Your Trusted Overhead Portable Gantry Crane Manufacturer & Supplier

1 Ton to 10 Ton Portable Gantry Crane for Sale

Ultimate Guide to Portable Gantry Cranes: Types, Specifications, and Buyer Considerations

Introduction to Portable Gantry Cranes

Portable gantry cranes are some of the most practical lifting tools you can have in a workshop or factory. They are designed to move materials easily, handle heavy loads safely, and adapt to different workspaces. Whether you're running a small machine shop, a medium-sized warehouse, or doing maintenance work, portable gantry cranes provide flexibility that fixed cranes simply can't.

They are especially useful in situations where space is limited, or when you need to move heavy items from one area to another without the need for permanent installation. These cranes come in various types, including adjustable gantry cranes, electric portable gantry cranes, and motorized mobile gantry cranes, each offering different levels of lifting capacity and mobility.

Key practical advantages include:

- Mobility: Can be moved around the workshop or warehouse without disassembly.

- Adjustable height: Many models allow you to set the crane at different heights for varying lifting needs.

- Easy assembly and disassembly: Ideal for temporary setups or jobs that require frequent relocation.

- Flexible operation: Options for manual or electric hoist, depending on load weight and frequency of use.

- Cost-effective: Requires less investment than a fixed overhead crane, while still offering high utility.

What Is a Portable Gantry Crane?

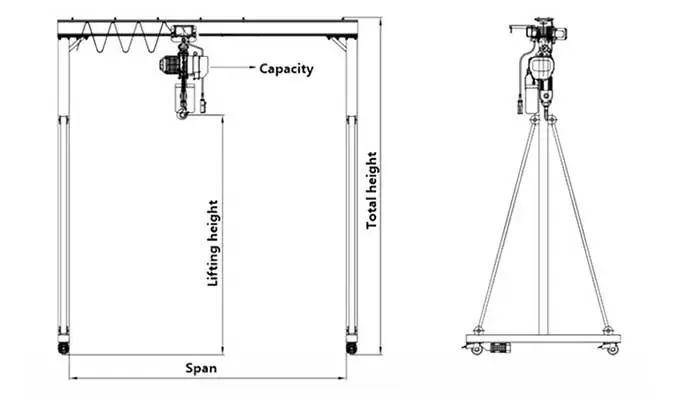

A portable gantry crane is essentially a freestanding lifting frame that supports a hoist. Unlike overhead cranes that are fixed to a ceiling or rail, portable gantry cranes can be moved from one location to another, making them highly versatile for different tasks.

They are used in a wide range of industries, including manufacturing, maintenance, warehousing, and construction. The key is that these cranes combine mobility with the ability to lift medium to heavy loads safely. Some models are lightweight for small workshops, while others are heavy-duty for industrial lifting.

Practical features to consider include:

- Load capacity: Typically ranges from 1 ton to 20 tons depending on the model.

- Max lifting height: Usually between 5 meters to 15 meters.

- Hoist type: Electric hoist for frequent and heavier lifting, manual hoist for occasional or lighter loads.

- Movement: Wheels allow manual movement, and some models include electric or motorized traveling for long distances.

- Structure: Lightweight models for easy transport versus heavier, industrial models for maximum stability.

Portable gantry cranes are not just tools—they are solutions that make lifting, moving, and installing heavy objects safer and faster. They save time, reduce the risk of workplace injuries, and can adapt to different working conditions, which is why they remain a common choice across small and medium industrial setups.

Common Applications?

Portable gantry cranes are used in a wide range of industries because they offer flexibility that fixed cranes cannot. They are particularly useful in environments where lifting tasks vary frequently or where space is limited. These cranes allow workers to move heavy loads safely and efficiently without requiring permanent installation, which makes them highly practical for both small-scale and industrial operations.

Some of the most common applications include:

- Industrial maintenance: Ideal for lifting machinery parts, tools, and equipment during repair or servicing.

- Workshop lifting and assembly: Helps technicians and engineers lift and position components accurately during assembly tasks.

- Small and medium manufacturing facilities: Supports day-to-day material handling and production line adjustments.

- Machine installation and relocation: Makes it easier to move heavy machines within a factory or workshop.

- Outdoor and indoor material handling: Suitable for loading, unloading, and transporting materials in different environments.

- Light to heavy-duty lifting operations: Depending on the model, portable gantry cranes can handle loads from 1 ton up to 20 tons safely.

With these applications, portable gantry cranes reduce manual labor, improve operational efficiency, and allow teams to complete tasks faster and more safely. They are especially helpful for workshops or factories that require frequent movement of equipment and materials.

Advantages of Portable Gantry Cranes

The main reason many companies invest in portable gantry cranes is the combination of flexibility, efficiency, and safety. Unlike fixed overhead cranes, portable models can be adapted to different tasks, moved to various locations, and adjusted according to the load and workspace requirements. This versatility makes them a practical choice for a wide range of industries.

Key advantages include:

- Mobile lifting for flexible workspaces: Easily reposition the crane wherever lifting is required.

- Adjustable height and span options: Some models allow you to adjust height and span to match the size and weight of the load.

- Quick assembly and disassembly: Can be set up or taken down in a short amount of time, which is helpful for temporary projects or workshops with limited space.

- Cost-effective compared to fixed cranes: Requires less investment while still providing high lifting capacity and versatility.

- Suitable for both electric and manual operation: Allows users to choose manual operation for occasional tasks or electric hoists for heavier and more frequent lifting.

These advantages make portable gantry cranes a reliable and practical tool for improving safety, efficiency, and productivity in material handling operations. They not only save time but also reduce the risk of workplace injuries by providing a stable and controlled lifting solution.

Your Trusted Overhead Portable Gantry Crane Manufacturer & Supplier

1 Ton to 10 Ton Portable Gantry Crane for Sale

PT Series – Industrial and Heavy-Duty Portable Gantry Cranes

The PT Series is designed for factories, workshops, and industrial spaces that need strong, reliable lifting equipment. These cranes can handle heavy loads while being easy to move and operate. They are perfect for lifting machinery, materials, or tools safely and efficiently.

PT-1 – Fixed Height Gantry Crane

The PT-1 is a simple, tough crane for everyday lifting tasks. It's ideal if you want a stable solution that works without extra setup.

Specifications:

- Load Capacity: 1–20 ton

- Maximum Height: 10 m

- Hoist Type: Electric or manual

- Movement: Electric or manual

Key Features:

- Fixed height and span – lift consistently without adjustments

- Quick assembly and disassembly – saves time

- Universal wheels with brakes – easy to move and position

- Stable and mobile – perfect for general workshop or factory use

If you need a reliable, heavy-duty portable crane that's easy to move and set up, the PT-1 is a practical choice. Contact us today to get a custom quote for your workshop or facility.

PT2-1 – Adjustable Gantry Crane

The PT2-1 is designed for workshops and factories where lifting tasks vary. Its adjustable height makes it flexible for different operations, while still being easy to move and operate.

Specifications:

- Load Capacity: 1–10 ton

- Maximum Height: 12 m

Key Features:

- Adjustable height with sub-stall positions for different lifting needs

- Universal wheels with brakes for easy movement and positioning

- Perfect for handling a variety of industrial lifting tasks

Use Case: Ideal for workshops that lift materials at different heights regularly.

PT2-2 – Full-Range Adjustable Gantry Crane

The PT2-2 is built for heavier and more precise lifting tasks. It offers full height adjustment within its technical limits, making it versatile for complex industrial operations.

Specifications:

- Load Capacity: 1–10 ton (supports heavier loads)

- Maximum Height: 10 m

Key Features:

- Fully adjustable height for maximum flexibility

- Universal wheels with brakes for mobility

- Mobile design allows precise positioning of heavy machinery

Use Case: Great for factories or workshops that require precision lifting and need a crane that adapts to different heights and load sizes.

PT2-3 – Light-Duty Mini Mobile Gantry Crane

The PT2-3 is perfect for smaller workshops or light industrial tasks. Its lightweight design and quick setup make it ideal when you need a simple crane that's easy to move.

Specifications:

- Load Capacity: 0.5 ton, 1 ton, 2Ton

- Maximum Height: 5 m

Key Features:

- Fast assembly and disassembly for convenience

- Lightweight and mobile structure for easy relocation

- Universal wheels with brakes for stable positioning

Best For: Small workshops, maintenance tasks, and light industrial lifting where mobility and speed are important.

PT-3 – Electric Motorized Mobile Gantry Crane

The PT-3 is built for heavy-duty lifting in larger workshops or industrial plants. Its motorized design allows it to move freely, even while lifting, making it ideal for confined spaces where flexibility is crucial.

Specifications:

- Load Capacity: 1–20 ton

- Maximum Height: 10 m

- Hoist Height: 15 m

Key Features:

- Electric traveling with 360° free movement and turning

- Can lift while moving or adjusting height

- Optional drive device with clutch for controlled operation

- Switchable between electric and manual operation for uneven floors

Use Case: Perfect for large workshops, industrial plants, or any space that requires mobile heavy lifting and flexible movement.

PT-4 – Electric Rail Travelling Gantry Crane

The PT-4 is ideal for fixed production lines or high-efficiency industrial setups. Its rail-mounted design offers maximum stability, making it perfect for repetitive lifting tasks where precision and safety are key.

Specifications:

- Load Capacity: 1–20 ton

- Maximum Height: 10 m

- Hoist Height: 15 m

Key Features:

- Rail-mounted for high stability and smooth operation

- Requires track installation for precise movement

- Excellent for repetitive industrial tasks

- Can be combined with PT2-1, PT2-2, or PT2-4 for height adjustment

Ideal For: Factories, fixed production lines, or industrial facilities needing high-efficiency, stable lifting operations.

Compared with Lightweight Aluminum Portable Gantry Cranes (1–5 ton)

Keywords: aluminum gantry crane, light-duty gantry crane, portable workshop crane, adjustable aluminum gantry, lightweight mobile crane

The LT Series of aluminum gantry cranes is perfect for small workshops, maintenance operations, and light industrial lifting. Made from lightweight yet strong aluminum, these cranes are easy to move, quick to assemble, and ideal for environments where heavy steel cranes would be too bulky. Aluminum gantry cranes offer the advantage of mobility without sacrificing stability or lifting capacity.

LT-1 – Fixed Height Aluminum Gantry Crane

The LT-1 is a simple, sturdy aluminum gantry crane designed for workshops that need a reliable, lightweight lifting solution. It's fixed height, making it easy to use for standard lifting tasks without adjustments.

Specifications:

- Load Capacity: 1–5 ton

- Maximum Height: 8 m

Key Features:

- Lightweight aluminum construction for easy movement

- Fixed height for straightforward lifting tasks

- Fast assembly and disassembly

- Universal wheels with brakes for safe positioning

Best For: Small workshops, light machine handling, and operations where mobility and speed are important.

LT-2 – Adjustable Height Aluminum Gantry Crane

The LT-2 offers adjustable height, making it ideal for workshops or maintenance tasks with varying lifting needs. Its aluminum structure ensures it remains lightweight while handling loads safely.

Specifications:

- Load Capacity: 1–5 ton

- Maximum Height: 8 m

Key Features:

- Adjustable lifting height for flexible tasks

- Lightweight aluminum design for easy mobility

- Quick assembly and disassembly for temporary or changing setups

Ideal For: Maintenance work, small industrial tasks, and workshops that require a portable crane with adjustable height.

LT-3 – Adjustable Span Aluminum Gantry Crane

The LT-3 combines adjustable height and span, making it versatile for wide or irregular loads. The aluminum frame ensures the crane is lightweight yet durable, ideal for small to medium workshops.

Specifications:

- Load Capacity: 1–5 ton

- Maximum Height: 8 m

Key Features:

- Adjustable height and span for versatile lifting

- Lightweight aluminum structure for easy transport

- Suitable for irregular or wide loads

- Mobile design for smooth positioning and relocation

Best For: Workshops handling irregular or wide loads, flexible production lines, and light industrial lifting tasks where a lightweight, portable aluminum crane is preferred.

Portable Gantry Crane Comparison Guide

Choosing the right portable gantry crane can be confusing with so many models, load capacities, and features available. A good way to simplify the decision is by comparing key specifications such as lifting capacity, maximum height, adjustability, movement type, and typical applications. This helps you quickly identify the crane that fits your workshop, factory, or industrial facility.

Below is a practical comparison of popular portable and lightweight gantry cranes, including heavy-duty, motorized, and aluminum options:

| Model | Load Capacity | Max Height | Adjustable Height | Adjustable Span | Movement Type | Key Application |

|---|---|---|---|---|---|---|

| PT-1 | 1–20 ton | 10 m | No | No | Manual/Electric | Heavy-duty fixed height lifting |

| PT2-1 | 1–10 ton | 12 m | Sub-stall | No | Manual/Electric | Variable height lifting |

| PT2-2 | 1–10 ton | 10 m | Full range | No | Manual/Electric | Precision heavy lifting |

| PT2-3 | 1 ton | 5 m | No | No | Manual/Electric | Light-duty small workshops |

| PT2-4 | 1–20 ton | 12 m | Full range | No | Manual/Electric | Heavy-duty adjustable lifting |

| PT-3 | 1–20 ton | 10 m | Yes | No | Motorized/Electric/Manual | Mobile lifting in confined spaces |

| PT-4 | 1–20 ton | 10 m | Yes (with PT2-1/2-2/2-4) | No | Rail-Mounted | Fixed-line production lifting |

| LT-1 | 1–5 ton | 8 m | No | No | Manual/Electric | Small workshops |

| LT-2 | 1–5 ton | 8 m | Yes | No | Manual/Electric | Maintenance & flexible tasks |

| LT-3 | 1–5 ton | 8 m | Yes | Yes | Manual/Electric | Irregular/wide load lifting |

This table highlights the key differences between heavy-duty, adjustable, motorized, and lightweight aluminum gantry cranes. It helps you quickly see which model fits your lifting capacity needs, workspace, and operational requirements.

When selecting a crane, consider not only the load and height but also whether you need adjustable height, mobility, or rail-mounted stability. This ensures you choose the right crane for your workshop or industrial facility, improving safety and efficiency while reducing setup time.