How Voltage Choices Affect Your EOT Crane Budget

Choosing the right voltage for your EOT crane impacts energy costs, performance, maintenance, and future scalability, affecting long-term budget.

Why Voltage and Power Supply Matter for Cranes

Voltage and power supply are one of the key factory to how an electric crane works. They decide how much energy your electric lifting crane uses, how well it performs, and how long it lasts. If you choose the wrong voltage, you could face higher costs, performance problems, and even extra repairs.

It's not just about making the electric travelling overhead crane work – it's about making it run efficiently and saving you money.

Purpose of the Article

This article will show you how different voltage choices affect EOT crane costs and efficiency. Here's what you'll learn:

- How voltage affects the price of the electric travelling crane

- The connection between voltage and energy savings

- How voltage affects long-term maintenance

- Why making the right choice is important for your eot crane budget

By the end, you'll understand why voltage matters and how to make the best choice to save money in the long run.

Crane Power Supply Requirements

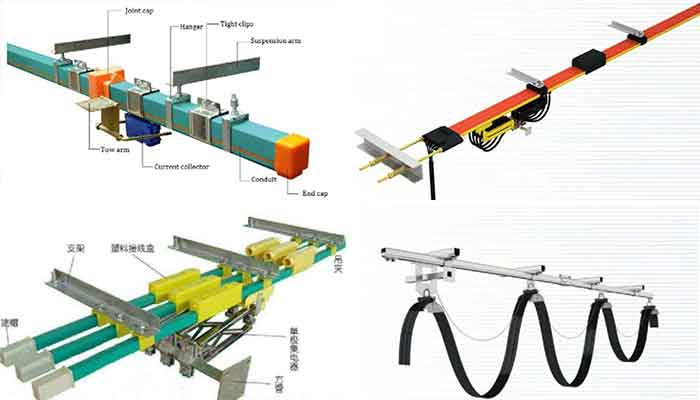

4 types of electric overhead travelling crane power supply lines

Basic Power Supply Needs for Electric EOT Cranes

Electric overhead travelling (EOT) cranes rely heavily on a stable and compatible power supply. The two main factors that influence crane performance are voltage and current. Voltage determines the electrical pressure needed to operate the crane, while current is the flow of electricity powering the motors.

For a overhead EOT crane, the right voltage and current are crucial for safe and efficient operation. A mismatch in power supply can lead to reduced performance, higher energy consumption, or even damage to the system over time.

Voltage and Current Considerations

- Voltage: The electrical pressure required to run the electric travelling EOT crane. Common voltage configurations include 110V, 220V, 380V, and 460V, depending on the overhead bridge crane's size and lifting capacity.

- Current: The flow of electricity through the travelling crane's motors and control systems. A higher current is needed for heavier lifting, but it also leads to higher energy usage.

It's essential to balance voltage and current correctly. Too low a voltage may result in insufficient lifting power, while too high a voltage can overload the electric travelling overhead crane's electrical components.

Different Power Supply Systems (Single-Phase vs. Three-Phase)

- Single-Phase Power: More common for smaller electric powered EOT cranes with lighter loads. It's less expensive and simpler to install but may not be suitable for heavier-duty operations.

- Three-Phase Power: Ideal for large, industrial electric cranes that lift heavy loads. Three-phase power provides a consistent and efficient power supply, making it the preferred choice for most high-capacity cranes.

Why Power Supply Compatibility Matters

Ensuring your electric crane's power requirements match the existing power infrastructure at your facility is essential. If your overhead travelling crane requires three-phase power but your facility only provides single-phase power, you'll need to upgrade the power system. This can result in extra costs for new transformers or wiring and delay your eot crane's installation.

By choosing the correct power supply that aligns with your current system, you can avoid unnecessary upgrades, reduce installation time, and ensure the crane runs at optimal efficiency right from the start.

Voltage Configurations and Their Impact on Crane Costs

Common Voltage Configurations

Electric Overhead Travelling EOT cranes can operate on different voltage configurations depending on the crane's size and the power demands of the operation. Some of the most common voltage options are:

- 110V: Often used in smaller, light-duty cranes or residential applications. It's affordable but may not support heavier lifting.

- 220V: Common in medium-duty cranes, this voltage is suitable for moderate lifting tasks and is often found in smaller industrial settings.

- 380V: Widely used in industrial settings, particularly for large electric EOT cranes that need more power for heavy lifting.

- 460V: Typically used for high-capacity, industrial cranes. It provides the necessary power for the most demanding applications and large-scale operations.

Choosing the right voltage depends on the crane's purpose, load capacity, and operating environment. But remember, different voltage configurations can have a significant effect on the overall crane cost.

Initial Equipment Costs

The voltage choice directly impacts the initial cost of the overhead EOT crane and its components, including motors and electrical systems. Here's how:

- Lower voltage configurations (110V, 220V): Generally cheaper to manufacture and maintain. However, they may require additional components, such as larger motors or specialized control systems, which can increase costs for certain applications.

- Higher voltage configurations (380V, 460V): These are more expensive to manufacture but are necessary for larger, high-capacity cranes. The motors and electrical components for these systems are more robust, which drives up the initial purchase price.

For example, while a smaller 220V crane may cost less to buy, if you're lifting heavy loads frequently, you'll need to invest in more powerful components over time. On the other hand, choosing a 380V or 460V crane will likely save on long-term energy costs and provide better performance, but it comes with a higher upfront cost.

Upfront Infrastructure Requirements

Installation costs can vary based on the voltage configuration you choose. Some of the factors to consider include:

- Need for additional transformers: If your facility's current power supply doesn't match the crane's voltage requirements, you may need to install new transformers to step up or step down the voltage.

- Converters: For certain voltage configurations, you may need converters to ensure compatibility between your crane and your existing power supply system.

- Additional wiring: High-voltage cranes like 380V or 460V models might require more robust wiring and safety equipment, leading to increased installation costs.

The installation costs can add up quickly if your facility needs significant upgrades to accommodate a high-voltage crane. It's essential to factor these costs into your budget to avoid unexpected expenses.

In summary, while choosing the right voltage configuration is crucial for efficient crane operation, it also has a direct impact on both initial equipment costs and upfront installation requirements. Understanding these costs helps you make a more informed decision and ensures your crane system operates within your budget.

Single girder eot crane pricce

Operational Efficiency and Energy Consumption

Impact on Energy Efficiency

The voltage setting of your electric EOT crane plays a significant role in its energy efficiency. The electric cranes operating on higher voltage configurations, such as 380V or 460V, typically have better power efficiency. This means they can handle heavy loads with less energy waste, reducing the overall energy consumption during operation.

- Lower voltage configurations (e.g., 110V, 220V) often require more current to do the same amount of work, which can lead to higher energy losses.

- Higher voltage configurations (e.g., 380V, 460V) are more energy-efficient, especially for larger material handling cranes, as they provide a more stable and consistent power supply, ensuring less wasted energy.

Choosing the right voltage can significantly impact your long-term operational costs. A higher voltage crane might cost more upfront, but it could save you money in the long run due to lower energy consumption.

Energy Savings with Optimized Voltage

There's always a tradeoff when choosing between lower and higher voltage configurations. While higher voltage cranes (380V, 460V) come with a higher initial cost, they offer energy savings over time. Here's why:

- Higher voltage cranes are designed for heavy-duty operations, making them more efficient when lifting large loads. This reduces the energy used per lift, leading to lower electricity bills in the long term.

- Lower voltage cranes, while cheaper initially, may use more energy over time for the same tasks. This can result in higher energy bills, which can add up if the crane is in constant use.

The key is to choose a voltage configuration that balances initial cost with energy efficiency. If you plan to run the crane regularly for heavy lifting, a higher voltage option could be a smarter investment in the long run.

Performance Considerations

Voltage not only impacts energy consumption but also plays a key role in crane performance. Here's how:

- Lifting Capacity: Higher voltage cranes (380V, 460V) provide more consistent and reliable power for lifting heavier loads. They can handle demanding tasks without straining the system, ensuring the crane operates at full capacity without overheating.

- Speed: Cranes with higher voltage are often faster and more responsive because they receive more consistent power. This means your crane can complete tasks quicker, improving overall operational efficiency.

- Reliability: A higher voltage crane is generally more reliable for industrial use. It's built to endure constant use and handle larger loads without wear and tear as quickly as lower voltage cranes.

While lower voltage cranes may work well for light-duty tasks, they might struggle with heavy lifting or prolonged operations. Over time, this can result in more maintenance and repairs, leading to higher costs.

In summary, the voltage setting of your electric EOT crane directly affects its energy efficiency, performance, and long-term operational costs. By choosing the optimal voltage configuration, you can achieve better energy savings, enhanced performance, and lower operational costs over time.

Long-Term Maintenance Costs

Voltage-Related Wear and Tear

Choosing the wrong voltage configuration for your electric travelling EOT crane can lead to increased wear and tear on the system. If the voltage is too low, the crane will need more current to handle heavier loads, putting extra strain on the motor and electrical components. This can cause overheating, quicker component degradation, and more frequent breakdowns.

On the flip side, using too high of a voltage can lead to overvoltage, which can damage the crane's motors, controllers, and other electrical parts. Mismatched voltage results in more frequent repairs, longer downtime, and higher maintenance costs.

System Longevity

The longevity of your electric travelling EOT crane is directly affected by its voltage configuration. Cranes running on the correct voltage will experience less stress, which means they'll last longer and require fewer repairs.

- Higher voltage cranes (e.g., 380V, 460V) are designed to handle heavy-duty operations and provide more consistent power. This results in a longer lifespan for components like the hoist, motor, and electrical systems.

- Lower voltage cranes (e.g., 110V, 220V) might be under more strain, causing faster wear and a shorter overall lifespan. This could lead to frequent repairs, replacements, and a higher total cost of ownership over time.

Choosing the right voltage ensures that your electric travelling EOT crane works reliably for many years, lowering your long-term maintenance costs.

The Importance of Choosing the Right Voltage for Consistent Operation

The key to reducing maintenance costs and ensuring the consistent operation of your electric travelling EOT crane is selecting the correct voltage. Cranes that run on the proper voltage experience fewer breakdowns, reduce the likelihood of component failure, and generally require less maintenance. If the voltage is mismatched, your crane may experience instability, overheating, and unnecessary wear, leading to higher costs over time.

Future Expansion and Flexibility

Considerations for Future Upgrades

When selecting a voltage configuration for your electric travelling EOT crane , it's crucial to consider future upgrades. As your operations expand, you may need to scale up the crane's capacity or upgrade to advanced lifting systems.

- Higher voltage systems (e.g., 380V, 460V) are typically more flexible and can support future upgrades, such as the addition of more hoists, advanced controls, or automation.

- Lower voltage systems (e.g., 110V, 220V) might not have the power capacity to handle such upgrades, which could limit your ability to expand your crane system as your needs grow.

Planning for future growth helps you avoid the costs and delays of needing a full replacement or a system retrofit when you want to scale up.

Adaptability of Power Systems

The right voltage configuration also determines how adaptable your electric travelling EOT crane is for future needs. As technology advances, your crane may need to incorporate new features like smart controls, automation, or energy-efficient systems.

- Three-phase systems (e.g., 380V, 460V) are usually more adaptable and can support advanced technology and future upgrades. They're better suited for more powerful motors and new systems, without needing major changes to your power infrastructure.

- Single-phase systems (e.g., 110V, 220V) may not support these future upgrades as well, especially for larger-scale operations. If you need to add more equipment or scale up, you might face additional costs and system overhauls.

By choosing the right voltage now, you ensure your crane system is ready for future growth and technological advancements, keeping your operations running smoothly and efficiently.

In summary, selecting the correct voltage configuration for your electric travelling EOT crane is critical not just for today's operations, but also for long-term reliability and future flexibility. By making the right choice, you'll reduce maintenance costs, ensure consistent performance, and set your system up for smooth expansion as your needs evolve.

Making the Right Voltage Choice for Your Crane Budget

Factors to Consider

When deciding on the right voltage configuration for your electric travelling EOT crane , there are several key factors to keep in mind that directly affect your crane budget and long-term efficiency:

- Facility's Existing Power Supply: Check what power system your facility currently uses. If your facility is already set up with a three-phase supply (e.g., 380V or 460V), it might make sense to choose a crane that operates on the same configuration for seamless integration. If your facility has a single-phase supply (e.g., 110V or 220V), you'll need to weigh the cost of upgrading your infrastructure against the benefits of choosing a higher voltage crane.

- Load Capacity Requirements: The larger and heavier the loads you need to lift, the more powerful the crane will need to be. If you're working with heavy-duty tasks, you'll likely require a higher voltage configuration (380V, 460V) for better efficiency and performance. For lighter tasks, a lower voltage crane (e.g., 110V or 220V) might suffice and be more cost-effective.

- Operational Environment: Consider the environmental conditions where your crane will operate. If you're working in extreme temperatures, hazardous locations, or need an explosion-proof crane, these factors may affect your choice of voltage. In harsh environments, a higher voltage crane is often more efficient and better suited for reliability and performance under tough conditions.

How to Balance Cost with Performance

Choosing the right voltage configuration for your crane isn't just about saving money upfront; it's about striking the right balance between cost and performance. Here are a few tips:

- If your facility has existing three-phase power and you need to handle heavy or frequent lifting, investing in a higher voltage crane like 380V or 460V could provide better energy efficiency in the long run, reducing operational costs.

- For lighter tasks or if you're working with a smaller budget, a lower voltage crane (110V or 220V) may meet your needs while reducing the initial investment. However, keep in mind that these might be less energy-efficient for heavy-duty operations.

- Also, consider the energy efficiency of each configuration. Although higher voltage cranes have a higher initial cost, they tend to have lower long-term energy costs. The more energy-efficient option could be the better investment when looking at the bigger picture.

Consulting with Experts

Making the right voltage choice for your electric travelling EOT crane can be complex, and it's important to seek expert advice. Here's why:

- Electrical Engineers: These professionals can assess your facility's power system and help you determine what voltage configuration is compatible with your existing infrastructure. They can also evaluate future growth needs, ensuring you choose a system that's scalable.

- Crane Manufacturers: When consulting with crane manufacturers, they can guide you in selecting the best crane based on your specific needs—whether it's for light-duty or heavy-duty operations—and can provide insight into the operational benefits and costs of different voltage configurations.

By involving experts in the decision-making process, you'll be able to make a more informed choice, ensuring that you select a crane with the right voltage configuration that balances cost, performance, and future scalability.

In conclusion, making the right voltage choice for your electric travelling EOT crane involves considering your facility's existing power supply, load capacity, and environmental conditions. Balancing cost with performance is key to optimizing both your budget and crane efficiency. And remember, consulting with electrical engineers or crane manufacturers will help you make the best decision for your specific operational needs.

Conclusion

The voltage and power supply choices for your electric travelling EOT crane can significantly impact both your crane costs and operational efficiency. Here's a quick recap of the key points:

- Higher voltage configurations (e.g., 380V, 460V) are ideal for heavy-duty operations, offering greater energy efficiency, longer system lifespan, and better performance for large or frequent lifting tasks. However, they come with higher initial costs.

- Lower voltage cranes (e.g., 110V, 220V) may work for lighter tasks but are less efficient and can lead to higher energy consumption over time. They also tend to wear out faster under heavy loads.

- Proper voltage selection can help reduce maintenance costs, ensure reliable operation, and prevent premature wear and tear. Inappropriate voltage can lead to frequent breakdowns, higher repairs, and more downtime.

Choosing the right voltage configuration for your crane isn't just about balancing upfront costs—it's about strategic planning to avoid future budget overruns and ensure optimal crane performance. When making your decision:

- Consider your facility's power supply, load requirements, and operational environment.

- Weigh the benefits of long-term energy savings with initial costs.

- Consult with electrical engineers or eot crane manufacturers to ensure the voltage configuration matches your needs and supports future upgrades.

Taking the time to select the best voltage setup will save you from costly mistakes and ensure your electric overhead travelling crane operates at its best, both now and in the future.