Pillar Mounted Jib Crane: 1 to 10 Ton Pillar Column Jib Crane Price

Pillar mounted jib cranes for sale. 1 to 10 tons pillar column mounted jib crane, customizable for various lifting. Affordable prices, high durability.

Category: Featured

Your Trusted Pillar Mounted Jib Crane Manufacturer & Supplier

Pillar Mounted Jib Crane: 1 to 10 Ton Pillar Column Jib Crane Price Guide

Pillar mounted jib cranes are a versatile and reliable solution for many lifting tasks. They are commonly used in various industries to move heavy loads with ease and precision.

What is a Pillar Mounted Jib Crane?

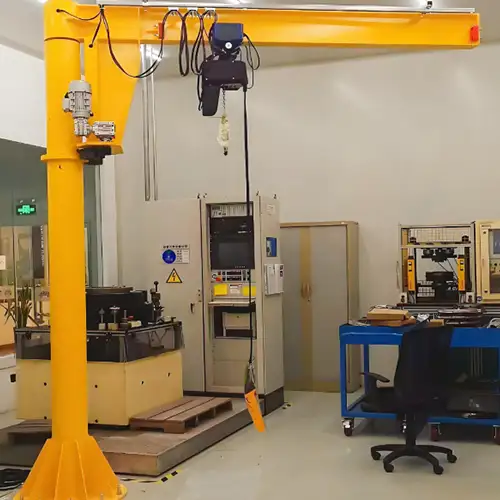

A pillar mounted jib crane is a type of overhead lifting device fixed to a vertical column (pillar). The crane's arm can rotate, allowing it to lift and move materials around a specific area. They are commonly known for their flexibility and ability to be installed in areas where other types of cranes, like overhead cranes, may not fit.

Role in Lifting Operations

These cranes are mainly used for lifting, loading, and unloading materials within a confined space. The crane’s arm, or jib, can move in a circular motion around the pillar, making it easier to lift loads in different directions. This makes pillar mounted jib cranes ideal for tasks that require efficient material handling in smaller or more compact workspaces.

Pillar mounted jib cranes help improve operational efficiency. They speed up material movement and reduce the manual labor needed to lift heavy loads. Plus, they’re easy to use and require less floor space than larger lifting systems.

Common Industries and Applications

Pillar mounted jib cranes are used across various sectors, including:

- Manufacturing: To move heavy parts or machinery in factories and production lines.

- Warehouses & Logistics: For lifting boxes, pallets, and goods in tight spaces or storage areas.

- Construction: To handle construction materials like steel beams or concrete blocks.

- Maintenance and Repair: In workshops for lifting tools, machinery, or engines.

These cranes are especially beneficial in environments where heavy lifting is needed but space is limited. They offer the flexibility of a free-standing crane with the added benefit of being easy to operate and maintain.

What is a Pillar Mounted Jib Crane?

A pillar mounted jib crane (also known as a pillar column jib crane) is a type of crane that is fixed to a vertical column or pillar. The crane's arm, or "jib," can rotate around the pillar, allowing it to lift and move materials across a specific area. These cranes are often used in tight spaces where other types of cranes might not fit, providing a space-efficient solution for lifting needs.

Differences Between Pillar Mounted Jib Cranes and Other Types of Jib Cranes

While pillar mounted jib cranes share some similarities with other jib cranes, there are key differences:

Pillar Mounted Jib Cranes vs. Wall-Mounted Jib Cranes:

- Pillar mounted jib cranes are supported by a free-standing pillar, making them more versatile in terms of placement. They can be installed anywhere there is enough space for the pillar.

- Wall-mounted jib cranes, on the other hand, are attached to a wall or existing structure. This limits their flexibility, as the crane's range is restricted by the position of the wall.

Pillar Mounted Jib Cranes vs. Overhead Cranes:

- Pillar mounted jib cranes are more compact and take up less space. They are ideal for smaller, more confined areas where overhead cranes would be impractical.

- Overhead cranes, while capable of lifting heavier loads, require more room and infrastructure. They also tend to be more expensive and complex.

Key Features and Advantages of Pillar Mounted Jib Cranes

- Flexibility: Since pillar mounted jib cranes are free-standing, they can be placed in virtually any open area, making them a great option for businesses with limited space.

- Space Efficiency: These cranes take up minimal floor space, especially compared to larger overhead cranes, and provide excellent maneuverability in confined areas.

- Ease of Operation: They are easy to operate, and workers can quickly move materials with minimal training. The rotating arm allows for efficient handling without requiring a lot of physical effort.

- Cost-Effective: Pillar mounted jib cranes are often more affordable than larger crane systems, making them a great solution for businesses with medium to heavy lifting needs but a limited budget.

- Versatility: These cranes can be used in a wide range of industries, from manufacturing to maintenance. They are suitable for lifting a variety of loads, from small parts to heavy machinery, depending on the crane’s specifications.

- Durability: Built to last, pillar mounted jib cranes are designed to withstand heavy usage, making them a long-term investment for any business. They require minimal maintenance, adding to their cost-effectiveness over time.

Specifications of Pillar Mounted Jib Cranes

Pillar mounted jib cranes come in a variety of sizes and configurations, making them suitable for different lifting needs. Here are the key specifications to consider when choosing a pillar mounted jib crane:

Lifting Capacity: 1 to 10 Tons

- What It Means: The lifting capacity refers to the maximum weight the crane can safely lift. For pillar mounted jib cranes, the typical range is from 1 ton to 10 tons.

- How It Affects Use: The right lifting capacity depends on the materials you need to handle. If you're lifting heavier loads, you'll need a crane with a higher capacity. For smaller operations, a 1 or 2-ton capacity may be sufficient.

Lifting Height: 3 to 6 Meters

- What It Means: This is the maximum vertical distance the crane can lift a load from the ground to its highest point.

- How It Affects Use: A crane with a higher lifting height is useful when you need to lift materials over other objects or to a greater height for storage or transportation. Most pillar mounted jib cranes typically offer a lifting height between 3 meters and 6 meters, giving you flexibility for various tasks.

Span: 3 to 6 Meters

- What It Means: The span is the horizontal reach of the crane's jib arm. It defines the area within which the crane can move loads.

- How It Affects Use: A 3 to 6 meter span allows the crane to cover a wide area for lifting and moving materials. If you need to reach a broader space within a workshop or warehouse, choose a crane with a larger span. If you only need to move loads within a more confined area, a shorter span may be more appropriate.

Power Supply: Range of Options (220-480V, 3-phase, 50Hz)

- What It Means: Pillar mounted jib cranes can be powered by different voltage and frequency options to match local electrical supply standards.

- How It Affects Use: A crane’s power supply depends on your facility’s electrical setup. Most pillar mounted jib cranes offer 220V to 480V, 3-phase power, and operate at a frequency of 50Hz. Ensure that the crane you choose is compatible with your local electrical grid.

Working Duty: A3 (Standard for Medium-Duty Operations)

- What It Means: The working duty refers to how often and how heavily the crane is expected to operate.

- How It Affects Use: An A3 working duty is standard for medium-duty applications. This means the crane is designed for moderate lifting tasks with regular use. It's perfect for most industrial and workshop settings where lifting happens frequently but not continuously, such as for loading or unloading materials.

These specifications provide a solid foundation for selecting a pillar mounted jib crane that matches your operational needs, space, and budget.

Pillar Mounted Jib Crane Price Range

When it comes to the cost of pillar mounted jib cranes, several factors play a role in determining the final price. These factors can include the crane's lifting capacity, span, lifting height, power supply options, and any additional specifications or customizations.

Overview of Factors Affecting Price

- Lifting Capacity: The higher the lifting capacity of the crane, the more it will generally cost. Larger cranes that can handle 10 tons will be more expensive than those designed to lift 1 ton.

- Span and Lifting Height: Cranes with a wider span and greater lifting height tend to cost more due to the increased material and design complexity needed for their operation.

- Power Supply: Different power supply configurations (such as voltage, phase, and frequency) can also influence the price. For example, a 3-phase crane might be more expensive than a single-phase one, depending on the electrical requirements.

- Customization and Special Features: Customization options like outdoor protection, corrosion-resistant coatings, or special safety features can add to the cost.

General Price Range for Different Lifting Capacities (1 Ton to 10 Tons)

- 1 Ton Capacity: $2,000 - $7,000

- 2 Ton Capacity: $2,500 - $9,000

- 3 Ton Capacity: $3,000 - $15,000

- 5 Ton Capacity: $5,000 - $20,000

- 10 Ton Capacity: $15,000 - $35,000

As the lifting capacity increases, so does the price. For example, a 10-ton pillar mounted jib crane may cost as much as $35,000, while a 1-ton crane will typically range from $2,000 to $7,000.

Example Price List for Pillar Mounted Jib Cranes (for Reference)

| Lifting Capacity | Span (m) | Lifting Height (m) | Power Supply (V) | Price Range (USD) |

|---|---|---|---|---|

| 1 Ton | 3-12 | 3-8 | 220-480/3/50 | $2,000 - $7,000 |

| 2 Ton | 3-12 | 3-8 | 220-480/3/50 | $2,500 - $9,000 |

| 3 Ton | 3-12 | 3-8 | 220-480/3/50 | $3,000 - $15,000 |

| 5 Ton | 3-12 | 3-8 | 220-480/3/50 | $5,000 - $20,000 |

| 10 Ton | 3-15 | 3-8 | 220-480/3/50 | $15,000 - $35,000 |

Impact of Span and Lifting Height on Pricing

- Span: A crane with a longer span will require more materials and engineering, making it more expensive. Cranes with spans of 6 meters and above tend to cost more than those with shorter spans of 3-4 meters.

- Lifting Height: The greater the lifting height, the more robust the crane needs to be to handle the increased load dynamics. As a result, cranes with lifting heights above 6 meters will generally be more expensive.

Power Supply and Specifications: How Different Power Options Influence Cost

- Power Supply Type: Cranes powered by 3-phase electricity tend to cost more than single-phase cranes, as they are designed for heavier lifting tasks and can operate more efficiently over long periods. Cranes that support higher voltage (e.g., 480V) may also come at a premium compared to those supporting 220V or 380V.

- Other Specifications: Additional features like explosion-proof designs, corrosion-resistant coatings for outdoor use, or custom-made features will add to the price.

In summary, while the price of pillar mounted jib cranes can vary based on lifting capacity, span, lifting height, and power supply, understanding your specific needs will help ensure you select a crane that offers the best value for your investment.

Factors Affecting Pillar Mounted Jib Crane Price

When considering the price of a pillar mounted jib crane, several factors influence the final cost. Each element, from lifting capacity to customization options, plays a role in determining the overall price. Here's a breakdown of the key factors that can impact the cost:

Lifting Capacity and Span (Larger Capacities Cost More)

- Lifting Capacity: The lifting capacity is one of the most significant factors affecting price. Cranes with higher lifting capacities, such as those capable of lifting 10 tons, generally cost more than smaller cranes with 1 or 2-ton capacities. The stronger the crane needs to be to lift heavier loads, the more it will cost.

- Span: The span refers to how far the crane's arm extends horizontally. A longer span allows the crane to cover a wider area, but it requires more materials and design effort, driving up the price. Larger spans (e.g., 6 meters) usually result in a higher cost compared to smaller spans (e.g., 3 meters).

Lifting Height and Crane Configuration

- Lifting Height: The height to which the crane can lift materials directly impacts the price. Cranes designed to lift materials to greater heights (e.g., 6 meters) are typically more expensive because they need additional structural support and more powerful lifting mechanisms.

- Crane Configuration: The configuration of the crane—such as the type of jib arm (e.g., hammerhead, straight) and the design of the pillar—also affects the price. Custom configurations that enhance the crane's functionality or make it more suited to specific tasks can increase the overall cost.

Power Supply Type (Single-Phase vs. Three-Phase, Voltage Variations)

- Single-Phase Power: Cranes with single-phase power are typically more affordable and are often used for lighter-duty operations. They are best suited for businesses with lower lifting needs and are generally less expensive.

- Three-Phase Power: Cranes with three-phase power are more expensive, as they are designed for heavier lifting tasks and more intense, continuous usage. These cranes are often used in larger industrial settings and require more robust electrical infrastructure.

- Voltage Variations: The voltage supply (e.g., 220V, 380V, 480V) can also influence the price. Cranes that support higher voltage (such as 480V) may cost more due to the additional engineering and materials required for handling higher electrical loads.

Market Conditions and Demand Fluctuations

- Demand: The price of pillar mounted jib cranes can fluctuate depending on market conditions and demand. If demand for cranes is high due to industry growth or large projects, the prices may increase. On the other hand, when demand is low, manufacturers might offer competitive prices.

- Market Trends: Global economic conditions, raw material costs, and supply chain issues can all affect the price. For example, if steel prices rise, the cost of manufacturing the crane may increase, leading to higher prices for buyers.

Customization Options (e.g., Outdoor Design, Special Coatings, Enhanced Safety Features)

- Outdoor Design: Cranes designed for outdoor use, especially in harsh conditions, may include features like weatherproof coatings, corrosion-resistant materials, and special seals. These features add to the overall cost of the crane.

- Special Coatings and Materials: Cranes used in environments where chemicals or extreme temperatures are present may require additional coatings or special materials to ensure durability. These customization options will increase the price.

- Enhanced Safety Features: Features like anti-collision systems, overload protection, and advanced safety controls can add to the price of the crane. While they provide additional value in terms of safety and functionality, they are often an additional cost to consider.

In summary, the price of a pillar mounted jib crane is influenced by factors such as lifting capacity, span, lifting height, power supply type, market conditions, and customization options. By understanding these factors, you can better plan for your crane investment and choose the best option for your operational needs and budget.

Applications of Pillar Mounted Jib Cranes

Pillar mounted jib cranes are versatile lifting solutions used in various industries. Their robust design and ability to handle moderate to heavy loads make them ideal for both indoor and outdoor applications. Let's explore the industries where these cranes are most commonly used and how they contribute to improved efficiency, safety, and productivity.

Industries Where Pillar Mounted Jib Cranes Are Most Commonly Used

Manufacturing

- Use: In manufacturing plants, pillar mounted jib cranes are used for moving heavy components or materials between workstations, assembly lines, and storage areas.

- Benefit: They help streamline operations by reducing manual lifting and transporting tasks, allowing workers to focus on more complex tasks while improving overall throughput.

Construction

- Use: In construction sites, these cranes are often used to move building materials, such as steel beams, concrete blocks, and tools, from one area to another.

- Benefit: Their mobility and flexibility in positioning help speed up the construction process, while also reducing the risk of injury due to manual material handling.

Warehousing and Logistics

- Use: In warehouses and logistics centers, pillar mounted jib cranes assist in loading and unloading heavy goods from trucks, as well as handling large items like pallets and boxes within the warehouse.

- Benefit: They improve the flow of goods, increase storage efficiency, and reduce handling time, ensuring faster delivery of products and services.

Maintenance and Repair Workshops

- Use: Pillar mounted jib cranes are essential in maintenance and repair workshops, where they are used to lift and position large equipment, machinery parts, and tools during repairs or maintenance tasks.

- Benefit: By reducing the need for manual lifting, they allow workers to move and position heavy items more safely and efficiently, which is crucial in reducing downtime and enhancing the maintenance process.

How Pillar Mounted Jib Cranes Improve Efficiency, Safety, and Productivity

Efficiency:

- These cranes reduce the time and effort required to move heavy materials. This means tasks are completed more quickly and with less physical strain on workers, allowing operations to run more smoothly and efficiently.

Safety:

- With their ability to lift and position heavy loads safely, pillar mounted jib cranes minimize the risk of worker injury caused by manual lifting or handling. They also often come with safety features like overload protection and automatic brakes, ensuring that heavy loads are handled securely.

Productivity:

- By automating the lifting and transportation of heavy loads, these cranes free up workers to focus on higher-value tasks, thereby increasing overall productivity. The fast and efficient handling of materials ensures less downtime, allowing businesses to meet production targets more consistently.

In summary, pillar mounted jib cranes are used in a wide variety of industries, from manufacturing to construction and logistics. They improve efficiency by speeding up material handling, enhance safety by reducing manual lifting, and boost productivity by allowing workers to focus on more complex tasks. These cranes are a vital tool for businesses aiming to optimize their operations and ensure smoother workflow management.

Why Choose a Pillar Mounted Jib Crane?

Pillar mounted jib cranes offer distinct advantages over other types of cranes. Their robust design, flexibility, and efficiency make them a top choice for businesses looking to improve their lifting operations. Here are some reasons why businesses choose pillar mounted jib cranes:

Benefits of Pillar Mounted Jib Cranes Over Other Types of Cranes

- Independence from Structural Supports: Unlike wall-mounted cranes, pillar mounted jib cranes are free-standing, meaning they don't rely on existing building structures. This makes them versatile and easy to install in various locations, especially where walls or ceilings may not be strong enough to support a wall-mounted crane.

- 360-Degree Rotation: Many pillar mounted jib cranes provide full 360-degree rotation, allowing them to cover a larger working area. This feature enables more flexibility in moving materials or tools across the workspace without having to reposition the crane.

- Compact Design: These cranes have a compact footprint, making them ideal for spaces where overhead space is limited. Their design also allows them to be placed in locations where other crane types might not fit, optimizing the use of available space.

Why Businesses with Medium to Heavy Lifting Needs Prefer Pillar Mounted Jib Cranes

- Heavy Load Handling: Businesses with medium to heavy lifting needs, such as manufacturing, construction, and warehousing, often turn to pillar mounted jib cranes because they are designed to handle heavier loads (up to 10 tons). Their sturdy pillar base and stable structure make them suitable for heavy-duty applications, providing the strength needed to lift and position large materials safely.

- Cost-Effective: Compared to larger overhead cranes or gantry cranes, pillar mounted jib cranes offer a more affordable solution for medium-duty lifting. They can provide excellent value for businesses that don’t require the full-scale capabilities of larger cranes but still need reliable, heavy-duty lifting equipment.

Durability, Long-Term Value, and Return on Investment

- Durability: Pillar mounted jib cranes are built to last. Made from high-quality steel and designed to withstand demanding lifting operations, these cranes are a long-term investment that can serve your business for many years with minimal maintenance.

- Long-Term Value: Investing in a pillar mounted jib crane offers value in the long run. Its ability to streamline operations, improve safety, and reduce manual labor costs translates into enhanced productivity and cost savings over time.

- Return on Investment (ROI): The efficiency, safety improvements, and reduced downtime these cranes provide contribute to a strong return on investment. They help businesses meet production targets and improve overall workflow, leading to more efficient operations and better profit margins.

How to Choose the Right Pillar Mounted Jib Crane

When selecting the right pillar mounted jib crane for your business, it's important to consider several factors to ensure you choose the model that best fits your operational needs. Here are the key considerations to help guide your decision-making:

Key Considerations for Selecting the Right Crane for Your Needs

Lifting Capacity Requirements

- Determine the maximum load weight your crane needs to lift. Choose a crane with a lifting capacity that suits your heaviest load. A 1-ton crane may be sufficient for light-duty tasks, while a 5-ton or 10-ton crane may be needed for heavy-duty operations.

Space Availability and Layout Considerations

- Consider the available space in your facility. Measure the area where you plan to install the crane to ensure there’s enough clearance for its operation. Think about the crane’s rotation range and whether it can move freely without obstacles. A compact design may be beneficial in tight spaces.

Operating Environment (Indoor vs. Outdoor)

- Think about whether your crane will be used indoors or outdoors. For outdoor environments, you might need a crane with added features like weather-resistant coatings, corrosion protection, and robust power options to handle harsher conditions.

Safety Features and Customization Options

- Look for cranes with safety features like overload protection, emergency stop buttons, and anti-collision systems. Customization options such as special coatings, protective covers, or specific lifting attachments may also be important, depending on your operational requirements.

Matching Crane Specifications to Your Specific Business Requirements

- Match Lifting Capacity to Your Needs: Ensure the crane's lifting capacity meets your daily lifting demands. Overestimating capacity may result in unnecessary costs, while underestimating it could lead to safety concerns or operational inefficiencies.

- Consider the Span and Lifting Height: Think about the span and height you need. If your workspace requires covering a large area or lifting high above the ground, make sure the crane can meet these specifications.

- Power Supply Considerations: Based on your facility’s electrical setup, choose a crane with the appropriate power supply (single-phase or three-phase). If your business operates in an industrial setting with higher power demands, a three-phase crane may be necessary.

By carefully considering these factors, you can select the pillar mounted jib crane that best fits your business needs, providing the necessary lifting capacity, flexibility, and durability for efficient operations.

Send Inquiry

We understand that choosing the right pillar mounted jib crane is a significant decision for your business, and we are here to help every step of the way. If you have specific requirements or need more detailed information about pricing and customization options, we encourage you to reach out to us. Our team is ready to provide personalized solutions tailored to your lifting needs.

Why You Should Reach Out:

- Detailed Quote: Get an accurate quote based on your specific requirements, including lifting capacity, span, and customization options.

- Customization Options: Whether you need special coatings, outdoor designs, or unique features, we can customize the crane to fit your exact specifications.

- Expert Advice: Our experienced team is available to help guide you in choosing the right crane for your operations.

Conclusion

In summary, pillar mounted jib cranes offer numerous advantages, including:

- Increased efficiency: Streamlined material handling leads to improved workflow.

- Safety: Reduce manual lifting and minimize workplace injuries.

- Cost-Effectiveness: Affordable and reliable lifting solutions for medium to heavy-duty tasks.

- Long-Term Value: Durable and built for long-lasting performance, making them a wise investment for your business.

We invite you to reach out for more information or to get a customized quote based on your specific needs. Our team is ready to help you make the right choice for your business.

Send your inquiry today and get started on improving your lifting operations with a pillar mounted jib crane. Whether you're looking for a crane with a specific lifting capacity, custom features, or special coatings, we can provide the right solution. We look forward to assisting you!

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch