50 Ton Overhead Crane for Sale, Heavy Lift Euro Open Winch Crane

European-style 50 ton overhead cranes with open winch trolleys, ideal for precision, safety & heavy lifting. Get your 50 ton overhead open winch crane!

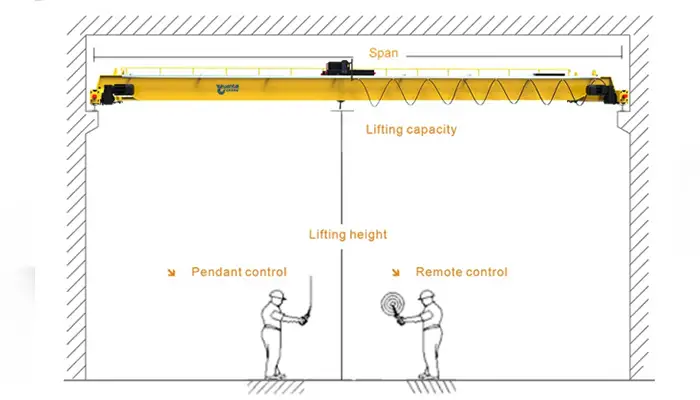

| Crane type | double girder overhead crane with open winch trolley |

| Crane span | 10.5-31.5m |

| Lifting height | As your request |

| Note | Customized solution provided. |

Category: 50 Ton Overhead Crane

Your Trusted Overhead Crane Manufacturer & Supplier

50 Ton Overhead Crane with European Open Winch for Sale

50 Ton Overhead Crane for Sale – European Open Winch Trolley for Heavy Lifting

If you need a reliable 50 ton overhead crane, buying directly from the manufacturer is your best option. It means you get a fair price without extra costs from middlemen.

Our cranes are built tough for heavy-duty jobs. They are widely used in steel plants, foundries, and machine workshops — places where lifting heavy loads safely and efficiently is critical.

When you choose us, you're not just buying equipment. You get full support from design to delivery. We work with you to customize the crane to fit your exact needs, whether it's lifting height, span, or special features.

To get started, simply share your project details with us. We'll help you with a tailored layout, technical advice, and a clear price quote — fast and hassle-free.

Why Choose a European-Style Open Winch 50 Ton Overhead Crane?

If you are searching for a reliable 50 ton overhead crane for sale, the European-style open winch crane stands out for many reasons.

First, its design is modular and compact, which means it fits well even in tight workshop spaces without sacrificing strength or safety.

The operation is smooth and precise thanks to frequency inverter controls. This lets you control lifting speeds easily, which is important when handling heavy and sensitive loads like steel coils, turbines, or large dies.

Mmain advantages of choosing this type of 50 ton overhead crane with European Style Open Winch :

- Space-saving, modular design that fits many factory layouts

- Smooth lifting and lowering with variable speed control

- Longer service life due to reduced mechanical wear

- Lower maintenance costs because of a robust, simple structure

- Ideal for heavy lifting tasks requiring precision and reliability

Compared to traditional hoist trolley cranes, the European open winch model offers better performance, longer lifespan, and less downtime.

For anyone looking to invest in a heavy-duty 50 ton overhead crane for sale, this design combines efficiency and durability in a proven package.

Main Specifications of 50Ton /10 Ton Overhead Crane with Open Winch for Sale

Lifting Capacity | t | 50/10 | ||||||||||

Span | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | |||

Lifting Height | Main Hook |

| 10 | |||||||||

Auxiliary Hook |

| 12 | ||||||||||

Speed | Main Hoist |

A5 |

m/min | 0.47-4.7 | ||||||||

Auxiliary Hoist | 0.53-5.3 | |||||||||||

Hoist Travelling | 2-20 | |||||||||||

Crane Travelling | 4-40 | |||||||||||

Motor Model | Main Hoist |

KW | YZPEJ280M-8/45/735 | |||||||||

Auxiliary Hoist | YZPEJ160M-4/11/1460 | |||||||||||

Hoist Travelling | YZPEJ100L,/2×2.2/1390 | |||||||||||

Crane Travelling | YZPEJ132S-4 | YZPEJ132M-4 | ||||||||||

Main Dimensions | H | 2304 | 2454 | 2458 | 2558 | 2558 | 2558 | 2560 | 2560 | |||

H1 | 894 | 1044 | 1048 | 148 | 1148 | 1148 | 1150 | 1150 | ||||

H2 | 140 | |||||||||||

H3 | 1184.5 | 1034.5 | 1030.5 | 930.5 | 930.5 | 930.5 | 928.5 | 928.5 | ||||

H4 | 994 | |||||||||||

h | 1410 | |||||||||||

K | 2500 | |||||||||||

B | 5700 | |||||||||||

W | 4700 | |||||||||||

Wc | 2800 | |||||||||||

b | 175 | |||||||||||

F | 99 | 124 | 128 | 178 | 328 | 478 | 628 | 730 | ||||

S1 | 1138.5 | |||||||||||

S2 | 2303.5 | |||||||||||

S3 | 1923.5 | |||||||||||

| S4 | 3088.5 | ||||||||||

Weight | Hoist | kg | 9441 | |||||||||

Total Weight | 20646 | 24007 | 27308 | 30922 | 34155 | 38345 | 41999 | 45894 | ||||

Maximum Wheel Pressure | KN | 143 | 159 | 168 | 176 | 182 | 190 | 196 | 203 | |||

Crane Total Power | KW | 82.4 | 90.4 | |||||||||

Recommended Crane Rail | 43Kg/m | |||||||||||

Power Supply | Three-Phase AC380V 50HZ | |||||||||||

Key Features of the 50 Ton Bridge Crane

When looking for a reliable 50 ton overhead crane for sale, understanding its key features can help you make the right choice. Our 50 ton bridge crane is designed with quality, safety, and durability in mind. Below are its main components and systems.

Open Winch Trolley System

The European style open winch trolley system is one of the standout features of this crane. It is designed to optimize the lifting height, giving you more working space under the hook without reducing the crane's capacity. The hook approach is minimized, allowing easier access to the load, which is especially useful in tight spaces.

This crane uses either dual-speed or stepless frequency-controlled hoisting motors. The frequency inverter ensures smooth, precise lifting and lowering, which protects your heavy and sensitive loads from shocks or jerks.

The integrated gearbox includes overload protection to stop lifting when the load exceeds safe limits. This safety feature prevents damage to the crane and enhances operator safety.

- Optimized lifting height to maximize working space

- Minimized hook approach for better load accessibility

- Dual-speed or stepless frequency inverter control for smooth operation

- Integrated gearbox with overload protection for safety

Heavy-Duty Components

To handle the heavy demands of a 50 ton overhead crane, the components are built to rigorous standards. Motors and reducers comply with DIN and FEM standards, ensuring high performance and durability.

The crane is equipped with oversized drums and high-strength wire ropes to safely carry heavy loads. Larger drums reduce wear on the wire rope, extending its lifespan and improving safety.

Hardened wheels are used to support the crane's movement along the runway. These wheels resist wear and deformation, which lowers maintenance costs and keeps the crane running smoothly for longer periods.

- Motors and reducers built to DIN/FEM standards for reliability

- Oversized drums to reduce wire rope wear and extend service life

- High-strength wire ropes for safe heavy lifting

- Hardened wheels designed for durability and smooth operation

Structural Design

The crane uses a double girder structure, typically constructed from box-beams or welded steel plates. This design provides excellent strength and stability needed to lift 50 tons safely.

Before manufacturing, the entire structure is analyzed using Finite Element Analysis (FEA). This ensures the crane can handle the stresses and loads expected during operation without deformation or failure.

The steel structure is coated with industrial-grade paint systems that protect against corrosion and wear. These coatings are suitable for both indoor and outdoor environments, ensuring the crane lasts even in harsh conditions.

- Double girder design for maximum strength and stability

- Box-beam or welded steel construction

- Strength verified through Finite Element Analysis (FEA)

- Industrial coatings for corrosion resistance and durability

Electrical and Safety Systems

The electrical system uses high-quality control panels from trusted brands such as Siemens or Schneider. These provide reliable and stable crane operation.

Safety is a priority, so the crane includes built-in overload limiters to prevent lifting beyond capacity. Travel limit switches automatically stop the crane and trolley at track ends, avoiding accidents.

Operators have options for control modes. Besides the standard pendant control, you can choose radio remote control for flexible operation or a cabin controller for improved visibility and comfort when handling large or complex loads.

- High-quality Siemens or Schneider control panels

- Overload limiters to ensure safe lifting loads

- Travel limit switches to prevent crane overrun

- Optional radio remote control or cabin operation for convenience

Applications and Industries

A 50 ton overhead crane is a versatile piece of equipment that serves many heavy-duty industries. Its strong lifting capacity and reliable performance make it ideal for a wide range of applications where handling heavy loads safely and efficiently is critical.

Below are some of the main industries and uses for this type of crane:

- Steel and Metal Processing Plants: In steel mills and metal fabrication facilities, these cranes are used to move heavy coils, slabs, and finished metal products. Their precision and power help maintain smooth production flow while ensuring worker safety.

- Foundries and Casting Facilities: Foundries rely on overhead cranes to transport heavy ladles of molten metal and large castings. The 50 ton capacity accommodates the weight of these materials while providing accurate handling to reduce risks.

- Power Station Turbine Maintenance: Maintaining turbines and heavy equipment in power plants often requires lifting very heavy components. The 50 ton overhead crane provides the strength and precision needed for safe disassembly and installation work.

- Heavy Machinery Assembly and Manufacturing: In factories producing large machinery or vehicles, this crane assists with moving bulky parts during assembly. Its reliability helps avoid production delays caused by lifting equipment failures.

- Shipbuilding and Marine Applications: Shipyards use these cranes to lift heavy ship components, such as engine parts and hull sections. Their robust construction and safety features are essential in this demanding environment.

- Large Mold Handling in Injection or Die Casting Industries: Manufacturing plants that use large molds benefit from the crane's ability to lift and position molds accurately and safely during the production cycle.

This broad range of applications highlights why the 50 ton overhead crane for sale is a popular choice across industries requiring dependable heavy lifting solutions.

Advantages of Buying Direct from Overhead Crane Manufacturer from China

When purchasing a 50 ton overhead crane, working directly with an experienced overhead crane manufacturer from China offers several important benefits. It not only helps reduce costs but also ensures better technical support, faster delivery, and greater flexibility in customization.

Here's what you gain by buying direct:

- Competitive Factory-Direct Pricing: Buying directly from the crane manufacturer eliminates the markup added by trading companies or agents. You get transparent pricing based on your actual specifications, with no hidden costs. This makes it easier to plan your budget and invest in better equipment without overpaying.

- Engineering Support and Custom Layout Design: Direct manufacturers typically have in-house technical teams that can assist with project planning, layout optimization, and structural integration. Whether you're installing a crane in an existing workshop or designing a new facility, this technical support ensures your 50 ton bridge crane fits correctly and functions efficiently.

- Availability of Spare Parts and Long-Term Technical Support: After-sales service is often stronger when you deal directly with the source. Spare parts are readily available, and the manufacturer can offer guidance for routine maintenance, repairs, and future upgrades. This reduces downtime and ensures your equipment stays reliable over the years.

- Streamlined Production and Faster Delivery Timelines: Working directly with a factory allows for quicker coordination and shorter lead times. From order confirmation to production and shipment, the process is more efficient. This is especially important for projects with tight schedules or urgent installation needs.

- Proven Export Experience with Clients in Over 60 Countries: Leading Chinese crane manufacturers have extensive export experience and understand the documentation, standards, and packaging required for international deliveries. Whether you're based in Southeast Asia, the Middle East, Africa, or Europe, they can ship and support your crane efficiently and professionally.

By partnering directly with a qualified overhead crane manufacturer from China, you get better value, tailored solutions, and dependable support throughout the entire lifecycle of your 50 ton overhead crane.

Optional Features for Your 50 Ton Overhead Crane

Every lifting operation has its own set of demands. That's why our 50 ton overhead cranes can be equipped with a variety of optional features to better suit your working environment, lifting precision, safety standards, and special requirements. These custom options enhance performance, improve operator safety, and help extend the service life of your crane.

Here are the most commonly selected upgrades:

- Explosion-Proof Components for Hazardous Areas: For operations involving flammable gases, dust, or chemicals, we offer explosion-proof motors, limit switches, and control panels. These are especially useful in petrochemical plants, paint workshops, or certain mining applications.

- Anti-Sway System for Improved Load Control: An anti-sway system reduces the swinging motion of the load during travel or sudden stops. This ensures safer, more precise placement of heavy items, which is especially important in narrow or congested spaces.

- Load Monitoring and Weighing Systems: Real-time load indicators help prevent overloading and allow operators to monitor lifted weights with precision. Optional integration with digital displays or wireless transmission can improve both safety and operational tracking.

- Service Platforms and Walkways for Maintenance: For cranes installed in areas where regular maintenance is needed, platforms and walkways can be added to the girder. These provide safe access to the hoist, motors, and control systems.

- Double Trolley or Dual-Hook Configurations: If your lifting tasks require handling long or uneven loads, two trolleys or dual hooks can be configured to operate independently or in sync. This setup improves balance and control when lifting large or complex objects.

- Weatherproof or Outdoor Adaptations: When your 50 ton bridge crane is used in outdoor environments, we can provide weather-resistant features such as IP55/65 rated motors, rain covers, rust-proof paint systems, and heated cabinets for cold regions.

These optional features are available based on your project's specific requirements. Let us know what kind of working conditions and lifting challenges you face, and we'll help configure the right setup for your 50 ton overhead crane.

Frequently Asked Questions (FAQs)

Before purchasing a 50 ton overhead crane, many buyers have common questions about pricing, design options, and usage environments. Here are answers to a few of the most frequently asked questions we receive.

What is the price of a 50 ton overhead crane?

The price of a 50 ton overhead crane varies depending on several factors, including:

- Span (the distance between the rails)

- Lifting height

- Duty class (how frequently and intensively the crane will be used)

- Customizations or optional features such as anti-sway systems, dual trolleys, or outdoor protections

Because these specifications affect both design and materials, it's difficult to provide a one-size-fits-all price. To receive an accurate quote, simply send us the basic requirements of your project, and we'll calculate everything based on your needs.

What's the difference between an open winch trolley and a standard hoist trolley?

This is a key question for buyers considering performance and long-term value.

- Open winch trolleys are built for heavy-duty use, offering higher precision, better load control, and longer service life. They're suitable for continuous lifting operations and large loads, like steel slabs, turbines, or foundry ladles.

- Standard hoist trolleys, while more economical, are typically used for light to medium duty lifting. They may not offer the same level of speed control, capacity, or durability over time.

If your operations involve frequent or heavy lifting, the open winch system is usually the better choice for a 50 ton bridge crane.

Can you customize the crane for outdoor or high-temperature environments?

Yes. We frequently design 50 ton overhead cranes for harsh working conditions, including outdoor use, high-temperature areas, and dusty or corrosive environments.

Available customizations include:

- IP-rated motors for dust and water resistance

- Rust-resistant or marine-grade paint systems

- Sun and rain covers for electrical cabinets and motors

- Heat-resistant hoist components for use near furnaces or casting lines

- Heated enclosures or dehumidifiers for cold or humid climates

Let us know the specific conditions in your facility, and we will design a crane to perform safely and reliably in that environment.

How to Request a Quote

If you're considering a 50 ton overhead crane for your facility, we're here to help you get a fast, accurate quote based on your exact requirements. To provide you with a tailored proposal and technical solution, we need a few basic details about your project.

What Information Should You Prepare?

The more specific your input, the more accurate and cost-effective your crane solution will be. Before reaching out, please prepare the following:

- Crane span and lifting height: Specify the distance between crane rails and the required hook height from the floor.

- Application type and working frequency: Let us know what the crane will be used for, and how often it will operate each day.

- Duty classification and lifting environment: Indicate the required duty group (A5, A6, A7, etc.) and any special conditions like high temperature, outdoor use, or dusty environments.

- Power supply requirement: Provide voltage, phase, and frequency. For example, 380V/3Ph/50Hz or any other local standard.

- Installation conditions: Tell us whether this is a new workshop or a retrofit project, and whether runway beams are already in place or need to be included.

How to Send Your Inquiry

You can submit your crane inquiry in several convenient ways:

- Email us directly with your specs, project drawings, or photos

- Use our online inquiry form to fill in standard fields

- Upload your layout drawings or technical documents to help us design around your space

Once we receive your details, our engineering and sales team will evaluate your project and respond with a complete quotation and crane layout—typically within 24 hours.

Case Studies and Customer Projects

Seeing how others use their 50 ton overhead crane can give you a clearer idea of what to expect — and what's possible — for your own project. Below are real examples of installations completed for international clients with varying needs and environments.

Saudi Arabia: Steel Rolling Mill Project

We supplied and installed a 50 ton European-style open winch overhead crane for a leading steel rolling mill in Saudi Arabia.

- Crane Type: Double girder bridge crane with open winch trolley

- Span: 22 meters

- Lifting Height: 16 meters

- Duty Class: A7 (for intensive, continuous operation)

- Environment: High-temperature indoor plant, operating 24/7

- Result: The crane provided smooth and reliable operation, handling heavy steel coils in a demanding production cycle.

Additional Projects Include:

- Vietnam: 50 ton bridge crane for heavy machinery assembly in a state-owned factory.

- Egypt: Open winch crane with dual-trolley system used for turbine maintenance in a hydroelectric power station.

- Bangladesh: Outdoor overhead crane with weatherproof components used for shipyard part handling.

- Pakistan: Retrofit crane system integrated into an existing steel structure with limited clearance.

We have delivered custom lifting solutions to over 60 countries worldwide. If needed, we can provide photos, video walkthroughs, or layout drawings from past projects to help you plan your own crane system more effectively.

Contact us to Get Your Customized 50 Ton Open Winch Overhead Cranes

Start your 50 ton overhead crane project with confidence. Whether you're expanding production, upgrading equipment, or building a new facility, we'll help you design the right crane solution from the ground up.

Here's how we support you:

- Technical consultation to understand your lifting needs

- Custom crane layout and design drawings

- Factory-direct pricing and clear delivery timelines

- Full documentation and export support

- Long-term after-sales service and spare parts availability

Let's build your next crane together.

Contact us today to request a detailed quote, share your layout, or speak with a crane engineer. Our team is ready to support your project from consultation to commissioning.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch