50/10 Ton Explosion-Proof Crane for Sale- Key Safety Features

50 ton explosion proof overhead crane for sale. Check essential safety features of 50/10 ton explosion-proof crane for hazardous, high-risk industry use.

Category: Explosion Proof Cranes

Your Trusted Overhead Crane Manufacturer & Supplier

50/10 Ton Explosion-Proof Crane for Sale: Unveiling Critical Safety Features

50 ton explosion proof crane project for your reference. Discover essential safety features of the 50/10 ton explosion-proof crane built for hazardous, high-risk industrial environments.If you have any need of explosion proof cranes from 1 ton to 320 ton, please feel free to contact us to get your customized explosion proof crane solution for industrial material handling in indoor or outdoor operations.

Introduction:Explosion-Proof Crane: Built for Hazardous Zones

An explosionproof overhead crane is not just a lifting machine—it's a safety solution. When you're working in environments where flammable gases, vapors, or dust are present, standard equipment simply won't cut it. You need gear that won't spark, overheat, or fail under pressure. That's where the explosion proof bridge crane comes in.

These cranes are specially engineered to operate safely in explosive atmospheres—like in oil refineries, chemical plants, paint shops, and gas facilities. Their job is not only to lift, but to protect.

Meet the 50/10 Ton QB Explosion-Proof Crane

This heavy-duty explosion proof bridge crane offers:

- Main hook capacity: 50 tons

- Auxiliary hook capacity: 10 tons

- Span: 21.5 meters

- Lifting height: 15 meters (main), 16 meters (auxiliary)

It's a QB double girder explosionproof overhead crane, built for both performance and safety in demanding industries. Whether lifting large machinery or supporting maintenance operations, it's designed to handle it all—without risking a spark.

What This Expproof Crane Delivers

This crane does more than lift—it gives you peace of mind. Its safety-first design includes:

- Spark-free components and wiring

- Explosion-proof electrical enclosures

- Dual braking systems for emergency stops

- Sealed, dust-proof construction

- Controlled, steady movement speeds

Technical Overview of the 50/10 Ton QB Explosion Proof Overhead Crane Double Girder

The 50/10 Ton QB explosion proof bridge crane is designed for demanding environments where both heavy lifting and safety matter. Let's break down what makes this crane technically reliable and functionally smart.

Lifting Capacity

- Main Hook: 50 tons: Built for lifting large and heavy loads like reactors, tanks, or steel components.

- Auxiliary Hook: 10 tons: Used for lighter tasks, fine-tuning positions, or backup during dual-lifting operations.

Having two hooks gives you flexibility—switch between large loads and detailed positioning without switching equipment.

Span: 21.5 Meters

This crane is made for wide workshops and industrial bays. The long span allows it to travel across a large area, improving material flow and work efficiency.

Whether it's a warehouse or a chemical plant, this span gives excellent coverage.

Lifting Height

- Main Hook: 15 meters: High enough for vertical clearance in most industrial setups.

- Auxiliary Hook: 16 meters: Slightly higher than the main hook—useful when performing precise adjustments or supporting operations that need more headroom.

This configuration is common in setups where both lifting height and control are critical.

Double Girder Design

The double girder structure is more than just stronger—it adds safety.

- Better load distribution reduces stress on the crane and the building.

- Supports heavier-duty explosion-proof hoists with greater stability.

- Offers smoother travel and lifting with less vibration or sway.

Double girders are also easier to equip with maintenance walkways and explosion-proof lighting if needed.

Explosion-Proof Classification & Use Case

The 50/10 Ton QB explosion-proof overhead crane is specifically built for use in hazardous zones where explosive gases or vapors may be present. It meets strict safety standards and is trusted across high-risk industries.

Explosion-Proof Standards

This crane complies with internationally recognized explosion-proof safety codes, including:

- ATEX (EU Standard) – for equipment used in explosive atmospheres

- IECEx (International Standard) – ensuring electrical safety in hazardous locations

- GB3836 (Chinese National Standard) – China's classification for explosion protection in gas environments

All electrical components, enclosures, and mechanical parts are selected and built to prevent ignition from sparks, heat, or friction.

Hazardous Area Classification

It is suitable for use in:

- Zone 1: Where explosive atmospheres are likely to occur occasionally during normal operation

- Zone 2: Where explosive atmospheres are not likely during normal operation but may happen occasionally and briefly

This makes the crane versatile enough to handle both higher and lower-risk environments.

Common Uses

This explosion proof bridge crane is ideal for industries that store or process flammable materials. Typical applications include:

- Oil Refineries: For lifting heavy process equipment safely in areas with hydrocarbon vapors

- LNG Terminals: Where flammable gas is present and safety is non-negotiable

- Paint and Chemical Factories: Handling drums, containers, or mixers in volatile areas

- Fuel Depots: For loading/unloading in zones with diesel, gasoline, or kerosene vapors

Where safety can't be compromised, this crane delivers controlled power and reliability in the most sensitive environments.

Key Safety Features of Explosion Proof Overhead Crane

Safety is the top priority when operating in explosive environments. The 50/10 ton explosion-proof crane is equipped with specially designed features to minimize risk, prevent ignition, and ensure safe, reliable lifting. From its sealed electrical system to dual braking and controlled speeds, every detail supports safe operation in hazardous zones.

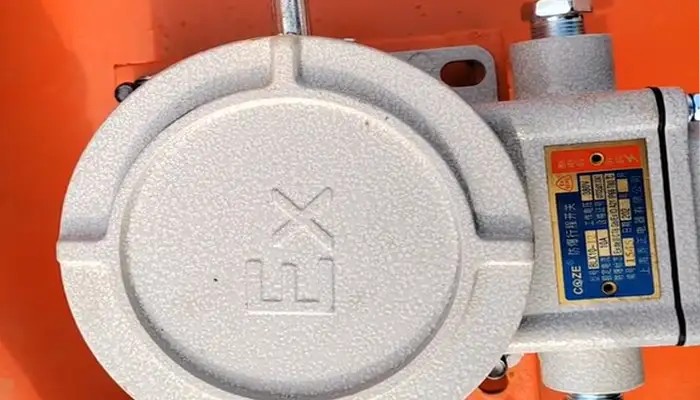

a. Explosion-Proof Electrical System

Explosion-proof overhead cranes, like this 50/10 ton double girder model, must be equipped with electrical systems that prevent any chance of sparks, overheating, or gas ignition. Below are the key safety design elements built into its electrical system:

Enclosed Control Boxes Keep Hazards Out

The explosion proof control panels are fully sealed to isolate electrical components from explosive environments.

- All control boxes are tightly enclosed to keep out dust, moisture, and gas.

- Explosion-proof casing prevents any internal spark or heat from escaping.

- Certified to operate safely in hazardous gas zones.

Top Entry and Bottom Exit for Cables

This layout keeps moisture and dust from collecting inside.

- Cables enter from the top and exit from the bottom, reducing contamination risk.

- Gravity helps keep out water and fine dust particles.

- Cable runs are smooth and secure to avoid damage or wear.

Single Wire Per Terminal Hole

One wire per terminal means stronger connections and easier maintenance.

- Each terminal accepts just one sealed wire to reduce the risk of loose connections.

- Helps maintain system integrity, especially under vibration or heat.

- Safer for both operation and maintenance crews.

Clear, Permanent Wire Labels

Identification matters when time is short or conditions are harsh.

- Wires and terminals are labeled with durable, permanent tags.

- Makes it easy for technicians to trace circuits during checks or repairs.

- Speeds up diagnostics, improving uptime and safety.

Dust-Proof and Flameproof Enclosures

All housing units are built to prevent ignition or internal explosion spread.

- Explosion-proof casings hold internal pressure and block flame paths.

- Dust-proofing ensures reliable operation even in fine-particle environments.

- Offers double protection in oil, gas, and chemical plants.

This explosion-proof bridge crane's electrical system isn't just about performance—it's about keeping people and facilities safe. Every part is designed to contain hazards and meet high industry standards.

b. Dual Explosion-Proof Braking System

When working in explosive environments, brake failure isn't an option. That's why this 50/10 ton QB explosion-proof overhead crane features a dual braking system—built not just for performance, but for protection.

- Two brakes per hoist: Each hoist is equipped with two independent braking systems. If one fails due to wear or damage, the second brake will automatically take over, preventing load drop and ensuring operator safety.

- Explosion-proof brake design: The braking system is specially sealed and built to prevent sparks or excess heat. This is essential for use in areas where flammable gases or vapors are present, such as Zone 1 and Zone 2 hazardous areas.

- High thermal resistance: During continuous or heavy lifting, brake components can heat up. These brakes are made of high-temperature resistant materials that can handle long operations without risk of overheating or failure.

- Emergency stop functionality: The crane includes a quick-response emergency stop system. In case of any abnormal movement or emergency, operators can stop the crane immediately, reducing accident risk.

- Durability and low maintenance: The dual brake system is engineered for long-term reliability, meaning fewer service interruptions and less frequent part replacement—even in tough environments.

This combination of redundancy, heat resistance, and explosion protection makes the braking system one of the most critical safety features of the entire crane.

c. Controlled and Safe Operating Speeds

In explosive environments, speed control isn't just about performance—it's about safety. This explosion-proof bridge crane operates at controlled speeds to minimize risk during lifting and movement.

- Travel speed up to 25 m/min: The crane and trolley move at a moderate pace to avoid sudden stops or jerks. This keeps suspended loads stable, reducing the chance of dangerous swinging.

- Lifting speed up to 8 m/min: Hoisting is slow and steady, which is especially important when lifting flammable materials or operating near sensitive equipment. It helps prevent shock loads or accidental collisions.

- Balanced for precision and safety: These speed limits strike the right balance—fast enough for efficient work, yet slow enough to allow careful positioning and safe operation in hazardous zones.

This level of control helps protect workers, equipment, and the environment when handling critical materials.

d. Optimized Wiring & Power System

The wiring system in an explosion-proof overhead crane plays a critical role in maintaining electrical safety and preventing ignition risks. Every cable and connection is planned with protection in mind.

- Flexible cables with grounding wire: All power cables are flexible and equipped with a grounding wire. This reduces the chance of electrical shock and ensures safe discharge of any static buildup—important in flammable atmospheres.

- No mid-line cable joints: Cable joints in the middle of a line are potential weak points. By avoiding them entirely, the system reduces fire hazards and boosts overall reliability.

- Structured cable layout for clarity and safety: The wiring system follows a clear structure: Main power wiring runs on the left side. Control wiring is routed on the right side

- Neatly arranged and aligned cabling: All cables are carefully organized with vertical and horizontal alignment. This not only helps with heat dissipation but also simplifies inspection, repair, and long-term maintenance.

A clean, logical wiring setup helps reduce error, supports long-term performance, and is a must-have for any explosion-proof bridge crane working in high-risk areas.

Crane Duty Class & Performance

The 50/10 Ton explosion-proof crane is built to handle demanding work environments while ensuring long-lasting reliability and safety.

- Duty Class A5: This classification means the crane is designed for moderate to heavy use. It can handle frequent lifting cycles and tough workloads without wear or failure.

- Ideal for 8-hour shifts: The crane supports continuous operation during a full workday, making it perfect for industrial settings that require consistent performance.

- Standard maintenance cycles: Routine upkeep is straightforward and keeps the crane running smoothly, minimizing downtime and extending service life.

- Reliable in hazardous zones: Engineered specifically for explosive atmospheres, this crane maintains efficiency and safety even in high-risk environments like oil refineries or chemical plants.

With these features, the crane balances durability, safety, and productivity for demanding industrial applications.

Applications in Hazardous Environments

This 50/10 Ton explosion-proof double girder crane is built to safely handle heavy lifting in the most challenging and hazardous industrial settings.

- Handling flammable and dangerous materials: It is ideal for moving raw materials like flammable liquids, chemicals, and pressurized containers. Safety is critical when working with these substances to prevent accidents.

- Designed for Zone 1 and Zone 2 areas: These zones are classified as hazardous due to the presence of explosive gases or vapors. The crane meets strict standards to operate safely in such environments.

Common use cases include:

- Transferring flammable barrels between storage and processing areas

- Loading chemical reactors with raw materials or catalysts

- Handling fuel tanks and valves during manufacturing or maintenance

- Supporting maintenance tasks at gas compressor stations and fuel depots

With its explosion-proof design and robust performance, this crane is a trusted tool for industries where safety and precision matter most.

Buyer's Checklist andSend Us An Inquiry on Explosion Proof Overhead Cranes

Before reaching out for a quote or consultation, it's important for buyers to prepare some key information. This helps ensure you get the most accurate and tailored crane solution.

- Application environment: Specify the hazard classification and zone where the crane will operate. For example, Zone 1 or Zone 2 flammable gas areas. This ensures the crane meets the right explosion-proof standards.

- Power supply details: Provide voltage, frequency, and power source info. Knowing this upfront helps avoid electrical compatibility issues and speeds up design.

- Crane runway dimensions: Share the length and width of the crane runway. Accurate measurements help us recommend the correct span and installation setup.

- Operation method: Let us know how you want to operate the crane—whether by cabin control, remote control, or pendant control. This affects safety features and operator convenience.

Ready to find the perfect explosion-proof crane for your needs? Contact us today for a detailed quotation or expert engineering consultation.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch