40 Ton Overhead Crane Upgraded or Replaced? How to Decide

A practical guide comparing costs, downtime & savings to help choose between upgrading or replacing your 40 ton overhead crane. Get eot crane solution!

Category: Featured

Your Trusted 40 Ton Overhead Crane Manufacturer & Supplier

Upgrade or Replace?

Make Decision for Your Aging 40 Ton Overhead Crane

A Practical Guide Weighing Upfront Costs, Downtime, & Long-Term Savings

A 40-ton overhead crane is not a small piece of equipment—it's a major workhorse in any industrial facility. Found in steel plants, machinery workshops, fabrication yards, and heavy assembly lines, these cranes are designed to lift large, heavy materials and keep production flowing. When that crane starts showing signs of wear or just isn't keeping up with the pace, it puts more than just your lifting capacity at risk—it can slow down the entire operation.

At some point in the crane's service life, every facility manager or plant owner has to face this question: should we upgrade the existing crane or replace it entirely?

It's not a decision to rush. Both options have pros and cons, and what works for one workshop may not work for another. An upgrade might be more affordable up front but could leave you with older structural components. A replacement offers newer technology and longer service life, but it also comes with a higher cost and possibly more downtime.

This guide is here to help you weigh the two paths—upgrading vs. replacing your 40-ton overhead crane—based on:

- Current condition and age of your crane

- Maintenance costs and frequency of breakdowns

- Available budget and production deadlines

- Long-term goals for lifting performance and safety

- Compatibility with future expansion plans or automation

Whether you're a maintenance manager trying to reduce recurring failures, or a business owner planning a plant expansion, this guide will help you make a clear, informed decision. Not just based on guesswork—but grounded in practical, technical, and economic realities.

Common Reasons for Evaluating Your Crane

No crane lasts forever—especially one working hard day in and day out lifting 40 tons. Over time, even the most durable overhead cranes show signs of aging. You might be thinking about upgrading or replacing your crane because something just doesn't feel right anymore, or because production isn't running as smoothly as it used to. Here are the most common reasons plant operators start evaluating their 40-ton crane:

Aging Equipment Nearing or Exceeding Its Service Life

Most heavy-duty cranes are built to last 20 to 30 years with proper maintenance. But after decades of lifting, the structural components, motors, hoist brakes, and control systems start to wear out. Even if it's still working, performance may be unreliable—and safety risks increase.

- Cracks, corrosion, or warping in the main girder or end trucks

- Obsolete or unsupported electrical systems

- Mechanical fatigue, especially in hoists and gearboxes

Rising Maintenance Frequency and Repair Costs

If your crane is frequently out of service, you're not just losing time—you're spending more on emergency repairs, spare parts, and technician call-outs. Over time, these costs start to add up and could even exceed the price of a well-planned upgrade.

- Replacing hoist ropes or motors more than once a year

- Frequent downtime from electrical panel failures

- Escalating spare part costs due to discontinued components

Performance Is Holding You Back

Even if the crane works, it might not be working well enough for your current needs. Maybe it's too slow, or the control system is outdated and lacks precision. Maybe it can't reach the new working height after a building expansion.

- Low lifting speed or inconsistent motion

- Jerky or inaccurate travel movements

- Limited hook height or insufficient span for new workflows

New Safety or Compliance Standards

Many countries have updated their safety standards for overhead cranes in the past decade. If your crane doesn't meet current electrical, mechanical, or emergency stop requirements, you could face compliance issues—or worse, accidents.

- Missing overload protection or travel limit switches

- Inadequate rail guards, emergency brakes, or alarms

- Non-compliance with updated ISO or CE standards

Production Needs Are Growing

If your output has doubled, but your crane is still operating at the same pace as ten years ago, it's probably time to reassess. Newer equipment can help speed up operations, reduce cycle times, and improve material handling efficiency.

- Larger or heavier loads are now standard

- Need for two hooks or tandem lifting not supported by the old system

- Expansion of work areas requiring wider spans or new runways

Taking the time to recognize these signs early can prevent more costly issues later on. Whether it's a hoist replacement or a full crane system redesign, understanding why you're evaluating the crane is the first step to finding the right solution.

Option 1: Upgrading Your 40 Ton Overhead Crane

Sometimes, your crane doesn't need to be replaced from the ground up—it just needs the right parts refreshed to bring it back to life. If the steel structure is still solid and the foundation is stable, upgrading your existing 40-ton overhead crane can be a smart and cost-effective choice. Here's what that could involve.

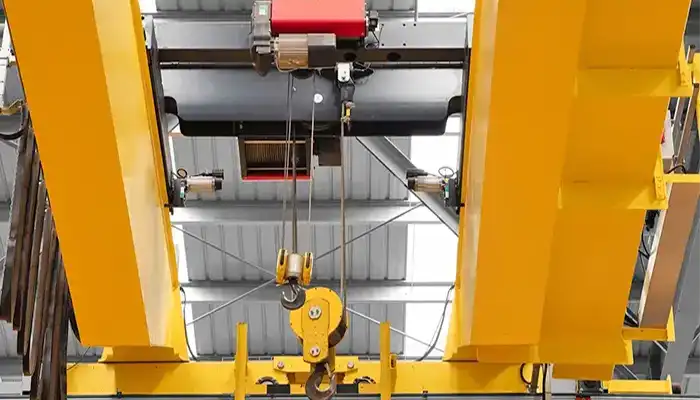

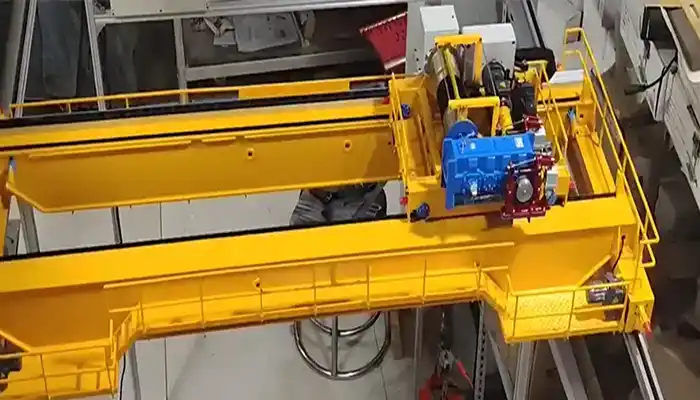

What Can Be Upgraded?Many of the most critical crane components can be replaced or modernized without touching the main structure. Depending on what's worn out or outdated, these are some of the upgrade options available:

- Electrical Systems: Modern control panels, Variable Frequency Drives (VFDs), and Programmable Logic Controllers (PLCs) can improve speed control, reduce energy usage, and support newer safety features.

- Hoisting Mechanism: If your hoist is noisy, overheating, or underperforming, you can replace key parts like the hoist motor, gearbox, brake system, or rope drum—without swapping the entire crane.

- End Trucks and Drives: Worn-out drive systems, cracked wheels, or malfunctioning buffers can be upgraded to improve travel motion and reduce the risk of derailment or jerky movement.

- Control & Safety Systems: You can switch from a pendant to wireless remote control, or even upgrade to semi-automation. Modern safety features like anti-sway, overload protection, and limit switches can also be added.

- Runway Modifications: If your crane struggles with travel alignment or load sway, adjusting or reinforcing the runway beam and rail system might be necessary—especially in older workshops.

Upgrading instead of replacing your crane offers several real-world advantages, especially if your production can't afford long interruptions.

- Lower Upfront Cost: You'll save significantly by retaining the crane's main structure. Focused upgrades on worn or outdated parts are generally less expensive than a complete rebuild.

- Shorter Downtime: Many upgrades can be completed in phases, meaning you don't have to halt production for weeks. In some cases, only a day or two of shutdown is required.

- Minimal Civil Work: Since you're keeping the same girders, columns, and foundation, there's no need to tear up flooring or reinforce supports—reducing both cost and complexity.

- Preserve Familiar Layout: Operators and maintenance staff don't need to relearn how the crane functions. The workflow remains consistent, with only improvements in performance or control.

Of course, upgrading isn't always the right move. There are situations where patching up an old crane may only offer temporary relief or leave critical limitations unresolved.

- Structural or Capacity Limits Stay the Same: If the main beam or runway is worn or undersized, no amount of component upgrades will allow for heavier loads or longer spans.

- Compatibility With Modern Tech May Be Restricted: Some older cranes simply weren't designed for the level of automation or smart monitoring now available. You might find yourself investing heavily just to force-fit new technology.

- Shorter Remaining Lifespan: Upgrades may extend your crane's life by 5 to 10 years—but if the base structure is already 25 years old, you'll still face a full replacement soon enough.

Bottom Line: If your crane's bones are good and your lifting needs haven't changed much, upgrading can be a smart move. But don't skip a full condition assessment—knowing what's still reliable and what's not is key to getting value from your upgrade investment.

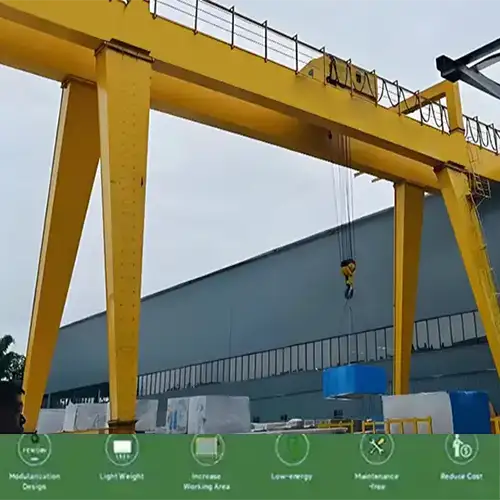

Option 2: Replacing the 40 Ton Overhead Crane

There comes a point when upgrading just won't cut it. If your crane is struggling to keep up with production, failing more often than not, or holding your operation back, a full replacement might be the smarter long-term solution. Yes, the upfront cost is higher—but in many cases, it pays off in reliability, efficiency, and peace of mind.

When Full Replacement Is WarrantedNot every crane can be saved with new parts. Some issues go deeper—into the structure, the design limitations, or simply the fact that your operation has grown beyond what the crane was originally built for.

- Structural Fatigue or Cracks: If inspection reveals cracks in the girders, corrosion in key joints, or warping from overuse, it's no longer safe to operate—even with upgrades.

- Repeated Mechanical Failures: Constant breakdowns of the hoist, trolley, or electrical systems—despite frequent repairs—are a clear sign that the crane is nearing the end of its usable life.

- Outgrown Capacity or Speed: Your production might have scaled up, but your crane hasn't. If it's too slow, lacks lifting height, or can't handle the volume of your workload, it's holding you back.

- You're Planning Expansion or Automation: Older cranes weren't built for smart controls, remote monitoring, or future modular upgrades. If you're aiming for automation or dual-hoist systems, a modern crane is the better base.

Replacing your crane opens the door to features and performance levels that just aren't possible with older models. It's an investment in both capacity and control.

- Better Performance Across the Board: A new 40-ton overhead crane will come with updated drive systems, smarter controls, and better energy efficiency. Lifting, traveling, and lowering are smoother and faster.

- Opportunity to Modernize: Now's your chance to switch to a more space-efficient design, like a European-style low-headroom crane. You can also upgrade your lifting capacity or span, depending on your building's layout.

- Lower Maintenance Burden: New cranes typically come with longer warranties and fewer service issues in the early years. You also avoid the challenge of sourcing discontinued parts.

It's important to go into a full crane replacement with your eyes open. While it brings long-term value, it also requires more planning, budget, and coordination.

- Higher Upfront Investment: Replacing a 40-ton crane is a major capital expense. The crane itself, plus dismantling, shipping, installation, and commissioning, must all be factored in.

- Downtime and Project Timeline: Depending on complexity, a replacement project might take several weeks. This includes removing the old crane, preparing the site, installing the new system, and testing.

- Possible Structural Work: If your current runway, building columns, or foundation can't support the new crane's specs, modifications may be needed—adding time and cost.

A word of advice: If your current crane is limiting your production, eating into your maintenance budget, or causing safety concerns, replacement isn't just a cost—it's a path to smoother operations and a safer workplace. Don't wait until something breaks at the worst time. Plan ahead and choose a crane system that's built for the next 20+ years of your business.

Cost Breakdown: Upgrade vs. Replace for Your 40 Ton Overhead Crane

When you're operating a 40 ton overhead crane or 40 ton bridge crane, the financial decisions you make can directly affect your plant's productivity, safety, and maintenance costs. Choosing whether to upgrade or replace your crane involves more than just comparing price tags. You need to think about operational downtime, expected service life, long-term maintenance costs, and future requirements.

Here's a clear cost comparison to help you navigate this decision:

| Category | Upgrade Your 40 Ton Crane | Replace with New 40 Ton Crane |

|---|---|---|

| Initial Cost | Lower ($30,000–$60,000 typical) | Higher ($100,000–$150,000+ typical) |

| Downtime | Shorter (few days to 1 week) | Longer (2 to 3+ weeks) |

| Customization | Limited by existing structure | Fully customizable for your operation |

| Long-Term Savings | Moderate savings from fewer repairs | Higher savings from reliability, efficiency |

| Warranty & Lifespan | Partial warranty on new parts (1–2 yrs) | Full warranty (1–3 yrs), new 20+ yr life |

Example: 40 Ton Bridge Crane Decision in a Steel Fabrication Workshop

Situation: A steel fabrication plant in the Middle East runs a 40 ton bridge crane installed in 2001. The crane is still in use, but several problems have emerged:

- The hoisting motor has overheated twice in the past six months

- The crane still uses contactor controls, which are inefficient and unreliable

- Wheel wear and rail alignment issues are causing jerky movements

- Lifting speed no longer meets increased production demand

Option 1: Upgrade the 40 Ton Overhead Crane

- New hoist and motor unit: $22,000

- Modern electrical panel with VFD and wireless remote: $15,000

- Wheel and end truck repair: $7,000

- Installation, tuning, testing: $5,000

- Total: $49,000

- Downtime: ~5–7 working days

- Lifespan Extension: 8–10 years

- Warranty: 1–2 years (component-specific)

Option 2: Replace with New 40 Ton Bridge Crane

- European-design low-headroom double girder crane: $105,000

- Optional second hoist for dual-lifting tasks: +$18,000

- New crane rails and runway adjustments: $20,000

- Installation, testing, and load certification: $12,000

- Total: $135,000–$150,000

- Downtime: ~2–3 weeks

- Lifespan: 20+ years

- Warranty: 12 to 36 months, extendable

Choosing the Right Investment for Your 40 Ton Crane

If your existing 40 ton overhead crane is structurally sound and your production demands haven't changed significantly, an upgrade might be the smarter short-term move. It reduces downtime and avoids major structural work. But if your crane is aging, unreliable, or lacks modern safety and efficiency features, replacement is the better long-term investment.

Quick Tip: Calculate how much production you lose each time your crane breaks down. Then compare that loss over a year to the cost of a new 40 ton bridge crane. You might be surprised at how fast a new crane pays for itself.

Long-Term ROI and Operational Impact of Your 40 Ton Overhead Bridge Crane Decision

Upgrading or replacing a 40 ton overhead crane isn't just about what it costs today. It's about how that decision will affect your operations over the next 10 to 15 years. A well-performing crane isn't just a tool—it's a core part of your workflow. If it fails, production slows. If it runs smoothly, your entire operation benefits.

Lifecycle Costs Over Time

A replacement 40 ton bridge crane generally offers a better long-term return. While the upfront cost is higher, you're getting a brand-new system with modern technology and fewer breakdowns. An upgrade is more budget-friendly now, but you may end up spending again within a decade.

- An upgraded crane might need further investment after 8 to 10 years

- A new crane typically provides 20 or more years of service

- Over time, replacement often saves more by reducing repair costs and unscheduled downtime

Productivity and Efficiency Gains

An upgraded or new 40 ton crane can speed up your workflow. That might mean faster load cycles, smoother operation, and more consistent lifting across shifts. Small time savings in each lift can add up significantly across the week or month.

- Improved hoisting speed and smoother motion

- Reduced load sway and more precise positioning

- Fewer delays from inconsistent travel or worn-out drives

Reduced Maintenance and Emergency Repairs

Old cranes often break down when you least expect it. Even with regular maintenance, wear and tear becomes harder to manage as the years go by. A new system offers a fresh start, with standardized parts and a full warranty.

- Less time spent troubleshooting aging components

- Easier access to spares and support from the manufacturer

- Reduced technician call-outs and emergency stoppages

Insurance and Safety Compliance

Modern 40 ton overhead cranes are built with updated safety features as standard. This not only protects your team but can also improve compliance scores during audits or help reduce insurance costs.

- Integrated overload protection and safety limit switches

- Modern emergency stop systems and travel limiters

- Easier documentation for CE, ISO, or local inspection requirements

Expert Evaluation: Key Questions to Ask Before You Decide

Before choosing whether to upgrade or replace your 40 ton bridge crane, it's important to take a step back and ask the right questions. A technical assessment can help you understand what's working, what's at risk, and what your operation truly needs going forward.

What's the Current Structural Health of Your Crane?

Not all damage is visible at first glance. It's worth checking if the main girder, end trucks, or weld joints are showing signs of fatigue, stress, or distortion.

- Has the crane ever been overloaded or in a collision?

- Are there any signs of cracking, corrosion, or deformation?

- When was the last thorough inspection carried out?

Are the Runways and Supports Still Reliable?

Your crane is only as good as the structure it moves on. Misaligned rails or aging support columns can cause problems, no matter how new the hoist or control system may be.

- Are rails level and in good condition?

- Do the runway beams or supports show any sagging or twisting?

- Are there any unusual vibrations or noises during travel?

Will Production Needs Increase in the Near Future?

If your lifting needs are likely to grow, upgrading might fall short. Replacing the crane now could prevent limitations later.

- Are you handling heavier or longer loads than in the past?

- Will you need better hook coverage, faster speeds, or a second hoist?

- Is automation, remote operation, or smart monitoring being considered?

How Much Downtime Can You Afford Right Now?

How Much Downtime Can You Afford Right Now?

Both upgrading and replacing require shutdown time—but a rushed or temporary solution may cost more later.

- Can the work be done during a planned plant shutdown?

- Do you have backup lifting systems or rental options?

- How much does each day of crane downtime cost your production line?

A 40 ton overhead crane is a major asset. Treat it like one. The more you understand its current condition and future role, the easier it will be to make the right choice—one that serves both your production team and your budget for years to come.

Conclusion

There's no simple answer when it comes to deciding whether to upgrade or replace your 40 ton overhead crane. The best choice depends on several factors: the current condition of your crane, your budget, and your company's future plans.

If the crane's structure is still strong and your production demands haven't changed much, upgrading can be a practical and cost-effective solution. It lets you extend the life of your crane with less downtime and lower initial expense.

However, if your crane is struggling to meet capacity, safety standards, or reliability expectations, replacement is often the wiser option. A new crane can bring improved performance, better safety features, and longer-term peace of mind.

Whatever path you choose, it's always smart to consult with crane experts or the original equipment manufacturer (OEM). Their experience and knowledge can help you avoid costly mistakes and find the solution best suited to your needs.

Get Your 40 Ton Overhead Crane Solution

Ready to take the next step? Start with a thorough condition assessment of your current crane. This will give you a clear picture of what upgrades are possible or if a full replacement is necessary.

You can also request tailored quotes for both upgrade kits and new crane systems. This side-by-side comparison will help you make an informed decision.

Contact us today for a free consultation. We'll work with you to find the best investment for your 40 ton overhead crane—one that keeps your operation running safely and efficiently for years to come.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch