can control hoists remotely, especially in hazardous zones.

- Features: Explosion-proof certified wireless remotes designed for safe, reliable operation from a distance, minimizing operator exposure to dangerous dust.

- Typical Applications: Dusty or confined environments where operator mobility is limited, large plant floors, and maintenance operations requiring remote control.

How to Select the Right Explosion-Proof Chain Hoist

Choosing the proper explosion-proof chain hoist is crucial for safety, performance, and compliance in hazardous dusty environments. The right hoist fits your workspace, meets your lifting needs, and follows safety regulations. Here's how to make an informed decision:

Confirm Hazardous Area Classification

The first step is to know your facility's hazardous dust zone. Typically, combustible dust areas are classified as Zone 21 (where dust clouds may occur occasionally) or Zone 22 (where dust clouds are unlikely but possible during abnormal conditions).

- Why it matters: Each zone requires specific explosion-proof features and certifications. Hoists for Zone 21 usually have stricter requirements than Zone 22.

- Tip: Consult safety engineers, hazard assessments, or regulatory bodies to determine your exact zone. Ensure the hoist carries appropriate GB or IECEx certifications for that zone.

Define Operational Requirements

Clearly specify the hoist's working parameters:

- Load Capacity: Know the maximum weight the hoist will lift. Include a safety margin of at least 10-20% to handle unexpected overloads.

- Lifting Height: Measure the vertical distance the hoist must cover, considering both minimum and maximum lift points.

- Duty Cycle: Determine how often and how long the hoist will operate daily. Continuous use requires heavier duty hoists designed for long hours.

- Tip: Overloading or undersizing the hoist can cause safety risks or costly downtime. Always match specifications closely to your actual workload.

Choose Mounting Method

Select the installation style that suits your crane system and work process:

- Hook Suspension: Simple and flexible, suitable for fixed overhead setups with limited mobility needs.

- Push Trolley: Allows manual horizontal movement along the beam, good for small workshops or light loads.

- Motorized Trolley: Provides powered movement, ideal for larger spans or frequent positioning in big plants.

- Tip: Consider beam size, runway configuration, and how much maneuverability operators need when choosing mounting.

Decide Control System

Choose how operators will control the hoist safely and effectively:

- Pendant Control: Wired and reliable, with buttons or switches for precise operation. Easy to use in confined or controlled environments.

- Wireless Remote Control: Explosion-proof certified remotes improve operator safety by enabling control from a distance, reducing exposure to hazardous dust zones.

- Tip: Factor in operator comfort, visibility, and plant layout. Wireless is great for wide or complex areas but requires reliable signal coverage.

Verify Power Supply and Installation Constraints

Ensure your facility's power and physical space support the hoist installation:

- Power Supply: Check voltage, current, phase, and frequency compatibility with the hoist's electrical design. Explosion-proof hoists require certified wiring and proper grounding.

- Installation Space: Measure crane runway dimensions, overhead clearance, and any obstacles. Confirm the hoist fits and can move freely without interference.

- Tip: Coordinate with your electrical and installation teams early to avoid surprises during setup. Verify local electrical codes and explosion-proof installation rules.

By thoroughly assessing these factors—hazard zone, operational needs, mounting, controls, and installation—you'll select a chain hoist that's safe, reliable, and efficient for your dusty hazardous environment.

Case Studies of Customized Solutions

Customizing explosion-proof electric chain hoists to fit specific industry needs can greatly enhance safety, reliability, and efficiency. Here are real-world examples from different sectors illustrating how tailored solutions solve unique challenges.

Pharmaceutical Cleanroom

Challenge:

Pharmaceutical manufacturing requires extremely clean environments where even tiny particles can contaminate products or processes.

Customized Solution:

- Hoist built with ultra-low contamination materials such as special stainless steel alloys and smooth, polished surfaces.

- Use of cleanroom-compatible lubricants that do not emit particles or harmful vapors.

- Designed with sealed joints and minimal dust traps to allow easy cleaning and sterilization.

Benefits:

- Maintains strict hygiene standards to meet regulatory requirements.

- Reduces downtime due to cleaning and contamination control.

- Ensures safe, explosion-proof operation in dust-sensitive areas.

Wood Processing Plant

Challenge:

Wood dust is highly combustible, and equipment must resist constant exposure to fine dust particles.

Customized Solution:

- Hoist with a dust-tight IP65 rated enclosure to prevent dust ingress.

- Stainless steel chain bag designed to resist corrosion and avoid sparks caused by dust accumulation.

- Robust explosion-proof electrical components meeting local GB and international standards.

Benefits:

- Minimizes fire and explosion risks in a high dust environment.

- Improves equipment longevity by protecting against dust and moisture.

- Provides reliable daily operation with minimal maintenance interruptions.

Grain Storage Facility

Challenge:

Grain dust is explosive and airborne, making operator safety a top priority.

Customized Solution:

- Explosion-proof hoist equipped with a wireless remote control to allow operation from a safe distance.

- Push trolley system for smooth horizontal movement across wide storage areas.

- Certified explosion-proof motor and electrical enclosures suitable for Zone 21 hazardous zones.

Benefits:

- Reduces operator exposure to dangerous dust clouds and confined spaces.

- Enhances operational flexibility by allowing easy load positioning.

- Complies with strict safety regulations, reducing liability and insurance costs.

How Customization Improves Safety, Reliability, and Efficiency

In each of these cases, customizing the explosion-proof hoist to meet the specific industry challenges led to:

- Increased Safety: Tailored features and certifications ensure compliance with hazardous area requirements and reduce risks of ignition.

- Higher Reliability: Appropriate materials and protection against dust and moisture extend equipment lifespan and reduce downtime.

- Operational Efficiency: Controls and mounting systems designed for each environment improve handling speed and operator comfort.

Custom solutions are not just about meeting regulations—they also bring practical benefits that help your facility run smoother and safer every day.

Why Choose Our Explosion-Proof Chain Hoists

Selecting the right supplier is just as important as choosing the right equipment. Our explosion-proof chain hoists are designed and manufactured to meet the highest industry standards, ensuring safety, reliability, and long-term value.

Advanced Manufacturing and Quality Assurance

We use state-of-the-art production facilities and strict quality control processes. Every hoist undergoes comprehensive testing to meet international safety and performance standards. Our products are certified with:

- CE (European Conformity)

- ISO (International Organization for Standardization)

- CNEX (China Explosion Protection Certification)

These certifications guarantee that our hoists are built to operate safely in hazardous, dust-prone environments.

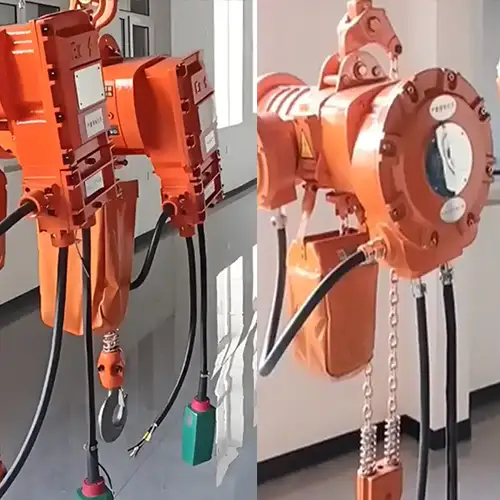

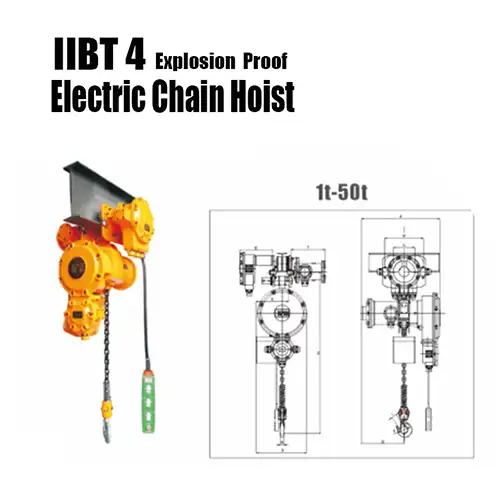

trolley mounted explosion proof electric chain hoist

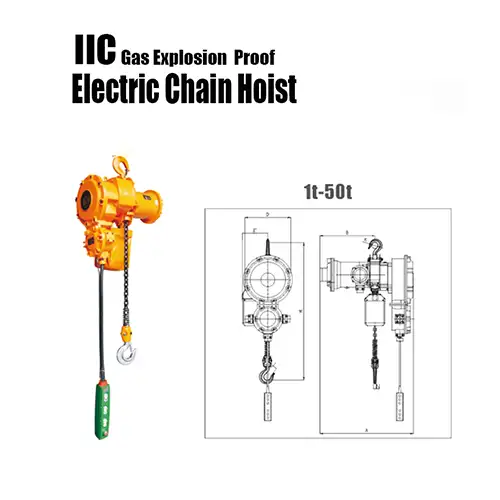

Hook mounted electric chain hois for material handling in explosive working environment

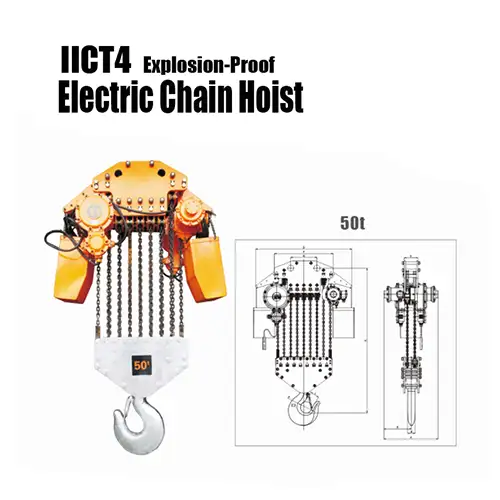

Heavy lifting llct4 explosion proof electric chain hoist

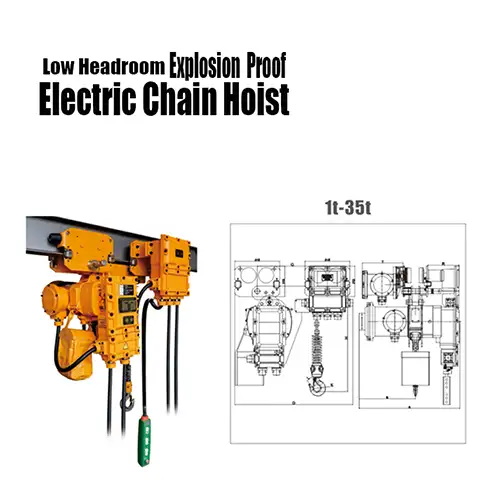

1 ton to 35 ton low headroom explosion proof electric chain hoist

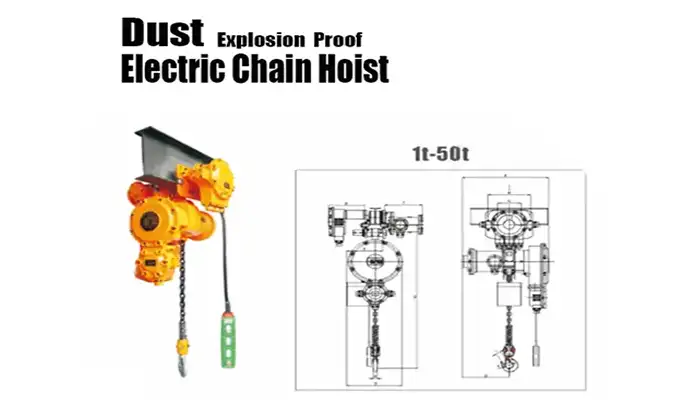

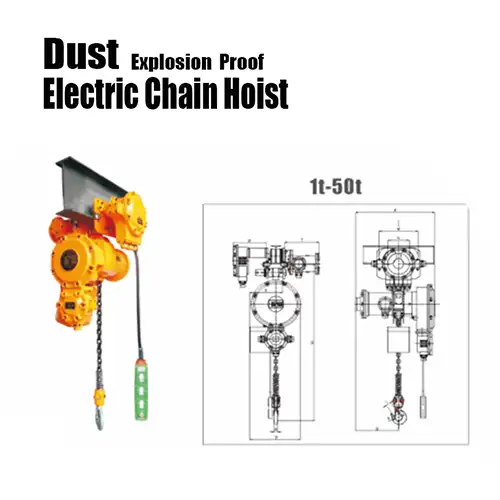

Explosion proof electric chain hoist 1 ton 50 ton for explosive dusty working environments

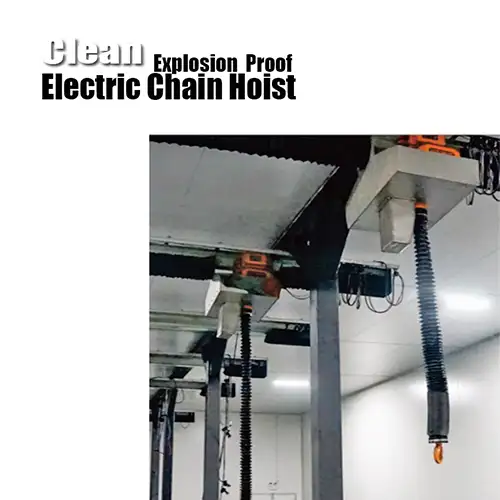

Explosion proof electric chain hoist for clean working environments

Extensive Customization to Fit Your Needs

We understand that every plant and application is unique. That's why we offer extensive customization options, including:

- Special materials and finishes for corrosive or cleanroom environments

- Low headroom designs for tight spaces

- Customized control systems (wired pendant or wireless remote)

- Tailored mounting solutions (hook, push trolley, motorized trolley)

Our engineering team works closely with you to design hoists that perfectly match your site conditions and operational requirements.

Proven Experience with Global Clients

With thousands of satisfied customers worldwide in industries like pharmaceuticals, grain storage, wood processing, and chemicals, we have a proven track record. Our hoists have been successfully deployed in challenging hazardous zones, demonstrating:

- High reliability under continuous use

- Compliance with local and international regulations

- Improved operational safety and efficiency

Responsive After-Sales Service and Support

Our commitment doesn't end at delivery. We provide:

- Fast and reliable spare parts supply to minimize downtime

- Technical support from experienced engineers to assist installation, maintenance, and troubleshooting

- Comprehensive training and guidance tailored to your team

This ensures your hoist stays in optimal condition and your operations run smoothly over the long term.

Choosing our explosion-proof chain hoists means investing in quality, safety, and a partner dedicated to your success in hazardous dusty environments.

Buyer's Checklist & Inquiry Preparation

Before contacting suppliers for an explosion-proof chain hoist, preparing clear and detailed information will help you get accurate quotes and suitable solutions. Use this checklist to gather the essential data.

Hazard Zone and Environment Classification

- Confirm if your working area is Zone 21 or Zone 22 for dust hazardous zones.

- Specify any additional environmental challenges like humidity, corrosive chemicals, or temperature extremes.

Required Hoist Capacity and Operational Parameters

- Provide the maximum load weight the hoist must handle, with a safety margin.

- Indicate the lifting height and typical duty cycle (how often and how long the hoist will be in use).

- Mention any special operational needs such as continuous use, slow lifting speeds, or precise load positioning.

Preferred Control Type and Mounting Method

- Choose your control system: wired pendant or wireless remote control (important for operator safety in hazardous areas).

- Specify the mounting method: hook suspension, push trolley, or motorized trolley depending on crane setup and workspace.

Site Power Supply Details and Installation Conditions

- Provide detailed electrical information: voltage, current, phase, and frequency.

- Describe the physical installation environment: crane runway dimensions, headroom clearance, and any space constraints.

Available Customization Requests

List any special customization requirements such as:

- Cleanroom compatibility for sterile environments

- Low headroom design for restricted vertical space

- Corrosion-resistant materials for humid or chemical exposure

- Specialized control options or additional safety features

By providing this information upfront, you enable suppliers to offer tailored, accurate, and cost-effective hoist solutions that meet your safety and operational needs.

Would you like a ready-to-use inquiry template based on this checklist?

| Category | Details to Provide | Notes / Examples |

|---|---|---|

| Hazard Zone and Environment | - Confirm Zone classification (Zone 21 or Zone 22) | - Mention any humidity, corrosive chemicals, temperature extremes |

| Hoist Capacity & Operational Parameters | - Maximum load weight (with safety margin) - Lifting height - Duty cycle (frequency & duration) | - Continuous use, slow speed, precise positioning |

| Control Type & Mounting Method | - Control system: wired pendant or wireless remote - Mounting: hook suspension, push trolley, motorized trolley | - Wireless for operator safety in hazardous areas |

| Power Supply & Installation Conditions | - Voltage, current, phase, frequency - Crane runway dimensions - Headroom and space constraints | - Ensure compatibility and ease of installation |

| Customization Requests | - Cleanroom compatibility - Low headroom design - Corrosion-resistant materials - Special controls or safety features | - Specify any extra needs to get tailored solutions |

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch