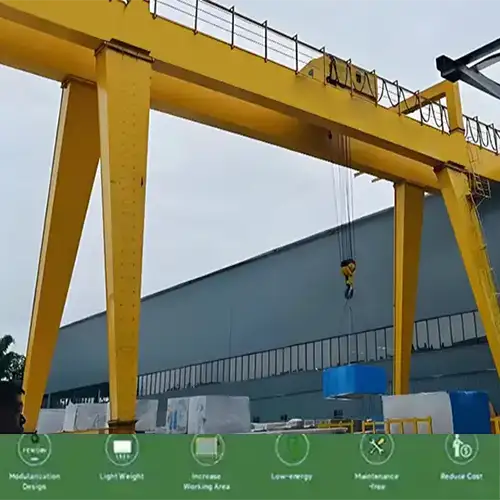

10 Ton to 40 Ton Gantry Cranes for Marble, Stone & Granite Yards

10 ton to 40 ton gantry cranes for outdoor marble, stone, &granite yards. Tailored 40 ton gantry crans for outdoor use & indoor use. Get your solution!

| Crane Type | double girder gantry crane |

| Crane Hoisty System | Electric hoist trolley or open winch trolley |

| Lifting Height | Customized. |

| Crane Span | Customized |

Category: 40 Ton Gantry Crane

Your Trusted Overhead Gantry Crane Manufacturer & Supplier

10 Ton to 40 Ton Gantry Cranes for Marble, Stone & Granite Yards

Good Price, Double Rail Crab Trolley for Crab Crane

10 ton to 40 ton gantry cranes for outdoor marble, stone, &granite yards. Tailored 40 ton gantry crans for outdoor use & indoor use. Get your solution!

Introduction

Stone processing — whether marble, granite, or other natural stones — is a complex and physically demanding industry. Across the world, yards range from small workshops to massive outdoor processing facilities. Countries like China, India, Turkey, Italy, and Brazil dominate production and processing, while new markets continue to grow as construction and export demand rises. The materials themselves are heavy, bulky, and irregular in shape, making efficient handling a challenge.

Why Outdoor Gantry Cranes Are Essential

Handling large stone blocks manually or with smaller machines is slow, inefficient, and unsafe. Outdoor gantry cranes solve these problems by providing:

- Wide coverage: Move blocks across long spans of the yard without rearranging equipment.

- Weather resistance: Built to operate safely in rain, sun, and dust.

- Precise lifting: Lift, position, and stack blocks without damaging the material.

- Safety: Reduce the risk of accidents caused by manual handling or forklifts.

Gantry cranes allow operators to work faster and safer, which is crucial in yards dealing with heavy stone and granite blocks every day.

Typical Lifting Capacities

Most stone processing yards use gantry cranes with lifting capacities ranging from 10 tons to 40 tons, depending on the material and block size. Here's a practical breakdown:

- 10 Ton to 15 tons: Small to medium marble or decorative stone blocks; common in workshops or smaller yards.

- 20 Ton to 25 tons: Medium to large marble and granite blocks; standard in most commercial stone processing yards.

- 30 Ton, 32 Ton to 40 tons: Heavy granite or export-sized blocks; used in large yards or shipping terminals.

Choosing the right capacity is not just about numbers. It's about understanding block weight, density, yard layout, and daily handling volume. Picking the correct crane ensures safer operation, reduces downtime, and improves productivity across the yard.

Why Stone Processing Yards Need Heavy Duty Gantry Cranes

Stone blocks are far from easy to handle. Their size, shape, and density make them challenging even for experienced operators. Understanding these characteristics is the first step in choosing the right gantry crane for your yard.

Characteristics of Stone Blocks

Stone blocks vary greatly depending on the material and quarry. Key factors include:

- Weight: Marble, granite, and other natural stone blocks can weigh anywhere from a few tons to over 30 tons. Lifting them manually or with small machinery is simply not practical.

- Density: Granite is denser than marble, which directly affects crane capacity requirements. Density influences both the lifting load and the stability needed during handling.

- Dimensions: Blocks can be irregularly shaped and large, often exceeding 2–3 meters in length, width, or height. Handling these safely requires a crane designed for wide spans and high lifting capacity.

Common Handling Challenges

Stone processing yards face specific challenges that make heavy-duty gantry cranes almost essential:

- Irregular block shapes: Stones are rarely uniform, so lifting and positioning require precise handling equipment.

- Outdoor yard conditions: Uneven ground, limited space, and long travel distances increase handling difficulty.

- Weather exposure: Rain, dust, and heat can affect smaller cranes or manual handling, reducing safety and efficiency.

- High volume operations: Large yards move hundreds of blocks daily. Efficiency drops dramatically without proper lifting equipment.

Advantages of Gantry Cranes

Gantry cranes provide practical solutions to these challenges. Their benefits include:

- Flexibility: Can cover large areas of the yard, moving blocks from quarry storage to cutting and polishing lines.

- High lifting height: Allows stacking multiple blocks safely, maximizing yard space.

- Independence from building structures: Outdoor gantry cranes don't require existing roof support, making them ideal for open-air stone yards.

- Improved safety and efficiency: Reduce the risk of accidents, minimize block damage, and speed up operations.

- Customizable capacity and span: Can be tailored to the yard's specific material size and operational needs, from 10 tons up to 40 tons.

Using the right gantry crane transforms a stone processing yard. Operators can move heavy blocks safely, reduce downtime, and organize the yard more efficiently — all without compromising safety or material quality.

Typical Lifting Requirements in Marble, Stone, and Granite Yards

Handling stone blocks effectively begins with understanding their weight, size, and density. Each type of material presents its own challenges and directly impacts the choice of gantry crane.

Marble Blocks

Marble is relatively lighter than granite but still too heavy for manual handling. Decorative blocks, slabs, or plates usually weigh between 5 and 20 tons, depending on size and thickness.

Typical Gantry Crane Types and Capacities:

- Single Girder Gantry Cranes: 5–15 tons, suitable for small workshops or tile processing

- Double Girder Gantry Cranes: 10–25 tons, ideal for medium to large marble yards and export facilities

Marble blocks are typically handled in indoor workshops, outdoor storage yards, and export packing areas. These locations require cranes that can operate safely over stacked materials or in compact spaces.

Common below-hook devices include vacuum lifters for smooth, polished slabs, adjustable plate clamps for slabs and sheets, and wire rope slings for bundled blocks. Selecting the right device helps prevent surface damage and ensures safe handling.

Handling notes for marble emphasize that smaller blocks (5–10 tons) are often moved in workshops or tile production areas, while medium to large blocks (10–20 tons) require precise positioning, careful stacking, and attention to weight distribution to prevent tipping or breakage.

General Stone Blocks (Sandstone, Limestone, etc.)

Other natural stones vary more in density and shape, with blocks typically weighing 5–15 tons, though some larger pieces may exceed 20 tons. Irregular shapes make precise handling essential to avoid damage.

Typical Gantry Crane Types and Capacities:

- Single Girder Gantry Cranes: 5–10 tons, for smaller blocks and indoor handling

- Double Girder Gantry Cranes: 10–20 tons, for larger or heavier blocks

- Semi-Portal Gantry Cranes: 15–25 tons, ideal for outdoor yards with uneven surfaces

These blocks are usually handled in stone workshops, outdoor storage yards, and construction material depots. Locations may vary from compact indoor spaces to large open-air yards, requiring flexibility in crane design and positioning.

Typical below-hook devices include adjustable stone clamps, C-hook clamps for irregular blocks, and chain or synthetic slings for heavier pieces. Choosing the correct device ensures safe, controlled lifting without chipping or cracking the stone.

Handling notes focus on verifying block weight, accommodating irregular shapes, and planning lifts carefully. Even blocks with similar dimensions can vary significantly in density, so proper crane selection and device use are critical to avoid damage and maintain operational safety.

Granite Blocks

Granite is dense and heavy, with blocks typically weighing 15–30 tons, while export-size blocks can reach 35–40 tons. Handling these loads requires strong crane structures and precise below-hook solutions.

Typical Gantry Crane Types and Capacities:

- Double Girder Box Girder Gantry Cranes: 25–40 tons, suitable for heavy outdoor yards and export handling

- Portal Gantry Cranes: 20–35 tons, for open-air operations requiring wide spans

- European-Style Gantry Cranes: 30–40 tons, for high-precision lifting in export facilities

Granite blocks are often handled in large outdoor yards, export loading docks, and stone processing or polishing plants. These locations usually demand cranes with high lifting heights and wide spans to transport blocks efficiently across the yard or onto trucks and containers.

Typical below-hook devices include heavy-duty stone clamps, C-hooks or block tongs for large export blocks, and multi-point slings for oversized or irregular shapes. Proper device selection is essential to maintain block integrity and ensure operator safety during heavy lifts.

Handling notes emphasize the importance of considering block weight, size, and orientation. Heavy granite blocks require stable crane structures like box girders, careful planning of lifts, and precise positioning to prevent tipping, surface damage, or operational delays.

Common Gantry Crane Capacities for Stone Industry (10–40 Tons)

Stone processing yards handle a wide range of block sizes and weights, which is why selecting the right gantry crane capacity is crucial. In most operations, cranes with lifting capacities from 10 to 40 tons cover the full range of requirements, from small decorative blocks to massive granite export blocks.

Reference Table: Material, Density, Block Size, and Crane Capacity

| Material | Approx. Density (kg/m³) | Typical Block Size (m) | Typical Block Weight (tons) | Recommended Crane Capacity |

|---|---|---|---|---|

| Marble | 2,600–2,800 | 2.0 × 1.2 × 1.2 | 5–20 | 10–25 tons |

| Stone (general) | 2,400–2,700 | 1.5 × 1.2 × 1.0 | 5–15 | 5–15 tons |

| Granite | 2,700–3,000 | 2.8 × 1.6 × 1.6 | 15–30 | 25–40 tons |

10 Ton Gantry Crane

A 10 ton gantry crane is typically used in smaller workshops or tile cutting operations where blocks are lighter and less bulky.

- Compact design fits into limited spaces, making it ideal for indoor or semi-outdoor yards.

- Economical option for businesses that do not require lifting large blocks frequently.

- Can handle smaller marble and stone blocks weighing up to 10 tons safely.

This type of crane is often found in tile factories or small-scale marble processing yards where precision and maneuverability are more important than heavy lifting.

20 Ton Gantry Crane

A 20 ton gantry crane is suitable for medium-sized processing yards. It offers more lifting capacity while remaining relatively easy to install and operate.

- Handles medium to large marble or stone blocks efficiently.

- Can be configured as a single girder or double girder crane, depending on block weight and yard layout.

- Supports faster operations and reduces the need for multiple smaller cranes.

This capacity is common in commercial yards processing blocks for construction and export, where daily block movement is moderate but consistent.

25 Ton Gantry Crane

The 25 ton gantry crane is the most common choice for handling both marble and granite blocks. It strikes a balance between lifting capacity and cost, making it ideal for most stone yards.

- Stable structure capable of handling heavier blocks safely.

- Can be equipped with a cabin or remote control operation, improving operator comfort and efficiency.

- Example: A 25 ton double girder gantry crane is used in a marble stone yard in Poland to move and stack large marble blocks daily.

- Suitable for both indoor and outdoor operations with medium to large spans.

This crane is often the backbone of stone processing yards that deal with blocks ranging from 10 to 25 tons.

32 Ton and 40 Ton Gantry Cranes

For large-scale yards, granite export terminals, or operations handling very heavy blocks, 30 ton 32 ton gantry cranes and 40 ton gantry cranes are the preferred choice.

- Box girder construction ensures maximum strength, rigidity, and long-term durability.

- Capable of lifting the heaviest granite blocks safely, often up to 40 tons per lift.

- Designed for outdoor yards with large spans and high lifting heights.

- Can handle continuous heavy-duty operations without compromising safety.

These cranes are ideal for yards handling export-size blocks or facilities that require stacking multiple layers of heavy granite and stone blocks efficiently.

Your Trusted Overhead Crane Manufacturer & Supplier

40 Ton Gantry Crnae for Sale,

Tailored Full / Semi Gantry & Sinlge/ Double Girder Gantry Cranes

Typical Types of Gantry Cranes for Marble, Stone & Granite Handling

Single Girder Gantry Cranes

- Typical Capacity: 5–15 tons

- Types of Crane Options: Light-duty indoor, outdoor with weather protection, hoist-equipped with vacuum lifters or clamps

- Applications: Small workshops, tile processing, light-duty indoor handling

- Features: Compact design, easy installation, suitable for limited-space operations

- Typical Block Sizes: 1–3 meters in length, 0.5–1.5 meters in width, 5–10 tons

- Best For: Handling small marble or stone blocks, slabs, and tiles; ideal for indoor operations or workshops where space is limited. Perfect for repetitive lifting of lighter decorative or processed blocks, such as marble slabs or limestone pieces, where precise placement is required.

Double Girder Gantry Cranes with Hoist Trolley

- Typical Capacity: 10–25 tons (marble/stone), up to 30 tons for dense granite

- Types of Crane Options: European-style double girder, outdoor heavy-duty, equipped with stone clamps or vacuum lifters

- Applications: Medium to large marble or stone yards, polishing plants, export facilities

- Features: Higher lifting height, longer span, greater rigidity and load capacity

- Typical Block Sizes: 2–6 meters in length, 1–2.5 meters in width, 10–25 tons

- Best For: Moving medium to large marble blocks, irregularly shaped stone blocks, and standard-size granite safely. Suitable for both indoor and outdoor yards, offering flexibility to lift, transport, and stack heavier blocks while minimizing risk of surface damage.

Double Girder Box Girder Gantry Cranes with Open Winch Trolley

- Typical Capacity: 25–40 tons

- Types of Crane Options: High lifting height, export-focused long span, equipped with multi-point lifting or block tongs

- Applications: Large granite yards, heavy-duty outdoor operations, export loading docks

- Features: Extra rigidity and stability, suitable for extremely heavy loads, wide spans, and high lifting heights

- Typical Block Sizes: 3–8 meters in length, 1.5–3 meters in width, 25–40 tons

- Best For: Handling ultra-heavy granite or stone blocks, including export-size blocks. Ideal for high-volume outdoor yards where stability and precise positioning are critical. Well-suited for long-distance transport of heavy blocks across large storage areas and for loading onto trucks or containers.

Semi-Portal Gantry Cranes

- Typical Capacity: 15–25 tons

- Types of Crane Options: Single-girder semi-portal, double-girder semi-portal, adjustable span for uneven or constrained areas

- Applications: Outdoor stone yards with uneven surfaces or irregular layouts

- Features: One side supported on wheels, flexible movement over restricted areas

- Typical Block Sizes: 2–5 meters in length, 1–2.5 meters in width, 15–25 tons

- Best For: Yards with irregular layouts or partially paved surfaces. Excellent for lifting medium-weight stone blocks, slabs, or marble pieces where traditional double girder cranes may not fit. Flexible for shifting blocks between storage areas without moving the entire crane structure.

Rubber-Tyred Gantry Cranes (RTG)

- Typical Capacity: 20–35 tons

- Types of Crane Options: Standard RTG for medium blocks, heavy-duty RTG for ultra-large granite, modular lifting systems for varied stone sizes

- Applications: Large open-air granite yards, export loading areas, containerized stone terminals

- Features: Mobile cranes with rubber wheels, capable of traveling long distances across yard surfaces

- Typical Block Sizes: 2–7 meters in length, 1–3 meters in width, 20–35 tons

- Best For: Handling large granite or stone blocks across extensive outdoor yards efficiently. Ideal for operations requiring frequent movement of heavy blocks between storage, processing, and shipping areas. Can lift, transport, and position blocks without needing a fixed runway, providing maximum flexibility for large-scale stone yards.

Structural and Design Options for Stone Yard Gantry Cranes

Selecting the right gantry crane isn't just about lifting capacity. The structure, design, and mobility features are equally important, especially in stone processing yards where blocks are heavy, irregular, and handled outdoors. Choosing the appropriate configuration ensures safety, efficiency, and long-term durability.

Box Girder vs Truss Girder Structures

The main structural types for gantry cranes are box girder and truss girder. Each has its own advantages depending on yard requirements:

Box Girder Gantry Cranes

- Solid rectangular or square beam construction.

- Provides excellent rigidity and stability, ideal for heavy loads like granite blocks.

- Minimal deflection over long spans, which reduces risk of accidents.

- Commonly used in outdoor yards where high durability is required.

Truss Girder Gantry Cranes

- Lightweight, lattice-like beam design.

- Economical and suitable for medium loads.

- Can cover long spans without adding excessive weight to the structure.

- Often used in medium-duty marble yards or smaller stone processing facilities.

Single Girder vs Double Girder Gantry Cranes

The number of girders directly affects the crane's lifting capacity and stability:

Single Girder Gantry Cranes

- Suitable for lighter blocks (10–20 tons).

- Simpler design, lower cost, and easier to install.

- Limited span and lifting height compared to double girder cranes.

Double Girder Gantry Cranes

- Recommended for heavier blocks (25–40 tons).

- Greater lifting height and larger span capability.

- More stable for heavy-duty operations and outdoor yards.

- Can support heavier hoists or multiple lifting accessories.

Rail-Mounted vs Rubber-Tired Gantry Cranes

Mobility is another key factor when choosing a crane:

Rail-Mounted Gantry Cranes

- Fixed rails allow precise movement along a designated path.

- Ideal for long-term installations with high block throughput.

- Less flexible if yard layout changes frequently.

Rubber-Tired Gantry Cranes (RTGs)

- Mobile and can be repositioned anywhere in the yard.

- Suitable for outdoor storage yards where blocks need to be moved across wide areas.

- Typically require a flat, paved surface for stability and safety.

Cantilever Design Options

Cantilevered gantry cranes are useful when loading or unloading trucks beyond the runway limits:

- Provides extra reach without extending the main runway.

- Reduces the need for additional handling equipment.

- Commonly used in yards that ship stone blocks directly to trucks or containers.

- Enhances operational flexibility and reduces block movement time.

Choosing the right structural and design options ensures your gantry crane meets your stone yard's operational needs, improves safety, and maximizes efficiency. Proper planning of girder type, crane configuration, and mobility features also reduces maintenance costs and extends the crane's service life.

Environmental and Operational Considerations

Outdoor stone processing yards present unique challenges for gantry crane operation. Unlike indoor workshops, cranes in open-air yards are exposed to weather, uneven ground, and fluctuating power conditions. Taking these factors into account during crane selection and installation ensures safety, durability, and efficient operation.

Outdoor Operation Requirements

Cranes used in stone yards must be designed to withstand the elements. Key features to consider include:

- Weatherproofing: Covers, enclosures, and protective materials prevent damage from rain, dust, and sunlight.

- IP-Rated Electrical Components: Ensure hoists, motors, and control systems are rated for outdoor exposure to prevent short circuits or failures.

- Anti-Corrosion Coatings: Paint, galvanization, or other protective coatings protect steel structures from rust, especially in humid or coastal areas.

Proper environmental design prevents downtime and reduces long-term maintenance costs.

Safety Features for Uneven Yard Surfaces and High Winds

Outdoor yards rarely have perfectly flat surfaces, and wind can affect heavy loads. To maintain safe operation:

- Leveling and Support: Gantry cranes must be installed on stable foundations or rails to prevent tilting during lifts.

- Wind Load Design: Outdoor cranes should be rated to operate safely under local wind conditions, especially when handling large blocks at height.

- Emergency Stop Systems: Quick response controls are essential to prevent accidents if a block swings or the crane becomes unstable.

- Load Stabilization: Anti-sway systems or rope guides help keep heavy blocks steady during transport.

Power Supply Considerations and Electrical System Protection

Reliable power is critical for outdoor crane operations:

- Voltage Compatibility: Confirm crane voltage matches the yard's available power supply to avoid motor damage.

- Electrical Protection Systems: Circuit breakers, surge protectors, and grounding prevent downtime and protect both operators and equipment.

- Backup Power Options: For critical operations, consider generators or UPS systems to maintain productivity during outages.

Crane Operation in Different Markets Around World

The stone processing industry varies widely around the world, and gantry crane requirements reflect differences in material type, block size, yard scale, and operational focus. Understanding these regional trends is essential for buyers who want to select cranes that fit both local conditions and material handling needs.

China: Large-Scale Stone Processing and Crane Manufacturing

China is the world's largest producer of marble and granite, with a wide range of processing facilities from small workshops to massive outdoor yards. Blocks vary in size and weight, so selecting the right crane capacity and configuration is crucial.

Typical locations, yard scale, block weight, and cranes used:

- Typical Locations: Fujian, Guangdong, Shandong, Zhejiang, Henan.

- Yard Scale: Small workshops to massive outdoor yards covering several hectares.

- Block Handling Weight: Marble and granite blocks from 5 to 35 tons.

Typical Cranes:

- Single girder gantry cranes for smaller blocks (10–15 tons).

- Double girder or box girder cranes for heavy granite blocks (25–40 tons).

- Rail-mounted for fixed yard paths; rubber-tired cranes for flexible outdoor operations.

China also exports custom-built gantry cranes worldwide, often featuring weatherproof systems, cabins, or remote controls for outdoor operation.

India: Granite Export Market

India is a major exporter of granite, with processing yards concentrated in southern and western states. Yard sizes and block weights vary, requiring cranes that can handle heavy loads efficiently.

Typical locations, yard scale, block weight, and cranes used:

- Typical Locations: Rajasthan, Karnataka, Tamil Nadu.

- Yard Scale: Medium to large processing yards for export, often 2–5 hectares.

- Block Handling Weight: Granite blocks ranging 15–30 tons, occasionally heavier for export.

Typical Cranes:

- Double girder gantry cranes for large granite blocks.

- Single girder gantry cranes for marble and smaller stone blocks (10–20 tons).

- Mix of rail-mounted cranes for high-traffic paths and rubber-tired gantries for flexible positioning.

These cranes allow Indian yards to maintain productivity while handling heavy granite blocks safely in outdoor conditions.

Turkey: Marble Export Hub

Turkey is one of the world's largest marble producers. Export yards require cranes that balance lifting capacity with outdoor durability and precision handling.

Typical locations, yard scale, block weight, and cranes used:

- Typical Locations: Afyon, Mugla, Bilecik, Istanbul region.

- Yard Scale: Small to medium outdoor yards (1–3 hectares), often near quarries or export terminals.

- Block Handling Weight: Marble blocks typically 10–25 tons.

Typical Cranes:

- Single girder gantry cranes for medium blocks.

- Double girder or box girder cranes for larger marble blocks near export zones.

- Outdoor yards require cranes with anti-corrosion coatings and stable foundations due to uneven terrain.

Turkey focuses on mid-sized blocks, so crane selection prioritizes both durability and precision handling.

Italy and Spain: Precision Marble Handling

Italy and Spain specialize in high-quality marble products for architecture and decoration. Cranes are selected for smooth, precise handling rather than heavy lifting.

Typical locations, yard scale, block weight, and cranes used:

- Typical Locations: Carrara (Italy), Verona (Italy), Macael (Spain), Novelda (Spain).

- Yard Scale: Small indoor workshops to medium outdoor yards (0.5–2 hectares).

- Block Handling Weight: High-quality decorative marble blocks 5–20 tons.

Typical Cranes:

- Single girder gantry cranes with smooth, precise hoisting for delicate blocks.

- Double girder cranes in yards handling larger slabs (15–25 tons).

- Anti-sway hoists and controlled lifting for polished marble products.

These yards focus on precision, so smooth operation and careful block handling are more important than maximum capacity.

Brazil and Egypt: Heavy Granite and Stone Operations

Brazil and Egypt handle very heavy granite and stone blocks for export, requiring cranes with robust structures and high lifting capacities.

Typical locations, yard scale, block weight, and cranes used:

- Typical Locations (Brazil): Minas Gerais, Espírito Santo, Bahia.

- Typical Locations (Egypt): Aswan, Sinai, Cairo region quarries.

- Yard Scale: Large outdoor processing and export yards, often 3–6 hectares.

- Block Handling Weight: Granite and hard stone blocks 25–40 tons, sometimes exceeding 40 tons.

Typical Cranes:

- Double girder box girder cranes for heavy blocks.

- High-lifting capacity cranes with spans up to 40–50 meters.

- Rail-mounted for structured yard paths, sometimes supplemented with rubber-tired cranes for flexibility.

- Equipped with cabins or remote control for safety and efficient block movement.

These regions focus on heavy-duty outdoor operations, so cranes are built for long-term durability and continuous use.

Global Insights for Buyers

Selecting the right crane depends on yard scale, block weight, and local terrain.

- 10–15 tons: Small marble blocks in workshops (Italy, Spain, smaller yards in China and Turkey).

- 20–25 tons: Medium marble and granite blocks (Turkey, India, export-focused China yards).

- 25–40 tons: Heavy granite or export-size blocks (China, Brazil, Egypt, large Indian yards).

Configurations: Single vs. double girder, box vs. truss girder, rail-mounted vs. rubber-tired based on yard layout and operational needs.

How to Select the Right Gantry Crane Capacity (Buyer's Guide)

Choosing the correct gantry crane is more than just picking a number from a catalog. Stone yards handle heavy, irregular blocks, and improper crane selection can lead to safety risks, reduced productivity, and costly downtime. This guide helps buyers evaluate the key factors when selecting a crane.

Calculating Block Weight

The first step in selecting the right crane is determining the total weight to be lifted.

- Block Weight: Start with the actual weight of the marble, granite, or stone block.

- Lifting Tools and Accessories: Add the weight of spreaders, hooks, clamps, or slings that will be used.

- Safety Margin: Include at least a 10–20% margin above the maximum expected load to prevent overloading and ensure safety.

Accurate weight calculation ensures the crane is neither underpowered nor excessively oversized, which affects both cost and efficiency.

Choosing the Correct Girder Type, Span, and Lifting Height

Once the load is known, the crane's structure and design must match operational needs.

Girder Type:

- Box girder: Ideal for heavy granite blocks and long spans; provides rigidity and reduces deflection.

- Truss girder: Suitable for medium loads; lightweight and cost-effective for moderate spans.

Span: Ensure the crane can cover the full width of the yard or processing area without obstruction.

Lifting Height: Consider both block stacking requirements and transport clearances for trucks, conveyors, or polishing lines.

Proper girder selection, span, and height are essential for safe, efficient, and long-term operation.

Considering Future Yard Expansion and Capacity Upgrades

Stone yards evolve over time, and your crane should be able to keep up with changing needs.

- Future Growth: If block sizes or yard coverage are expected to increase, select a crane that can accommodate heavier loads or wider spans.

- Capacity Upgrades: Some cranes allow upgrading hoists or trolleys to increase lifting capacity without replacing the full structure.

- Operational Flexibility: A slightly higher-rated crane than currently needed can prevent costly replacements later.

Planning for future expansion ensures your investment remains valuable for years.

Importance of Selecting CE and ISO-Certified Manufacturers

Not all gantry cranes are built to the same standard. Certification ensures quality, safety, and compliance with international standards.

- CE Certification: Confirms compliance with European safety standards, often required for export or international operations.

- ISO Certification: Ensures the manufacturer follows strict quality management processes for consistent performance and durability.

- Third-Party Inspection: Independent verification of crane components, load testing, and operational safety adds confidence.

Selecting certified manufacturers reduces risk, guarantees reliable operation, and ensures compliance with local regulations.

Proper calculation, design selection, and certification checks allow buyers to choose gantry cranes that maximize safety, productivity, and long-term ROI in stone processing yards.

Tailored Crane System Solutions for Stone Yards

Every stone processing yard has unique requirements. From small marble workshops to large granite export yards, choosing the right gantry crane system is critical for operational efficiency, safety, and long-term performance. Tailored crane solutions allow buyers to match their exact needs, rather than relying on off-the-shelf equipment.

Custom-Manufactured Gantry Cranes (10–40 Tons)

Stone yards handle a wide range of block sizes and weights, which means crane capacities must be carefully selected.

- Cranes are custom-built to handle loads from 10 to 40 tons depending on material type and yard operations.

- Single girder gantry cranes are suitable for lighter marble or small stone blocks.

- Double girder or box girder cranes provide stability for heavy granite blocks and large outdoor yards.

- Customization ensures the crane fits the yard layout, block sizes, and workflow.

Designed for Outdoor Use

Outdoor yards require robust cranes that can withstand harsh environmental conditions.

- Corrosion Protection: Anti-rust coatings, galvanization, and weatherproof paint protect structural steel.

- Weatherproof Systems: Electrical components, hoists, and motors are rated for outdoor exposure (IP-rated).

- Durability: Heavy-duty wheels, rails, and structural reinforcements ensure stability and long service life.

These features reduce downtime and maintenance costs while ensuring safe operations in open-air conditions.

CE and ISO Certified for Safety and Performance

Certification is essential to guarantee quality and compliance with international standards.

- CE Certification: Confirms compliance with European safety standards, often required for export or international operations.

- ISO Certification: Ensures consistent manufacturing quality and reliability.

- Third-Party Inspections: Optional verification of load testing, electrical systems, and operational safety adds confidence for buyers.

Certified cranes reduce operational risk and give buyers confidence in long-term performance.

Case Studies and Project References

Practical examples help buyers understand how tailored gantry cranes perform in real-world stone yards.

- Poland: 25-ton double girder gantry cranes moving large marble blocks in outdoor yards.

- Egypt: 32-ton box girder cranes handling dense granite for export operations.

- India: 20–25 ton cranes combining rail-mounted and rubber-tired systems for medium to large granite blocks.

- Turkey: Single and double girder cranes for marble export yards with moderate block sizes (10–25 tons).

These examples show how customized solutions can be applied to different yard sizes, block weights, and operational conditions globally.

Inquiry Checklist for Buyers

Before requesting a quote, buyers should gather key information to ensure the crane solution fits their yard needs:

- Required lifting capacity and expected maximum block weight.

- Span of the crane to cover the working area.

- Lifting height required for stacking and handling operations.

- Block type and dimensions to determine hoist and girder requirements.

- Site conditions including yard layout, ground stability, power supply, and weather exposure.

Providing this information allows manufacturers to design the most efficient and cost-effective crane solution for your stone yard.

Conclusion

Selecting the right gantry crane is more than just matching a number to your block weight. It directly affects safety, operational efficiency, and long-term costs. A crane that fits your yard layout, block types, and workflow ensures smooth handling, reduces downtime, and protects both workers and materials.

Consulting with experienced crane manufacturers or suppliers can make a significant difference. They can provide a customized solution that accounts for block weight, span, lifting height, environmental conditions, and future yard expansion.

Investing time in proper crane selection upfront not only improves daily operations but also ensures a reliable, durable system that will serve your stone yard for many years.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch