How to Position Overhead Cranes to Cover All Maintenance Areas

Position overhead cranes strategically to cover all maintenance zones, improving efficiency, minimizing downtime, & ensuring smooth operational workflow.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

How to Position Overhead Cranes to Cover All Maintenance Areas Efficiently

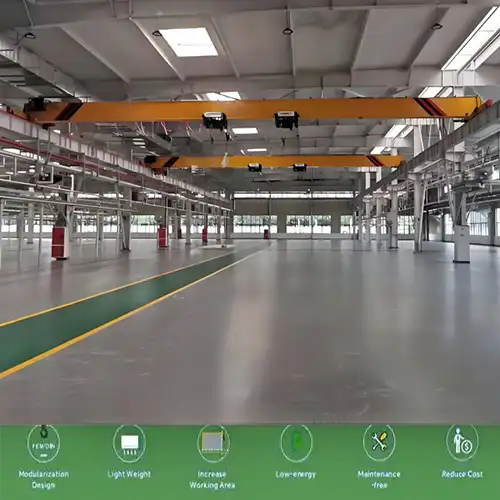

Overhead cranes are a key part of any maintenance workshop. They handle heavy equipment, large tools, and bulky components, making maintenance faster, safer, and more efficient. Without them, moving heavy parts would require more labor and time, and could even create safety risks. Check types of mainteance cranes to improve your workshop mantenance works and repaire works.

Why Placement Matters

Where you position an overhead crane isn't just about fitting it in the workshop. It directly affects:

- Accessibility: Can your team reach all maintenance areas without moving loads awkwardly?

- Efficiency: Are lifts quick and smooth, or are there wasted movements?

- Safety: Is there enough clearance around equipment and workers to avoid accidents?

A poorly positioned crane can slow operations and increase fatigue. A well-placed crane, on the other hand, keeps work flowing and ensures every area can be reached with minimal effort.

What You Will Learn

This guide focuses on practical steps to place overhead cranes effectively:

- Understanding your workshop layout and identifying maintenance zones.

- Choosing the right crane type and capacity for your needs.

- Planning crane placement to cover all areas without blind spots.

- Maintaining safety and smooth workflow while lifting heavy loads.

By the end, you'll have a clear idea of how to position your overhead cranes so that they support your maintenance operations efficiently and safely.

Assessing Maintenance Area Requirements

Before placing an overhead crane, it's essential to fully understand your workshop or maintenance facility. Every facility is different, and a one-size-fits-all approach rarely works. Proper assessment ensures that your crane can reach all areas safely and efficiently.

Mapping the Workshop or Facility

Start by creating a detailed map of your maintenance areas. This helps you visualize the space and identify where the crane will be most effective.

- Identify all maintenance zones: Include machinery, repair stations, and areas where heavy components are regularly moved.

- Mark high-traffic areas: Note pathways used by personnel, forklifts, or other equipment.

- Note obstacles and restrictions: Columns, low ceilings, walls, or safety barriers can limit crane movement, so mark them clearly.

A clear map reduces surprises during installation and ensures the crane will serve all key areas.

Determining Material Flow Patterns

Next, look at how materials and equipment move during maintenance operations. Understanding these patterns will help position the crane for minimal travel and maximum efficiency.

- Analyze typical workflows: Observe daily operations to see where loads are lifted most often.

- Identify frequent lift paths: Mark areas where heavy components are moved repeatedly.

- Consider storage and replacement locations: Include material storage racks, spare parts areas, and workstations where parts are replaced or repaired.

By studying flow patterns, you can avoid placing the crane in a way that causes congestion or requires unnecessary handling.

Load and Capacity Requirements

Knowing the weight of the loads in each area is crucial. Overloading a crane or placing it where it can't reach the heaviest components can slow down operations or create safety risks.

- Determine maximum load per area: Record the heaviest equipment or components that will be lifted.

- Plan for future changes: Consider potential increases in load size or weight, as well as possible facility expansions.

- Safety margin: Ensure the crane's capacity exceeds the maximum load by at least 10–20% to account for unexpected weight variations.

Types of Overhead Crane Layouts

Selecting the right crane layout is crucial to make sure all maintenance areas are covered efficiently. The choice impacts lifting capacity, reach, and workflow in your facility.

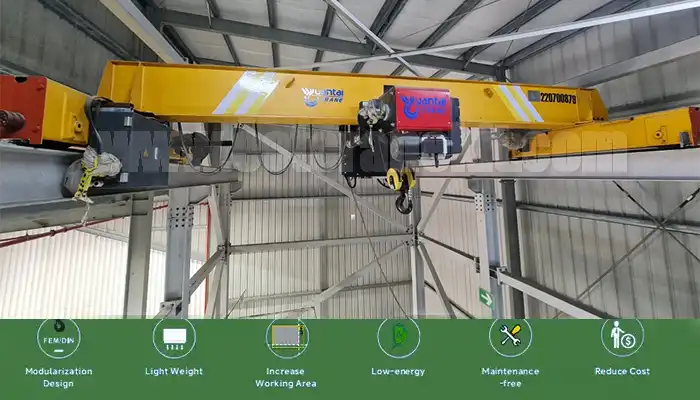

Single-Girder vs. Double-Girder Cranes

- Best for lighter loads, typically up to 10–15 tons.

- Easier and faster to install, with lower cost.

- Requires less headroom, ideal for workshops with lower ceilings.

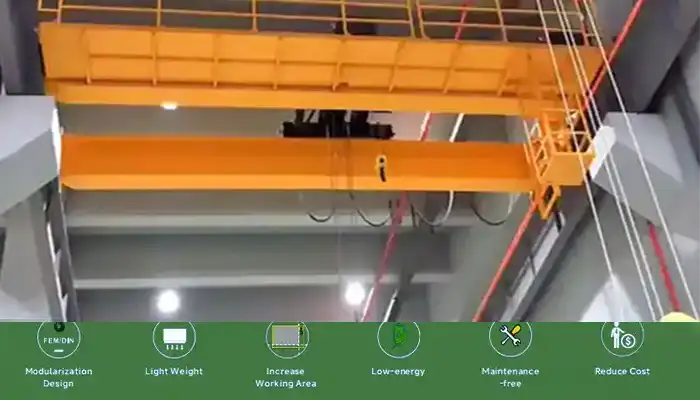

- Handles heavier loads, often 15 tons and above.

- Offers better stability and longer spans.

- Suitable for frequent heavy lifts or large equipment.

Quick Tip: For mixed lifting requirements, single-girder cranes work for light zones, while double-girder cranes cover heavier zones.

Fixed vs. Multiple Crane Configurations

Single Fixed Monorail Crane

- Covers smaller or medium-sized areas.

- Simple installation and lower maintenance needs.

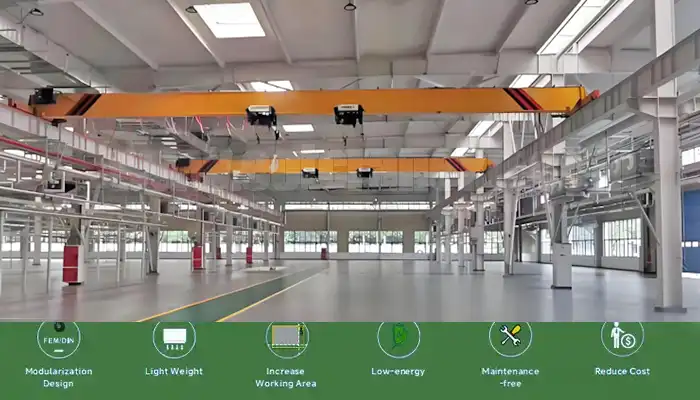

Multiple Overhead Cranes for Tandem Lifting for Larges or long Loads Handling and Improve Efficiency

- Ideal for large workshops or multi-zone facilities.

- Allows simultaneous operations in different zones.

- Reduces blind spots and ensures complete coverage.

Practical Advice: Plan lift paths and overlapping zones to prevent collisions and maintain smooth workflow.

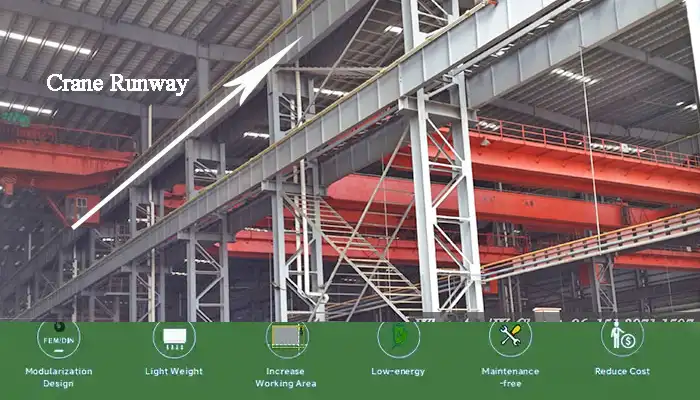

Bridge Span and Runway Placement

- Should cover the full width of the maintenance area.

- Longer spans allow wider coverage but require stronger girders.

Runway Placement

- Place crane runways along the edges of the facility.

- Maintain clearance for other equipment, workers, and obstructions.

Spacing Considerations

- Keep runway spacing balanced for even load distribution.

- Allow room for future expansion or additional cranes.

Pro Tip: Create a mock layout or diagram before installation to ensure full coverage and safe operation.

Principles for Efficient Crane Positioning

Proper crane positioning is the foundation of safe, efficient, and productive maintenance operations. Getting it right ensures every area can be accessed without extra effort, downtime, or risk.

Maximum Area Coverage

The crane should reach all critical maintenance points without needing frequent repositioning.

- Plan lift zones: Map out every location where heavy components are moved or serviced.

- Consider reach limits: Ensure the trolley and hoist can access all required points along the bridge.

- Avoid blind spots: Areas that are hard to reach may slow down operations or create unsafe lifting situations.

Practical Tip: Think of crane coverage like a grid—each square should be accessible without moving the crane.

Minimizing Interference and Congestion

A crane isn't helpful if it constantly collides with obstacles or other equipment.

- Check for obstructions: Account for machinery, storage racks, walls, and low ceilings.

- Coordinate with other cranes: In multi-crane setups, plan paths to prevent overlaps or collisions.

- Maintain clear walkways: Ensure personnel and mobile equipment can move safely around the crane's path.

Pro Tip: Use physical markers or digital layouts to visualize crane movement and identify potential conflicts before installation.

Load Handling Efficiency

Positioning affects how quickly and safely materials can be moved. The goal is to reduce unnecessary travel or extra lifts.

- Minimize trolley travel: Place cranes close to areas with frequent lifts.

- Align with material flow: Position the crane along natural movement paths for tools and parts.

- Optimize storage reach: Ensure cranes can access storage racks, spare parts areas, or repair stations without extra effort.

Practical Tip: Observe daily operations to identify bottlenecks—sometimes small adjustments in placement save hours over a week.

Safety Considerations

Safety should never be compromised for convenience. Proper positioning reduces risks to personnel and equipment.

- Maintain safe distances: Keep the crane clear of walkways, workstations, and sensitive equipment.

- Follow standards: Comply with OSHA, ISO, or local regulations for overhead crane installation and operation.

- Plan for emergency stops: Ensure operators have clear visibility and access to controls in case of unexpected events.

Pro Tip: Safety isn't just rules—it's about designing your crane layout so that the team can work confidently without taking risks.

Evaluating Crane Motion and Accessibility

After selecting and positioning your overhead crane, it's important to evaluate how it will move and interact with your maintenance workflow. Proper motion planning ensures smooth lifts, reduces unnecessary travel, and keeps operations safe.

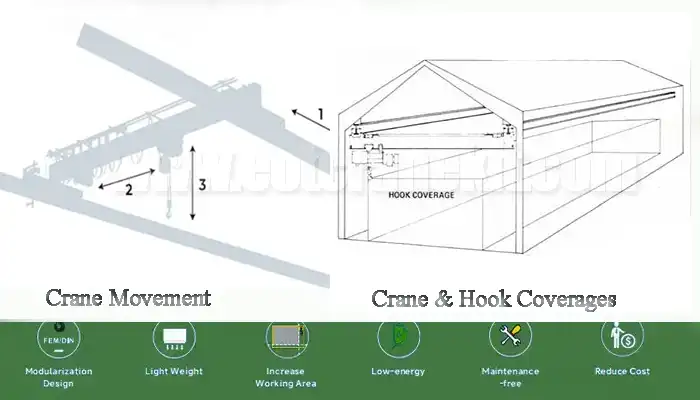

Horizontal Movement

The bridge's horizontal movement along the runway determines how efficiently the crane can cover the facility.

- Optimize bridge travel: Position runways so the crane can reach all critical areas without having to backtrack or make extra passes.

- Avoid dead zones: Ensure the crane can move freely without obstructions like columns, walls, or stored equipment.

- Smooth operation: Check for straight and level runway alignment to prevent jerky movements and wear on the crane components.

Practical Tip: Walk the full travel path and imagine lifting the heaviest load—can it reach all points safely?

Trolley and Hoist Movement

The trolley and hoist provide vertical and horizontal movement across the bridge. Their reach is just as important as the bridge itself.

- Full coverage across the span: Make sure the hoist can access every maintenance point along the bridge.

- Check lifting angles: Avoid situations where loads must be lifted at awkward angles, which can be unsafe or inefficient.

- Balance load handling: Ensure the trolley can move smoothly under heavy loads without strain on the crane or support structure.

Practical Tip: Simulate lifts with maximum weight to verify the trolley and hoist reach all areas safely.

Integration with Other Equipment

Cranes often work alongside other equipment, and their movement must be coordinated.

- Conveyors and lifts: Align crane paths with material handling systems to reduce manual transfers.

- Mobile cranes or forklifts: Plan overlapping zones to prevent collisions or workflow interruptions.

- Maintenance equipment access: Ensure the crane doesn't block critical machinery or emergency exits during operations.

Practical Tip: Draw a simple floor layout showing crane paths and all other equipment—this helps spot conflicts before installation.

Planning for Future Expansion or Changes

When planning crane placement, it's not enough to think only about your current maintenance needs. Facilities change over time, and your crane system should be flexible enough to adapt without costly modifications.

Flexibility in Crane Placement

A good crane layout should allow adjustments as workflows or maintenance zones evolve.

- Plan extra clearance: Leave room around runways and bridges for potential expansion.

- Adjustable positions: Consider slightly longer spans or repositionable runways to accommodate new machinery.

- Future access points: Ensure new maintenance zones can be reached without major crane relocation.

Practical Tip: Think of crane placement like planning roads—leave space for growth.

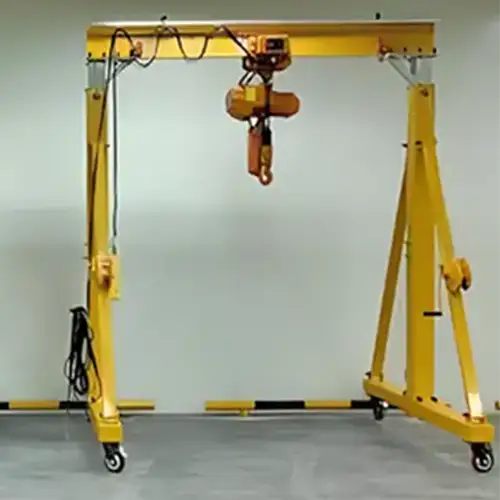

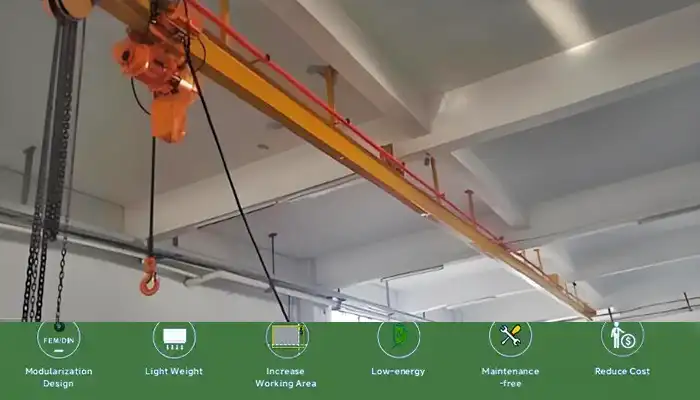

Consider Modular or Adjustable Crane Systems

Modular cranes provide flexibility that traditional cranes cannot. They are easier to expand, reconfigure, or replace parts.

- Modular components: Allow adding extra spans or trolleys as lifting needs increase.

- Adjustable height and span: Useful if ceiling heights change or if new equipment is installed.

- Cost-effective upgrades: Avoid replacing the entire crane system when minor adjustments are needed.

Practical Tip: Modular cranes may have higher upfront costs but save money and downtime in the long run.

Anticipate Increased Load Requirements

Maintenance operations can grow heavier over time. Planning for future load increases prevents crane overloading and safety risks.

- Record potential future loads: Identify components or machines that may require heavier lifts.

- Plan for extra capacity: Choose cranes that can handle 10–20% more than current maximum loads.

- Account for additional maintenance areas: New zones may require expanded coverage or extra cranes.

Practical Tip: Regularly review maintenance operations and equipment upgrades to adjust crane planning before it becomes an issue.

Practical Steps for Implementation

Once you've assessed your maintenance areas, chosen the crane type, and planned positioning, it's time to turn that plan into action. Following these practical steps ensures your overhead crane system will be effective, safe, and efficient from day one.

Conduct a Site Survey

Start by visiting the facility and taking precise measurements. A site survey provides the foundation for all planning.

- Measure the full width, length, and height of maintenance areas.

- Note obstacles, columns, low ceilings, and equipment locations.

- Record distances between potential crane runways and critical work zones.

Practical Tip: Walk the paths where loads will move to spot any hidden obstructions that measurements alone may miss.

Create a Coverage Diagram

A visual map helps you see how much of the facility each crane can reach.

- Highlight all critical maintenance points and lifting zones.

- Draw the crane's maximum bridge and trolley reach for reference.

- Identify areas that may be hard to access or require additional coverage.

Practical Tip: Use color-coded zones for easy visualization of high-traffic and heavy-lift areas.

Simulate Crane Operation Paths

Before installation, test how the crane will move in your layout. Simulation helps uncover potential problems early.

- Move "virtual" loads along the planned path to check for interference.

- Look for blind spots where loads or personnel may be at risk.

- Adjust plans if the crane cannot safely or efficiently reach certain points.

Practical Tip: Even simple sketches or digital floor plans can reveal issues that are easy to fix before installation.

Adjust Runway Placement or Add Cranes

Finally, make any necessary adjustments to maximize coverage and efficiency.

- Reposition runways if critical areas are out of reach.

- Consider adding a second crane for large or complex zones.

- Ensure spacing and alignment maintain safety and structural balance.

Practical Tip: Don't try to make one crane do everything if multiple cranes or slight adjustments will improve workflow—it's worth the extra effort.

Conclusion

Strategic positioning of overhead cranes is not just about installing equipment—it's about making your maintenance operations safer, faster, and more efficient. A well-planned crane layout ensures every area is accessible, reduces unnecessary travel, prevents interference with other equipment, and keeps personnel safe.

Investing time in proper planning, mapping your facility, and evaluating crane motion pays off in smoother daily operations and long-term flexibility. Whether it's choosing the right type of crane, optimizing reach, or preparing for future expansions, every detail matters.

Key Takeaways:

- Plan crane placement around actual maintenance workflows, not just available space.

- Consider load requirements, coverage, and future growth when designing layouts.

- Simulate movements and adjust runways or add cranes to eliminate blind spots.

- Professional consultation or an experienced crane supplier can help ensure your layout is efficient, safe, and ready for future needs.

Final Thought: Take a practical, step-by-step approach. The goal is to have cranes that work with your team, not against them, making maintenance operations smoother and more reliable every day.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch