Pillar Jib Crane

Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton. Get pillar mounted jib crane design now!

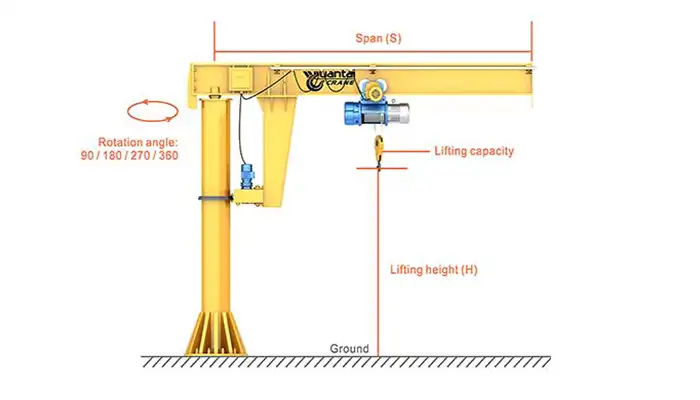

| Crane Type | Pillar jib crane with free standing jib design |

| Crane Capacity | 0.25 ton to 16 ton |

| Arm Length | up to 16 m |

| Lifting Height | up to 12 |

| Rotating Degree | 180, 270, or 360 degree |

Category: Jib Crane

Your Trusted Pillar Jib Cranes Manufacturer & Supplier

Pillar Jib & Pillar Mounted Jib Design

Free Standing Jib Cranes

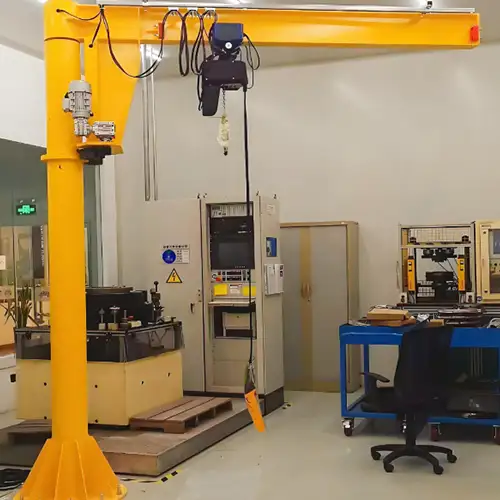

Pillar mounted jib cranes is a type of free standing jib crane with the crane pillar mounted on the floor foundation,without other supporting of the facility, used for short distance material handling or as an economical supplemental overhead travelling crane solution for crowded place. With custom pillar mounted jib crane design and180 degree to 360 degree rotating jib cantilever arm, the pillar crane with electric or manual hoists can lift and transport loads, efficiently in semi circles or full circles centered around the floor mounted pillar in work cells for general material handling with capacity up to 10 ton and slewing jib cantilever length up to 16 meters. Various custom pillar jib crane designs with wide crane specifications and parameters are available.

Pillar Jib Cranes for Sale: Customizable Lifting Solutions for Every Industry

Pillar jib cranes for sale offer versatile, heavy-duty lifting solutions with customizable features for various industrial applications.

Pillar jib cranes, also known as pillar-mounted jib cranes, are versatile lifting devices commonly used in various industrial environments to move heavy loads with precision and ease. These cranes consist of a vertical pillar or column securely anchored to the floor, with a horizontal boom that rotates around the pillar. The boom can support a hoist or lifting mechanism that moves along the length of the arm, allowing for efficient material handling within a circular area around the crane.

Function of Pillar Jib Cranes

The primary function of a pillar jib crane is to lift, move, and position loads within a specific radius. The crane's rotating boom allows for easy maneuvering of materials, making it ideal for repetitive lifting tasks in confined spaces. Whether moving components along an assembly line or loading and unloading materials from vehicles, pillar jib cranes provide a reliable and flexible solution for handling materials of various sizes and weights.

Importance of Pillar-Mounted Jib Cranes in Industrial Settings

In industrial settings, efficiency and safety are paramount. Pillar-mounted jib cranes play a crucial role in enhancing workflow by providing localized lifting solutions. They reduce the need for manual handling, which can lead to injuries and fatigue, and improve productivity by allowing workers to move loads more quickly and safely. These cranes are particularly valuable in environments where floor space is limited or where overhead cranes cannot be installed due to structural constraints. Their compact design allows them to be placed strategically at workstations, optimizing space and increasing operational efficiency.

Key Benefits of Using Pillar Jib Cranes

- Versatility and Flexibility: Pillar jib cranes are highly adaptable to various applications, making them suitable for diverse industries such as manufacturing, automotive, warehousing, and shipping. Their ability to rotate and cover a wide area allows for efficient material handling without requiring additional equipment.

- Improved Safety and Ergonomics: By taking on heavy lifting tasks, pillar jib cranes reduce the physical strain on workers, thereby minimizing the risk of injuries and promoting a safer work environment. The use of a crane for lifting also ensures that loads are moved smoothly and steadily, reducing the likelihood of accidents.

- Ease of Installation and Maintenance: Pillar-mounted jib cranes are relatively easy to install and can be customized to fit specific site requirements. Once installed, they require minimal maintenance, making them a cost-effective solution for long-term use. Their simple design also allows for easy troubleshooting and repairs, minimizing downtime and ensuring continuous operation.

- Enhanced Efficiency and Productivity: With their ability to handle repetitive tasks quickly and accurately, pillar jib cranes significantly increase productivity. Operators can move loads swiftly from one point to another, reducing the time spent on material handling and allowing for a more streamlined workflow.

- Durability and Reliability: Constructed from robust materials, pillar jib cranes are designed to withstand harsh industrial environments. Their sturdy construction ensures long-term reliability, providing a dependable lifting solution that can handle frequent use and heavy loads.

Overall, pillar jib cranes are an essential tool in many industrial settings, providing a versatile, safe, and efficient solution for material handling needs. Their ability to improve productivity while maintaining safety makes them a valuable investment for any operation.

Typical Capacities of Pillar Jib Cranes for Sale

Pillar jib cranes come in a variety of capacities to suit different lifting needs. The capacity of a pillar jib crane refers to the maximum weight it can safely lift and move. These capacities are carefully determined to match the demands of various industrial applications, ensuring both safety and efficiency.

Overview of Common Capacities

Pillar jib cranes are available in a wide range of lifting capacities to accommodate different types of loads:

- 0.5 Ton Pillar Mounted Jib Crane: Ideal for light-duty applications such as lifting small parts or tools in workshops and maintenance areas. These cranes are often used for precise, low-weight tasks where mobility and ease of use are crucial.

- 1 Ton Pillar Mounted Jib Crane: Suitable for medium-duty tasks in warehouses, small manufacturing facilities, or assembly lines. A 1-ton pillar jib crane can handle moderate weights, making it a versatile choice for a variety of applications.

- 2 Tons Pillar Mounted Jib Crane: This capacity is commonly used in automotive and small to mid-sized industrial settings where heavier components or assemblies need to be moved regularly. It offers a good balance between lifting power and operational flexibility.

- 5 Tons Pillar Mounted Jib Crane: Often found in larger industrial plants, these cranes are used for more demanding tasks, such as lifting heavy machinery parts or bulky materials. They provide a higher load capacity without compromising on maneuverability.

- 10 Tons Pillar Mounted Jib Crane: Designed for heavy-duty applications, such as in large manufacturing plants, shipyards, or construction sites. A 10-ton pillar jib crane can lift very heavy loads, making it essential for handling large equipment or substantial material loads.

How to Select the Appropriate Capacity Based on Application Needs

Choosing the right capacity for a pillar jib crane depends on several key factors related to the specific application:

- Nature of the Load: Understand the weight and type of loads to be lifted. For example, frequent handling of heavy machinery parts requires a higher capacity crane, whereas light assembly work may only need a lower capacity crane.

- Frequency of Use: Consider how often the crane will be used. If the crane will be in constant operation, a slightly higher capacity than the actual load weight may be recommended to prevent overloading and ensure durability.

- Operational Environment: Assess the environment where the crane will be used. In harsher conditions, such as outdoors or in facilities with high dust or moisture levels, choosing a robust crane with a higher capacity can provide additional safety and longevity.

- Future Needs: Think about potential future requirements. It may be more cost-effective to purchase a crane with a slightly higher capacity than immediately necessary to accommodate future growth or increased load demands.

Factors Influencing the Choice of Crane Capacity

Several factors play a crucial role in determining the appropriate crane capacity:

- Load Characteristics: The weight, size, and shape of the load affect crane selection. Larger or unevenly balanced loads may require a higher capacity to ensure safe handling.

- Operational Range: The working radius and height to which the crane needs to lift affect the capacity choice. A longer boom or higher lift height typically requires a crane with a higher load capacity.

- Safety Margins: Incorporating a safety margin is essential for preventing accidents. It's often advisable to choose a crane that can handle slightly more than the maximum load weight to ensure safe operation.

- Regulatory Standards: Compliance with local and international safety standards may dictate specific capacity requirements, especially in industries with strict safety protocols.

- Installation and Space Constraints: The available installation space and mounting conditions might limit the choice of crane capacity. It's important to select a crane that fits within the physical constraints of the work area while still meeting operational needs.

Selecting the right capacity for a pillar jib crane involves a careful evaluation of current and future operational needs, ensuring that the crane not only meets immediate requirements but also offers flexibility and safety for ongoing use.

Main Parameters of Pillar Jib Crane

The pillar mounted jib crane is a type of small and medium duty freestanding crane with the pillar or column mounted or installed on the floor foundation, without any support from the building. The lifting capacity of floor mounted jib crane ranges from 0.5 ton to 10 tons and the working class is A3. The main crane specifications of free standing jib crane are for your reference.

Main parameters of freestanding floor mounted jib crane:

- Safe working load free standing jib crane:up to 16 tons

- Crane rotation of free standing jib crane: 180, 270, or 360 degree

- Arm length of free standing jib crane : up to 16 m

- Hoisting system of free standing jib crane: Double speed/single speed wire rope hoist or chain hoist

- Hoisting heights of free standing jib crane : up to 12 m (floor to underside of boom)

- Working temperature of free standing jib crane : -20~+40℃

- Control model of free standing jib crane : Pendant handle, remote and cabin

- Applications of free standing jib crane : Widely used in all kinds of industry

- Power supply of free standing jib crane : AC 380V, 50HZ, 3P

Pillar jib cranes are designed with various specifications to meet diverse operational needs in different industrial environments. These specifications ensure the cranes are capable of delivering reliable performance, safety, and efficiency. Click to learn more jib crane specificaitons. and besides of complete pillar mounted jib crane system, the jib crane kit without steel structures are also provided, which is a much more economical jib crane solution. If you have any need, please feel free to contact us. WhatsApp: + 86 151 3871 1597.

Design and Structure of Pillar Mounted Jib Cranes

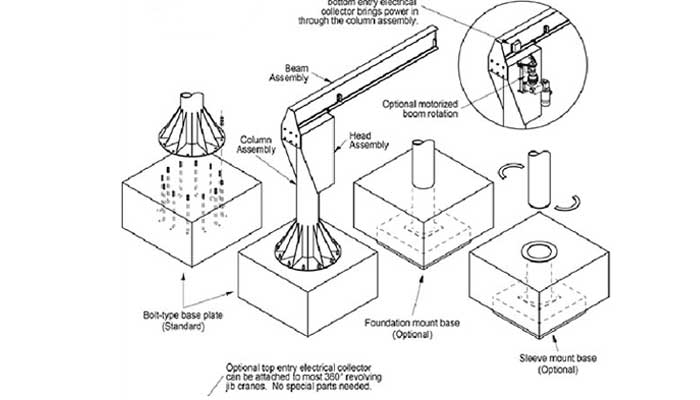

Description of the Pillar Design and Its Significance

The pillar design of a jib crane is central to its functionality and stability. The vertical pillar, also known as the mast, is typically made from high-strength steel and is securely anchored to the ground or floor, providing a stable base for the crane. The significance of the pillar design lies in its ability to support the rotating boom and the lifting mechanism without tipping over, even when handling heavy loads. This design allows the crane to lift and move loads efficiently within its operational area while maintaining a small footprint, which is particularly beneficial in confined spaces where other types of cranes may not be suitable.

Different Mounting Options for Flexibility and Versatility

Pillar jib cranes offer various mounting options to enhance flexibility and versatility in different work environments:

- Base Plate Mounted: This mounting option uses a wide base plate anchored to the floor with heavy-duty bolts. It provides a stable and secure installation, suitable for permanent locations where the crane will not need to be moved frequently.

- Foundation Mounted: In this setup, the pillar is anchored into a concrete foundation, providing maximum stability and load-bearing capacity. This is ideal for heavy-duty applications requiring robust support, especially in environments where vibrations or dynamic loads are common.

- Movable Mounted: Some pillar jib cranes are designed with a movable base that allows them to be relocated as needed. This type of mounting is advantageous in workshops or factories where tasks and workstations frequently change, offering the flexibility to adapt to different operational needs.

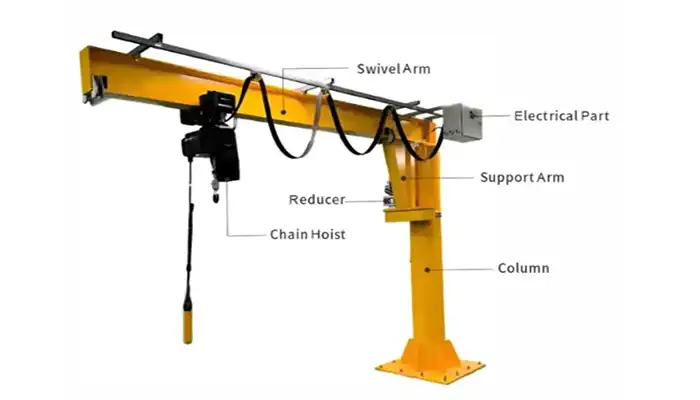

The floor mounted pillar jib cranes are designed to stand on the floor all by themselves with a foundation mounted on the floor but without any other support from the workshop building. The floor mounted pillar jib crane is mainly consisted of supporting pillar column ,and a horizontal cantilever arm, with hoisting system , rotating devices and safety devices, etc.

Rotational Range and Boom Length

Common Rotational Angles (e.g., 180°, 270°, 360°)

Pillar jib cranes are available with different rotational capabilities, allowing them to cover a wide operational area:

- 180° Rotation: Limited to half-circle movement, this range is suitable for applications where the crane operates in a restricted space or against a wall. It provides enough flexibility for tasks that do not require full circular motion.

- 270° Rotation: Offers greater coverage, suitable for larger work areas where the crane needs to access multiple points without obstructions. This range allows for more versatile material handling compared to a 180° rotation.

- 360° Rotation: Provides full circular movement around the pillar, allowing the crane to service a complete area around its base. This range is ideal for maximizing the operational zone, especially in central locations where access to all sides is required.

Jib Cantilever Designs of Pillar Jib Cranes

The jib cantilever can be designed into various types such as I beam type, box girder with I beam type, tid rod type or other customized type, etc.The hoisting system are available from the options of manual hoists, electric wire rope hoists, electric chain hoists, & fem standard hoists, etc.

Typical Boom Lengths and Their Impact on Reach and Coverage

The boom length of a pillar jib crane determines how far the crane can extend its reach:

- Short Boom Lengths (e.g., 2-4 meters): Suitable for compact areas where the crane needs to operate in tight spaces or close to walls. Shorter booms provide precise handling for smaller items or tasks requiring minimal reach.

- Medium Boom Lengths (e.g., 4-6 meters): Offers a balance between reach and maneuverability, making them suitable for medium-sized work areas. These boom lengths provide adequate coverage for general industrial tasks.

- Long Boom Lengths (e.g., 6-8 meters or more): Ideal for large, open areas where extensive reach is necessary. Long booms increase the crane's coverage area, allowing it to handle larger objects or service multiple workstations without repositioning.

Custom gearing rotating jib crane - Free standing jib cranes for sale

Pillar jib cranewith combined box girder with I beam cantilever design- Free standing jib cranes for sale<

Tid rod pillar jib crane design - Free standing jib cranes for sale

Pillar jib crane design with I beam cantilever,- Free standing jib cranes for sale

Customized pillar jib crane with process cantilever design- Free standing jib cranes for sale

Truss cantilever jib crane design- Free standing jib cranes for sale

Rotating System & Jib Hoists System of Pillar Jib Cranes

Lifting Mechanism and Speed

Types of Lifting Mechanisms Used (Manual vs. Electric)

Pillar jib cranes are equipped with different types of lifting mechanisms to accommodate various operational needs:

- Manual Lifting Mechanisms: Utilize a hand-operated chain or lever hoist for lifting. These mechanisms are cost-effective and suitable for low-capacity cranes or applications where precision lifting is required, but speed is not a critical factor.

- Electric Lifting Mechanisms: Use an electric motor to power the hoist, providing faster and more efficient lifting. Electric mechanisms are ideal for higher capacity cranes or environments where frequent and rapid lifting is necessary. They reduce operator fatigue and increase productivity by automating the lifting process.

Lifting Speed Variations and Their Impact on Operational Efficiency

Lifting speed refers to how quickly the crane can raise and lower loads:

- Slow Lifting Speeds: Suitable for delicate operations where precision and control are more important than speed. Slow speeds help prevent damage to sensitive loads and ensure accurate positioning.

- Moderate Lifting Speeds: Offer a balance between control and efficiency, making them appropriate for general-purpose applications where a steady workflow is needed without the risk of damaging materials.

- Fast Lifting Speeds: Essential for high-throughput environments where speed is critical to maintaining productivity. Fast speeds enable quick loading and unloading of materials, reducing cycle times and enhancing operational efficiency.

Rotating System

Slewing motion of slewing pillar mounted jib crane can be operated manually or electrically.

Jib Hoists System of Pillar Jib Cranes

Various type of jib hoist options are available, such as, manual jib hoist, geared trolley jib hoist,, electrical chain hoist, motorized trolley jib hoist and other types of jib hoist designs, etc.

European Style Electric Hoist - Pillar Mounted Jib Hoist

The jib hoists are applicable for various types of single girder overhead travelling crane, single beam crane, H beam crane, I beam crane, monorail crane, and other types of single girder cranes, etc.

Chinese Style Electric Wire Rope Hoist- Pillar Jib Crane Hoist

The Chinese type jib hoists are applicable for various types of single girder overhead travelling crane, single beam crane, H beam crane, I beam crane, monorail crane, and other types of single girder cranes, etc.

Electric Trolley Electric Chain Hoist, Freestanding Pillar Jib Crane Hoist

Types of jib crane hoist designes are available for your single girder overhead travelling crane. Contact us to get your overhead crane design and good overhead crane price.

Low Headroom Electric Chain Hoist, Pillar Jib Crane Hoist

Types of jib crane hoist designes are available for your single girder overhead travelling crane. Contact us to get your overhead crane design and good overhead crane price.

Mini small electric chain hoist with single phase for Small Pillar Jib Crane with Manual Rotating Design

Mini electric wire ropes hoists - fixed hoist design & electric trolley type- 0.2 ton- 1 ton mini rope lift, single phase mini electric hoists, cheap small hoist for sale.

Manual and hand chain hoist & chain block for manual Pillar Jib Crane

Manual chain block & manual chain hoist for sale. Light,economical & handy manual hoists & hand hoists of 250kg, 1 ton, 1.5 ton , 2 ton , 3 ton , 4 ton , 5 ton , 6 ton,etc.

Materials and Construction

Material Choices (e.g., Steel, Stainless Steel) for Different Environments

The choice of materials for a pillar jib crane depends on the operating environment and the specific application requirements:

- Steel: The most common material used for jib cranes, offering excellent strength and durability. Steel is suitable for most indoor and outdoor applications, providing a cost-effective solution with a good balance of strength and weight.

- Stainless Steel: Used in environments where corrosion resistance is crucial, such as in food processing, chemical handling, or marine applications. Stainless steel cranes offer superior protection against rust and corrosion, ensuring long-term reliability in harsh environments.

Durability Features Like Anti-Corrosion Coatings and Robust Construction

To enhance the durability and lifespan of pillar jib cranes, several features are often included in their construction:

- Anti-Corrosion Coatings: Protective coatings, such as galvanization or epoxy paint, are applied to steel surfaces to prevent rust and corrosion, especially in outdoor or corrosive environments. These coatings extend the life of the crane and reduce maintenance needs.

- Robust Construction: The design and fabrication of pillar jib cranes prioritize durability and strength. Features like reinforced joints, high-quality welding, and thick-walled pillars ensure that the crane can withstand heavy use, dynamic loads, and environmental stresses without compromising safety or performance.

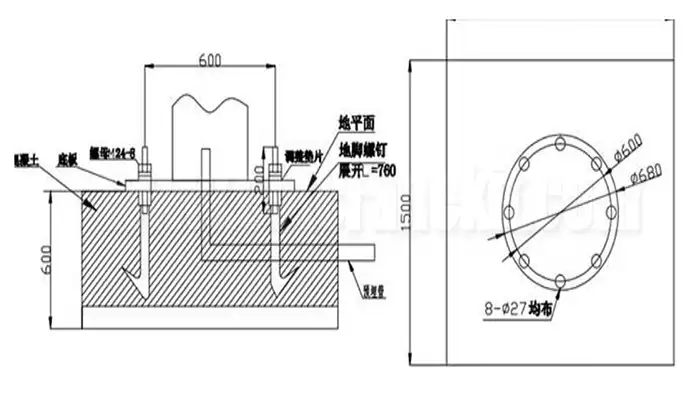

Pillar Jib Crane Foundation Designs

The free standing pillar jib crane is designed to stand on themself with a floor mounted foundation, which usually comes into 3 different types: Bolt-type base plate mounted foundation, Insert mount foundation or sleeve insert mounted foundation.

- Bolt typebase-plate mount foundation is the first and most frequently used jib crane foundation design, the pillar of the jib crane has a base-plate, bolted to the concrete floor securely.

- Insert mount foundation is with a permanent pillar jib crane foundation with the jib column mounted within the concrete floor for a permanent crane solution.

- Insert sleeve mounted pillar jib crane foundation is designed to construct a separate steel sleeve installed permanently in the concrete floor., which enables the jib to be slid into or removed out of the sleeve quickly and easily.

With the favorable pillar jib crane design and floor mounted crane foundation, the free standing jib crane is able to offer large capacity, longer cantilever length and greater rotation range, comparing with wall mounted jib crane and, which is a good option for various workstation applications with customized designs.

pillar mounted jib crane foundation construction for your reference

With years of studying and expediencies in jib crane design and manufacturing, pillar mounted jib cranes with customized designs are available, such as small pillar jib crane, heavy duty pillar jib crane, electric floor mounted jib crane, and manual pillar jib crane, 180, 270, or 360 degree rotating pillar jib crane, etc. All of our floor mounted jib crane are designed and processed to offer customized overhead jib crane solution with high quality at cost-effective crane price. Contact us to get more information on individualized free standing jib crane design and jib crane price.

Features & Advantages of Pillar Jib Cranes

Floor mounted jib cranes with free standing jib crane designs are widely used in various industrial applications due to the following features and advantages:

- High efficiency, good jib crane price:Floor mounted jib crane offers high efficiency overhead travelling solution for short-distance, material handling with high frequency and intensity but with relative low crane price compared with overhead bridge cranes and gantry cranes.

- Maximum versatility, wide application:Free standing pillar jib crane is one of the most versatile cranes, which can be used almost anywhere indoors or outdoors, either all by themselves or functioned as a supplementary lifting equipment of other types of overhead travelling crane in a assembly lines in various applications. The installation and relocation of free standing jib cranes are very simple without disassembling.

- Compact design, light weight, easy installation and transportation:Withcompact structure design , the free standing jib cranes has light dead weight and simple structure which improves thespace utilization rateof working areas, narrows hook operation distanceand makes the crane installation and transportation easy and simple.

- Smooth, fast loading, excellent performance:Withstep-lessfrequency conversion control system , the floor mounted jib cranes can move loads smoothly and steadily,locate the loads quickly & accurately,brake stablyto handle your material handling with highperformand reliability.

- Ease of operation:Crane pendentcontrol and remote controls are optional, the operation of which is very easy, simple and accurate which will reduce the damage caused by miss-operation which will eventually improve the safety and prolong the working lifting.

- Safer, reliable, using free maintenance design:With advanced crane designs and technology, the floor mounted jib crane is with high safety and efficiency. With perfect braking systems and various safety devices such as emergency stop button, overload limiters, height limiters thesafety and reliabilityof pillar mounted jib cranes are improved. With dust-proof design,the pillar cranes can reach up a long working life. With hardened and polished tooth surface, the operation of jib crane are smoothand are free from maintenance.

Slewing steel structure:

tough and strong, wear resistant, practical, and economical. Low profile jib arm enables large lifting height .

Cable of jib crane:

Trailing cable system running in C rail beside the crane jib cantilever.

Pillar of cantilever crane:

The pillar of cantilever jib crane is made of tough and strong steel structure with high wear resistance, durable and economical.

Motor of free standing cantilever crane:

Better lifting performance with high stability, durability and easy operation.

Applications of Pillar Jib Cranes

Pillar jib cranes, also known as pillar-mounted jib cranes, are versatile lifting solutions used across various industries. Their design allows for efficient material handling in settings where flexibility, reach, and reliability are crucial. The following sections provide an overview of the industries that commonly use these cranes, specific tasks where they excel, and examples of successful implementations.

The free standingjib cranes can be used almost anywhere indoors or outdoors.The floor mounted jib cranes are goodchoices for material handlingin short-distance within the coverage circleof the jib cantilever.Free standing jib crane also can be functioned as a supplementary solution of a large overhead travelling cranein various applications.

However, regularfree standing jib cranes are not supposed to be used in hazardousapplications where is inflammable, explosive, and corrosive, etc, What's more, standard pillar crane are not suitable for loads such as molten metalor materials with features of toxic and inflammable and explosive, etc.

Specifically, Pillar jib cranes are widely usedin various industries such as workstations,, warehouse, workshop, storage,dock, yard, construction sites and other places where the pillar crane can be installed.

Overview of Industries Using Pillar Jib Cranes

Pillar jib cranes are employed in a wide range of industries due to their adaptability and robust design:

- Manufacturing: In manufacturing plants, pillar jib cranes are used to lift and move heavy parts and materials during the production process. They are particularly valuable in workstations where repetitive tasks such as welding, assembly, and inspection are performed. The crane's ability to swing and rotate smoothly allows workers to position loads with precision, enhancing productivity and safety.

- Warehouses and Distribution Centers: These cranes play a crucial role in warehouses and distribution centers, where they are used to load and unload goods, organize inventory, and transport items to different storage locations. The crane's ability to handle varying weights and sizes of materials makes it an essential tool for improving operational efficiency and reducing handling times.

- Automotive Industry: In the automotive sector, pillar jib cranes are used to lift and position car parts, engines, and other components during assembly and maintenance. Their flexibility and reach make them ideal for handling heavy, irregularly shaped objects, ensuring that parts are transported safely and accurately within the assembly line or workshop.

- Ports and Shipyards: Pillar jib cranes are often utilized in ports and shipyards for loading and unloading cargo, as well as for handling ship maintenance and repair tasks. Their sturdy construction and ability to withstand harsh marine environments make them suitable for these demanding applications, where reliability and strength are paramount.

- Mining and Construction: These cranes are also used in mining and construction sites to move heavy equipment and materials. Their robust design allows them to handle tough conditions and heavy loads, making them an ideal choice for outdoor and industrial applications where durability and flexibility are required.

Specific Tasks Where Pillar-Mounted Jib Cranes Excel

Pillar jib cranes excel in various specific tasks, providing efficient and reliable solutions for material handling needs:

- Material Handling: One of the primary functions of pillar jib cranes is material handling. Whether it's moving raw materials to processing areas or transporting finished products to storage, these cranes provide the flexibility and strength needed to perform these tasks efficiently. Their ability to rotate and reach different areas makes them ideal for handling materials over a wide operational area.

- Loading and Unloading: In warehouses, ports, and manufacturing plants, pillar jib cranes are commonly used for loading and unloading goods from trucks, containers, or pallets. Their ability to handle different weights and dimensions ensures that goods are moved safely and quickly, minimizing the risk of damage and improving throughput.

- Assembly Line Support: In industries such as automotive and electronics, pillar jib cranes are used to support assembly line operations. They help in positioning parts, tools, and equipment along the assembly line, ensuring smooth and efficient production processes. The cranes' precision and control allow for careful handling of delicate or complex components, enhancing assembly quality and speed.

- Maintenance and Repair: Pillar jib cranes are valuable tools for maintenance and repair tasks in various industries. Whether it's lifting heavy machinery parts for repair or positioning equipment for inspection, these cranes provide the necessary reach and flexibility. Their sturdy design ensures that even heavy components can be handled safely, reducing downtime and improving maintenance efficiency.

Specalized Pillar Jib Crane, Custom Industrial Jib Cranes For General Manufacturing

Pillar jib cranes can be adapted for a variety of industrial applications by customizing their design and features to suit specific environmental conditions. Here's a look at how pillar jib cranes are processed and modified for different industrial environments:

Customization for Manufacturing:

Pillar jib cranes used in manufacturing facilities are engineered to handle the demands of heavy-duty applications. They are designed with a focus on robust construction to support significant loads and withstand frequent use. This heavy-duty construction is essential for maintaining stability and reliability in high-demand environments.

Incorporating advanced precision control systems, these cranes offer accurate lifting and positioning. This ensures that components are handled with care, reducing the risk of damage and enhancing overall operational efficiency.

Safety is a primary concern, and manufacturing pillar jib cranes come equipped with enhanced safety features. Key safety mechanisms include overload protection, emergency stop buttons, and limit switches. These features safeguard both equipment and personnel, minimizing the risk of accidents and ensuring safe operations.

Durability is also a critical factor. These cranes utilize high-strength steel and wear-resistant coatings to resist abrasion and corrosion. This durability extends the crane's lifespan and lowers maintenance costs by ensuring reliable performance even in harsh conditions.

Typical Applications:

Pillar jib cranes in manufacturing are utilized for several key tasks:

- Material Handling in Assembly Lines: These cranes facilitate the movement of parts and materials along assembly lines, optimizing production flow and reducing manual handling.

- Support for Machinery Loading and Unloading: They assist in positioning and relocating heavy machinery, enhancing flexibility in equipment setup and reconfiguration.

- Moving Heavy Components and Subassemblies: The cranes provide the necessary lifting and positioning for large and heavy components during assembly or maintenance, ensuring safe and efficient handling.

Typical Pillar Jib Cranes for Manufacturing:

Heavy-duty pillar jib cranes are specifically designed for manufacturing applications. These cranes feature:

- High Load Capacities: Capable of lifting up to 10 tons or more, making them suitable for handling heavy parts and assemblies.

- Robust Construction: Built to endure the demands of frequent and heavy-duty use.

- Advanced Control Systems: Providing precise control for accurate handling of components and machinery.

For high-load and high-frequency operations, pillar jib cranes are customized with reinforced materials and advanced precision control systems. This customization ensures that the crane performs reliably under heavy loads and frequent use, which enhances both productivity and operational safety.

Warehouses and Distribution Centers

Customization for Warehouses and Distribution Centers:

Pillar jib cranes in warehouses and distribution centers are tailored to enhance efficiency in material handling and storage operations. These cranes are designed with a compact and space-efficient framework, making them ideal for environments where space is at a premium. Their design allows for optimal use of available space while maintaining functionality.

Equipped with versatile rotation ranges and varying boom lengths, these cranes offer flexibility in reaching different areas within the warehouse. The compact design and adjustable features help in navigating narrow aisles and tight spaces, ensuring effective material handling throughout the facility.

For smooth and efficient operations, these cranes often come with both manual and electric lifting mechanisms. The choice between manual and electric systems depends on the operational requirements and the frequency of use. Electric mechanisms generally offer faster and more consistent lifting speeds, which can significantly boost productivity.

Safety is also a key consideration. Warehouses often implement safety features such as overload protection and emergency stop buttons to prevent accidents and ensure safe operation. These features are crucial in busy environments where safety is a top priority.

Typical Applications:

Pillar jib cranes in warehouses and distribution centers are used for:

- Material Handling: Moving goods and materials within the warehouse, including picking and placing items on shelves or conveyors.

- Loading and Unloading: Assisting in the loading and unloading of goods from trucks or containers, improving efficiency in logistics operations.

- Storage Management: Helping to organize and manage inventory by moving items to and from storage areas.

Typical Pillar Jib Cranes for Warehouses and Distribution Centers:

Compact pillar jib cranes are commonly used in these environments. They feature:

- Space-Efficient Designs: Compact and versatile, designed to maximize use of available space in storage areas.

- Medium Load Capacities: Typically supporting up to 5 tons, suitable for the handling of most warehouse and distribution materials.

- Flexible Rotation and Boom Lengths: Adjustable features to reach various areas and navigate narrow aisles effectively.

Customization:

To meet the needs of warehouse and distribution center operations, pillar jib cranes are customized with space-efficient designs and versatile features. The choice between manual and electric lifting mechanisms is made based on operational needs, while safety features are integrated to ensure safe and efficient handling of materials. This customization helps in optimizing warehouse operations and improving overall productivity.

Automotive Industry

Customization for Automotive Plants:

In the automotive industry, pillar jib cranes are highly specialized to cater to the specific needs of vehicle production and maintenance.

- Specialized Attachments: These cranes are equipped with custom grabs, hooks, and other attachments designed for handling various automotive parts such as engine components, chassis parts, and body panels. These specialized attachments ensure that components are lifted and moved with precision and care, minimizing the risk of damage.

- Precision Movement: Automotive plants require precise handling of delicate components. To meet this need, pillar jib cranes are fitted with advanced control systems that provide fine-tuned movements. These systems ensure accurate positioning and lifting, which is crucial for assembling intricate parts and maintaining high-quality standards.

- Enhanced Mobility: To improve operational efficiency, these cranes may feature electric or hydraulic rotation systems. Enhanced mobility options allow the crane to cover a wider area and perform smooth, efficient movements, making it easier to handle heavy and bulky automotive parts within the plant.

Typical Applications:

Pillar jib cranes in the automotive industry are used in various key applications:

- Supporting Assembly Lines: These cranes play a crucial role in moving parts and components along assembly lines, facilitating the smooth progression of the manufacturing process and reducing manual handling.

- Moving and Positioning Automotive Parts: They are essential for the accurate positioning of automotive parts during assembly, repair, or modification processes, ensuring components are in the right place at the right time.

- Assisting in the Maintenance and Assembly of Vehicles: The cranes support the maintenance and assembly of vehicles by handling heavy and cumbersome parts, thus improving efficiency and reducing the physical strain on workers.

Typical Pillar Jib Cranes for Automotive Industry:

Pillar jib cranes used in automotive plants typically feature:

- Specialized Attachments: Custom-designed grabs and hooks for handling specific automotive components, enhancing versatility and precision.

- Precision Control Systems: Advanced systems for fine-tuned movements and accurate positioning of parts.

- Enhanced Mobility Options: Electric or hydraulic rotation systems to improve coverage and operational efficiency.

Customization:

For automotive plants, pillar jib cranes are customized with specialized attachments and advanced control systems to meet the specific demands of vehicle assembly and maintenance. Enhanced mobility options further contribute to operational efficiency, allowing for smooth and precise handling of automotive components.

Ports and Maritime Operations

Customization for Ports:

Pillar jib cranes used in ports and maritime operations are specially tailored to handle the demanding conditions of maritime environments.

- Corrosion-Resistant Materials: To withstand the harsh marine environment, these cranes are constructed from stainless steel or coated with anti-corrosion materials. This ensures long-term durability and performance despite constant exposure to saltwater and humid conditions.

- Explosion-Proof Features: Given the potential presence of hazardous materials, these cranes are equipped with explosion-proof features. They comply with strict regulations to safely handle and operate around flammable or explosive substances, ensuring safety and regulatory compliance.

- Robust Construction: The design of these cranes includes reinforced structures to endure strong winds and heavy maritime conditions. This robust construction guarantees stability and reliability during operation, even in challenging weather conditions.

Typical Applications:

Pillar jib cranes in ports and maritime operations serve several crucial functions:

- Loading and Unloading Cargo from Ships: These cranes are essential for efficiently transferring cargo between ships and dock areas. They facilitate quick and safe handling of various types of cargo, including containers and bulk materials.

- Handling Containers and Bulk Materials: The cranes are used to manage and position containers and bulk materials, improving logistics and operational efficiency in busy port environments.

- Support for Ship Maintenance and Repair Operations: In addition to cargo handling, pillar jib cranes assist in the maintenance and repair of ships. They enable the lifting and positioning of heavy parts and equipment required for ship repairs.

Typical Pillar Jib Cranes for Ports and Maritime Operations:

- Corrosion-Resistant Cranes: Made from stainless steel or coated with anti-corrosion materials to ensure durability in marine environments.

- Explosion-Proof Models: Equipped with features to safely operate in environments where hazardous materials are present, complying with safety regulations.

- Robustly Built Cranes: Designed to withstand the effects of saltwater, strong winds, and other challenging maritime conditions.

Pillar jib cranes for ports are customized with corrosion-resistant materials, explosion-proof features, and robust construction to meet the unique demands of maritime operations. These customizations ensure that the cranes perform reliably and safely in the harsh and variable conditions typical of port environments.

Chemical and Pharmaceutical Industries

Customization for Chemical Plants:

Pillar jib cranes used in chemical and pharmaceutical industries are designed with specialized features to address the unique challenges of these environments.

- Anti-Corrosion Coatings: To combat the effects of corrosive chemicals, these cranes are equipped with anti-corrosion coatings. These special coatings protect the crane from chemical damage and extend its lifespan, ensuring consistent performance in harsh conditions.

- Explosion-Proof Design: In facilities where hazardous or explosive materials are present, pillar jib cranes incorporate explosion-proof motors and controls. This design prevents the risk of sparks or ignition, complying with stringent safety regulations and safeguarding personnel and equipment.

- Cleanroom-Compatible Features: For pharmaceutical production environments, cranes are designed to meet strict hygiene and cleanliness standards. Features may include smooth, easy-to-clean surfaces and contamination-resistant materials, ensuring compliance with cleanroom protocols and preventing contamination of sensitive products.

Typical Applications:

Pillar jib cranes in chemical and pharmaceutical industries are used for various critical tasks:

- Handling Chemicals and Pharmaceutical Ingredients: These cranes facilitate the safe and efficient movement of chemicals and pharmaceutical ingredients, ensuring precise and careful handling to avoid contamination or spillage.

- Supporting Production Processes in Controlled Environments: They assist in production processes within controlled environments, such as cleanrooms or specialized chemical processing areas, ensuring operational efficiency while maintaining strict hygiene standards.

- Loading and Unloading Sensitive Materials: The cranes are used to load and unload sensitive materials, including hazardous chemicals and delicate pharmaceutical products, with precision and safety.

Typical Pillar Jib Cranes for Chemical and Pharmaceutical Industries:

- Anti-Corrosion Models: Equipped with coatings and materials designed to resist chemical corrosion, enhancing durability and longevity.

- Explosion-Proof Cranes: Designed with explosion-proof components to safely operate in environments with flammable or explosive materials.

- Cleanroom-Compatible Cranes: Features designed to meet cleanliness standards, including easy-to-clean surfaces and contamination-resistant materials.

Customization:

Pillar jib cranes for chemical and pharmaceutical industries are customized with anti-corrosion coatings, explosion-proof designs, and cleanroom-compatible features to address the specific needs of these sectors. These customizations ensure the cranes perform reliably and safely, meeting the stringent requirements of handling hazardous chemicals and sensitive pharmaceutical materials.

Food Processing Facilities

Customization for Food Processing:

Pillar jib cranes used in food processing facilities are specially designed to meet the stringent hygiene and safety standards required in the food industry.

- Hygienic Design: These cranes feature smooth, easy-to-clean surfaces and are constructed from stainless steel. This design prevents the accumulation of dirt and bacteria, facilitating thorough cleaning and maintaining high sanitary standards.

- Food-Grade Lubricants: To ensure safety and compliance with food industry regulations, pillar jib cranes use food-grade lubricants and materials. These lubricants are safe for use in environments where they may come into contact with food products, minimizing the risk of contamination.

- Sanitary Attachments: Custom attachments are designed for safe handling of food products. These attachments are built to avoid contamination and facilitate the hygienic movement of ingredients and finished products.

Typical Applications:

Pillar jib cranes in food processing facilities are employed in several key functions:

- Moving Raw Ingredients and Finished Products: They assist in the efficient transfer of raw materials from storage to processing areas and move finished products to packaging or storage, streamlining production workflows.

- Supporting Packaging and Processing Lines: The cranes support various stages of the production process, including packaging and processing, by providing precise handling and placement of products.

- Assisting in the Loading and Unloading of Food Items: They are crucial for loading and unloading food items from containers, trucks, or storage areas, ensuring smooth logistics and reducing manual handling.

Typical Pillar Jib Cranes for Food Processing Facilities:

- Hygienic Design Cranes: Constructed with smooth, stainless steel surfaces and easy-to-clean features to maintain cleanliness and prevent contamination.

- Food-Grade Lubricant Models: Equipped with food-safe lubricants and materials to ensure safety and compliance with food industry standards.

- Sanitary Attachments: Designed specifically for safe handling of food products, minimizing contamination risks.

Customization:

Pillar jib cranes for food processing facilities are customized with hygienic designs, food-grade lubricants, and sanitary attachments to meet the rigorous standards of the food industry. These customizations ensure that the cranes not only perform efficiently but also uphold the highest levels of safety and cleanliness in handling food products.

Construction Sites

Customization for Construction:

Pillar jib cranes used on construction sites are tailored to meet the demanding requirements of construction environments.

- Heavy Load Capacity: These cranes feature a reinforced design capable of handling the heavy loads typical of construction materials and equipment. Their robust construction ensures they can manage the substantial weights involved in building and infrastructure projects.

- Mobility Enhancements: To offer greater flexibility on-site, pillar jib cranes can be equipped with mobile bases or tracks. This mobility allows the crane to be repositioned easily, adapting to various tasks and site layouts without the need for permanent installation.

- Weather-Resistant Features: Given the exposure to outdoor elements, these cranes are designed with weather-resistant coatings and materials. These features protect the crane from rain, wind, and other environmental factors, ensuring durability and reliable performance in all weather conditions.

Typical Applications:

Pillar jib cranes on construction sites are employed for several critical tasks:

- Lifting and Positioning Construction Materials: They are used to lift and position heavy construction materials such as beams, concrete blocks, and steel components. This facilitates efficient and precise placement of materials during construction.

- Supporting Installation of Heavy Equipment: The cranes assist in the installation of large construction equipment and machinery, such as generators and HVAC units, by providing the necessary lifting capacity and precision.

- Assisting in Site Logistics and Material Handling: They play a key role in managing site logistics by handling and moving materials, tools, and equipment throughout the construction site, improving overall workflow and efficiency.

Typical Pillar Jib Cranes for Construction Sites:

- Heavy Load Capacity Models: Built to handle substantial weights and withstand the rigors of construction environments.

- Mobile Base or Track Options: Designed for easy repositioning and flexibility, accommodating various site layouts and tasks.

- Weather-Resistant Cranes: Equipped with protective coatings and materials to endure outdoor conditions and maintain performance.

Customization:

Pillar jib cranes for construction sites are customized with heavy load capacities, mobility enhancements, and weather-resistant features to address the unique challenges of construction environments. These customizations ensure that the cranes provide reliable, efficient service while adapting to the demands of lifting, positioning, and handling materials and equipment on-site.

Case Studies or Examples of Successful Implementations

Case Study 1: Automotive Assembly Line Enhancement

A leading automotive manufacturer installed several pillar jib cranes along its assembly line to improve the efficiency of engine and transmission installations. The cranes, with a capacity of 2 tons and a 360° rotational range, were able to position heavy components with precision, significantly reducing assembly time and improving worker safety. The implementation led to a 20% increase in production throughput and a noticeable reduction in workplace injuries due to manual handling.

Case Study 2: Port Loading Efficiency

A major port implemented pillar jib cranes to enhance its cargo handling operations. The cranes, with a capacity of 5 tons and a boom length of 6 meters, were strategically placed to maximize coverage and reach. This setup allowed the port to streamline its loading and unloading processes, reducing ship turnaround times and improving overall cargo throughput. The robust design of the cranes also ensured reliable performance despite exposure to salty, corrosive marine environments.

Case Study 3: Warehouse Space Optimization

A large distribution center installed multiple pillar jib cranes to improve inventory management and space utilization. By using cranes with a capacity of 1 ton and a 270° rotational range, the warehouse was able to optimize its floor layout, reduce clutter, and enhance picking efficiency. The cranes enabled faster and safer movement of goods, contributing to a 15% improvement in order fulfillment times and a reduction in manual handling injuries.

Through these applications and examples, it is evident that pillar jib cranes are indispensable in various industries for improving efficiency, safety, and productivity in material handling tasks. Their customizable features and robust construction make them a versatile solution for a wide range of industrial challenges.

Light duty pillar jib crane with electric chain hoist - Pillar mounted jib hoist crane with kbk cantilever design

Pillar mounted jib crane- Pillar jib crane with vacuum lifter for steel plate handling

Pricing of Pillar Jib Cranes

When considering the purchase of a pillar jib crane, understanding the pricing structure is essential for making an informed decision. The cost of a pillar jib crane can vary significantly based on several factors, including capacity, materials, customization options, and brand. This section provides an overview of these factors, outlines average price ranges for different capacities and specifications, and highlights the cost-benefit analysis of investing in a pillar jib crane for long-term use.

Factors Affecting the Price

- Capacity: The lifting capacity of a pillar jib crane is one of the primary factors influencing its price. Cranes with higher lifting capacities, such as 5 tons or 10 tons, are generally more expensive than those with lower capacities, such as 0.5 ton or 1 ton. This is because larger capacities require more robust construction, stronger materials, and more powerful lifting mechanisms, all of which increase the overall cost.

- Materials: The materials used in the construction of the crane also affect its price. For instance, cranes made from high-strength steel or stainless steel are typically more expensive than those made from standard steel due to their superior durability, corrosion resistance, and load-bearing capabilities. In environments where corrosion resistance is critical, such as coastal or chemical facilities, the use of specialized materials can significantly increase costs.

- Customization: Customization options, such as special mounting configurations, extended boom lengths, or additional safety features, can add to the price of a pillar jib crane. Custom cranes are designed to meet specific operational needs, which often requires additional engineering, specialized components, and unique design modifications. This level of customization ensures that the crane perfectly fits the intended application, but it also adds to the overall cost.

- Brand and Manufacturer: The brand or manufacturer of the crane can also influence its price. Established brands with a reputation for quality, reliability, and customer support may charge higher prices compared to lesser-known manufacturers. However, investing in a reputable brand often ensures better build quality, longer warranties, and superior after-sales service, which can be valuable for long-term use.

- Additional Features and Accessories: The inclusion of additional features such as variable speed controls, advanced safety systems, remote controls, and automation capabilities can also impact the price. These features enhance the crane's functionality and safety, but they come at an additional cost.

Average Price Ranges for Different Capacities and Specifications

The price of pillar jib cranes can vary widely based on the factors mentioned above. Below are the typical price ranges for different capacities and specifications:

- 0.5 Ton to 1 Ton: The average price for a pillar jib crane with a capacity of 0.5 to 1 ton typically ranges from $1,500 to $5,000. These cranes are suitable for light-duty applications, such as small workshops and assembly lines, where smaller loads need to be lifted and moved.

- 2 Tons to 5 Tons: For medium-capacity cranes ranging from 2 to 5 tons, prices generally range from $5,000 to $15,000. These cranes are commonly used in larger manufacturing facilities, warehouses, and construction sites where moderate to heavy loads are handled.

- 10 Tons and Above: Heavy-duty pillar jib cranes with capacities of 10 tons or more can range from $15,000 to $50,000 or higher, depending on the specific features and customization options. These cranes are often used in industrial environments that require lifting large, heavy loads, such as shipyards, ports, and heavy manufacturing plants.

Cost-Benefit Analysis: Why Investing in a Pillar Jib Crane is Cost-Effective for Long-Term Use

Investing in a pillar jib crane may seem like a significant expense upfront, but it can be highly cost-effective in the long run. Here's why:

- Improved Efficiency and Productivity: Pillar jib cranes enable faster and safer material handling, reducing the time and labor required for lifting and moving heavy objects. This efficiency translates to increased productivity, allowing businesses to handle more tasks in less time.

- Reduced Labor Costs: By automating and streamlining lifting operations, pillar jib cranes reduce the need for manual labor, lowering labor costs and minimizing the risk of workplace injuries. This is especially valuable in industries where heavy or repetitive lifting is required, as it helps prevent employee fatigue and injuries.

- Versatility and Adaptability: The ability to customize pillar jib cranes for specific applications means they can be adapted to a wide range of tasks and environments. This versatility ensures that businesses can use the same crane for multiple purposes, reducing the need for multiple types of lifting equipment.

- Durability and Longevity: High-quality pillar jib cranes are built to last, with durable materials and robust construction designed to withstand heavy use and harsh conditions. This longevity ensures that the initial investment is spread over many years of reliable service, making it a cost-effective choice for long-term use.

- Enhanced Safety Features: Investing in a well-built pillar jib crane with advanced safety features reduces the risk of accidents and equipment damage, further lowering maintenance costs and downtime. The peace of mind that comes from knowing that operations are safe and efficient adds significant value to the investment.

- Resale Value: Pillar jib cranes, especially those from reputable brands, often retain their value well. If a business no longer needs the crane or upgrades to a different model, it can resell the existing crane and recoup a portion of the initial investment.

In conclusion, while the upfront cost of a pillar jib crane can vary based on several factors, the long-term benefits make it a valuable investment for any business that requires efficient and reliable material handling solutions. The combination of improved productivity, reduced labor costs, and enhanced safety features ensures that businesses can achieve a favorable return on investment over time.

Top Concerns and Questions About Pillar Jib Cranes

Understanding the common concerns and questions about pillar jib cranes is crucial for making an informed purchase and ensuring safe, effective operation. This section addresses the most frequently asked questions, providing insights into maintenance, installation, safety features, and how to choose the right crane for specific needs.

What are the Maintenance Requirements?

To ensure the longevity and optimal performance of a pillar jib crane, routine maintenance is essential. Maintenance tasks can be divided into daily, weekly, and monthly activities:

- Daily Maintenance Tasks: Before starting operations, conduct a visual inspection of the crane's main components, including the boom, pillar, and lifting mechanism, to check for any signs of wear, corrosion, or damage. Ensure that all moving parts are adequately lubricated to reduce friction and wear. Check the crane's controls and safety features, such as emergency stop buttons and overload protection systems, to confirm they are functioning properly.

- Weekly Maintenance Tasks: Perform a more detailed inspection of the crane's electrical and mechanical systems. This includes checking the electrical connections for any loose wires or signs of overheating and inspecting the crane's hoist and lifting mechanism for any unusual sounds or operational issues.

- Monthly Maintenance Tasks: Conduct a thorough inspection of the entire crane structure, including the mounting bolts and the foundation, to ensure there is no structural damage or loosening. Test all safety devices, such as limit switches and overload devices, to ensure they are operational. Replace any worn-out parts and address any minor issues before they become major problems.

- Common Issues and Troubleshooting Tips: Common issues with pillar jib cranes may include abnormal noises during operation, reduced lifting speed, or difficulty in rotating the boom. These issues can often be resolved by checking for proper lubrication, tightening any loose components, or replacing worn-out parts. For electrical issues, ensure all connections are secure and check for any signs of short circuits or power loss.

How to Install a Pillar Jib Crane?

Installing a pillar jib crane requires careful planning and execution to ensure safety and operational efficiency. Here are the key steps involved in the installation process:

- Site Preparation: Before installation, ensure that the site is properly prepared. This includes confirming that the foundation is level, stable, and strong enough to support the crane and its maximum load capacity. The area should be cleared of any obstructions, and adequate space should be allowed for the crane's rotation and movement.

- Mounting and Assembly: Depending on the crane design, the pillar may need to be bolted or anchored to the floor. Ensure that all mounting bolts are of the correct grade and size and are securely tightened to prevent any movement. The boom and other crane components are then assembled according to the manufacturer's instructions, ensuring all parts are correctly aligned and secured.

- Electrical and Mechanical Setup: For cranes with electric lifting mechanisms, connect the crane to the power supply according to local electrical codes and standards. Install and test all control systems, including the pendant or remote controls, to ensure they are functioning properly.

- Testing and Inspection: After installation, perform a thorough inspection and test the crane's operation. This includes checking the rotation of the boom, lifting mechanism, and all safety features. Conduct a load test to ensure the crane can handle its rated capacity without any issues.

- Considerations for Site Preparation and Mounting: Ensure that the installation area is free from any potential hazards that could interfere with the crane's operation. The foundation must be designed to accommodate the forces exerted by the crane during lifting operations, including any dynamic forces from sudden stops or starts.

What Safety Features are Included?

Safety is a paramount concern when operating pillar jib cranes, and most models come equipped with a variety of safety features to protect operators and prevent accidents:

- Standard Safety Features: Common safety features include overload protection, which prevents the crane from lifting loads that exceed its maximum capacity, and emergency stop buttons that allow the operator to quickly halt all crane operations in case of an emergency. Limit switches are also included to prevent the crane from over-rotating or moving the load beyond a safe range.

- Additional Safety Measures for Specific Environments: In certain environments, such as those with flammable or explosive materials, additional safety measures may be required. These can include explosion-proof components, such as spark-resistant materials and sealed electrical components, to prevent ignition sources. In environments with corrosive chemicals, cranes may be equipped with anti-corrosion coatings and stainless steel construction to enhance durability and safety.

How to Choose the Right Pillar Jib Crane for Your Needs?

Selecting the right pillar jib crane requires careful consideration of several factors to ensure it meets your specific operational needs:

- Capacity: The crane's lifting capacity is one of the most important factors to consider. Determine the maximum weight that needs to be lifted and select a crane with a capacity that exceeds this weight to provide a margin of safety.

- Environment: Consider the environment in which the crane will be used. For outdoor or corrosive environments, choose a crane with weather-resistant or anti-corrosion features. For environments with flammable materials, opt for cranes with explosion-proof components.

- Application: Identify the specific tasks the crane will perform, such as loading/unloading, assembly line support, or material handling. Choose a crane with the appropriate boom length, rotational range, and lifting speed for these tasks.

- Customization Options: If your operation has unique requirements, consider customization options such as specialized mounts, extended boom lengths, or additional safety features. Customizing a crane ensures it fits perfectly into your workflow and maximizes operational efficiency.

Process Pillar Jib Crane Design, Economical Free Standing Jib Crane Price

Customizedpillarjib cranes with process crane design and particular jib crane specifications for your specific applications are the most cost-effective crane solutions.

In order to give your specific quotation quickly, could you please send us the inquiry with the details of the jib crane for us to quoteof wall mounted jib crane:

- The type of the jib crane:

- Lifting capacity of pillar jib crane: ____?

- Lifting height of pillar jib crane: ____?

- Valid Radius (the jib length) of pillar jib crane:____?

- Installation type: 1) Embedded concrete colts, 2. Concrete floor, 3. Poured concrete ground.

- It will be depending to the application situation of your work place.

- Rotating Type: 1) Manual 2) Electric

- Hoisting trolley type: 1)Manual 2) Electric

- The rotating angleo f pillar jib crane:180, 270, 360 or other degree?

- The power voltageof pillar jib crane:____( 380v50Hz 3phase)

If you do not know about how to select the jib crane, please feel free to leave us a message or email to us. The reply of our jib crane engineer will be given within 24 hours. Contact us to get the free free standing jib crane drawing and specific pillar jib crane price now.

Conclusion: Send us An Inquiry to Get Your Pillar Jib Crane Solution

Pillar jib cranes offer significant benefits and versatility for a wide range of industrial applications. Their robust design, ease of use, and flexibility make them an invaluable asset in environments such as manufacturing, warehousing, automotive industries, and ports. By providing efficient material handling solutions and supporting various tasks, from assembly line operations to heavy-duty lifting, pillar jib cranes enhance productivity and safety in the workplace.

Selecting the right pillar jib crane involves careful consideration of factors such as capacity, environment, and specific application needs. It is highly recommended to consult with industry experts or crane manufacturers to ensure that the crane you choose is perfectly suited to your operational requirements. Experts can provide valuable insights into customization options and safety features, ensuring that your investment in a pillar jib crane delivers maximum efficiency and longevity.

Investing in a pillar jib crane is a strategic decision for any business seeking to improve operational efficiency, safety, and cost-effectiveness. With proper selection, installation, and maintenance, these cranes can provide reliable service for many years, proving to be a worthwhile investment that supports the growth and success of your industrial operations.

Related Products

Latest project

Workshop Overhead Crane 5 Ton & 10 Ton Buying Guide

Practical guide for selecting, installing, and maintaining 5 ton to10 ton workshop overhead cranes for safe, efficient, and reliable material handling.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch