50/10 Ton Overhead Crane Specs & Dimensions, European Open Winch

50 /10 ton overhead crane for sale. Detailed specs and dimensions for open winch double girder cranes with 50/10 ton capacity, ideal for heavy lifting.

Category: 50 Ton Overhead Crane

Your Trusted Overhead Crane Manufacturer & Supplier

50/10 Ton Overhead Crane Specifications & Dimensions

Complete Guide to European Style Open Winch Double Girder Overhead Crane 50 Ton Design

When you're dealing with heavy lifting in an industrial setting, choosing the right overhead crane isn't just about load capacity—it's about how well it fits your workflow, building layout, and long-term usage. The 50/10 ton overhead crane is a double-girder bridge crane equipped with both a main and auxiliary open winch trolley. It's designed for heavy-duty tasks that demand high precision, consistent operation, and safe control of large or awkward loads.

This type of crane is widely used in industries such as steel processing, foundries, turbine handling, power station maintenance, and large-scale machinery manufacturing. Whether you're lifting heavy dies, coils, or rotating equipment, the combination of a 50-ton main hook and a 10-ton auxiliary hook gives you the flexibility to handle various lifting jobs efficiently.

Why focus on the open winch trolley design?

- Smooth and precise operation under variable speeds thanks to frequency-controlled motors

- Longer service life due to robust mechanical components and modular build

- Better accessibility for maintenance with walkways and clear gear layout

- Dual-hook system enables simultaneous or independent lifting for complex operations

The full specifications and dimensions of a 50 ton overhead crane is critical when planning your installation. It's not just about lifting capacity—it's also about hook approach, lifting height, span, runway layout, and power supply. These details affect everything from your building structure to workflow efficiency and long-term maintenance.

50/10 Ton Overhead Crane Overview

The 50/10 ton overhead crane is built as a double girder bridge crane fitted with an open winch trolley system—a setup well-suited for heavy lifting, long-term use, and demanding environments. This type of configuration provides more lifting precision, smoother control, and better maintenance access compared to standard wire rope hoist designs.

In this model, the main and auxiliary winches are mounted on a robust trolley frame that travels along the top of both girders. The main hook is rated for 50 tons, while the auxiliary hook handles 10 tons. Together, they cover a wide range of lifting needs in workshops that deal with large components or need extra flexibility during assembly or maintenance.

Standards Specifications of 50 Ton/10 Ton Overhead Cranes

Lifting Capacity | t | 50/10 | ||||||||||

Span | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | |||

Lifting Height | Main Hook |

| 10 | |||||||||

Auxiliary Hook |

| 12 | ||||||||||

Speed | Main Hoist |

A5 |

m/min | 0.47-4.7 | ||||||||

Auxiliary Hoist | 0.53-5.3 | |||||||||||

Hoist Travelling | 2-20 | |||||||||||

Crane Travelling | 4-40 | |||||||||||

Motor Model | Main Hoist |

KW | YZPEJ280M-8/45/735 | |||||||||

Auxiliary Hoist | YZPEJ160M-4/11/1460 | |||||||||||

Hoist Travelling | YZPEJ100L,/2×2.2/1390 | |||||||||||

Crane Travelling | YZPEJ132S-4 | YZPEJ132M-4 | ||||||||||

Main Dimensions | H | 1394 | 1544 | 1548 | 1648 | 1648 | 1648 | 1650 | 1650 | |||

H1 | 894 | 1044 | 1048 | 1148 | 1148 | 1148 | 1150 | 1150 | ||||

H2 | 140 | |||||||||||

H3 | 1184.5 | 1034.5 | 1030.5 | 930.5 | 930.5 | 930.5 | 928.5 | 928.5 | ||||

H4 | 994 | |||||||||||

h | 1410 | |||||||||||

K | 2500 | |||||||||||

B | 5700 | |||||||||||

W | 4700 | |||||||||||

Wc | 2800 | |||||||||||

b | 175 | |||||||||||

F | 99 | 124 | 128 | 178 | 328 | 478 | 628 | 730 | ||||

S1 | 1138.5 | |||||||||||

S2 | 2303.5 | |||||||||||

S3 | 1923.5 | |||||||||||

| S4 | 3088.5 | ||||||||||

Weight | Hoist | kg | 9441 | |||||||||

Total Weight | 20646 | 24007 | 27308 | 30922 | 34155 | 38345 | 41999 | 45894 | ||||

Maximum Wheel Pressure | KN | 143 | 159 | 168 | 176 | 182 | 190 | 196 | 203 | |||

Crane Total Power | KW | 82.4 | 90.4 | |||||||||

Recommended Crane Rail | 43Kg/m | |||||||||||

Power Supply | Three-Phase AC380V 50HZ | |||||||||||

Low Headroom Design 50 Ton/10 Ton Overhead Crane with Open Winch Trolley

Lifting Capacity (t) | 50/10 | ||||||||

Span S(m) | 10.5 | 13.5 | 16.5 | 19.5 | 225 | 25.5 | 28.5 | 31.5 | |

Lifting Height(m) | 16/18 | ||||||||

Working Duty | A6 | ||||||||

Lifting Speed(m/ min | Main Hook0.4-4Auxiliary Hook0.81-8.1 | ||||||||

HoistRunning Speed | 2.9-29 | ||||||||

CraneRunning Speed | 5.4-54 | 4.8-48 | |||||||

Basic Parameters | b | 192 | |||||||

H1 | 229 | 070 | 481 | 681 | 701 | 303 |

| 100 | |

H2 | 709 | 711 | 791 | 793 | |||||

H3 | 42744 | 28463046 | 6 | 3168 |

| 3368 | |||

H4 | 1959 | 196 | 204 | 2043 | |||||

H5 | 691 | 689 | 609 | 607 | |||||

H6 | 405 | ||||||||

H0 | 450 | ||||||||

L | 6592 | 6792 | |||||||

L1 | 4900 | 5100 | |||||||

L2 | 2000 | 2100 | |||||||

L3 | 446 | ||||||||

L4 | 1246 | ||||||||

L5 | 1379 | ||||||||

K | 900 | ||||||||

C | 1070 | ||||||||

C1 | 1020 | ||||||||

C2 | 2140 | ||||||||

Lk | 3000 | ||||||||

W | 2800 | ||||||||

Weight(kg) | Hoist | 10734 | |||||||

Crane | 2504327746 | 31299 | 34676 |

| 43343 | 478665168 | |||

Recommended Crane Rail | QU70 | ||||||||

Total Power(kw) | 72.5 | ||||||||

Maximum Wheel Pressure (KN) | 156 | 163 | 170 | 76 | 82 | 88 | 195 | 200 | |

Note: The specifications and data shared in this article are for reference only. If you have specific requirements or need detailed information, please feel free to contact us. We are here to provide personalized support and accurate solutions tailored to your needs.

Working Duty Classes

You can select the working class based on how frequently the crane will operate and under what conditions.

- A5 duty is recommended for general heavy-duty work—ideal for 1–2 shift operations or periodic high-load lifting.

- A6 duty is better suited for facilities with more continuous operation, higher lifting cycles, or more demanding workflows.

Choosing the right duty class not only affects component durability but also ensures you don't overspend on performance you don't need—or worse, underbuild for a job that requires more.

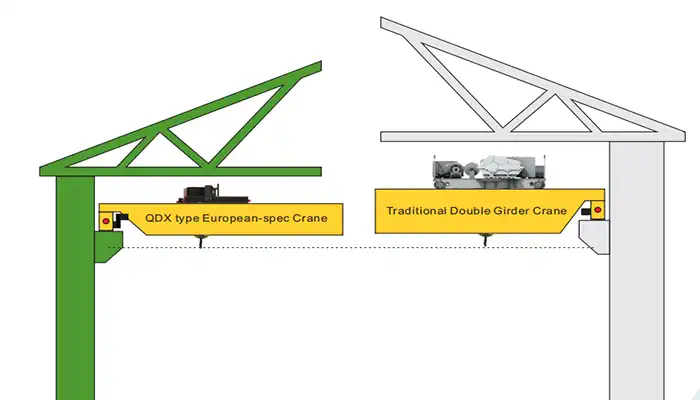

To fit a variety of building layouts, two configurations are offered:

- Standard headroom open winch crane design is used in workshops with ample vertical space. It provides straightforward installation and maintenance access.

- Low headroom open winch crane design minimizes the overall height of the crane, making it perfect for existing buildings with ceiling height restrictions or retrofit projects.

Main Hook and Auxiliary Hook, Dual Hook Usage

Each hook serves a distinct role in daily operation:

- The 50-ton main hook is intended for your primary lifting tasks—heavy molds, steel coils, turbines, or structural components.

- The 10-ton auxiliary hook is used for load positioning, handling smaller attachments, or assisting in tandem lifts where more control is needed.

This dual-hook setup saves time, increases flexibility, and reduces the need for additional lifting equipment on-site.

Lifting Capacity and Hook Configuration

The core strength of this overhead crane lies in its dual-hook setup. The main hook is rated at 50 tons, ready to handle your heaviest and most demanding loads. Meanwhile, the auxiliary hook, rated at 10 tons, offers added versatility for lighter lifts or load positioning.

This combination is designed specifically for heavy industries where flexibility and precision matter. It allows operators to switch between tasks quickly without needing to change equipment, saving time and improving workflow efficiency.

Why choose a dual-hook system?

- Load stability: Using the auxiliary hook can help balance loads during complex lifts or assist in carefully positioning heavy items.

- Maintenance lifting: The smaller hook is ideal for lifting equipment parts during crane maintenance or assembly line setups without interrupting main production lifts.

- Complex assembly: When working with multi-component loads, having two hooks lets you lift and maneuver parts independently or together, improving safety and precision.

This practical approach to lifting means your facility can handle a wider variety of tasks with fewer interruptions or equipment swaps, making the crane a real asset in your daily operations.

Available Span and Lifting Heights

When choosing an overhead crane, getting the right span and lifting height is just as important as selecting the lifting capacity. These dimensions determine how well the crane fits your workspace and how effectively it can handle your loads.

Span Options

The 50/10 ton overhead crane offers a range of standard spans from 10.5 meters up to 31.5 meters. This wide range allows the crane to fit small workshops as well as large industrial halls.

- Shorter spans (around 10.5 to 16.5 meters) work well for compact facilities with limited floor space.

- Longer spans (22.5 to 31.5 meters) are suitable for wider buildings, offering greater coverage and more flexibility in material handling.

Lifting Heights

Lifting height depends on the working duty class and the type of hook used:

- For the A5 duty design, the main hook lifts up to 10 meters, while the auxiliary hook reaches 12 meters.

- The A6 duty design—built for more frequent or intense operation—offers a higher lift: 16 meters for the main hook and 18 meters for the auxiliary.

Key Considerations for Span Selection

- Building width: The crane span should match the clear distance between runway rails inside your facility.

- Runway structure: Existing beams and supports may limit or determine your maximum span.

- Work process: Consider whether you need full coverage of the workspace or just partial span for specific tasks.

- Future expansion: If you anticipate growing operations, choosing a slightly longer span can save costly upgrades later.

Choosing the right span and lifting height ensures smooth crane operation without risking collisions or wasted space. In the next section, we'll cover lifting and travelling speeds to help you understand the crane's performance on the move.

Lifting and Travelling Speeds

The lifting and travelling speeds of an overhead crane have a direct impact on productivity and safety. The 50/10 ton overhead crane is designed with variable speeds to suit different lifting needs and operating conditions.

Lifting Speeds by Duty Class

For the A5 duty crane, which is suited for medium-heavy usage, the lifting speeds are as follows:

- Main hoist: 0.47 to 4.7 meters per minute

- Auxiliary hoist: 0.53 to 5.3 meters per minute

For more intensive operations under the A6 duty class, the speeds increase slightly to accommodate higher lifting cycles:

- Main hoist: 0.4 to 4.0 meters per minute

- Auxiliary hoist: 0.81 to 8.1 meters per minute

These speed ranges allow operators to switch between slow, precise movements for careful load positioning and faster lifts when moving loads vertically.

Travelling Speeds for Trolley and Crane

- Trolley travel speed: Typically ranges from 2 to 29 meters per minute, depending on the crane model and duty class.

- Crane travel speed: Varies between 4 and 54 meters per minute, providing flexibility for moving heavy loads across longer distances efficiently.

Smooth Operation with Frequency Inverter Technology

The crane motors are equipped with frequency inverter controls, which play a crucial role in:

- Allowing smooth acceleration and deceleration

- Reducing mechanical stress and wear

- Enhancing precise positioning of the load

- Improving overall operator control and safety

This technology not only extends the lifespan of the crane components but also helps maintain steady workflow with minimal downtime.

Motor Configuration

The 50/10 ton overhead crane uses reliable YZPEJ series motors designed specifically for smooth, variable frequency control. These motors help the crane achieve precise speed adjustment and energy-efficient operation.

- The main hoist motor delivers 45 kW of power, built to handle heavy loads consistently.

- The auxiliary hoist motor provides 11 kW, perfect for lighter lifts and positioning tasks.

- The trolley drive system uses dual motors, each rated at 2.2 kW, ensuring stable and balanced movement along the girders.

- Crane travelling motors vary depending on the span and load capacity, tailored to meet the specific performance requirements of your facility.

All motors are optimized for long service life and reliable operation under continuous industrial use, helping reduce downtime and maintenance costs.

Main Dimensions and Clearances

Understanding the crane's physical dimensions is key to ensuring it fits your workshop and operates safely.

- The overall height (H), trolley clearance heights (H1 to H6), and hook approach distances are precisely calculated for each available span.

- For buildings with limited vertical space, compact low headroom versions are available to maximize lifting capacity without compromising safety.

- Important width dimensions include the bridge width (B) and trolley width (W), which influence how the crane moves within your facility.

Knowing these measurements ahead of time helps you plan the crane runway and ensures the crane travels smoothly without any obstructions.

Weight, Wheel Load, and Power Consumption

The crane's weight and wheel load specifications impact structural requirements and energy use.

- The hoist itself weighs between 9,441 and 10,734 kilograms, depending on the model.

- Total crane weight ranges from around 20,600 kg to over 45,000 kg based on span and configuration.

- Maximum wheel pressures vary from 143 kN up to 203 kN for A5 cranes, and around 200 kN for A6 cranes. This affects the runway beam design and foundation requirements.

- Total installed power for the entire crane system typically falls between 72.5 kW and 90.4 kW.

- Recommended crane rails are 43 kg/m for A5 cranes and QU70 rails for heavier-duty A6 models.

These details are crucial when coordinating with civil and electrical engineers during the installation phase.

Power Supply and Environmental Adaptability

Standard cranes operate on three-phase AC 380V, 50Hz power supply, which fits most industrial environments globally.

- For specific regional requirements, custom voltages and frequencies can be provided.

- The crane's design can be adapted for harsh environments—whether it's extreme heat, outdoor weather exposure, or corrosive atmospheres.

- Protective coatings, sealed motor enclosures, and explosion-proof options ensure reliable operation even under challenging conditions.

This flexibility makes the crane a solid choice for a wide range of industries and geographies.

Selection Tips and Project Planning

Choosing the right crane means balancing your operational needs with technical specifications.

- If your operation involves medium-duty, less frequent lifts, the A5 duty crane is usually sufficient.

- For facilities with continuous heavy lifting or high-frequency cycles, the A6 duty class offers the durability and performance you need.

- Think about your lifting cycles, materials handled, and the span you require before finalizing specs.

- Lifting height and hook configuration should match your plant layout and load types.

- If ceiling height is limited, consider the low headroom design to maximize usable space.

- Whether it's a new facility or a retrofit, coordinate closely with your civil engineers to ensure proper runway beam support and crane installation.

Planning ahead saves time, reduces costs, and ensures the crane performs reliably for years.

Conclusion and Send An Inquiry

The 50/10 ton overhead crane is a versatile, durable solution designed for precision and heavy industrial use. With its open winch trolley, dual hooks, and flexible configurations, it meets a wide variety of lifting needs.

If you're considering this crane, reach out to the manufacturer for:

- Customized layout drawings

- Detailed pricing based on your specifications

- Technical consultation tailored to your facility

Fast, professional quotations and expert advice are available to help you move your project forward confidently.

Please note: All specifications and data provided are for reference purposes only. For any specific requirements or questions, please feel free to contact us. We are always ready to assist you with personalized solutions.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch