Motorized 2 Ton Gantry Cranes for Sale | Portable & 360° Rotating

Motorized 2 ton gantry cranes for sale featuring portable frames, easy travelling wheels, and 360° rotating designs for flexible material handling.

Category: 2 Ton Gantry Crane

Your Trusted Overhead Crane Manufacturer & Supplier

Motorized 2 Ton Gantry Cranes for Sale

Electric Motoried Travelling Portabe Gantry Cranes , 360 Degree Rotating Gantry Cranes

Introduction

2-Ton Gantry Cranes: A 2-ton gantry crane is a versatile lifting solution, a portable gantry cranes designed for small to medium industrial operations. It provides a practical balance of lifting capacity and flexibility, making it ideal for workshops, warehouses, and construction sites where space and efficiency matter.

Why Motorized, Portable, and Rotating Cranes Stand Out: These cranes are not all the same. Their key advantages include:

- Motorized Operation: Lift and move heavy loads with minimal manual effort, saving time and reducing operator fatigue.

- Portability: Easily relocate the crane between workstations or even different sites without complicated setup.

- 360° Rotation: Move and position loads precisely, even in tight or awkward spaces, which is especially helpful for confined workshops or outdoor yards.

Industries That Benefit Most: Motorized 2-ton gantry cranes find practical use across several industries:

- Manufacturing Workshops: Efficiently move raw materials, parts, and semi-finished products along assembly lines.

- Warehouses: Simplify loading, unloading, and storage of goods.

- Metal & Fabrication Workshops: Handle steel beams, sheets, and heavy machinery safely.

- Construction Sites: Move tools, equipment, and materials with more control and less labor.

A 2-ton gantry crane isn’t just a lifting device—it’s a solution for smoother, safer, and more efficient material handling. Whether you need motorized power, portability, or 360-degree rotation, these cranes help operators get the job done faster and with less strain.

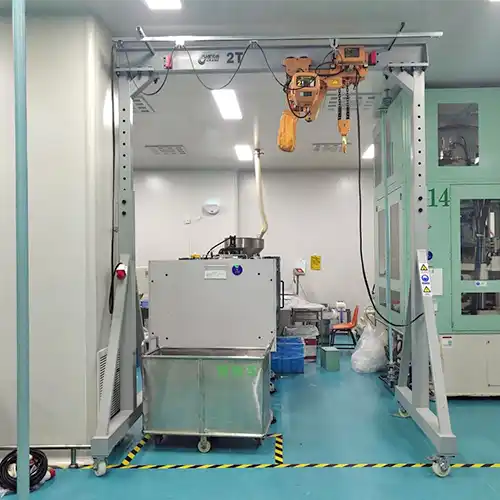

2 Ton Gantry Cranes with Motorized Portable Roller Travelling

A 2-ton motorized gantry crane with portable roller travelling combines electric lifting and smooth horizontal movement to make material handling easier. Unlike manual cranes, these systems use a motorized hoist and traveling mechanism, allowing operators to lift, move, and position loads with precision. The video on the left is the motorized travelling portable gantry crane 2 ton for subway light duty material handling. If you have any needs, please feel free to contact us.

Key features include:

- Electric motorized hoisting and traveling: Move loads along the crane's path without manual pushing or pulling.

- Precise and efficient load positioning: Perfect for tasks that require accurate placement of materials or equipment.

- Durable construction: Built to handle daily industrial use, often with steel or reinforced aluminum structures for longevity.

Benefits to Buyers

Investing in a motorized portable gantry crane brings several practical advantages:

- Reduced manual labor and improved safety: Operators no longer need to push heavy loads, lowering the risk of injuries.

- Faster operations and higher productivity: Motorized systems speed up lifting and moving, allowing more work to be completed in less time.

- Less operator fatigue: With lifting and traveling automated, workers can focus on positioning and handling materials safely rather than physical exertion.

Common Applications

These cranes are ideal for a wide range of industrial tasks, especially where mobility and precise positioning are required:

- Small to medium manufacturing workshops: Move raw materials, parts, or semi-finished products along assembly lines.

- Storage yards and warehouses: Load and unload materials efficiently, including pallets, steel components, or machinery.

- Maintenance, assembly, and material transport: Handle equipment, spare parts, or tools safely without excessive manual effort.

360-Degree Rotating Gantry Cranes

Structural and Functional Features

360-degree rotating gantry cranes are designed to give operators complete control over load positioning, especially in confined or complex spaces. These cranes use a rotating base or turntable, allowing the crane and load to move in a full circle without needing to reposition the entire structure.

Key features include:

- Rotating base or turntable: Enables full-circle operation, making it easy to lift and place loads in any direction.

- Motorized rotation: Move loads precisely without having to manually shift or adjust them.

- Flexible operation options: Can be operated via a cabin or remote control, depending on the site requirements and operator preference.

Benefits for Buyers

Investing in a 360-degree rotating crane improves both efficiency and safety:

- Maximum flexibility: Ideal for workshops or yards with limited space or complex layouts.

- Reduced manual handling: Long, awkward, or heavy loads can be positioned without repeated manual adjustments.

- Higher efficiency: Faster load placement reduces downtime and streamlines workflow.

Industries and Applications

These cranes are highly practical across industries that require versatile material handling:

- Manufacturing plants: Especially those with complicated floor plans where fixed cranes cannot reach all areas.

- Steel and metal fabrication workshops: Handle beams, sheets, and machinery components with precision.

- Outdoor storage yards: Easily maneuver materials like heavy pallets, long steel bars, or bulky equipment.

Key Buying Considerations

Before purchasing a 2-ton gantry crane, it’s important to look beyond the basic specifications. The right crane should match your operational needs, workspace layout, and safety requirements. Paying attention to these key factors will help you avoid costly mistakes and ensure smooth daily operations.

When evaluating a crane, consider the following:

- Verify lifting capacity with safety margins: Always confirm the maximum load the crane can handle and include a 20–30% safety buffer to prevent overloading.

- Determine mobility requirements: Think about how often the crane will need to move. Choose between a fixed, portable, or rotating crane depending on your workflow and site layout.

- Check power supply and motor compatibility: Ensure that the crane’s motor system matches your available electricity, voltage, and frequency.

- Consider structural material for outdoor use: If the crane will be used outdoors, opt for corrosion-resistant materials such as treated steel or aluminum to withstand weather conditions.

- Optional features: Some additional options can improve safety and efficiency, such as remote control operation, adjustable height, weatherproofing, and extra safety devices.

By considering these points, you can select a crane that not only meets your lifting requirements but also provides long-term reliability and operational efficiency.

Practical Buying Checklist

Even after identifying the type of crane you need, it helps to follow a structured checklist before making a final decision. This ensures that all practical considerations are addressed, from workspace compatibility to supplier reliability.

Here are the steps buyers should follow:

- Define lifting and traveling requirements: Identify your maximum load, required lifting height, and travel distances to make sure the crane can handle your daily operations.

- Measure installation site, floor load, and ground conditions: Ensure the floor can safely support the crane’s weight and that there’s enough space for its movement and operation.

- Compare multiple crane models and suppliers: Don’t focus solely on price. Look at durability, certifications, warranty, and after-sales support to ensure you’re investing wisely.

- Request detailed quotations: Ask for a complete breakdown including shipping, installation, operator training, and any optional accessories to fully understand the total cost.

Conclusion

Why These Cranes Matter: Motorized, portable, and 360° rotating 2-ton gantry cranes aren’t just about lifting—they make daily operations smoother and safer. They help you move heavy loads precisely, reduce manual strain, and improve workflow, whether in a workshop, warehouse, or outdoor yard.

Making the Right Choice: Selecting the right crane means looking beyond just the tonnage. Consider your workspace layout, mobility needs, power supply, and optional features. A well-matched crane boosts productivity, minimizes downtime, and keeps your team safe.

Take Action: Don’t guess—get the crane that fits your needs. Contact a trusted supplier today for a personalized 2-ton motorized gantry crane quotation. Ensure your investment works efficiently for your operations from day one.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch