Marble, granite & stone handling crane

Various types of Industrial cranes and hoist services for marble , granite, slate and stone handling in the stone quarry, pits and warehouses from efficient stone block extraction to slab delivery in the granite & stone processing industries, which including the outdoor used gantry cranes and warehouse applicable overhead cranes and workstation cranes, etc. Tailored industrial hoists and cranes are available for your specific stone processing applications.

Industrial challenges

How does the industrial cranes help the processing of marble, granite & stone? In the specialized industrial application outdoors and indoors, the industrial material handling cranes are required to improve the working efficiency throughout the whole procedures of stone, granite and marble processing which including the following steps:

- Block extraction refers to the process of removing the huge and heavy stone blocks from a natural quarrel and pit by drilling and sawing, etc. For the heavy stone block handling, the outdoor used gantry cranes are required to withstand outdoor environments which are with the features of corrosion-resistant, weatherproof and high precision hoists to ensure the carefully handling of stones such as turning the stones and laying them flat. After extraction, the huge blocks will be transported to facilities for further processing.

- Gang sawing refers to the processing of cutting &breaking down the huge marble and granite blocks into finer pieces for finish work. The huge and heavy stone blocks are transported and pulled under the gang saws by heavy duty gantry cranes effectively and safely.

- Polishing and sealingrefers to the process that the artificial diamonds polish and smooth the surfaces of the stones to reveal the true value and character of the original stone.

- Waterjet cutting and wet sawing means that the stone is cut with a cooling water flow, with minimal heat and friction applied.

For lighter stone or slab handling, the overhead cranes or workstation cranes are used for efficient stone handling as required. Besides for material handling in the processing plants, the overhead travelling overhead crane and gantry cranes are also widely used in large scale marble and granite restorations and repairs, and other commercial work for efficient and safe handling.

Industrial stone crane, granite crane and marble cranes

Our industrial overhead cranes and gantry cranes are widely used for material handling in the granite, marble, and stone industry. Our process cranes can be well suited to your specific applications to maximize industrial safety and cost savings. There are several types of overhead travelling cranes for your selection.

1 ton~320 ton Double girder gantry crane for stone, marble and granite handling

Overhead gantry crane with a floor-based structure on wheels with the advantages of lightweight, portable, cost-effective, and wide crane configurations with various capacities, spans, and heights,etc.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Overhead travelling crane for stone, marble and granite plate handling

Overhead Hoist and Bridge Crane

Overhead bridge travelling cranes, travelling on crane rails mounted on the building structures or on free standing supporting beams, with the unlimited capacities, spans, and various overhead crane designs, pendant control, radio control, and driver's control, etc.

While some buildings allow a crane system to be built into the structural beams, others can't bear any further weight. We supply freestanding or floor-mounted cranes, and we work with customers to determine the best system for their workspace.

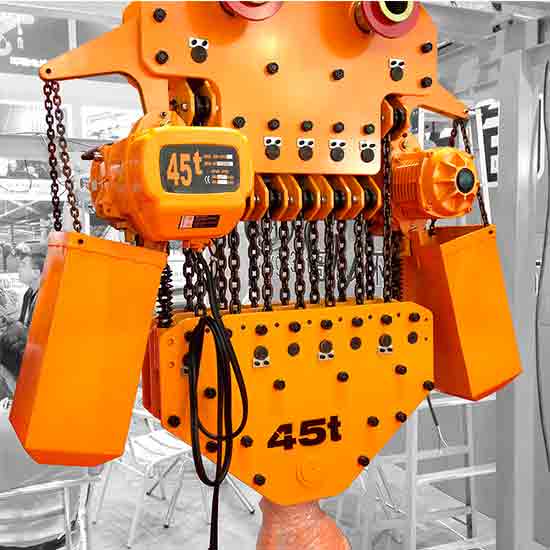

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

Slewing jib crane for light duty material handling like stone plate,etc.

Workstation Crane & Rotating jib cranes

Light duty overhead travelling crane with free standing crane design or ceiling mounted crane designs with capacity up to 2 ton for material handling within a defied area with the features of customized crane design , easy installation and relocation,etc.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

Freestanding or floor-mounted jib cranes designs, very economical workshop cranes with cost-effective price with capacity more than 20 tons , suitable for workshops which can not bear the lifting weight as required. Slewing jib cranes with specific specifications and designs are available to offer you the most suitable crane solution for your workshop applications.

Vacuum Lifting Attachments

Very specialized below hook devices with vacuum cups which makes the lifting much easier. The vacuum lifting attachments are mainly consisted of self-contained vacuum generator or plant air, movable vacuum cups which can easily lift and tilt the stone as required.

Turnkey services for your stone processing business

We but only offer you the industrial crane equipment but also offering turkey services for processing plants of marble, granite, slate and other stone handling, etc. No matter what type of industrial cranes you need,we can offer you the process overhead bridge cranes , gantry cranes, jib crane or workstation cranes to meet your industrial applications and your lifting requirement.