Your Trusted 2 Ton Gantry Crane Manufacturer & Supplier

2 Ton Gantry Crane for Sale Buying Guide

Portable Aluminum Gantrys vs Mobile Steel Gantry Cranes vs. Overhead Gantry Cranes,

to Get Your Economical Solution

Discover the ultimate 2 Ton gantry crane buying guide. Compare portable aluminum, mobile steel, and overhead gantry cranes. Learn applications, hoist options, pricing, and tips for workshops, warehouses, and industrial use.

Why 2 Ton Gantry Cranes Matter A 2 Ton gantry crane is a versatile lifting solution designed for workshops, small factories, warehouses, and light industrial settings. It handles loads up to two tons, making it perfect for everyday lifting tasks without the complexity or cost of larger cranes.

Where They Are Used These cranes are commonly found in:

- Workshop maintenance and fabrication areas

- Small manufacturing plants

- Storage and warehouse facilities

- Outdoor or semi-covered industrial yards

Using a 2 Ton gantry crane in these environments saves time, reduces manual labor, and improves overall workplace safety. For example, moving a heavy steel plate or machinery part manually is slow and risky. A 2 Ton crane handles it quickly, allowing workers to focus on other tasks.

Purpose of This Guide This guide is aimed at buyers who want to make an informed choice. By the end of it, you'll know:

- The main types of 2 Ton gantry cranes and their configurations

- How different hoist options affect lifting performance

- Which crane works best for specific industrial applications

- Key considerations like span, height, mobility, and durability

- Practical tips for safe operation and maintenance

Your Trusted Overhead Crane Manufacturer & Supplier

Types of 2 Ton Gantry Cranes for Sale

Light Duty 2 Ton Gantry Cranes

Light-duty 2 Ton gantry cranes are built for mobility, compactness, and ease of use. They are ideal for smaller lifting tasks, where space is limited, and flexibility is important. These cranes are commonly used in maintenance workshops, small warehouses, and light manufacturing facilities.

Key Applications:

- Moving materials in workshops

- Small-scale fabrication tasks

- Maintenance and repair operations

- Lifting and transferring equipment in warehouses

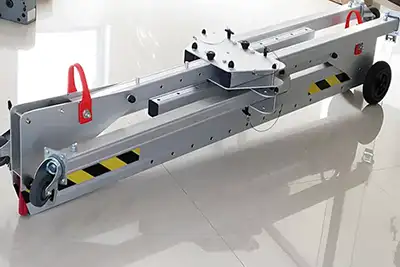

Portable gantry cranes are the most widely used type of light-duty 2 Ton crane. Their quick assembly, adjustable height, and mobility make them perfect for operations where the crane needs to be moved or stored after use.

Hoist Options:

- Manual Hoist – suitable for occasional lifting or lighter loads.

- Electric Hoist – ideal for frequent lifting, smoother operation, and higher efficiency.

- Portable Adjustable Gantry Crane – height can be adjusted, with manual or motorized travelling.

- Fixed Height Portable Gantry Crane – simpler design, available with manual or motorized travelling.

Aluminum Gantry Crane Options:

- Fixed Height Aluminum Gantry Crane – lightweight, corrosion-resistant, easy to move.

- Adjustable Aluminum Gantry Crane – variable height for different lifting tasks.

- Folding Gantry Crane – space-saving design, easy to store and transport.

- Telescoping Gantry Crane – adjustable boom height for versatile lifting requirements.

Your Trusted Overhead Crane Manufacturer & Supplier

Types of 2 Ton Gantry Cranes for Sale

Heavy Duty 2 Ton Gantry Cranes

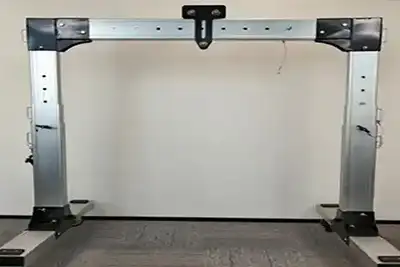

Overhead Gantry Cranes

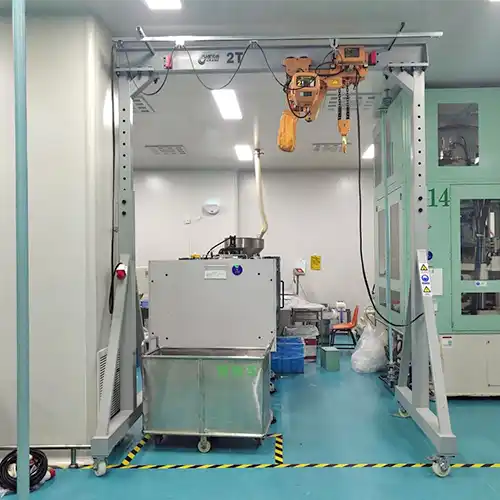

Overhead gantry cranes provide high repeatability, precise load handling, and reliable stability for industrial applications.

Heavy-duty 2 Ton gantry cranes are designed for fixed spans, high precision, and repeated industrial lifting tasks. These cranes are more robust than portable cranes and are suitable for continuous use in production lines, assembly lines, warehouses, and outdoor material handling.

Key Applications:Industrial production lines , Assembly operations ,Warehouse material handling , Outdoor loading/unloading tasks

Types of 2 Ton Overhead Gantry Cranes:

- Full Gantry Crane 2 Ton – spans the entire working area; suitable for indoor and outdoor use.

- Semi Gantry Crane 2 Ton – one side supported; ideal for space-constrained areas.

- Single Girder Gantry Crane – commonly used for standard 2 Ton applications. Can also be chosen as an economical solution using CD/MD hoists or as an advanced European-style low headroom crane.

- Double Girder Gantry Crane (Optional) – recommended for long spans or specialized lifting requirements.

Hoist Options:

- Electric Hoist – efficient for frequent or heavy lifting tasks.

- Manual Hoist – suitable for occasional use or lighter loads.

Industrial Applications and Suitable 2 Ton Gantry Crane Types

Before selecting a 2 Ton gantry crane, it's important to understand the types of applications, typical loads, and industrial environments. Different tasks require different crane configurations, hoist types, and mobility features. Below is a practical guide organized by industry to help buyers select the most suitable crane.

| Industry | Typical Loads | Recommended 2 Ton Gantry Crane Type |

|---|---|---|

| Steel Workshop / Fabrication | Steel plates, rods, small beams | Heavy-duty overhead gantry, single/double girder, electric hoist |

| Automotive Manufacturing | Engine blocks, molds, tools | Portable adjustable steel gantry, telescoping aluminum gantry |

| Maintenance Workshops | Machinery components, assemblies | Light-duty portable gantry crane, manual hoist options |

| Warehouse / Storage | Pallets, crates, containers | Portable/folding gantry crane, adjustable aluminum cranes |

| Small Manufacturing Plants | Small machinery, molds | Mobile gantry crane 2 ton, fixed height steel gantry crane |

| Outdoor Construction / Material Handling | Concrete forms, structural elements | Full gantry 2 ton, single or double girder overhead cranes |

Steel Workshops & Fabrication

Steel workshops and small fabrication plants often need to lift steel plates, rods, small beams, and other medium-sized components. Precision and repeatability are important, but mobility can also be critical in tight workshop spaces.

- Typical Applications: Lifting steel plates, rods, and small beams; moving fabricated components and assemblies

- Why it works: Portable steel gantry cranes with adjustable height allow easy relocation; fixed overhead cranes provide stability; electric hoists improve efficiency

- Recommended 2 Ton Gantry Crane Types: Heavy-duty overhead gantry cranes; single or double girder configurations; portable adjustable steel gantry cranes with electric or manual hoists

Maintenance & Repair Workshops

Maintenance workshops lift engines, machinery parts, tool assemblies, and other equipment. The focus here is mobility, safety, and occasional heavy lifting rather than continuous production.

- Typical Applications: Lifting engines and heavy machinery components; handling tool assemblies and repair equipment

- Why it works: Light-duty portable gantry cranes are easy to move; adjustable cranes allow height changes; aluminum cranes are lightweight and corrosion-resistant; manual or electric hoists can be chosen based on frequency

- Recommended 2 Ton Gantry Crane Types: Light-duty portable gantry cranes; adjustable steel or aluminum gantry cranes; manual or electric hoist options

Warehouse & Storage Handling

In warehouses, operators move pallets, crates, containers, and packaged equipment. Space can be tight, so mobility, adjustability, and quick setup are key.

- Typical Applications: Lifting pallets, crates, and containers; moving small packaged equipment efficiently

- Why it works: Folding or telescoping gantry cranes save space; aluminum cranes are light and corrosion-resistant; wheeled or motorized cranes improve workflow

- Recommended 2 Ton Gantry Crane Types: Folding portable gantry cranes; adjustable aluminum gantry cranes; wheeled or motorized travelling cranes

Automotive & Small Manufacturing Plants

Small manufacturing facilities and automotive workshops often lift molds, dies, and heavy machinery components. Workflow efficiency, precision, and space optimization are vital.

- Typical Applications: Lifting vehicle components and assemblies; handling molds, dies, and heavy tools

- Why it works: Portable adjustable steel cranes for flexibility; telescoping aluminum cranes for height; single girder 2 Ton cranes with CD/MD hoists; low headroom European-style cranes; mobile gantry cranes reduce manual movement

- Recommended 2 Ton Gantry Crane Types: Portable adjustable steel gantry cranes; telescoping aluminum gantry cranes; single girder 2 Ton cranes (manual or electric hoist); mobile gantry cranes

Outdoor & Construction Sites

Outdoor and construction environments require lifting concrete forms, lightweight structural elements, and temporary building materials. Stability, mobility, and durability are key.

- Typical Applications: Lifting concrete forms and structural elements; handling temporary construction materials

- Why it works: Full gantry cranes support entire span; single or double girder cranes adapt to long spans; adjustable or telescoping steel cranes; electric hoists improve efficiency; aluminum or corrosion-resistant steel frames ensure outdoor durability

- Recommended 2 Ton Gantry Crane Types: Full gantry 2 Ton cranes; single or double girder overhead cranes; adjustable or telescoping steel cranes; aluminum corrosion-resistant gantry cranes

Optional Features for Industrial 2 Ton Gantry Cranes

When selecting a 2 Ton gantry crane, buyers often look for features that simplify operations and improve safety.

- Adjustable or telescoping height for versatile lifting

- Single or double girder configurations for stability and longer spans

- Manual or electric hoist based on lifting frequency

- Folding, portable, or wheeled designs for storage and mobility

- Safety features: overload protection, limit switches, and lockable brakes

- Material choice: aluminum for lightweight, corrosion-resistant tasks; steel for heavier or outdoor lifting

Key Buying Considerations for 2 Ton Gantry Cranes

Buying a 2 Ton gantry crane involves more than lifting capacity. You need to consider materials, mobility, hoist type, and the operating environment. The right choice ensures safety, efficiency, and long-term reliability, whether you're in a small workshop, warehouse, or industrial plant.

Material

The crane's material affects strength, weight, and suitability for different industrial environments.

- Steel 2 Ton Gantry Cranes: Strong and durable; ideal for heavy-duty lifting, outdoor use, and harsh environments; can be treated with anti-corrosion coatings.

- Aluminum 2 Ton Gantry Cranes: Lightweight, portable, and corrosion-resistant; perfect for maintenance workshops, indoor factories, and dust-sensitive environments.

Mobility

Mobility impacts workflow, storage, and operational flexibility.

- Portable 2 Ton Gantry Cranes: Foldable, telescoping, or wheeled designs allow quick relocation; ideal for maintenance workshops, small plants, or temporary tasks.

- Fixed 2 Ton Overhead Cranes: Provide stability and precision for repeated lifts in production lines, warehouses, and outdoor construction sites.

Span and Lifting Height

Span and lifting height determine what the crane can reach and lift safely.

- Adjustable 2 Ton Gantry Cranes: Height can be changed for different workstations or material sizes.

- Telescoping Gantry Cranes: Allow variable lifting heights, especially useful in compact workshops.

- Fixed Height Overhead Cranes: Ideal for repetitive tasks where the lifting point is constant.

Hoist Type

The hoist is the heart of a 2 Ton gantry crane; choosing the right type affects efficiency and safety.

- Manual Hoist: Simple, economical; suitable for occasional lifts or smaller loads.

- Electric Hoist 2 Ton: Fast, smooth, and consistent lifting for frequent operations.

- Specialized Hoists: Explosion-proof or dust-proof hoists for hazardous environments like chemical or powder-handling industries.

Industrial Environment Requirements

The operating environment greatly influences crane design and durability.

- Indoor vs Outdoor: Indoor workshops can use aluminum or portable steel cranes; outdoor requires corrosion-resistant steel.

- Explosion-Proof: For chemical plants or flammable areas, use cranes with certified explosion-proof components.

- Dust-Free / Cleanroom: Aluminum or coated steel cranes with sealed hoists prevent contamination.

- Corrosion-Prone Areas: Anti-corrosion coatings, stainless steel, or aluminum cranes handle humid, coastal, or chemical environments.

Certification & Safety

Certified cranes provide confidence for operators and regulators.

- CE & ISO Certified: Compliance with international safety and quality standards.

- Local Standards: Check regional regulations for outdoor, hazardous, or industrial environments.

- Built-In Safety Features: Overload protection, limit switches, lockable brakes, and stable frames reduce operational risks.

Price and Purchasing Options for 2 Ton Gantry Cranes

Buying a 2 Ton gantry crane involves more than just comparing prices. Different types—portable steel, fixed-height, adjustable-height, aluminum, or overhead cranes—come with distinct features, mobility options, and industrial suitability. Understanding price ranges and supplier differences helps you make a practical, safe, and cost-effective choice.

Price Ranges

The price of a 2 Ton gantry crane varies depending on material, design, and hoist type:

- Portable Steel Gantry Cranes: Budget-friendly and durable; ideal for small workshops, maintenance, or light industrial lifting tasks. Manual hoists are cheaper, electric hoists increase cost.

- Fixed-Height Steel Gantry Cranes: Slightly higher price; provide stable lifting for repetitive tasks; suitable for warehouses and indoor fabrication areas.

- Adjustable-Height Steel Gantry Cranes: Flexible for different lifting heights; price rises with features like motorized wheels or telescoping frames.

- Aluminum Gantry Cranes: Lightweight, corrosion-resistant, portable; perfect for dust-free environments, small factories, or frequent relocation.

- Overhead Gantry Cranes (Single or Double Girder): Highest cost; designed for high-precision, repeated industrial lifting; ideal for production lines, assembly, and outdoor material handling.

Harbor Freight vs Branded Manufacturers

Many buyers compare affordable retail options with certified manufacturers:

- Harbor Freight or Retail Cranes: Lower upfront cost; suitable for occasional lifting or small workshop tasks; limited industrial features and customization.

- Branded Manufacturers (CE/ISO certified): Higher quality frames, optional electric hoists, anti-corrosion coatings, telescoping/adjustable heights, and reliable after-sales support; better for long-term industrial and outdoor use.

Focusing on quality, safety, and suitability often provides better long-term value than simply choosing the lowest price.

Tips for Comparing Suppliers

When choosing a 2 Ton gantry crane supplier, consider:

- Warranty Coverage: Structural parts, hoists, and electronics should be protected.

- After-Sales Support: Installation guidance, maintenance advice, and spare parts availability save time and cost.

- Customization Options: Ability to supply portable, aluminum, fixed-height, adjustable, or overhead cranes tailored to your environment.

- Industrial Environment Requirements: Ensure cranes suit conditions such as explosion-proof, corrosion-resistant, or dust-free facilities.

Proper research ensures your crane fits your industrial needs, performs reliably, and provides long-term value.

Maintenance and Safety Tips for 2 Ton Gantry Cranes

Proper maintenance and safe operation are essential for maximizing the lifespan of your 2 Ton gantry crane and protecting your team. Regular checks, correct handling, and proper hoist care not only reduce downtime but also prevent accidents in workshops, warehouses, and outdoor job sites.

Inspection Checklist

Before each use and at regular intervals, inspect your crane carefully:

- Daily Checks: Visual inspection of structural components, wheels, and hoist. Look for cracks, loose bolts, or unusual wear.

- Weekly Checks: Test limit switches, brakes, and electrical connections. Verify smooth travel along rails or wheels.

- Monthly Checks: Comprehensive review of girder alignment, hoist condition, and lubrication points. Replace worn or damaged parts immediately.

Consistent inspections help detect small issues before they become costly problems or safety hazards.

Proper Usage

Using your 2 Ton gantry crane correctly is as important as regular maintenance:

- Follow the rated load capacity and never exceed 2 tons.

- Conduct load tests for new installations or after major repairs.

- Avoid sudden starts, stops, or swinging loads to maintain stability and reduce wear.

Safe operation protects equipment, workers, and the materials being lifted.

Storage & Handling

How and where you store your crane affects its performance:

- Indoor Storage: Keep cranes sheltered from rain, dust, and corrosive environments.

- Protective Covers: Use covers for hoists and sensitive components when not in use.

- Wheel Maintenance: Regularly clean and lubricate wheels or travel mechanisms to ensure smooth mobility.

Proper storage prolongs service life and ensures readiness when lifting tasks arise.

Hoist Care

The hoist is the heart of your gantry crane, and it requires special attention:

- Lubrication: Follow manufacturer guidelines for all moving parts.

- Electrical Checks: Inspect wiring, controls, and safety devices regularly.

- Wear Inspection: Check chains, ropes, hooks, and sheaves for wear or damage. Replace immediately if worn beyond safe limits.

Regular hoist care ensures smooth, safe, and efficient lifting operations.

Frequently Asked Questions (FAQ) About 2 Ton Gantry Cranes

When buying a 2 Ton gantry crane, there are a few questions that come up all the time. Let's go through them in a practical, easy-to-understand way.

1. Where can I buy a 2 Ton gantry crane for sale?

2 Ton gantry cranes are widely available from certified industrial equipment suppliers, online marketplaces, and local distributors. For light-duty lifting, portable aluminum models from retail suppliers can work. For industrial applications, it's better to go with branded manufacturers that offer CE/ISO-certified steel cranes, warranty coverage, and after-sales support.

2. Which 2 Ton gantry crane is best for my workshop?

The "best" crane depends on your lifting needs, workshop layout, and workflow:

- Portable aluminum cranes: Lightweight, easy to assemble, perfect for occasional lifts in small workshops or maintenance areas.

- Mobile steel cranes: Heavier, more durable, ideal for frequent lifting in production lines or warehouses.

- Adjustable or telescoping cranes are useful if you need variable lifting heights.

- Single girder overhead cranes are cost-effective for repeated lifting tasks, while double girder designs suit longer spans or heavier applications.

3. Portable aluminum vs mobile steel 2 Ton gantry cranes – which should I choose?

- Portable aluminum 2 Ton gantry cranes: Easy to move manually, corrosion-resistant, great for occasional lifting, and can be stored or folded when not in use.

- Mobile steel 2 Ton gantry cranes: Designed for heavier-duty use, frequent travel, and industrial workflows. Can be wheeled or motorized to move loads efficiently across larger workshops or warehouses.

In short: If you lift occasionally in a small space, go for aluminum. If you need durability and frequent handling in a production environment, steel is the better choice.

4. How much does a 2 Ton gantry crane cost?

Prices vary depending on material, mobility, and features:

- Portable aluminum cranes: Lower-cost, lightweight, corrosion-resistant, ideal for workshops or maintenance tasks.

- Mobile steel cranes: Higher investment, built for industrial use, repeated lifting, and long spans.

- Overhead or double girder cranes: Highest cost but offer precision, stability, and repeated use efficiency.

Compare suppliers carefully, check warranty terms, and consider after-sales service for long-term reliability.

5. Can a 2 Ton gantry crane handle irregular-shaped loads?

Yes, with the right accessories. Slings, spreader bars, or special hooks can help lift irregular loads safely. For frequent handling of uneven shapes, an electric hoist or adjustable-height crane will provide better control and stability than manual lifting alone.

Conclusion: Get Your Tailored 2 Ton Gantry Cranes

Selecting the right 2 Ton gantry crane is all about matching the crane to your real-world needs. Before you decide, think carefully about:

- Crane type: Portable aluminum for light-duty, flexible lifting or mobile steel for heavier, frequent industrial use.

- Load requirements: What you lift most often—steel plates, machinery parts, pallets, or irregular-shaped items.

- Hoist options: Manual for occasional lifts, electric for frequent, smooth, and efficient operation.

- Portability and mobility: Will the crane move around your workshop, or stay in a fixed spot?

- Industrial environment: Indoor, outdoor, corrosive, dust-free, or special conditions like explosion-proof areas.

Careful planning makes all the difference. Talking with experienced suppliers or crane specialists can help you choose the safest, most efficient solution for your workspace.

Send Us An Inquiry

- Request a personalized quote.

- Download a detailed 2 Ton gantry crane specification checklist.

- Contact a supplier to discuss your specific lifting needs and industrial environment.

By taking the time to evaluate your options, you'll ensure the crane you select supports your workflow, keeps your team safe, and lasts for years to come.