Overhead & Gantry Cranes for Mining & Steel Mills in Uzbekistan

Check reliable mining crane Uzbekistan and steel mill crane Uzbekistan solutions for heavy lifting, harsh environments & efficient material handling.

Category: Uzbekistan

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead & Gantry Cranes for Mining and Metallurgy Plants in Uzbekistan

20 Ton to 50 Ton Heavy Duty Industrial Crane Solution for Your Needs

Mining & Metallurgy Industry Overview in Uzbekistan

Uzbekistan sits on a wealth of natural resources, including gold, copper, uranium, coal, and iron ore. These resources form the backbone of the country's mining and metallurgy sectors, which have been growing steadily over the past decade.

The nation's key metallurgy and steel production centers include:

- Navoi Mining & Metallurgy Combinat – primarily focused on gold and uranium extraction, with integrated metallurgical processes.

- Almalyk Mining & Metallurgical Complex – a major hub for copper and zinc production, with significant downstream processing facilities.

- Angren Ferroalloy Plant – specialized in ferroalloys, serving the domestic steel industry and export markets.

In these plants, overhead and gantry cranes play a critical role. They handle everything from raw materials to finished steel products, often in harsh conditions. Modernization efforts in recent years have pushed plants to expand capacity, which in turn increases demand for cranes capable of handling heavier loads with higher durability and reliability.

Key points:

- Cranes are essential for moving heavy ores, billets, slabs, and coils.

- Plant expansions in Uzbekistan require larger lifting capacities.

- Safety and reliability are major priorities due to the industrial environment.

Typical Materials Handled in Uzbekistan's Mining and Metallurgy Plants

Cranes in Uzbekistan's mining and metallurgy plants handle a wide spectrum of materials, shaped by the country's strong focus on gold, copper, uranium, steel, and non-ferrous metals. Each material type presents distinct challenges related to weight, temperature, density, and handling location, making material awareness a critical factor in crane selection.

Mining Materials (Navoi, Almalyk, Remote Mining Zones)

Uzbekistan's mining sector is concentrated in large, often remote regions where cranes must handle bulk, abrasive, and irregular materials.

- Gold and copper ores: Dense, irregular lumps requiring grab cranes or heavy-duty hooks, common in Navoi and Almalyk regions.

- Uranium-bearing materials: Controlled handling with enhanced safety and dust containment, often in semi-enclosed facilities.

- Coal: Bulk handling in power-generation-linked facilities, typically using grab buckets or clamshells.

- Aggregates (sand, gravel, crushed stone): Used in processing plants and infrastructure support, frequently moved in outdoor yards.

Metallurgical Materials (Steel & Non-Ferrous Plants)

Metallurgical plants in Uzbekistan handle both hot and cold metal products, requiring cranes with precise control, high duty ratings, and specialized attachments.

- Steel billets, slabs, and ingots: Extremely heavy, often hot, and moved continuously in steelmaking and rolling mills such as Bekabad.

- Steel coils: Cylindrical, high-density loads requiring C-hooks, coil grabs, or specially designed lifting beams.

- Copper anodes and cathodes: Handled in batches with strict positioning accuracy in refining plants.

- Ferroalloys and additives: Dense materials moved in smaller volumes but with high unit weight.

Equipment, Support, and Logistics Materials

Beyond raw materials and finished metals, cranes in Uzbekistan are heavily used for plant support and logistics operations.

- Large machinery and process equipment: Crushers, mills, furnaces, and transformers often lifted during installation or overhaul.

- Spare parts and maintenance components: Motors, gearboxes, rollers, and assemblies lifted frequently in workshops.

- Containers and packaged metals: Handling export-ready products and internal storage units in logistics zones.

Material Handling Challenges Specific to Uzbekistan

- High-temperature materials: Molten metal, hot slabs, and billets demand heat-resistant hooks, ladles, and hoist components.

- Abrasive dust: Ore crushing and stockpiling generate fine dust that accelerates wear on ropes, brakes, and bearings.

- Bulk density variation: Gold and copper ores vary significantly in density, requiring conservative capacity planning.

- Outdoor exposure: Many materials are handled in open yards with extreme summer heat and winter cold.

Practical Takeaway for Uzbekistan Projects

In Uzbekistan's mining and metallurgy sector, crane selection must start with a clear understanding of what material is lifted, where it is handled, and under what environmental conditions. A crane optimized for hot steel billets inside a rolling mill will not perform reliably in a dusty, open-pit ore yard—and vice versa. Matching crane design to material characteristics is essential for safety, efficiency, and long-term reliability.

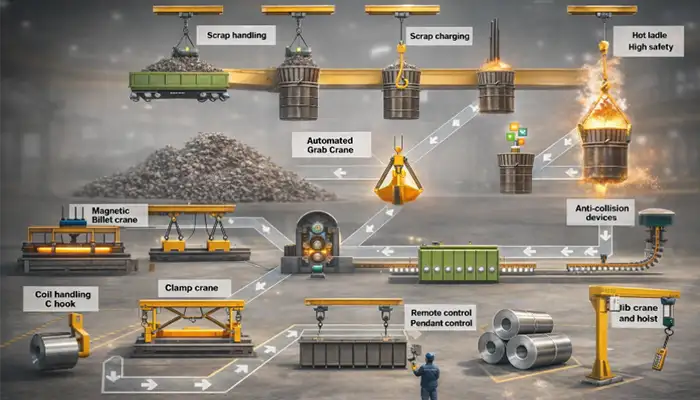

Crane Types Used in Mining and Metallurgy Plants

Selecting the right crane type is crucial for mining and metallurgy operations in Uzbekistan. With major industrial clusters located in Navoi, Almalyk, Tashkent Region, Bekabad, and Samarkand, crane selection is closely linked to plant layout, production process, and environmental conditions. Different crane types are typically deployed at specific stages of mining, smelting, rolling, and logistics.

Double Girder Overhead Cranes

Double girder overhead cranes are the primary lifting solution inside enclosed industrial buildings across Uzbekistan's metallurgical sector.

Typical locations and applications:

- Steel rolling mills (Bekabad, Tashkent Region): Handling slabs, billets, and finished steel products.

- Copper smelters (Almalyk): Transporting anodes, cathodes, and heavy furnace components.

- Gold processing plants (Navoi region): Precise lifting of equipment, molds, and processing units.

- Fabrication workshops: Assembly and movement of heavy machinery and structural parts.

Key features:

- Capacity range: 20–150+ tons for heavy industrial loads.

- High positioning accuracy for production-critical lifts.

- Compatible with ladles, magnets, grabs, and auxiliary hoists.

- Optimized for high duty cycles inside continuous production lines.

These cranes form the backbone of indoor metallurgy operations in Uzbekistan, where reliability and precise control directly affect output quality and safety.

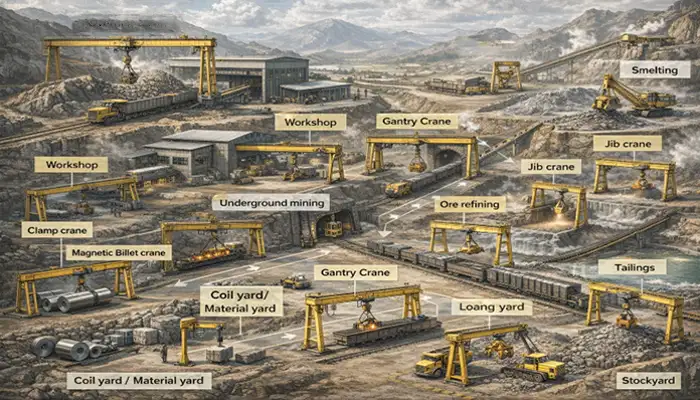

Gantry Cranes

Gantry cranes are predominantly used in outdoor industrial zones where large open spaces and long travel distances are required.

Typical locations and applications:

- Ore stockyards (Navoi Mining Area): Handling raw ore before processing.

- Bulk material yards: Loading and unloading coal, limestone, and scrap metal.

- Railway logistics zones: Transferring materials between railcars and storage areas.

- Port-like dry logistics hubs: Managing oversized equipment and prefabricated structures.

Key features:

- Single or double girder configurations.

- Long span capability for wide yards.

- Designed for outdoor operation under dust, heat, and wind.

- Rail-mounted or rubber-tyred options for site flexibility.

In Uzbekistan's mining industry, gantry cranes are essential for maintaining efficient material flow between extraction sites, processing plants, and transportation infrastructure.

Specialized Cranes by Industrial Area

Certain production zones require cranes engineered for specific materials or safety conditions.

- Magnetic cranes: Common in steel scrap yards and rolling mill charging areas for fast handling of ferrous materials.

- Grab cranes: Used in ore preparation plants, coal yards, and waste handling facilities.

- Ladle cranes: Dedicated to molten metal transfer inside steelmaking shops.

- Explosion-proof cranes: Installed in dust-prone environments, chemical processing areas, and uranium-related facilities.

- Maintenance cranes: Smaller overhead cranes used in turbine halls, pump stations, and equipment maintenance bays.

Matching crane type to the exact industrial location ensures compliance with safety standards while minimizing downtime and operational risk.

Crane Selection by Location: Practical Comparison

| Industrial Location | Typical Crane Type | Main Purpose |

|---|---|---|

| Steel rolling workshop | Double girder overhead crane | Billet and slab handling |

| Smelting & furnace area | Ladle / heavy-duty overhead crane | Molten metal transfer |

| Ore stockyard | Gantry crane with grab | Bulk ore handling |

| Scrap yard | Magnetic gantry or overhead crane | Scrap loading and sorting |

| Railway loading zone | Rail-mounted gantry crane | Logistics and transportation |

Practical takeaway: In Uzbekistan, crane selection is strongly location-driven. Indoor production halls favor overhead cranes for precision and safety, while outdoor yards and logistics areas depend on gantry cranes for flexibility, reach, and durability.

Typical Capacities

Understanding crane capacities is critical for mining and metallurgy plants in Uzbekistan. Capacity selection is closely linked to industrial location, process stage, and material type. From gold and uranium mining sites in Navoi to steel rolling mills in Bekabad and copper smelters in Almalyk, different areas of a plant typically require different crane capacity ranges.

Small-to-Medium Capacity Cranes (20–50 tons)

Cranes in the 20–50 ton range are widely used in auxiliary production areas and workshops across Uzbekistan's mining and metallurgical plants.

Typical locations and applications:

- Fabrication & maintenance workshops: Lifting spare parts, gearboxes, motors, and tooling.

- Steel finishing areas: Handling coils, bars, and bundled billets.

- Processing plant service bays: Equipment maintenance and component replacement.

- Warehouse and indoor logistics zones: Loading and positioning packaged materials.

Practical considerations:

- Commonly installed as single girder or compact double girder overhead cranes.

- Designed for frequent daily operation with moderate load variation.

- Ideal where building height or structural limits restrict larger cranes.

Medium-to-Heavy Capacity Cranes (50–150 tons)

This capacity range represents the core lifting requirement for most metallurgy operations in Uzbekistan and is commonly found in primary production halls.

Typical locations and applications:

- Steelmaking shops (Bekabad, Tashkent Region): Slab, billet, and ingot handling.

- Copper smelting and refining plants (Almalyk): Transport of heavy furnace components and anodes.

- Rolling mills: Continuous movement of hot and cold-rolled products.

- Mining processing plants: Lifting crushers, mills, and large processing equipment.

Practical considerations:

- Typically double girder overhead cranes or heavy-duty gantry cranes.

- Designed to withstand heat, dust, vibration, and high duty cycles.

- Often equipped with magnets, grabs, ladles, or dual-hoist systems.

Heavy-Duty Cranes (150+ tons)

Heavy-duty cranes above 150 tons are special-purpose installations used in limited but critical locations within Uzbekistan's largest industrial complexes.

Typical locations and applications:

- Primary smelting halls: Handling large ladles or oversized ingots.

- Equipment erection zones: Installation of furnaces, converters, and rolling mill stands.

- Heavy machinery assembly areas: Combined or tandem lifting operations.

Practical considerations:

- Custom-engineered for a specific bay or production process.

- Require reinforced runway beams and plant structures.

- Multiple safety systems, load monitoring, and redundant braking are standard.

Capacity Planning by Location: Safety and Load Considerations

- Production halls and smelting areas typically apply a 20–30% safety margin due to heat, dynamic loads, and material variability.

- Outdoor yards and gantry crane zones account for wind loads and uneven material distribution.

- Maintenance areas prioritize flexibility and duty cycle rather than maximum lifting capacity.

- All crane components—hoist, trolley, girders, runway beams—must be rated for the maximum real operating load, not just nominal capacity.

Practical takeaway: In Uzbekistan's mining and metallurgy sector, crane capacity selection is highly location-driven. Matching capacity to the exact production area ensures safety, avoids overinvestment, and supports long-term, reliable plant operation.

Harsh Environment Design Considerations

Mining and metallurgy plants in Uzbekistan operate under some of the most demanding environmental conditions in Central Asia. From desert-adjacent mining zones in Navoi to high-temperature smelting halls in Almalyk and outdoor steel yards in Bekabad, cranes must be engineered to withstand dust, extreme temperatures, wind, and site-specific industrial risks. These conditions directly influence crane design standards and component selection.

Dust and Abrasive Particles (Navoi & Mining Regions)

In gold, uranium, and polymetallic mining regions such as Navoi, dust and abrasive particles are a constant challenge. Ore crushing, screening, and conveyor transfer points generate fine dust that can rapidly degrade mechanical and electrical crane components.

Uzbekistan-specific design solutions:

- IP55–IP65 rated motors and control enclosures for mining and processing zones.

- Fully enclosed hoists and sealed bearings to prevent abrasive ingress.

- Pressurized electrical cabinets with filtered ventilation.

- Increased inspection intervals aligned with local dust load conditions.

Temperature Extremes (Continental Climate)

Uzbekistan's continental climate creates wide temperature fluctuations, with summer temperatures exceeding 40–45°C in outdoor yards and winter lows dropping below -5°C in northern and elevated regions. Inside smelting halls, radiant heat can exceed ambient conditions by a significant margin.

Uzbekistan-specific design solutions:

- Heat-resistant hoist motors and H-class insulation for smelting and rolling mill cranes.

- Low-temperature rated gear oils and greases for winter outdoor gantry cranes.

- Thermal expansion allowances in runway rails and girder connections.

- Ventilated or cooled electrical panels in high-heat metallurgical bays.

Corrosion and Surface Protection (Outdoor & Chemical Exposure)

While Uzbekistan has a generally dry climate, cranes in outdoor yards, chemical processing zones, and tailings-related facilities are exposed to moisture, chemicals, and fine mineral residues that accelerate corrosion.

Uzbekistan-specific design solutions:

- C3–C4 grade anti-corrosion paint systems for outdoor gantry cranes.

- Hot-dip galvanization for walkways, handrails, and structural accessories.

- Stainless or corrosion-resistant fasteners in high-maintenance zones.

- Drainage-oriented structural design to avoid moisture accumulation.

Wind, Open Yards, and Seismic Awareness

Many Uzbek industrial sites feature wide open yards with strong seasonal winds and, in some regions, moderate seismic considerations. Gantry cranes and outdoor overhead systems must be designed accordingly.

Uzbekistan-specific design solutions:

- Wind-rated gantry crane structures with storm locking systems.

- Rail clamps and anchoring devices for unattended outdoor cranes.

- Structural safety factors aligned with regional seismic and wind load requirements.

Optional Features Commonly Specified in Uzbekistan

To address Uzbekistan's site-specific industrial challenges, many plant operators specify additional crane features at the design stage:

- Remote and cabin-based operation: Essential for smelting halls and dusty mining zones.

- Explosion-proof components: Required in uranium processing, coal handling, and fine-dust environments.

- Reinforced duty classification: Higher FEM/ISO duty ratings for continuous production plants.

- Local-service-friendly design: Modular components to simplify maintenance in remote regions.

Practical takeaway: In Uzbekistan, harsh-environment crane design is not generic. Successful projects account for regional climate, mining dust levels, outdoor exposure, and metallurgical heat loads. Investing in these adaptations upfront delivers longer service life, safer operation, and lower total cost of ownership.

Buyer Checklist for Mining & Steel Mill Cranes in Uzbekistan

Buying a crane for mining or metallurgy operations is more than choosing capacity or price. In Uzbekistan, regional environmental conditions, plant locations, and material characteristics play a decisive role. From desert mining zones to high-temperature steel mills, this checklist highlights Uzbekistan-specific factors buyers should evaluate to ensure long-term performance and compliance.

1. Determine Load Type and Weight

Load characteristics in Uzbekistan vary significantly depending on industry and location.

Uzbekistan-specific considerations:

- Navoi mining region: Dense ore, bulk materials, and heavy process equipment.

- Bekabad steel mills: Hot slabs, billets, coils, and bundled steel products.

- Almalyk copper complex: Anodes, cathodes, furnace components, and scrap.

- Account for bundled or uneven loads common in rail-based logistics.

- Evaluate hot vs. cold handling requirements in smelting and rolling areas.

2. Select the Appropriate Crane Type by Location

Crane type selection in Uzbekistan is highly dependent on plant layout and site openness.

Typical crane placement in Uzbekistan:

- Indoor steelmaking & rolling halls: Double girder overhead cranes with high duty ratings.

- Outdoor ore and scrap yards: Rail-mounted or rubber-tyred gantry cranes.

- Remote mining sites: Simplified gantry or semi-gantry cranes with rugged design.

- Maintenance bays: Smaller overhead cranes (20–50 tons) for equipment servicing.

3. Assess Environmental and Site Conditions

Environmental exposure varies greatly across Uzbekistan and must be reflected in crane design.

Special location features to assess:

- Desert-adjacent mining areas (Navoi): High dust load, abrasive particles, limited on-site maintenance.

- Open steel yards: Strong winds, temperature extremes, UV exposure.

- Smelting halls: Radiant heat, fumes, and elevated ambient temperatures.

- Northern and elevated regions: Winter cold, frost, and rail contraction risks.

- Need for IP-rated electrical systems, heat-resistant components, and wind-locking devices.

4. Compliance, Certification, and Local Acceptance

Regulatory acceptance in Uzbekistan often involves both international and local review.

Considerations:

- Compliance with ISO/FEM standards commonly referenced in Uzbek industrial projects.

- Acceptance by local inspectors and plant engineering teams.

- Load testing documentation suitable for state or owner-led inspections.

- Electrical safety compatibility with local power supply conditions.

5. Maintenance and Service Support in Remote Areas

Many Uzbek mining and metallurgy plants are located far from major service centers.

Uzbekistan-specific considerations:

- Availability of spare parts without long import delays.

- Modular crane design for faster on-site repairs.

- Clear documentation and training for local maintenance teams.

- Reduced reliance on complex electronics in remote mining locations.

6. Budget vs. Long-Term Performance in Uzbek Conditions

Uzbekistan's harsh environments often expose the hidden cost of under-specified cranes.

Key trade-off considerations:

- Lower upfront cost vs. higher maintenance in dusty or high-heat areas.

- Energy-efficient drives for high electricity usage plants.

- Downtime risk in continuous steel and mining operations.

- Longer service life through enhanced coatings, sealed systems, and higher duty classes.

Practical takeaway: For Uzbekistan-based projects, selecting a crane designed for specific regional conditions—dust, heat, wind, and remoteness—delivers far better long-term value than choosing the lowest initial price.

Crane Buyer Checklist – Copy, Check & Match to Your Plant Needs

Practical takeaway: A thorough buyer checklist ensures your crane meets both operational and safety requirements in Uzbekistan's demanding mining and metallurgy plants. Proper planning reduces downtime, extends equipment life, and improves overall plant productivity.

1. Load Type & Weight

- Max lift: ☐ <10t ☐ 10–30t ☐ 30–60t ☐ >60t

- Material: ☐ Billets ☐ Slabs ☐ Coils ☐ Machinery

- Shape: ☐ Uniform ☐ Irregular / bulky

- Lift frequency: ☐ Low ☐ Medium ☐ High

- Temperature: ☐ Cold ☐ Hot

2. Crane Type & Operation

- Type: ☐ EOT ☐ Gantry ☐ Specialized (hook/magnet/grab)

- Environment: ☐ Indoor ☐ Outdoor

- Span: ☐ <20m ☐ 20–40m ☐ >40m

- Height: ☐ <10m ☐ 10–20m ☐ >20m

- Mobility: ☐ Fixed ☐ Movable

3. Environmental Conditions

- Temp range: ☐ 0–30°C ☐ -5–45°C

- Exposure: ☐ Dust ☐ Moisture ☐ Rain ☐ Snow ☐ Wind

- Protection: ☐ Standard ☐ Weatherproof ☐ Explosion-proof

4. Compliance & Certification

- Certs: ☐ CE ☐ ISO ☐ Local Uzbek

- Structural/Load Test: ☐ Required ☐ Optional

- Electrical/Safety: ☐ Required ☐ Optional

5. Maintenance & Service

- Spare parts: ☐ Local ☐ Imported ☐ Both

- Access: ☐ Easy ☐ Moderate ☐ Tight

- Support: ☐ Scheduled ☐ On-demand ☐ Training

6. Budget & Lifecycle

- CAPEX vs Lifespan: ☐ Low/short ☐ Medium/standard ☐ High/long

- Energy: ☐ Standard ☐ VFD / Optimized

- Downtime Risk: ☐ Low ☐ Medium ☐ High

Send Us An Inquiry to Get Your Tailored Industrial Solution. Contact us today to check what we can do for your material handling problems now!

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch