How to Choose Cranes for Each Stage in Oil Refineries?

How to Select Right Overhead Crane for Every Stage of Oil Refinery Facilities? 1 to 50 ton overhead crane,explosion proof crane, gantry crane, jib crane.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

How to Select Cranes for Every Stage in Oil Refinery Facilities From Raw Material to Finished Product

How to Select Cranes for Every Stage in Oil Refinery Facilities From Raw Material to Finished Product

Introduction: Overhead Crane In Oil Refinery Facilitiers

In oil refinery facilities, cranes play a crucial role in ensuring smooth and efficient operations. These lifting machines are essential for handling heavy and often hazardous materials, moving large equipment, and managing various production stages, from raw material intake to finished product packaging.

Selecting the right crane for each stage of the refinery process is vital for maintaining productivity and safety. Each stage—raw material handling, processing, storage, and packaging—has distinct requirements. Using cranes that are well-suited to these specific needs helps prevent operational delays, reduce risk, and optimize performance.

This guide aims to provide a clear understanding of how to choose the appropriate crane for every stage in an oil refinery. We will explore the types of cranes best suited for each stage, the key features to consider, and practical examples of their applications. By following this guide, you will be equipped to make informed decisions that enhance the efficiency and safety of refinery operations.

Understanding Oil Refinery Stages

Raw Material Handling

The initial stage of oil refining involves handling raw materials, primarily crude oil and various chemicals. Crude oil is transported to the refinery from extraction sites and is often delivered in large quantities by tanker ships, pipelines, or rail. Chemicals used in the refining process, such as catalysts and solvents, also need to be moved and managed efficiently. Cranes at this stage must be robust and capable of lifting heavy and potentially hazardous materials, ensuring safe and effective loading and unloading operations.

Processing and Conversion

Once raw materials are on site, they undergo various processing stages to convert them into usable products. This includes processes like distillation, where crude oil is heated and separated into different components based on boiling points; and cracking, which breaks down larger molecules into more valuable products such as gasoline and diesel. Cranes used in these stages need to handle large equipment such as distillation columns, reactors, and separators. Precision and stability are crucial to avoid damage to equipment and ensure safe handling of materials under high temperatures and pressures.

Storage and Handling

After processing, intermediate products and refined substances are stored in tanks or silos before being packaged or further processed. This stage requires cranes capable of managing large storage vessels and transferring materials between storage areas. Cranes must be equipped to handle the weight and dimensions of these storage containers and must be able to operate in confined or elevated spaces to facilitate efficient storage and retrieval.

Packaging and Distribution

The final stage involves packaging the refined products for distribution to end users. Finished products, such as gasoline, diesel, and lubricants, are typically packaged into containers or barrels and prepared for shipment. Cranes used in this stage should be versatile and fast, handling various container types and integrating with packaging lines. Efficient crane operation at this stage helps speed up the distribution process and ensures that products are safely loaded onto trucks, ships, or railcars for delivery to market.

Each stage in the oil refining process has unique demands, and selecting the appropriate crane ensures smooth transitions between stages, minimizes downtime, and enhances overall operational efficiency.

Cranes for Raw Material Handling

Types of Overhead Cranes

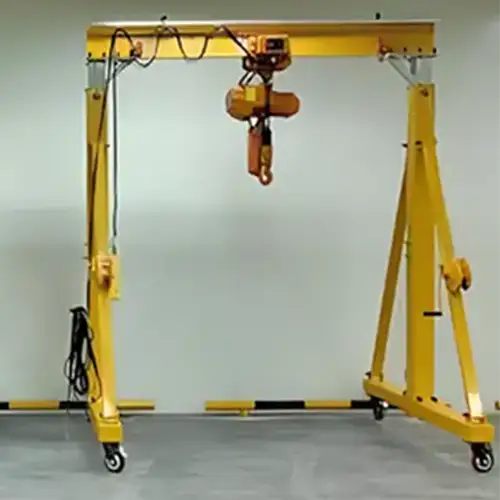

Gantry Cranes

Gantry cranes are ideal for raw material handling in oil refineries due to their ability to cover large areas and handle substantial loads. They are typically used in outdoor environments and can lift and transport heavy barrels or containers of crude oil and chemicals with ease. Their design, which includes vertical supports and a horizontal beam, allows them to span large spaces and provide versatile lifting solutions.Overhead Cranes

Overhead cranes, also known as bridge cranes, are commonly used in indoor settings where raw materials need to be moved across production areas. They are mounted on fixed tracks along the ceiling, providing a clear and unobstructed workspace below. These cranes are well-suited for moving heavy loads such as large containers and equipment used in initial processing stages.Jib Cranes

Jib cranes offer flexibility and precision for handling raw materials in confined spaces or specialized areas. With their rotating arm, jib cranes can move materials in a circular area around their base, making them useful for loading and unloading tasks where maneuverability is crucial. They are often used for handling smaller quantities or more localized tasks within the refinery.Key Features to Consider

Load Capacity and Reach

When selecting a crane for raw material handling, the load capacity and reach are critical factors. The crane must be able to support the weight of the materials being handled, such as large barrels of crude oil or chemical containers. Additionally, the crane's reach must accommodate the dimensions of the storage or transport areas to ensure effective handling and minimal maneuvering.Environmental Conditions

Oil refineries often operate in harsh environments where cranes are exposed to corrosive substances, high temperatures, and hazardous conditions. Choosing cranes with suitable protective features, such as corrosion-resistant coatings and high-temperature tolerances, is essential to maintain durability and safety. Additionally, cranes should be designed to handle the specific hazards of the refinery environment, including potential spills or leaks.Applications

Handling Large Barrels or Containers of Raw Materials

Gantry and overhead cranes are commonly used to lift and move large barrels or containers of raw materials from delivery trucks or ships to storage areas. These cranes provide the strength and reach needed to handle heavy loads efficiently and safely.Loading/Unloading from Trucks or Ships

For unloading raw materials from transportation vehicles, such as trucks or ships, gantry and overhead cranes are typically employed. They enable the precise placement of materials into storage areas or processing units, facilitating smooth and efficient operations. Jib cranes may also be used in specialized areas where space is limited and precise control is required.Selecting the right type of crane for raw material handling ensures that operations are carried out efficiently, safely, and in compliance with the demanding conditions of oil refineries.

Overhead Cranes for Processing and Conversion Stages

Types of Overhead Cranes

Bridge Cranes

Bridge cranes, also known as overhead cranes, are well-suited for the processing and conversion stages of oil refining. Their ability to travel along fixed tracks mounted on the facility's ceiling allows them to cover extensive areas and handle large, heavy equipment. These cranes are ideal for lifting and positioning major processing components such as distillation columns and reactors, providing both the strength and precision needed for this stage.Semi-Gantry Cranes

Semi-gantry cranes offer a versatile solution for processing stages where space or structural constraints limit the use of full gantry cranes. These cranes have one side mounted on a rail (similar to an overhead crane) and the other side supported by adjustable legs or wheels. They are useful for moving large equipment within specific areas of the facility, such as transferring processing units between different stations.Key Features to Consider

Precision and Control

In the processing and conversion stages, precision and control are crucial. The crane must be capable of accurate positioning to avoid damaging delicate equipment or disrupting the production process. Features such as fine-tuned controls, load position indicators, and advanced hoisting mechanisms enhance the crane's ability to handle processing components with high accuracy.Safe Operation in High-Temperature Areas

Processing areas often involve high temperatures due to the nature of the refining processes. Cranes used in these environments must be designed to withstand heat and potential exposure to hot materials. This includes having heat-resistant components, cooling systems, and protective coatings to ensure safe and reliable operation under extreme conditions.Applications

Moving Large Distillation Columns

Bridge cranes are commonly used to handle large distillation columns, which are critical components in separating crude oil into different fractions. The crane's ability to lift and position these heavy columns with precision ensures that they are correctly installed and aligned, which is essential for the efficiency of the distillation process.Handling Processing Equipment and Components

During the conversion stages, semi-gantry cranes can be used to move various pieces of processing equipment, such as reactors, separators, and heat exchangers. Their flexibility allows them to operate in confined spaces or specialized areas, making them suitable for tasks like installing or removing equipment and transferring components between different parts of the processing unit.Using the right type of crane for the processing and conversion stages ensures that heavy and complex equipment is managed safely and effectively, contributing to the smooth operation of oil refining processes.

Overhead Cranes for Storage and Handling of Intermediate Products

Types of Overhead Cranes

Storage Cranes

Storage cranes, also known as stacker cranes, are designed specifically for handling and managing products within storage systems. These cranes are optimized for use in warehouses or storage areas, where they move materials in and out of high-density storage racks. In oil refineries, they efficiently manage intermediate products by moving them to and from storage locations, ensuring organized and accessible inventory management.Automated Cranes

Automated cranes are equipped with advanced technology to perform lifting and handling tasks with minimal human intervention. These cranes are integrated into automated storage and retrieval systems, providing precise and efficient handling of materials. In the context of oil refining, automated cranes streamline the storage and retrieval of intermediate products, reducing labor costs and increasing throughput.Key Features to Consider

Storage Height and Space Optimization

In refineries, optimizing storage space is crucial due to the high volume of intermediate products. Cranes used in storage areas must be capable of operating at various heights and fitting into compact spaces. Features such as adjustable reach and height capabilities, along with efficient load handling mechanisms, help maximize vertical and horizontal storage space.Automated Systems for Efficiency

Automated cranes enhance efficiency by reducing the need for manual intervention and minimizing human error. These systems can operate continuously and integrate seamlessly with inventory management systems, enabling real-time tracking and management of stored products. Features such as automated controls, real-time data reporting, and precise positioning capabilities are essential for maintaining high efficiency in storage operations.Applications

Storing and Retrieving Intermediate Products

Storage cranes are commonly used to manage intermediate products in large tanks or containers. They facilitate the efficient storage of materials such as processed oil or chemical by-products and ensure quick retrieval when needed for further processing or packaging. Their ability to operate at various heights allows for optimal use of vertical storage space.Managing Large Tanks or Silos

Automated cranes can be employed to handle large tanks or silos used for storing bulk intermediate products. These cranes can move heavy tanks into position, retrieve materials from high storage areas, and ensure that tanks are correctly filled or emptied. Their precision and automation capabilities help streamline operations and reduce manual handling, improving overall efficiency and safety in storage areas.Using the right cranes for storage and handling of intermediate products is essential for maintaining an organized, efficient, and safe storage environment in oil refineries.

Overhead Cranes for Packaging and Distribution

Types of Overhead Cranes

Mobile Cranes

Mobile cranes are versatile and can be used in various locations around a refinery. They are particularly useful in packaging and distribution areas where flexibility and mobility are required. Mobile cranes can quickly move between different sections of the facility, making them ideal for handling finished products and facilitating the packaging process.Jib Cranes

Jib cranes offer exceptional maneuverability and precision for packaging tasks. Their rotating arm allows for easy handling of materials within a limited radius, making them suitable for tasks such as positioning products on packaging lines or transferring items between different stages of the packaging process. Jib cranes are especially useful in areas where space is constrained.Key Features to Consider

Speed and Flexibility

For packaging and distribution, cranes must operate quickly and adapt to varying tasks. The ability to rapidly move and position products helps maintain a fast-paced packaging line and ensures timely distribution. Features like adjustable speeds and quick response controls enhance the crane's performance in high-demand environments.Integration with Packaging Lines

Cranes used in packaging areas should integrate seamlessly with packaging machinery and systems. This includes features such as programmable controls that synchronize with automated packaging lines, allowing for smooth and efficient handling of products. Ensuring compatibility with existing equipment helps streamline the overall packaging process.Example Applications

Moving Finished Products to Packaging Stations

Mobile and jib cranes are often used to transfer finished products from production areas to packaging stations. They can handle various types of products, from barrels to pallets, ensuring that items are positioned correctly for packaging. This capability supports efficient workflow and minimizes delays in the packaging process.Loading Products Onto Trucks or Containers

In the distribution phase, cranes are essential for loading finished products onto trucks, containers, or other transport vehicles. Mobile cranes can be used to handle large quantities of products quickly, while jib cranes can assist with precise placement of products into containers. Both types of cranes help ensure that products are securely loaded and ready for shipment, optimizing the distribution process.Selecting the right cranes for packaging and distribution enhances operational efficiency, supports a smooth workflow, and ensures that finished products are handled safely and effectively throughout the final stages of production.

Factors Influencing Crane Selection

Load Capacity and Reach

Matching Crane Capacity with Load Requirements

The primary factor in selecting a crane is its load capacity. It is essential to choose a crane that can safely handle the maximum weight of materials or equipment it will be lifting. For oil refineries, this means considering the heaviest components, such as large distillation columns or heavy barrels of raw material. Additionally, the crane's reach—its ability to extend and maneuver over different areas—must be sufficient to access all necessary parts of the facility. Properly matching crane capacity and reach ensures that operations are performed safely and efficiently.Environmental Conditions

Adapting to Harsh Environments and Safety Regulations

Oil refineries often operate in challenging environments, including high temperatures, corrosive substances, and potentially hazardous conditions. Cranes must be equipped to handle these environmental factors. Features such as corrosion-resistant materials, heat-resistant components, and protective enclosures are crucial for maintaining crane performance and safety. Compliance with safety regulations is also essential; cranes should meet industry standards for operation in hazardous areas, including proper insulation and explosion-proof designs where necessary.Safety and Compliance

Ensuring Cranes Meet Safety Standards and Regulations

Safety is paramount in crane operations, especially in high-risk environments like oil refineries. Cranes must comply with local and international safety standards and regulations. This includes features such as overload protection, emergency stop functions, and regular maintenance checks. Ensuring that cranes are certified by relevant safety organizations and that operators are trained to use them properly helps prevent accidents and ensures a safe working environment.Maintenance and Longevity

Choosing Cranes with Low Maintenance Requirements and Long Service Life

Selecting cranes that require minimal maintenance and have a long service life can significantly reduce operational costs. Look for cranes with durable construction, reliable components, and design features that facilitate easy maintenance and repairs. Regular maintenance schedules and the availability of spare parts also contribute to the crane's longevity. Investing in high-quality cranes that are built to last minimizes downtime and ensures consistent performance over time.By carefully considering these factors—load capacity and reach, environmental conditions, safety and compliance, and maintenance needs—you can select cranes that will enhance efficiency, safety, and reliability in oil refinery operations.

Conclusion

Summary of Key Points

Throughout the guide, we've explored the critical role of cranes in oil refineries and how they are essential at various stages of production. From raw material handling to packaging and distribution, the right crane can significantly impact efficiency, safety, and operational success. We discussed different types of cranes suited for each stage, including gantry cranes, bridge cranes, and automated systems, and highlighted the importance of matching crane features with specific needs such as load capacity, environmental conditions, and safety regulations.Final Recommendations for Selecting Cranes at Different Refinery Stages

- Raw Material Handling: Opt for robust cranes like gantry or overhead cranes that can handle heavy and potentially hazardous materials with precision. Ensure they have adequate load capacity and are equipped to withstand harsh environments.

- Processing and Conversion: Choose cranes with high precision and control, such as bridge or semi-gantry cranes, to manage large equipment and components. Ensure they are capable of operating safely in high-temperature areas.

- Storage and Handling: Utilize storage and automated cranes to optimize space and efficiency. Look for cranes that can handle varying heights and integrate smoothly with automated systems.

- Packaging and Distribution: Select mobile and jib cranes for their flexibility and speed. These cranes should be able to efficiently move finished products to packaging stations and handle various transport needs.

The overhead crane industry is continually evolving, with several emerging trends and innovations shaping the future of crane technology in oil refineries. These include:

- Automation and Robotics: Advances in automation are leading to more sophisticated crane systems that can operate with minimal human intervention. Automated cranes are becoming more common, offering enhanced efficiency and precision in handling and storage.

- Smart Technology: Integration of smart technology, such as IoT sensors and real-time data analytics, is improving crane monitoring and management. These technologies provide insights into crane performance, maintenance needs, and operational efficiency.

- Enhanced Safety Features: New safety innovations, including advanced load sensors and collision avoidance systems, are making cranes safer to operate. These features help prevent accidents and ensure compliance with evolving safety regulations.

- Eco-Friendly Designs: As environmental concerns grow, crane manufacturers are focusing on eco-friendly designs and energy-efficient technologies. This includes using sustainable materials and optimizing energy consumption to reduce the environmental impact of crane operations.

If you have any need of hoist or crane for oil and gas industrrial sector , please feel free to contact us to get free constuction on overhead crane for your oil plant and factory!

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch