How to Plan Overhead Crane Runway Layouts for Maximum Coverage

Learn practical strategies to design overhead crane runways, ensuring full coverage, safety, and operational efficiency in any workshop layout.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

How to Plan Bridge Crane Runway Layouts for Maximum Coverage

Getting your crane runways in the right place is more important than most people realize. It's not just about "fitting a crane" into the workshop. Where you put the runways directly affects how smoothly materials move, how safe your team is, and how efficiently your operations run.

A poorly planned layout can cause blind spots, slow down material handling, and even create safety risks. On the other hand, a thoughtful layout lets your overhead bridge cranes work smarter, not harder.

Why Proper Runway Planning Matters

- Safety: Correct spacing reduces the risk of collisions with machines, structures, or workers.

- Efficiency: overhead bridge cranes can reach all necessary areas with fewer movements, saving time and energy.

- Flexibility: A well-planned layout can handle heavier loads, additional overhead bridge cranes, or future workstations without major changes.

What "Maximum Coverage" Means

When we say "maximum coverage," we're talking about designing the runways so overhead bridge cranes can reach every key area of your workshop:

- No blind spots where materials can't be lifted.

- Smooth travel paths that avoid unnecessary back-and-forth.

- The ability for one or more overhead bridge cranes to serve multiple stations without interference.

In short, maximum coverage isn't just about distance—it's about creating a workspace where materials move safely and efficiently, now and in the future.

overhead crane runway

crane hook coverages - overhead crane

Your Workshop or Plant Layout

Before you even think about where to place crane runways, you need a clear picture of your facility. Every building is different, and a layout that works perfectly in one workshop may create bottlenecks in another. Taking the time to map out your space will save you a lot of trouble later.

Map Facility Dimensions and Existing Structures

Start by measuring the full length, width, and height of the building. Include all walls, columns, mezzanines, and other permanent structures. Even small projections can affect crane movement or restrict trolley travel. Accurate measurements are the foundation for a safe and efficient runway layout.

- Measure building length, width, and ceiling height

- Note structural beams, columns, and supports

- Identify areas with height restrictions that could limit crane hook travel

Identify Critical Work Zones and Material Flow Paths

Next, think about how materials actually move through your workshop. Where are the loading and unloading points? Which stations are busiest? Knowing this helps you position the crane runways where they will do the most work with the least wasted movement.

- Highlight key areas where materials are loaded, unloaded, or processed

- Track common routes for forklifts, carts, or other equipment

- Consider peak load zones that need frequent crane access

Note Constraints: Walls, Columns, and Low Ceilings

Every workshop has limitations. Low ceilings, columns in the middle of the floor, or walls close to the operational zone can all affect how your crane moves. Make a list of these constraints so you can design runways that avoid collisions or clearance issues.

- Check minimum hook-to-ceiling clearance

- Ensure trolley and bridge travel won't hit columns or beams

- Identify spots where additional protective measures may be needed

Assess Existing Equipment That Could Interfere

overhead bridge cranes share the workspace with other machines and tools. Conveyor belts, large presses, or storage racks can get in the way if not accounted for. Understanding what's already there lets you adjust your runway layout to avoid interference and maintain smooth operations.

- Locate fixed machinery or equipment along potential crane paths

- Check for overhead pipes, ducts, or lighting that could obstruct crane travel

- Plan for protective barriers or rerouting if equipment cannot be moved

By carefully studying your workshop layout, you can position crane runways for maximum coverage, minimize interference, and keep operations running smoothly.

Step-by-Step Tips for Aligning Runways

Aligning crane runways correctly is crucial for smooth operations. A well-planned layout ensures that overhead bridge cranes can cover all required areas efficiently while keeping safety a top priority. Here's a practical, step-by-step guide.

1. Conduct a Site Survey

Before making any decisions, walk the site carefully and measure everything. Dimensions matter, and even small mistakes can create problems later. Document every structural element and potential obstruction so nothing is overlooked.

- Measure the full span, width, and height of the intended crane area

- Note all columns, beams, walls, and mezzanines

- Identify any obstructions, such as piping, ductwork, or overhead lighting

- Take photos or create sketches to use during planning

2. Determine Coverage Requirements

Think about what the crane actually needs to do. Which areas are critical? How often will materials move between different stations? Understanding this helps you decide whether one crane can handle the workload or if multiple overhead bridge cranes are necessary.

- Identify all work zones that require crane access

- Track the most frequent material paths to minimize unnecessary movement

- Decide on a single crane versus multiple overhead bridge cranes based on workflow efficiency

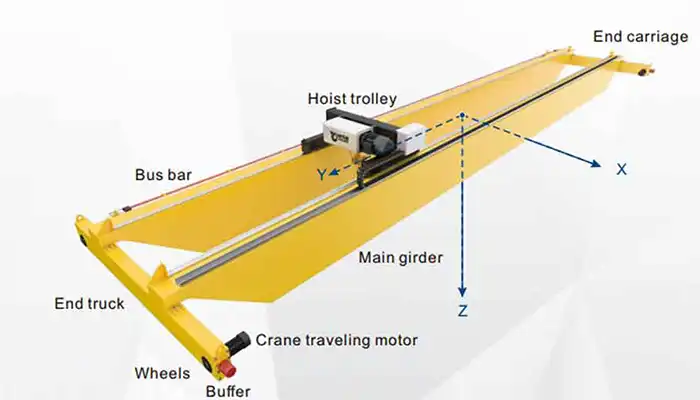

3. Select Crane Types and Capacities

Not all overhead bridge cranes are created equal. Choose overhead bridge cranes that match your lifting requirements and the physical layout of your runways. Larger spans may need double girder overhead bridge cranes, while smaller areas can use single girder overhead bridge cranes for cost efficiency.

- Match crane capacity to maximum load and expected duty cycle

- Consider single or double girder options based on span and weight requirements

- Account for future expansion or heavier loads when selecting crane type

4. Define Runway Paths

The path your crane takes is just as important as the crane itself. Whenever possible, align runways parallel to material flow. Ensure enough clearance around walls, machines, and overhead structures to avoid collisions and make operation safer.

- Align runways along main workflow directions

- Maintain clearance for safe trolley and bridge travel

- Avoid sharp turns or tight spaces that could limit crane operation

5. Plan for Safe Operation

Safety should always come first. Ensure that runways allow smooth, uninterrupted travel and include areas where overhead bridge cranes can stop safely in emergencies. Proper planning can prevent accidents and reduce downtime.

- Design smooth trolley and bridge travel paths

- Incorporate emergency stopping zones along the runway

- Ensure adequate space for operators to safely access the crane and load areas

Avoiding Interference with Existing Equipment

Even the best-planned crane runway can run into trouble if you don't account for existing equipment. overhead bridge cranes share space with machines, storage racks, piping, and other infrastructure. Ignoring these obstacles can lead to collisions, damage, and costly downtime.

Identify Fixed Obstacles

The first step is knowing exactly what's in the way. Walk through the workshop and note every fixed object that could interfere with crane movement. The more detailed your observations, the fewer surprises you'll encounter during installation and operation.

- Locate machines, presses, conveyors, and storage racks along the crane path

- Note overhead pipes, lighting fixtures, and ventilation ducts

- Record any low-hanging obstacles that could restrict hook travel

Maintain Minimum Clearance

overhead bridge cranes need space to move safely. Keeping proper clearance distances is essential for both operator safety and equipment protection. Always follow manufacturer guidelines and local safety regulations when defining these clearances.

- Maintain adequate space between crane and walls or structures

- Ensure trolley and bridge can move freely without risk of collision

- Include extra room for load swing and hook height adjustments

Consider Relocation or Protective Measures

Sometimes, obstacles can't be avoided. In those cases, plan practical solutions to reduce risk. This may involve relocating equipment or adding protective barriers and shielding. The goal is to allow overhead bridge cranes to operate efficiently while keeping equipment and personnel safe.

- Relocate movable machines or racks if possible

- Install protective guards or bumpers around fixed equipment

- Use signage or visual markers to alert operators to restricted areas

Plan Electrical and Control Systems Carefully

Crane electrical lines and control systems can conflict with existing wiring or infrastructure if not properly planned. Ensure all connections are routed safely and do not interfere with other equipment or operations.

- Route power cables away from moving machinery and storage areas

- Plan control panels for easy access without obstructing workflow

- Coordinate with existing electrical systems to avoid overloads or hazards

By identifying obstacles early and planning practical solutions, you can prevent interference, keep overhead bridge cranes operating safely, and maintain smooth material flow throughout the workshop.

Optimizing for Future Expansion

When planning crane runways, it's easy to focus only on today's needs. But in most workshops or plants, requirements change over time. Adding new equipment, heavier loads, or additional overhead bridge cranes is common. Planning for future expansion from the start saves a lot of headaches later.

Allow Extra Runway Length and Reinforcement

Even if you only need one crane today, consider leaving extra runway length and structural capacity for another crane in the future. Reinforcing runway beams and supports now is much easier than retrofitting later.

- Extend runway beams beyond current operational zones

- Ensure columns and supports can handle additional loads

- Consider higher-quality materials or stronger connections for future-proofing

Design Flexible Layouts

A flexible layout can adapt to new equipment, larger loads, or changes in workflow without major reconstruction. Think ahead about how material paths might change or expand.

- Space overhead bridge cranes to allow easy installation of heavier or wider loads

- Keep open areas for future workstations or storage expansions

- Plan bridge and trolley paths that won't need rerouting for new machines

Keep Options for Tandem or Dual-Hoist Operations

Some operations require two overhead bridge cranes or dual hoists lifting together. Designing with this in mind ensures you don't have to rebuild the runway when workloads increase.

- Ensure sufficient distance between multiple crane runways

- Allow for synchronized operation zones if dual lifting is needed

- Plan control and power systems that can handle multiple overhead bridge cranes safely

Practical Implementation Steps

Planning is one thing, but putting it into practice is another. Even the best-laid runway plans can reveal issues during installation if you don't test them first. Following practical implementation steps ensures your overhead bridge cranes operate safely and efficiently from day one.

Use CAD or 3D Modeling

Modern tools make it easier to visualize crane paths before any physical work begins. Using CAD or 3D modeling helps identify potential conflicts with existing structures, equipment, or other overhead bridge cranes.

- Create a digital layout of your workshop including all structures and obstacles

- Simulate bridge and trolley movements to check reach and coverage

- Adjust dimensions virtually before committing to installation

Conduct Mock Operations

Even with digital planning, nothing beats a real-world trial. Conducting mock operations allows you to spot blind spots, interference points, and any operational inefficiencies.

- Use temporary markers or lightweight test loads to simulate crane travel

- Observe crane movement through all operational zones

- Identify areas where clearance or alignment adjustments are needed

Adjust Runway Placement

Once potential issues are identified, make the necessary adjustments before final installation. Small changes now prevent costly rework later and reduce downtime once the crane is in use.

- Modify runway length, alignment, or support positions as needed

- Ensure all adjustments maintain structural integrity and load capacity

- Confirm clearance for safe operation along the entire crane path

Document Final Layout

A detailed record of the final runway layout is essential for operators, maintenance teams, and future expansions. Clear documentation helps everyone understand safe operation zones and prevents mistakes.

- Include diagrams showing crane coverage and travel paths

- Note clearance distances, stop zones, and emergency access points

- Maintain a copy for reference during maintenance or expansion

By carefully implementing these steps, you ensure your crane runways deliver maximum coverage, safe operation, and long-term reliability.

Strategic Runway Layout

Strategically planning crane runway layouts is more than just drawing lines on a floor plan. When done right, it directly impacts safety, efficiency, and operational flexibility in your workshop or plant. A well-thought-out layout ensures overhead bridge cranes can cover all critical areas, reduce interference, and handle material flow smoothly.

Key Benefits of a Strategic Runway Layout

- Safety: Proper spacing and clearance reduce collision risks and protect both operators and equipment.

- Efficiency: overhead bridge cranes can reach every work zone with minimal wasted movement, saving time and energy.

- Flexibility: A layout designed for future growth accommodates additional overhead bridge cranes, heavier loads, or new workstations without major redesign.

Conclusion

Strategically planning crane runway layouts is more than just drawing lines on a floor plan. When done right, it directly impacts safety, efficiency, and operational flexibility in your workshop or plant. A well-thought-out layout ensures overhead bridge cranes can cover all critical areas, reduce interference, and handle material flow smoothly.

Key Benefits of a Strategic Runway Layout

- Safety: Proper spacing and clearance reduce collision risks and protect both operators and equipment.

- Efficiency: overhead bridge cranes can reach every work zone with minimal wasted movement, saving time and energy.

- Flexibility: A layout designed for future growth accommodates additional overhead bridge cranes, heavier loads, or new workstations without major redesign.

Professional Planning Matters

Complex workshops with multiple overhead bridge cranes or heavy machinery often require expert planning. Consulting with experienced crane engineers or suppliers ensures your runway layout is practical, safe, and compliant with local regulations.

- Expert input can prevent costly mistakes during installation

- Helps identify potential blind spots and interference before construction

- Ensures your overhead bridge cranes meet both current and future operational needs

Plan for the Future

Even if today's workflow is simple, consider tomorrow's needs. Leaving room for growth, equipment upgrades, or workflow changes saves time and money in the long run.

- Design for tandem or dual-hoist operations if needed later

- Keep extra runway length or structural reinforcement for expansion

- Maintain clear documentation for future adjustments or maintenance

In short, taking the time to plan crane runways carefully pays off in safer operations, smoother workflows, and long-term flexibility for your workshop.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch