2 Ton Aluminum Telescoping Gantry Crane for Clean Rooms

2 ton gantry crane for sale. 2 ton aluminum gantry crane with telescoping height & low-headroom hoist improves clean room efficiency, safety, & mobility.

Category: 2 Ton Gantry Crane

Your Trusted 2 Ton Gantry Crane Manufacturer & Supplier

2 Ton Telescoping Gantry Cranes for Compact Workspaces

Case Study: 2 Ton Aluminum Gantry Crane with Telescoping Design and Low-Headroom Hoist for Clean Room Applications

Why choose a telescoping gantry crane for tight workspaces

When workspaces get tighter but the lifting jobs keep coming, a telescoping gantry crane can make all the difference. It's designed for environments where ceiling height, floor space, or layout doesn't allow for a fixed-height or permanent overhead crane. These cranes feature adjustable columns that can extend or retract, letting operators change the lifting height to match the space available. Whether it's moving molds in a small workshop, lifting test equipment in a lab, or handling components inside a clean room, a telescoping gantry crane gives flexibility that fixed models simply can't.

Practical benefits buyers care about:

- Easily adjusts to fit under low ceilings or ductwork.

- Can be rolled or disassembled to move between work areas.

- Requires no fixed installation—ideal for rented or shared facilities.

- Provides safe, controlled lifting for maintenance or assembly tasks.

Focus on 2 Ton Capacity

A 2 ton gantry crane hits a sweet spot in many light industrial and precision work settings. It's strong enough to lift machinery, molds, pumps, or lab equipment, yet light enough to remain portable and easy to handle.

In clean workshops, R&D labs, or assembly zones, overhead cranes often aren't practical due to limited headroom or strict cleanliness rules. That's where a 2 ton telescoping model fits perfectly—it provides the right balance of lifting power, cleanroom adaptability, and user-friendly operation.

Why 2 ton models are widely chosen:

- Handles most light-to-medium assembly and maintenance work.

- Compatible with manual chain or compact electric hoists.

- Simple to set up or move without requiring a heavy support structure.

- Cost-efficient solution for occasional lifting needs in multiple areas.

Relevance to You

More buyers today are searching for compact, mobile lifting equipment that doesn't interfere with their workspace layout. Industries like pharmaceutical manufacturing, electronics assembly, and precision engineering often have strict requirements—clean surfaces, quiet operation, and low particle emission. Traditional steel cranes can be too heavy or difficult to clean.

A 2 ton aluminum telescoping gantry crane fits that need. It's lightweight, corrosion-resistant, and can be equipped with a low-headroom hoist to make the most of limited ceiling space. Many cleanroom users appreciate that it can be rolled in, set up, and used without permanent fixtures or structural changes to the facility.

Growing buyer trends:

- Demand for portable gantry cranes in compact production lines.

- Preference for modular and adjustable designs that adapt to changing workstations.

- Increased focus on cleanroom-compatible materials such as anodized aluminum.

- Need for equipment that supports easy relocation and quick setup between zones.

In short, the 2 ton telescoping gantry crane is becoming a trusted choice for clean, compact, and controlled environments where space and flexibility are just as important as lifting strength.

What Is a Telescoping Gantry Crane?

A telescoping aluminum gantry crane 2 ton is a type of mobile lifting equipment built with adjustable vertical columns that allow the beam height to move up or down. In simple terms, it's a gantry crane that can "grow taller" or "shrink lower" to match your workspace.

This flexibility makes it ideal for places where ceiling height or overhead obstructions change from one area to another — like under air ducts, sprinkler pipes, or lighting fixtures. Instead of being locked to one size, operators can adjust the crane height using locking pins, hand cranks, or screw mechanisms depending on the design.

Typical applications include:

- Maintenance and equipment lifting in workshops with variable ceiling heights

- Assembly work in laboratories and clean rooms

- Lifting and moving molds, small machines, or test setups in production lines

- Mobile service work where lifting height changes frequently

Key Functional Features

Telescoping gantry cranes combine several features that make them practical for modern workshops, testing facilities, and small-scale production areas.

Adjustable Height and Span Options

- The height can be manually or mechanically adjusted, often within a range of 1.8 to 3.5 meters, depending on model.

- Adjustable spans make it easier to fit through doors or narrow aisles.

- Users can fine-tune lifting height to match hoist type and load requirements.

Portable or Stationary Frame Designs

- Portable models come with caster wheels, allowing the entire crane to be pushed or pulled by one or two operators.

- Stationary types are used for semi-permanent setups where mobility isn't needed.

- Casters often include locks or brakes for stable positioning during lifting.

Easy Disassembly and Transport

- The modular frame allows quick breakdown into 3–4 parts — ideal for tight storage or moving between job sites.

- Aluminum versions are light enough for manual handling without lifting equipment.

- Some models even fit into small trucks or elevators for easy relocation.

Why these features matter

These features make telescoping gantry cranes a practical, space-saving choice for users who need flexibility without installing permanent lifting systems.

Comparison with Fixed-Height Gantry Cranes

When Fixed-Height 2 Ton Gantry Cranes Are Still Useful:

- For repetitive lifting in a single, uniform space.

- When maximum rigidity or heavy-duty performance is required.

While both telescoping and fixed-height gantry cranes serve similar lifting purposes, their usability differs greatly depending on the workspace.

Advantages of Telescoping Gantry Cranes:

- Adjustable clearance: Works under different ceiling heights and structures.

- Compact storage: Lower the beam to minimize space when not in use.

- Multi-zone operation: Move easily between production or maintenance areas.

- Cost-effective flexibility: One crane can serve multiple stations with different height limits.

In short, a telescoping gantry crane gives you more freedom and flexibility in workspace planning. You can lift where you need, when you need, without worrying about permanent installations or clearance restrictions — a big advantage in compact, modern work environments.

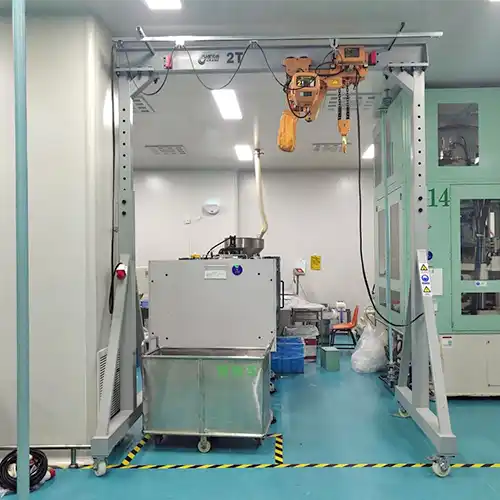

Case Study: 2 Ton Aluminum Telescoping Gantry Crane for Clean Room

Project Background

A pharmaceutical equipment manufacturer approached Yuantai Crane with a very specific problem — how to lift and position precision instruments inside a clean room with limited headroom and tight movement areas. The facility operated under strict air purity and cleanliness standards, leaving no room for heavy or dusty lifting equipment.

The client needed a lifting system that could:

- Fit under low ceilings and air ducts.

- Move freely between zones without disturbing airflow or introducing particles.

- Support up to 2 tons of delicate machinery during assembly and maintenance.

- Comply with cleanroom cleanliness levels and safety protocols.

A standard steel gantry crane was immediately ruled out because of its weight and potential for surface oxidation. The solution had to be light, corrosion-resistant, and easy to clean — all without compromising stability or lifting safety.

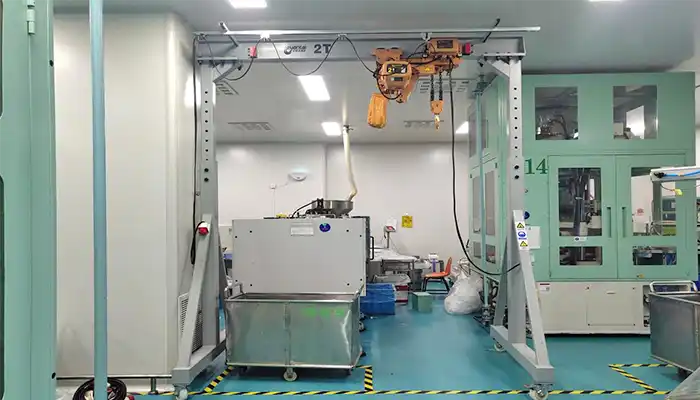

2 ton telescoping gantry crane with low headroom electric chain hoist to get required lifting height in low built workshops and facilities

cleanroom gantry crane 2 ton with aluminum telescoping design, cleanroom crane for sale

Customized Crane Solution

Our factory's crane engineering team proposed a 2 ton aluminum gantry crane tailored to the client's workspace and cleanroom requirements. The goal was to provide full lifting flexibility while maintaining strict hygiene and height limitations.

Key customizations included:

- Frame Material – Anodized Aluminum:

Lightweight yet strong, aluminum made it easy for two operators to move the crane manually. Its anodized finish prevented corrosion and made it simple to wipe down after each use. - Telescoping Design – Adjustable Height from X mm to Y mm:

The telescopic columns allowed the beam to slide up or down as needed, fitting perfectly under overhead air ducts and filters. This ensured the crane could handle multiple cleanroom zones with varying clearance heights. - Low-Headroom Electric Chain Hoist:

A compact hoist was fitted to keep the overall hook height as low as possible, maximizing the lifting stroke within the restricted ceiling space. Despite its small size, it provided smooth, precise lifting control suitable for sensitive instruments. - Wheel and Brake System – Non-Marking Casters:

The crane used cleanroom-grade polyurethane casters that leave no marks or debris on epoxy or vinyl flooring. Each caster had a double-locking brake to secure the frame during operation. - Surface Finish – Smooth and Dust-Resistant:

All surfaces were polished and coated to minimize dust buildup. This design prevented particle shedding and met the client's cleanliness level requirements under ISO Class 7 standards.

Installation and Operation

The installation was intentionally simple — no welding, no bolting to the floor, and no structural modification to the cleanroom.

Ease of setup and use:

- The crane was delivered in a modular kit and assembled in less than half a day.

- Each section could be disassembled for cleaning or relocation between rooms.

- The crane rolled smoothly along narrow aisles, and its adjustable height meant it could pass through doorways without disassembly.

- The electric hoist operated quietly, minimizing vibration and noise that could affect sensitive equipment.

For maintenance crews, this setup eliminated the need to bring in forklifts or external lifting services, saving both time and cost while maintaining cleanroom integrity.

Outcome and Buyer Benefits

After installation, the client reported a clear improvement in lifting efficiency and operational flexibility. They could move precision instruments safely without contamination risks, and routine equipment handling became smoother and faster.

Key results achieved:

- Safe and clean lifting of sensitive laboratory and production equipment.

- Zero contamination incidents after several months of operation.

- Reduced equipment downtime since the crane could be moved directly to different cleanroom zones.

- Compliance with ISO cleanroom and safety standards, verified through internal audits.

The client later added two more identical cranes to support expansion work — a strong sign that the aluminum telescoping gantry crane met both their technical and practical needs in a demanding cleanroom environment.

Key Design Advantages

Every buyer who looks at a 2 ton telescoping gantry crane wants to know what makes it worth choosing over other lifting options. The main strengths come from its height adjustability, portability, material flexibility, and cleanroom compatibility. These design advantages make it not only a practical tool for daily operations but also a long-term solution for changing workspace needs.

Height Adjustability

One of the most useful features of a telescoping gantry crane is its ability to adjust height according to the workspace. Whether the crane is working in a cleanroom with air ducts or a low-ceiling maintenance area, the beam height can be changed in just a few minutes. This flexibility ensures safe and efficient operation without having to modify the building structure.

Benefits of adjustable height:

- Easily fits under low ceilings or ductwork.

- Allows better hook travel for higher lifting range.

- Saves time when shifting between different work zones.

- Reduces the need for multiple cranes with different sizes.

With a telescoping frame, operators can fine-tune the working height for each lifting task—something fixed-height cranes simply can't do.

Portability

In modern workspaces, mobility matters. A telescoping gantry crane is built with casters and a balanced frame so it can move between different stations or rooms. This makes it perfect for buyers who operate in multi-zone workshops, cleanrooms, or temporary setups where the layout changes often.

Why portability adds value:

- Serves several workstations with a single crane.

- Easy to roll and position, even in narrow aisles.

- Can be stored away when not in use to save space.

- No permanent rails or foundation needed, lowering setup cost.

Instead of installing a heavy overhead system, buyers can rely on one mobile crane to handle different lifting jobs across the site.

Material Options

The construction material affects not only performance but also maintenance and safety. Yuantai offers both aluminum and steel options, allowing buyers to match the crane to their working environment.

Material choices and uses:

- Aluminum: Light, corrosion-resistant, and easy to clean. Ideal for cleanrooms, labs, and precision assembly lines.

- Steel: Strong, durable, and suitable for heavy-duty or outdoor work. Often used in workshops, storage yards, and factories.

Aluminum telescoping gantry cranes are especially favored in clean or controlled environments. They can be moved by hand, require minimal maintenance, and resist wear from cleaning chemicals used in sterile facilities.

Cleanroom Compatibility

For cleanroom users, surface quality and material selection are critical. The aluminum telescoping gantry crane is specifically designed to meet these requirements. Its smooth anodized surfaces prevent dust buildup, while all joints and fasteners are sealed to minimize particle release.

Cleanroom design advantages:

- Non-shedding materials with smooth, polished finishes.

- Non-marking casters suitable for epoxy or vinyl flooring.

- Corrosion-resistant components, including stainless bolts and fittings.

- Quiet and low-vibration hoist operation to maintain air stability.

Practical Buying Considerations of 2 Ton Telescoping Gantry Cranes

Before finalizing a purchase, it's worth taking a closer look at how the crane will actually fit and perform in your workspace. A 2 ton telescoping gantry crane offers flexibility, but getting the details right from the start ensures smooth operation and long service life. The points below are what experienced buyers check carefully before confirming their order.

Workspace Height and Clearance Measurements

Every workspace has its limits — air ducts, sprinklers, lighting fixtures, or low ceilings. Telescoping cranes solve part of the problem, but accurate measurement is still essential.

What to check:

- Measure from floor to the lowest obstruction, not the ceiling itself.

- Leave enough clearance for the hoist and hook travel.

- Note doorway heights if the crane needs to move between rooms.

Accurate dimensions prevent costly modifications and help your supplier recommend the correct telescoping range and beam span for your site.

Load Dimensions and Lifting Frequency

Knowing what you'll lift and how often you'll do it has a major impact on crane design and hoist selection.

Key points to consider:

- Maximum load weight and average working load.

- Shape and balance of the item being lifted — wide loads may need more span.

- Frequency of lifting operations per day or week.

For cleanroom or lab use, loads are lighter but require high precision. Occasional lifts may use a manual hoist, while frequent operations benefit from an electric hoist with smooth control.

Hoist Type

The hoist is the working heart of the gantry crane — choosing the right one affects efficiency and operator comfort.

Common options:

- Manual chain hoist: Simple, low-cost, suitable for occasional use.

- Electric chain hoist: Compact and efficient for frequent light-to-medium duty work.

- Electric wire rope hoist: Better for smoother, faster lifting and heavier cycles.

For most 2 ton telescoping gantry cranes, the electric chain hoist is preferred for easy control, low noise, and compact design — especially when headroom is limited.

Caster Type and Floor Surface Compatibility

Mobility is a main advantage of a gantry crane, but the wrong caster type can cause damage or poor movement. The wheel material should match your floor surface.

Recommendations:

- Polyurethane or nylon casters for epoxy or vinyl cleanroom floors.

- Rubber or steel casters for rough concrete or outdoor use.

- Always choose locking casters or floor brakes for stable lifting.

Non-marking wheels are essential for clean environments where dust or streaks must be avoided.

Assembly and Disassembly Frequency

If your crane needs to move between job sites or zones, quick setup and breakdown are key. Aluminum telescoping gantry cranes can be assembled without welding or special tools.

What to evaluate:

- Number of people needed for assembly.

- Whether parts fit through standard doorways or elevators.

- Time required to set up and secure the crane.

A modular frame with bolts and locking pins provides the best balance of strength and convenience.

Certification and Inspection Standards

Safety and compliance should never be overlooked. Reputable suppliers provide cranes built to meet international standards, especially for regulated environments like cleanrooms or pharmaceutical facilities.

Key certifications to look for:

- CE Marking – ensures conformity with EU safety and quality standards.

- ISO Certification – verifies quality assurance in manufacturing.

- Cleanroom grade documentation – confirms surface finish and material suitability.

Proper certification guarantees operator safety and simplifies audits or approvals in controlled environments.

Conclusion and Buyer Takeaways

When it comes to lifting in compact or clean environments, a 2 ton telescoping gantry crane is a practical and reliable choice. Its adjustable height, portable design, and low-headroom capabilities make it ideal for workshops, laboratories, and production lines where space is limited.

Why buyers choose telescoping gantry cranes:

- Flexibility: Adjusts to different ceiling heights and overhead obstacles.

- Mobility: Can be relocated easily between rooms or workstations.

- Cleanroom-ready: Aluminum frames with smooth, non-shedding surfaces meet hygiene requirements.

- Versatile: Suitable for both light manufacturing and precision laboratory lifting tasks.

In addition, the aluminum structure keeps the crane lightweight while providing strength and corrosion resistance, making it perfect for sensitive or controlled environments. For heavier-duty applications, steel models offer additional durability without sacrificing performance.

Send Us an Inquiry

- Contact Us for a customized 2 ton telescoping aluminum gantry crane.

- Get a solution tailored to your workspace, cleanroom standards, and lifting needs.

- Ensure your equipment meets both operational efficiency and safety compliance from day one.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch