Your Trusted 50 Ton Overhead Bridge Crane Manufacturer & Supplier

50 Ton Overhead Crane for Sale, Affordable Overhead Crane Price

4 Popular Types of 50 Ton Overhead Cranes & Customized Industrial Overhead Crane Solution

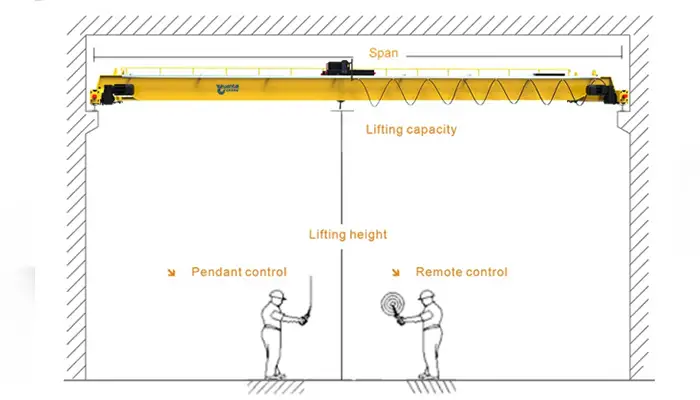

When your job involves lifting and moving 50 tons of material, you need equipment that's built for the task—no compromises. A 50 ton overhead crane is one of the most practical and reliable tools for handling large, heavy loads in industrial settings. It allows safe, efficient, and controlled movement of heavy parts or raw materials across workshops, yards, and production areas.

These cranes aren't just for lifting—they're part of the core workflow in many heavy industries. Whether it's a steel slab being moved in a rolling mill or a large mechanical part being assembled in a fabrication shop, the crane makes it possible.

Industries That Rely on 50 Ton Overhead Cranes

These cranes are commonly used across a wide range of sectors where loads regularly exceed 30 to 40 tons, and the handling must be both smooth and dependable.

- Steel plants and rolling mills – Handling hot slabs, coils, and billets

- Shipyards – Lifting engines, hull sections, or assemblies

- Machinery manufacturing – Moving large machine parts or equipment frames

- Power stations – Lifting turbines and heavy components during maintenance

- Furnace workshops and foundries – Feeding, lifting molds, and hot metal transport

- Construction and prefab plants – Moving structural steel, precast concrete, or assembly fixtures

Why This Guide Is Helpful for Crane Buyers

If you're currently searching for a 50 ton overhead crane or want to understand what makes one suitable for your facility, this guide will walk you through the practical details. From commonly used models and how they work, to tailored configurations for unique applications, we'll break down what matters when choosing the right crane.

- Learn which crane types fit your industry's needs

- See which features are standard, and what can be customized

- Understand the real-world benefits of each design

- Get guidance on how to choose and what to ask suppliers

Whether you're outfitting a new facility or replacing old equipment, having a clear picture of your crane options—and how they'll perform in your environment—can save time, money, and headaches later on.

Not all 50 ton overhead cranes are built the same. Depending on your workshop conditions, load handling frequency, and required precision, the right type of crane can make your workflow smoother—and more cost-efficient. Below are four widely used 50 ton crane models, each with its own strengths and ideal applications.

QD Series Overhead Crane (Hot-Sale Standard Model)

The QD type 50 ton ovehread crane is one of the most common heavy-duty overhead cranes used in factories and industrial workshops. It's built for strength, durability, and frequent use, making it a solid choice for general-purpose heavy lifting.

- Double girder design equipped with an open winch trolley, which allows larger lifting height and better stability.

- Capacity: Up to 550 tons, with 50 tons being a standard configuration.

- Span: 10.5 – 31.5 meters

- Lifting height: 6 – 24 meters

- Lifting: 2.1–11.5 m/min

- Trolley travel: 27–40 m/min

- Crane travel: 42–75 m/min

- Work duty: A3–A7 (depending on usage frequency and intensity)

Why choose QD double girder overhead crane ?

- Affordable for its class

- Rugged and reliable for daily operations

- Great for steel plants, heavy machinery shops, and large warehouses

LH Series 50 Ton Overhead Crane (Affordable Hoist Trolley Design) for Sale

If you're looking for something lighter in structure but still strong enough for 50 ton handling, the LH type is a practical, economical option. It's especially suited to workshops where space or floor load capacity is limited.

- Double girder crane with a wire rope hoist trolley, compact and simple in structure.

- Capacity: 5 – 63 tons (50 tons frequently applied)

- Span: 10.5 – 31.5 meters

- Lifting height: 6 – 30 meters

- Speed specs: Lifting: 0.18–8 m/min,Trolley & crane: 20 m/min,

- Work duty: A3–A4

Why choose LH overhead crane 50 ton ?

- Lower cost for lighter duty cycles

- Easier installation and maintenance

- Ideal for light manufacturing, assembly lines, and moderate material handling

QDX Series 50 Ton Overhead Crane for Sale (European Style Advanced Design)

Looking for smoother performance and energy efficiency? The QDX series is a modernized, European-style overhead crane with frequency conversion and a compact design. It uses an open winch trolley but with more precise motion control.

- Double girder compact structure, advanced layout with optimized headroom and wheel pressure

- Capacity: 5 – 320 tons (includes 50 ton configuration)

- Span: 10.5 – 31.5 meters

- Lifting height: 6 – 24 meters

- Speed specs: Lifting: 0.2–10.7 m/min, Trolley: 2.4–33 m/min, Crane: 4.2–68 m/min,

- Work duty: A3–A5

Why choose QDX bridge crane ?

- Smooth, quiet operation

- Energy-efficient with frequency conversion

- Compact and elegant, suitable for workshops with space constraints

- Stable load handling, ideal for machining workshops and precision material positioning

NLH Series 50 Ton Overhead Crane for Sale (European Style with Hoist Trolley)

The NLH type brings the benefits of European design and lighter dead weight, but with a hoist trolley instead of an open winch. It's perfect for buyers who want high performance in a slightly less intensive environment.

- Double girder construction with a compact trolley system

- Capacity: Up to 80 tons (50 ton configuration available)

- Span: 10.5 – 31.5 meters

- Lifting height: 6 – 18 meters

- Speed specs: Lifting: 0.4–5 m/min, Trolley: 2–20 m/min, Crane: 3–30 m/min,

- Work duty: A5

Why choose NLH electric hoist overhead crane ?

- Lightweight and efficient

- Smooth operation with advanced drive systems

- Ideal for indoor facilities with precise or automated workflows

- Good for lifting tasks requiring accurate positioning

Each of these four crane types serves different needs. Whether you need brute strength, refined motion, or a balance of both, there's a 50 ton overhead crane to match your application. If you're unsure which design fits your project best, reach out to a supplier with your working conditions, and they'll help guide you toward the right solution.

Typical and Optional Features of 50 Ton Overhead Cranes

A 50 ton overhead crane is more than just a lifting machine—it's a carefully engineered system designed to match your working environment, safety needs, and load handling precision. Depending on your application, you can choose from standard configurations or add features that better support your operation.

Standard Features You'll Find on Most 50 Ton Cranes

Most 50 ton cranes, especially in industrial settings, are designed for reliability, safety, and structural strength. The following features are typically included in standard builds:

- Double Girder Top Running Design: This setup provides maximum stability for heavy-duty lifting. The crane travels on top of elevated runways, making it suitable for long spans and high lifting heights.

Lifting Systems: Hoist Trolley or Open Winch Trolley

- Hoist trolley: Compact and cost-effective, ideal for standard duty conditions

- Open winch trolley: Heavy-duty and more customizable, used when higher lifting speeds or better precision are required

Work Duty Rating (A3–A7): Based on usage frequency and load intensity. Most standard cranes fall in the A5–A6 range for moderate to heavy use.

Optional Features to Match Special Working Conditions

Depending on your workspace and what you're lifting, optional features can make your crane safer, more flexible, or more productive.

Low Headroom Designs: For workshops or warehouses with limited ceiling space, a low-profile hoist and reduced beam height design can maximize lifting height even with vertical restrictions.

Explosion-Proof Options: In industries like mining, chemical processing, or paint shops, explosion-proof models are essential. These cranes are built with spark-resistant materials and sealed components to reduce ignition risk.

Automation-Ready Systems: Automation is becoming more common in heavy industry. 50 ton cranes can be outfitted for semi or full automation, allowing for:

- Repetitive, precise movement in production lines

- Safer remote operation

- Integration with MES systems and factory controls

High-Precision Speed Control and Anti-Sway Systems: Especially useful for delicate or dangerous loads, these features help maintain stability during movement.

- Variable frequency drive (VFD) enables smooth acceleration and deceleration

- Anti-sway control reduces pendulum movement for accurate placement

- Precision improves both efficiency and safety in tight or busy workspaces

Choosing the right mix of features depends on your actual usage, not just the crane's capacity. A workshop handling heavy steel all day will need a different configuration than a plant lifting occasionally but with strict space constraints. It's always smart to assess your lifting needs and talk to your supplier about what's necessary—and what's not—for your environment.

Typical Applications of 50 Ton Overhead Cranes

A 50 ton overhead crane isn't just a large piece of lifting equipment—it's a workhorse in many industries where handling heavy loads is a daily task. These cranes are designed to safely move large and bulky items that would be impossible or unsafe to lift manually or with smaller equipment. Let's take a closer look at where and how they're used.

Industries Using 50 Ton Cranes

A variety of industries depend on 50 ton overhead cranes to keep operations running efficiently. These cranes often form the backbone of material handling systems in facilities where weight and volume are non-negotiable.

- Steel Manufacturing and Rolling Mills: These cranes are used to move hot steel slabs, coils, ingots, and billets from production lines to cooling zones, storage, or processing stations. Some are also equipped with magnetic or grab attachments for handling scrap or finished products.

- Shipbuilding and Heavy Machinery Manufacturing: Lifting large sections of ship hulls, diesel engines, or machine housings is routine in these environments. A 50 ton crane helps maintain alignment and safety during assembly, welding, or transport.

- Construction and Power Plants: In construction yards or hydroelectric stations, these cranes handle heavy steel frames, turbines, concrete molds, or large generator parts. They're essential when precision and lifting power must go hand-in-hand.

- Mining, Metallurgical, and Furnace Industries: Whether feeding raw materials to furnaces or transporting molds and cast components, 50 ton cranes are widely used in the harsh and heat-intensive environments of smelters and foundries.

- Warehousing and Bulk Material Handling: In large-scale logistics operations, especially with materials like steel plates or fabricated goods, these cranes support quick and safe storage and dispatch activities.

Common Materials and Loads Handled

The loads these cranes move vary depending on the industry, but in general, they are built to handle large, dense, or awkward items that demand both strength and control.

- Steel Slabs, Billets, Coils, and Plates: These heavy metal products are often hot, uneven, or difficult to grip. Specialized attachments like magnetic lifters or clamps are used to handle them efficiently.

- Heavy Machinery Components: From engine blocks to fabricated frames, these loads are usually lifted during the production or assembly phase. Accurate positioning is key.

- Large Structural Steel Beams: Often used in construction or prefabrication yards, beams are long, heavy, and difficult to balance—making a 50 ton crane the safe and reliable choice.

- Bulk Materials with Grabs or Electromagnetic Devices: For operations dealing with scrap, waste, or ore, these cranes can be fitted with grapples or magnets to lift large volumes in each cycle.

In short, 50 ton overhead cranes are used where weight, volume, and safety meet. Whether you're in a steel plant or a manufacturing yard, they keep operations flowing and downtime low.

Your Trusted 50 Ton Bridge Crane Manufacturer & Supplier