40 Ton Overhead Crane for Steel Factories & Warehouses

Check tailored 40-ton overhead cranes for steel factories and warehouses. Efficient, safe, and customizable for heavy-duty lifting and material handling.

| Crane Type | Top running double girder overhead crane |

| Crane Capacity | 40 ton |

| Lifting Height | As your request |

| Crane Span | Customized. |

Category: 40 Ton Overhead Crane

Your Trusted Overhead Crane Manufacturer & Supplier

40 Ton Overhead Crane for Sale

40 Ton Overhead Crane for Steel Factories & Warehouses

Introduction

Purpose of the Article

In steel factories and large warehouses, moving heavy materials safely and efficiently is not just a convenience—it's a necessity. Overhead cranes are a core part of industrial operations, helping lift, transport, and position heavy loads that forklifts or manual labor simply cannot handle. For operations dealing with steel coils, slabs, machinery, or stacked goods, a reliable overhead crane ensures smooth workflow, reduces damage to materials, and keeps workers safe.

Key Points to Consider:

- Overhead cranes are essential for handling heavy or awkward loads.

- They improve efficiency in warehouses and manufacturing plants.

- Safety is a major factor—proper cranes reduce workplace accidents.

Why 40 Ton Capacity Matters

Not every factory or warehouse needs a 40-ton crane, but when you do, it's for a reason. Steel processing plants, heavy machinery warehouses, and equipment storage yards often deal with extremely heavy loads like steel slabs, machinery parts, or bundled materials. A 40-ton overhead crane provides the lifting capacity needed for these heavy-duty operations without putting extra strain on equipment or operators.

Practical Examples Where 40 Tons Is Ideal:

- Steel mills moving large slabs or billets.

- Industrial warehouses handling heavy machinery or press parts.

- Construction material storage yards with stacked concrete or metal components.

- Logistics hubs that move oversized or bundled loads.

A crane that matches the load requirement ensures stability, reduces mechanical wear, and maintains a safer working environment.

Tailored Solutions

While standard cranes work for many situations, every facility has its own challenges. Factors like building height, span width, lifting frequency, and environmental conditions can affect performance. That's why tailored 40-ton overhead cranes are increasingly preferred. Customization allows the crane to fit the factory layout perfectly, optimize lifting paths, and adapt to specific operational requirements.

Tailoring Can Include:

- Adjusted span lengths or lifting heights for unique warehouse dimensions.

- Customized control systems, including pendant, cabin, or remote options.

- Special coatings or protections for outdoor or humid environments.

- Hoist and trolley configurations designed for the type of material handled.

A properly tailored crane isn't just about lifting—it's about making daily operations smoother, safer, and more predictable.

40 Ton Overhead Cranes

A 40-ton overhead crane is a heavy-duty lifting solution designed for industrial operations that move extremely heavy materials. From steel factories to large warehouses, these cranes are essential for handling loads that forklifts or manual labor cannot manage safely.

Types of 40 Ton Overhead Cranes

Bridge Cranes (EOT Cranes)

- Mounted on rails along the building walls.

- Moves materials across the entire factory span.

- Best suited for indoor operations like steel processing or warehousing.

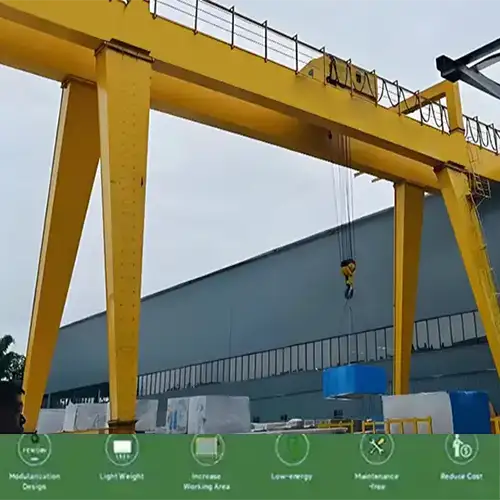

- Supported by legs that allow movement along the ground.

- Can be installed indoors or outdoors.

- Ideal for industrial yards, loading docks, or locations without overhead rails.

Structural Configurations

Single Girder

- One main beam with hoist on top.

- Cost-effective and easier to install.

- Suitable for moderate lifting frequency within 40-ton capacity.

Double Girder

- Two main beams supporting the hoist in between.

- Provides superior stability for heavy loads.

- Recommended for frequent or full 40-ton lifts over long spans.

Typical Applications

40-ton cranes are not just powerful—they improve efficiency and safety in everyday industrial work. Common use cases include:

Steel Manufacturing and Processing

- Lifting steel slabs, billets, and coils.

- Positioning components for rolling, forging, or assembly.

Warehousing Heavy Goods

- Moving machinery, industrial equipment, or bundled raw materials.

- Stacking products in high racks or large storage areas.

Industrial Yard Operations

- Loading and unloading trucks, rail cars, or containers.

- Handling large or awkward loads that forklifts cannot manage.

These scenarios show why 40-ton cranes are a practical choice for heavy industries.

Advantages of a 40 Ton Crane

Investing in a 40-ton overhead crane is more than buying lifting capacity—it's about smoother operations, safer workplaces, and better long-term performance.

Stable Heavy Lifting

- Can handle full 40-ton loads with minimal sway.

- Ensures precise placement of materials.

Improved Efficiency

- Moves materials faster than forklifts or manual handling.

- Reduces production and storage bottlenecks.

Versatile Coverage

- Capable of spanning wide factory floors or long warehouse aisles.

- Adjustable lifting heights for different facility needs.

In short, a 40-ton crane supports heavy-duty lifting while keeping operations safe, reliable, and efficient.

Key Technical Considerations

When choosing a 40-ton overhead crane, it's not just about lifting the weight—it's about making sure the crane fits your facility, operates safely, and works efficiently every day. Understanding the technical details ensures long-term reliability and prevents costly mistakes.

Load Capacity and Safety Margin

Every crane has a maximum rated load, but that doesn't mean it should always lift right up to that limit. Steel handling, in particular, demands extra caution because heavy materials can shift or swing during lifting.

Practical Points:

- Rated Load vs. Operating Load: Always plan to operate at a safe fraction of the maximum rated load. For a 40-ton crane, this means considering factors like material weight tolerance and lifting angle.

- Safety Factors: Industrial standards recommend a safety factor (often 1.25–1.5) to account for unexpected load variations, wear, or uneven weight distribution.

- Why It Matters: Overloading can lead to premature wear, hoist failure, or even accidents—making safety margins essential for both workers and equipment longevity.

Span and Lifting Height

The physical dimensions of your facility determine how a crane can move and what it can lift. Span and lifting height are critical to match the crane to your workflow.

Key Considerations:

- Span Selection: Measure the distance between runway beams carefully. Too short, and the crane won't cover the workspace. Too long, and it may require a heavier structure or additional supports.

- Height Requirements: Consider ceiling height, material stacking, and the highest lifting points. Lifting too close to the ceiling can restrict operations, while insufficient height can prevent stacking pallets or steel slabs efficiently.

- Factory Workflow: Ensure that the crane's movement doesn't interfere with machinery, storage racks, or personnel pathways. A well-planned span and height can significantly improve material flow.

Hoist Selection

The hoist is the heart of any overhead crane. For 40-ton cranes, choosing the right type of hoist directly impacts safety, efficiency, and maintenance requirements.

Options and Practical Tips:

Electric Wire Rope Hoist:

- Ideal for heavy loads and long lifting heights.

- Durable and designed for frequent use in steel factories or warehouses.

Chain Hoist:

- Better for shorter lifts and less frequent operations.

- Simpler design, easier to maintain, but generally limited in maximum load and speed.

Duty Cycle and Frequency:

- High-duty cranes (e.g., daily 8–10 hour operations) need robust wire rope hoists.

- For occasional lifts, a chain hoist may be sufficient, but always check the rated load and duty class.

Choosing the correct hoist ensures the crane operates smoothly, reduces wear on components, and keeps lifting operations safe.

Customization Options

Every facility is different. Even two steel factories handling the same materials can have very different layouts, workflows, and environmental challenges. That's why tailoring a 40-ton overhead crane to your specific needs can make a big difference in efficiency, safety, and long-term performance.

Structural Design

The steel structure of the crane is the foundation for everything else. Customizing it ensures the crane fits your facility and performs reliably under daily use.

Practical Options:

Tailored Steel Structure:

- Designed to match the exact span and lifting height of your building.

- Supports safe lifting of maximum loads without unnecessary stress on beams or hoists.

Modular Design:

- Allows for easier assembly and future modifications.

- Simplifies maintenance because individual components can be replaced without disassembling the entire crane.

A well-planned structural design ensures your crane operates safely, covers the required workspace, and lasts for years.

Control Systems

The way operators control the crane affects productivity, precision, and safety. Different control options can be chosen based on the type of operation and operator preference.

Common Control Configurations:

- Pendant Control: Direct, wired control for close-range operation. Simple and reliable.

- Radio Remote Control: Provides flexibility and safety for operators who need to move freely around the facility.

- Cabin Operation: Ideal for long spans or high-frequency operations where the operator stays onboard for better visibility.

- Optional Automation: For repetitive tasks, automated or semi-automated systems reduce human error and maintain consistent lifting speed.

Choosing the right control system improves efficiency, reduces fatigue, and enhances operational safety.

Environmental Adaptations

Industrial environments vary. A crane built for a dry, indoor warehouse may not perform well in a humid, dusty, or hazardous environment. Custom adaptations can protect the crane and maintain its reliability.

Adaptation Options:

- Corrosion-Resistant Coatings: Prevent rust and deterioration in humid or coastal areas.

- Explosion-Proof Versions: Required in zones with flammable gases, dust, or chemicals. These cranes meet strict safety standards to prevent sparks or overheating.

Environmental adaptations help protect both the crane and the materials being handled.

Additional Features

Some operational challenges require specialized features to ensure smooth and safe lifting.

Optional Features:

- Anti-Sway Systems: Reduce load swing for precise placement of heavy or long materials.

- Multiple Hook Options: Different hooks or spreader bars for lifting coils, slabs, machinery, or other non-standard shapes.

These custom features make everyday operations easier and safer, while also protecting materials and equipment from damage.

Installation and Maintenance Considerations

A 40-ton overhead crane is a heavy investment. To get the most out of it, proper installation and routine maintenance are crucial. Without these, even a high-quality crane can underperform or face early failures.

Installation Essentials

Installing a heavy crane isn't just about putting it in place—it's about making sure the building and supporting structures can handle the load safely.

What to check before installation:

Runway Beam Requirements

- Beams must support the crane's weight plus the maximum lifting load.

- Proper alignment is critical to prevent uneven wear or jerky movement.

- Check deflection limits—too much bending can reduce safety and precision.

Foundation and Building Load Capacity

- Verify that columns, walls, and foundations can handle crane operations.

- Heavy loads like steel slabs or machinery may require reinforcement.

- Prevents structural damage and ensures safe daily operations.

A well-planned installation sets the foundation for years of reliable crane performance.

Maintenance Practices

Once installed, the crane requires regular attention. Small problems left unchecked can quickly lead to downtime or costly repairs.

Key Maintenance Actions:

Routine Inspections

- Hoist, trolley, bridge, and hook mechanisms should be checked for wear.

- Brakes, limit switches, and electrical systems need regular testing.

Lubrication & Component Care

- Bearings, wire ropes, and gearboxes require proper lubrication and tension checks.

- Watch for unusual noises, vibration, or jerky movements—early signs of problems.

Spare Parts and Support

- Keep essential components available locally.

- Partner with suppliers who provide quick maintenance support to reduce downtime.

Benefits of Tailored 40-Ton Cranes

Choosing a tailored 40-ton overhead crane is more than just selecting a heavy-lifting machine—it's about creating a solution that fits your facility, your workflow, and your long-term needs. Customization brings tangible benefits in efficiency, safety, and return on investment.

Operational Efficiency

A crane that is designed specifically for your building layout and material flow can save time and reduce bottlenecks. When every lift is optimized, productivity improves naturally.

How tailored cranes improve efficiency:

- Reduced Downtime: Fewer mechanical issues and smoother operation mean less unplanned downtime.

- Faster Lifting Cycles: Properly sized spans, hoists, and trolley speeds allow quicker load movement.

- Optimized Workflow: The crane fits the facility layout, reducing travel distance and avoiding obstacles.

Enhanced Safety

Safety isn't just about adding protective devices—it's about designing the crane to match the tasks and materials it handles. Custom features make operations more predictable and reduce the chance of human error.

Safety benefits of a tailored crane:

- Precise Load Handling: Anti-sway systems, multiple hook options, and correct hoist selection reduce accidental swings or misplacement.

- Operator-Friendly Controls: Pendant, remote, or cabin controls positioned for visibility reduce strain and improve accuracy.

- Adapted to Environment: Explosion-proof or corrosion-resistant options protect both workers and equipment in challenging conditions.

Long-Term ROI

A well-designed crane pays off over time. Tailored solutions reduce maintenance costs, last longer, and adapt to changing operational needs.

Financial advantages:

- Durability: High-quality materials and designs matched to load and frequency ensure the crane withstands years of heavy use.

- Reduced Maintenance Costs: Correct sizing, proper installation, and local support mean fewer repairs and lower spare parts consumption.

- Future Adaptability: Modular designs and custom features allow upgrades or reconfigurations if your workflow or load requirements change.

Choosing the Right Supplier

Selecting the right supplier is just as important as choosing the crane itself. A reliable partner ensures that your 40-ton overhead crane is designed, installed, and maintained correctly, keeping your operations safe and efficient.

Experience with Heavy-Duty Cranes

Experience matters, especially when handling large loads like steel slabs or machinery. A supplier familiar with heavy-duty cranes can help you avoid design or operational mistakes.

What to look for:

- Proven Track Record: Look for suppliers with successful projects in steel factories, warehouses, and industrial yards.

- Industry Knowledge: Understanding of load handling, factory layouts, and material flow helps them provide practical recommendations.

- Problem-Solving Ability: Experienced suppliers can anticipate challenges in installation, operation, and maintenance.

Certifications

Certifications indicate that the supplier meets recognized quality and safety standards. These are crucial when dealing with heavy loads and strict industrial regulations.

Important Certifications:

- ISO Certification: Ensures quality management systems are in place.

- CE Marking: Confirms compliance with European safety standards.

- Third-Party Inspections: Independent verification of crane performance and safety adds confidence.

Certified suppliers are more likely to deliver a crane that meets both safety requirements and operational expectations.

After-Sales Support

Even a high-quality crane needs ongoing support. A supplier with strong after-sales services helps maintain reliability and reduces unexpected downtime.

Key Support Services:

- Installation Guidance: Expert supervision or instructions for proper setup.

- Maintenance Contracts: Scheduled inspections and preventative care to extend crane life.

- Spare Parts Supply: Quick access to replacement components prevents costly operational delays.

Reliable after-sales support ensures that your investment in a 40-ton crane continues to deliver value for years.

Conclusion

Selecting a 40-ton overhead crane is more than just picking a lifting machine—it's about choosing a solution that fits your facility, workflow, and long-term operational needs. Tailored cranes offer advantages that standard models cannot match, from efficiency and safety to durability and adaptability.

Summary of Key Points

- Operational Efficiency: Customized cranes reduce downtime, optimize material flow, and speed up lifting cycles.

- Enhanced Safety: Features like anti-sway systems, proper hoist selection, and environmental adaptations minimize operator error and material damage.

- Long-Term ROI: Durable designs, lower maintenance needs, and future adaptability ensure your investment pays off over time.

- Supplier Selection Matters: Experienced, certified suppliers with strong after-sales support ensure your crane operates safely and reliably.

Call to Action

Before purchasing, assess your specific requirements carefully: building layout, lifting height, load types, and operational frequency. Then consult with a reputable crane manufacturer who can provide a tailored 40-ton overhead crane designed for your facility.

A properly customized crane is not just a machine—it's a long-term partner for safe, efficient, and reliable material handling in steel factories and large warehouses.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch