Overhead Cranes Riyadh: Smart Choices for Expanding Factories

Explore overhead cranes 3 to 320 ton options in Riyadh tailored for tight spaces, quick installation, and growing factory needs in key industrial sectors.

Category: Saudi Arabia

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Cranes for Sale Saudi Arabia

Best Options for Growing Factories and Warehouses in Riyadh

Introduction

Saudi Arabia is rapidly expanding its industrial landscape, with new factories and warehouses being built across key regions. From the Eastern Province's oil-related industries to the growing manufacturing hubs in Riyadh, businesses are investing heavily in infrastructure to support increased production and logistics. This growth creates a strong demand for reliable material handling equipment that can keep operations running smoothly.

Overhead cranes play a crucial role in this development. Whether in steel workshops, prefab housing plants, or large warehouses, these cranes help move heavy loads safely and efficiently. But picking the right crane isn't just about capacity—it's about matching the crane to your facility's size, the types of loads you handle, and how quickly you need it installed.

In Saudi Arabia, terms like overhead crane, EOT crane, and bridge crane are commonly used to describe cranes that run on elevated rails, maximizing floor space. For businesses in Riyadh and beyond, choosing the right crane can mean the difference between a smooth production line and costly downtime.

Important points to consider:

- Saudi Arabia's industrial zones require cranes that fit different workshop sizes and load demands.

- Overhead cranes (or EOT cranes/bridge cranes) are essential for handling materials in factories and warehouses efficiently.

- Selecting the right crane improves safety, speeds up work, and supports expanding operations in Riyadh and other regions.

If your business is growing in Saudi Arabia, understanding these factors will help you find the best overhead crane solution tailored to your needs—especially in fast-developing areas like Riyadh.

Types of Overhead Cranes Suitable for Riyadh's Growing Factories and Warehouses

Choosing the right crane depends on your facility's size, the type of loads you handle, and the space you have available. In Riyadh, these three types of overhead cranes are the go-to options for many growing factories and warehouses.

We offer a full range of overhead bridge cranes for sale in Saudi Arabia, from 1 ton light-duty cranes to 320 ton heavy-duty cranes. Our product line includes single girder, double girder, gantry, and specialized bridge cranes, providing the perfect solution for workshops, factories, warehouses, and industrial plants worldwide.

- 1 ton overhead crane, 2 ton overhead crane, 3 ton overhead crane,

- 5 ton overhead crane, 10 ton overhead crane, 15 ton overhead crane, 20 ton overhead crane,

- 40 Ton Overhead Crane, 50 Ton Overhead Crane , 50 Ton above to 550 Ton Overhead Crane

Single Girder Overhead Cranes (5–20 Ton Capacity)

These cranes are a solid choice for many mid-sized workshops. Here's why they work well:

- Simple design: They have a single beam, which means less weight and easier installation.

- Cost-effective: Generally cheaper than double girder cranes, making them a good fit for moderate budgets.

- Good for common loads: Perfect for moving palletized goods and machine parts weighing between 5 and 20 tons.

- Space-friendly: Ideal for workshops with limited ceiling height since they take up less vertical space.

If your operation doesn't require very heavy lifting or long spans, single girder cranes are a reliable and practical option.

Underhung overhead crane single girder - ceiling mounted for low headroom workshops and warehouses,

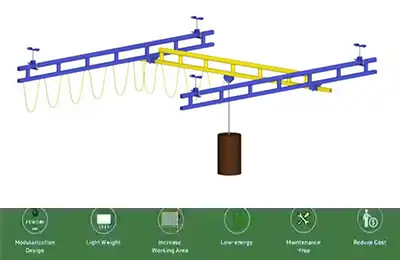

When flexibility and fast setup matter, modular EOT cranes and modular kbk cranes come into play. These cranes offer:

- Quick assembly: Pre-engineered parts let you put the crane together faster on site.

- Expandable design: Easily adjust the span or lifting height as your factory grows or changes.

- Adaptable capacity: Handles loads from 2 up to 15 tons, so it's versatile for different industries like prefab housing and machinery production.

- Reduced downtime: Because of modular design, upgrades or reconfigurations don't mean long stoppages.

If your factory or warehouse needs a crane that can keep up with changing demands, modular EOT systems are a smart choice.

enclosed track kbk modular crane- ceiling mounted, tailored stacker cranes for light material handling in warehouses

enclosed track kbk modular cranes - floor mounted

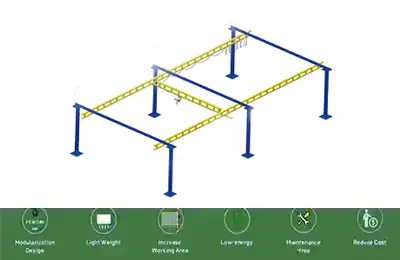

Free-Standing and Low-Headroom Cranes

In facilities where ceiling height or building structure limits crane options, these cranes provide excellent solutions:

- Low-headroom cranes: Designed with compact hoists and slim beams, they maximize lifting height even in spaces with low ceilings.

- Free-standing cranes: Don't require fixed runway beams; they stand independently, which is perfect for factories without built-in crane supports.

- Flexibility: Easy to move or adjust if your factory layout changes, which is common in expanding industrial zones.

- Space optimization: These cranes make the most of tight indoor spaces without costly building modifications.

For new or expanding Riyadh factories facing space or height limits, free-standing and low-headroom cranes keep material handling efficient and safe.

freestanding overhead crane, overhead bridge crane with freestanding runway

Tailored low headroom cranes for limited workshop and warehouses

Whether you're working with limited space, needing fast installation, or want the option to expand later, these crane types cover most needs in Riyadh's growing industrial sectors. Single girder cranes offer simplicity and value; modular EOT cranes deliver flexibility; and free-standing or low-headroom cranes solve tricky space problems.

Why Choose Overhead Cranes in Riyadh for Growing Industrial Sectors

Riyadh's industrial sector is expanding rapidly, driven by prefab housing, machinery production, warehousing, and logistics. Each industry faces unique lifting challenges, yet all share one need—reliable overhead cranes designed for efficiency and safety.

Key Industrial Sectors Using Overhead Cranes in Riyadh

- Prefab Housing: Supports large-scale construction projects with cranes designed to lift heavy frames and wall panels safely and efficiently.

- Machinery Production: Handles precise movement of machinery components where accuracy and safety are vital in confined workshops.

- Warehousing: Speeds up loading, unloading, and internal logistics—especially when forklifts are limited or space is tight.

- Logistics Hubs: Uses flexible crane systems to move varying load sizes with quick turnaround times.

Common Features of Riyadh's Workshops and Plants

- Most facilities are mid-sized with limited ceiling height, requiring cranes with optimized headroom.

- Many are built in emerging industrial zones with tight layouts and evolving floor plans.

- Modular and easy-to-assemble designs are preferred for flexibility and quick installation.

These features make adaptable and space-efficient crane systems a must for sustainable industrial growth.

Fast Project Turnover and Flexible Assembly Needs

- Projects in Riyadh often run on tight construction and production schedules—cranes must be delivered and installed quickly.

- Modular EOT and free-standing cranes offer the flexibility to expand or relocate as production needs grow.

- Quick on-site assembly reduces downtime and improves workflow efficiency for dynamic operations.

Businesses benefit from cranes that grow and adapt with their production pace and capacity demands.

The Role of Overhead Cranes in Industrial Growth

In Riyadh's fast-moving industries, overhead cranes aren't just lifting equipment—they're strategic assets that enhance productivity, safety, and flexibility.

Choosing a crane tailored to your sector's workflow and plant layout ensures efficient operations and a competitive edge in the growing Saudi market.

Workshop and Warehouse Features in Riyadh Influencing Crane Selection

Understanding the unique characteristics of Riyadh's industrial workshops and warehouses is essential when choosing the right overhead crane. Several key facility features play a big role in determining which crane will work best.

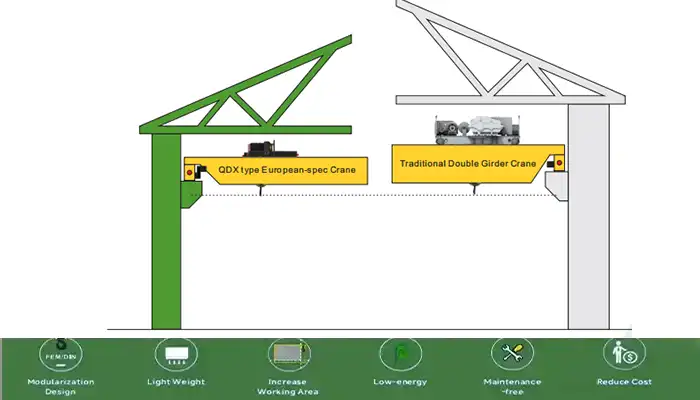

Mid-Sized Warehouses with Lower Ceiling Clearance

Many warehouses and workshops in Riyadh are built to serve mid-sized operations. These facilities typically have:

- Ceiling heights lower than large industrial plants, often designed to optimize floor space rather than vertical volume.

- Structural constraints that limit the installation height of crane girders and hoists.

Impact on crane choice:

- Traditional overhead cranes with large, tall girders won't fit or will significantly reduce usable lifting height.

- Low-headroom cranes are the preferred solution. These cranes feature compact hoists and slim girder designs, allowing the hook to travel closer to the ceiling, maximizing lifting height in tight vertical spaces.

- Single girder cranes often work better here due to their simpler, lighter structure.

Benefits:

- Maximizes lifting capacity without costly building modifications.

- Maintains safe clearance between crane components and workshop ceiling.

- Increases usable workspace under the crane.

New and Expanding Factory Zones with Space Constraints

Riyadh's expanding industrial zones present unique challenges:

- Factories and warehouses are often located on compact plots with limited space around or above the building.

- Expansion plans mean facility layouts can change frequently, requiring adaptable equipment.

Considerations for buyers:

- Fixed crane runways can be expensive and difficult to modify if your facility layout changes.

- Modular crane systems that can be extended or reconfigured provide flexibility to match growth plans.

- Free-standing cranes eliminate the need for permanent runway beams, enabling easy relocation or adjustment.

Practical solutions:

- Choose modular EOT crane systems designed for easy assembly and future expansion.

- Consider free-standing cranes or low-headroom cranes where runway installation is limited.

- Factor in space for crane controls and operator movement.

Need for Short Lead Times and Flexible Crane Installation

Many industrial projects in Riyadh operate on tight schedules. Fast crane delivery and quick installation are often critical to staying on track.

Why this matters:

- Delays in crane delivery can push back entire production schedules.

- Complex installations that require building modifications increase downtime and cost.

What to look for:

- Suppliers offering pre-fabricated crane kits that arrive ready to assemble on-site.

- Cranes designed with modular components for quick, straightforward installation.

- Local support teams familiar with Riyadh's industrial environment to speed up setup and commissioning.

Advantages:

- Reduces downtime and disruption during installation.

- Allows factories and warehouses to begin or resume operations faster.

- Improves return on investment by accelerating project completion.

Challenges and Solutions for Tight Indoor Spaces

Space is often at a premium in Riyadh's industrial workshops and warehouses. Tight aisles, packed equipment, and multiple workstations can restrict crane movement and operator visibility.

Challenges include:

- Limited room for large crane girders and trolleys.

- Difficulty maneuvering loads safely in narrow or crowded areas.

- Restrictions on adding runway beams or support columns.

Effective solutions:

- Low-headroom overhead cranes with compact hoists to reduce space usage.

- Free-standing cranes that don't require runway beams attached to the building.

- Remote and pendant control systems to improve operator safety and precision in confined areas.

- Customized crane spans and lifting heights tailored to the exact dimensions of your facility.

Riyadh's mid-sized, growing industrial facilities come with specific constraints that influence overhead crane selection. Low ceilings, tight spaces, expanding factory layouts, and fast project deadlines require cranes that are compact, flexible, and quick to install. Choosing the right crane type and design ensures your operation runs smoothly, safely, and efficiently without costly building changes or delays.

Typical Loads and Overhead Crane Applications in Riyadh's Industrial Sectors

The types of materials handled in Riyadh's factories and warehouses are varied—but most fall within a common weight range and follow similar movement patterns. Understanding what's being lifted helps determine the right crane type, capacity, and features.

Palletized Goods in Warehouses and Logistics

In the logistics and distribution hubs of Riyadh, handling palletized goods is a daily task. These goods can include anything from packaged machinery parts to bulk construction materials.

- Typical load weights: 2 to 5 tons per pallet (sometimes higher for heavy-duty items)

- Movement needs: Loading and unloading from delivery vehicles, transferring between storage zones, and staging for dispatch

Best-fit cranes:

- Single girder overhead cranes with 5 to 10-ton capacity

- Free-standing cranes when runway systems aren't available

- Cranes equipped with radio or pendant controls for precise operation in busy warehouse layouts

- These applications require cranes that are easy to operate, efficient, and capable of quick lifting cycles with low downtime.

Machine Components and Equipment in Machinery Production

Machinery production workshops in Riyadh commonly handle medium-weight parts such as motor housings, mechanical arms, and assembled units that need to be moved between workstations.

- Typical load weights: 3 to 12 tons depending on part size

Lifting challenges:

- Frequent lifting and repositioning within limited floor space

- Precise placement onto machines or test stands

- Load safety and operator control during complex handling

Recommended crane setups:

- Modular EOT cranes with low-headroom hoists

- Cranes with smooth trolley travel and variable speed control

- Maintenance platforms and walkways if frequent servicing is needed

These operations benefit from cranes designed to handle awkward-shaped loads and repetitive use without sacrificing safety or accuracy.

Building Frames and Prefab Housing Materials

Prefab housing factories are a growing sector in Riyadh's construction push. These plants handle large frame sections, roof panels, and wall systems made from steel or composite materials.

- Typical load weights: 5 to 15 tons per lift

Handling specifics:

- Long structural elements often requiring two-point or dual hoist lifting

- High safety needs to avoid damage to large panels during movement

- Indoor and outdoor material handling as frames move from production to staging

Most suitable cranes:

- Double hoist single girder cranes or tandem lifting systems

- Cranes with anti-sway functions for long load stability

- Free-standing or modular cranes for flexible layouts during facility expansion

Crane systems in these plants need to accommodate irregularly shaped, heavy materials while keeping operations safe and steady.

Matching Crane Capacity to Load Ranges

Across all sectors, the majority of loads fall between 2 to 15 tons. Matching the crane's lifting capacity correctly is not only about safety—it's about ensuring efficiency and equipment longevity.

Key tips for buyers:

- Always allow a safety margin—crane capacity should exceed your heaviest expected load by at least 20–25%.

- If your loads vary widely, consider cranes with adjustable hoists or dual lifting speeds.

- Discuss your exact load types and handling patterns with the supplier to select the correct hoist, trolley, and girder configuration.

From warehouse pallets to machine components and prefab building sections, overhead cranes in Riyadh must be built for a wide range of lifting tasks. Selecting the right type and capacity ensures reliable operation and supports the fast-paced demands of Saudi Arabia's growing industrial sectors.

Key Benefits of Buying Overhead Cranes in Riyadh

If you're running or expanding a factory or warehouse in Riyadh, you already know how important it is to get the right equipment at the right time. Overhead cranes aren't just about lifting—they're about keeping your production moving, your workers safe, and your project on schedule. Here's why buying locally suited overhead cranes in Riyadh makes a real difference.

Fast Lead Times to Match Fast-Paced Projects

Deadlines in Riyadh's industrial zones can be tight. Whether it's a new facility or an upgrade, you often don't have time to wait for long overseas deliveries.

- We offer cranes that can be delivered and installed quickly—some in just a few weeks.

- Pre-engineered kits mean less time designing and more time building.

- On-site support ensures the crane is up and running without delays.

If your project is under pressure, this speed can be a real advantage.

Flexible Assembly for Tight and Evolving Workspaces

Workshops and warehouses in Riyadh come in all shapes and sizes. Some have height limits, others are built in phases, and many are still expanding.

- Modular cranes let you adjust the span or capacity later if your layout changes.

- Free-standing cranes work well when your building can't support traditional runway beams.

- Low-headroom designs help you get the most out of limited ceiling space.

It's not just about fitting the crane—it's about making sure it keeps fitting even when your shop grows.

Built to Meet Industrial and Safety Standards

No factory manager wants to deal with rejected inspections or safety issues. That's why our cranes are designed with compliance in mind from the start.

- Fully certified to CE, ISO, and SASO standards.

- We can provide third-party inspection reports where needed.

- Designed to meet the requirements of oil-linked and government projects in Saudi Arabia.

You'll know your equipment is safe, legal, and ready for work.

Support You Can Count On—Locally

When something goes wrong with a crane, every hour matters. That's why local support makes a huge difference.

- We provide fast technical assistance and spare parts.

- You can get help with installation, operator training, and future upgrades.

- Long-term service plans are available so you don't have to chase down maintenance later.

You're not left waiting on a foreign technician or dealing with overseas shipping for a small part. Help is close by.

How to Choose the Right Overhead Crane for Your Riyadh Facility

Buying an overhead crane isn't something you do every day—and in a growing market like Riyadh, making the right choice early can save significant time, money, and effort. Here's a practical guide to selecting the most suitable crane for your facility.

Start with Your Workshop's Height and Layout

Before anything else—look up. Your facility's height, beam positions, and available floor space determine which crane designs fit best.

- Low ceilings? Choose a low-headroom hoist or compact single girder crane to maximize height.

- Limited building support? A free-standing crane system avoids heavy structural attachments.

- Tight workspace? Plan how the load will move and where the crane needs to reach.

Accurate measurements of your span, clear height, and obstructions make design and planning smoother.

Know What You're Lifting—and How Often

Choosing the right crane means understanding your load type, weight, and lifting frequency.

- Type of load: Palletized goods, machinery, or structural materials?

- Weight range: Most Riyadh operations lift between 2–15 tons; allow margin for the heaviest load.

- Duty cycle: Frequent use requires a higher duty class and more robust motors.

- Precision needs: For delicate or oversized loads, dual-speed control or tandem hoisting is ideal.

Be specific—your supplier can then recommend the most efficient hoist and control system.

Consider Lead Times and Installation Requirements

Project schedules in Riyadh vary—some need fast delivery, others coordinate with construction timelines.

- Short deadlines? Go for modular or pre-engineered cranes to reduce setup time.

- Expanding facilities? Choose adjustable or extendable cranes for future growth.

- Minimal disruption? Free-standing systems are quick to install without heavy building modification.

Aligning crane delivery and installation with your project timeline helps avoid delays and extra costs.

Work With a Supplier Familiar With Riyadh's Industry

Partnering with an experienced local or regional crane supplier ensures better support and smoother project execution.

- Choose a supplier with a proven track record in Riyadh's industrial and logistics sectors.

- Ask for help with crane selection, layout design, and compliance with CE, ISO, and SASO standards.

- Request site visits or technical drawings—professional suppliers will offer these services willingly.

Finding a trusted local partner guarantees your crane is built to match your workflow and environment.

Final Thoughts: Plan for Efficiency and Future Growth

Choosing the right overhead crane for your Riyadh facility isn't just about specifications—it's about how well it fits your operations and long-term plans.

With proper planning, accurate data, and the right supplier, you'll have a system that's safe, efficient, and ready to grow with your business.

Conclusion

As Riyadh's industrial sectors continue to grow—whether in prefab housing, machinery production, logistics, or warehousing—the need for efficient, space-smart, and reliable overhead cranes is greater than ever. From compact single girder cranes for tight workshops to modular EOT systems that grow with your operation, the right crane can make daily material handling safer, faster, and more cost-effective.

We've covered the types of cranes that work best in Riyadh's mid-sized facilities, the typical loads they handle, and the key features to consider—like low headroom, flexible installation, and short lead times. But every facility is a little different, and that's why it's so important to match your crane choice to your actual working conditions and project goals.

Need help deciding what fits your plant?

Let us walk you through it. Contact us today for a free consultation. We'll review your site layout, load requirements, and timeline, then offer a customized overhead crane solution—complete with pricing, drawings, and delivery schedule.

Let's build the right crane for your Riyadh workshop—together.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch