Small Jib Crane & Mini Overhead Cranes for Jewelry & Electronics

Small Jib and Mini Overhead Cranes (0.2–2 t) for Jewelry and Electronics Laser Work: Buyer Insights

Why Buyers Choose 0.2–2 t Cranes for Precision Laser Micro-Welding

Key Takeaways (at the very beginning)

- Cranes in this range (0.2–2 t) are essential for delicate laser work, where precision is critical.

- They reduce operator fatigue, protect sensitive components, and improve production speed.

- Selecting the right type, features, and capacity ensures accuracy, safety, and long-term ROI.

Why Small Cranes Are Vital for Jewelry & Micro Electronics

In jewelry repair or micro-electronics laser work, precision is non-negotiable. Even the tiniest misalignment can ruin a weld or damage a delicate component. That's where small jib cranes and mini overhead cranes (0.2–2 t) come in—they're not just lifting devices, they're essential tools for accuracy, safety, and efficiency.

Working Safely in Tight Spaces with Fragile Items

These cranes are particularly important because operators often work in tight spaces with fragile items—think gemstones, thin metal sheets, or micro-circuit boards. Manual lifting here is risky, slow, and tiring. A small crane handles the heavy lifting, rotation, and positioning with micrometer-level control, so operators can focus on the laser work without risking mistakes.

Protect Delicate Parts

Small cranes smoothly lift trays, gemstones, and micro-components, preventing drops, bending, or accidental damage. Jewelry pieces and micro-electronics are extremely sensitive, and even a small impact can be costly. Using the right crane significantly reduces handling risks.

Ensure Precise Alignment for Laser Work

Fine positioning and smooth rotation keep parts perfectly aligned with laser heads or welding tips. This level of control reduces rework, supports consistent weld quality, and ensures high-precision results in jewelry repair and micro-electronics applications.

Reduce Operator Fatigue & Improve Workflow

By minimizing manual handling of tiny, sensitive components, small cranes reduce operator fatigue and errors. This allows technicians to focus fully on laser welding or assembly, streamlining workflow and protecting both the parts and the operator.

Buyer Tip: What to Look for in a Small Crane

When selecting a small crane, prioritize a compact footprint for tight workstations, an electric hoist with smooth control, rotation or tilt capability for precise positioning, and integrated safety features such as overload protection and an emergency stop. These features are critical for jewelry labs, micro-electronics assembly, and 3C electronics laser stations.

Typical Crane Types and Capacities for Jewelry & Micro Electronics (0.2–2 t)

When handling tiny components and delicate trays in jewelry repair or micro-electronics laser work, the right crane type makes all the difference. Small cranes in the 0.2–2 t range provide precision, safety, and ergonomic support. Let’s look at the two most common options:

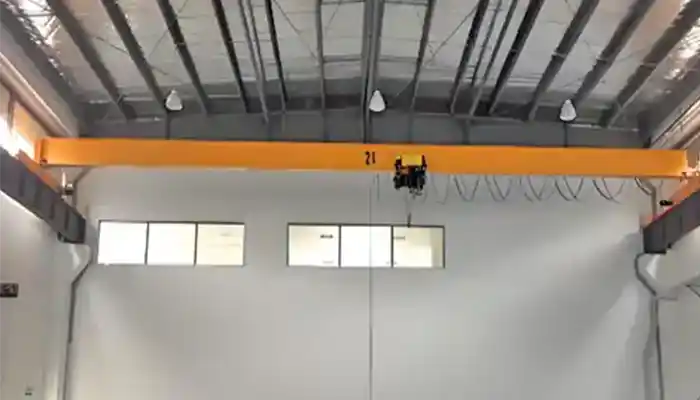

Mini Overhead Cranes (0.2–2 t)

Where They Work Best:

- Micro-laser benches, electronics assembly stations, and jewelry worktables.

Why Buyers Choose Them: Mini overhead cranes allow operators to lift and position tiny parts without strain. Their compact design fits small labs, and smooth hoist control ensures micrometer-level accuracy.

Key Features:

- Electric hoist for precise and smooth lifting.

- Fine positioning to align trays or micro-components exactly.

- Compact span that fits tight workstations.

- Rotation arm for adjusting part orientation.

Practical Benefits:

- Handles delicate parts safely, reducing risk of damage.

- Minimizes operator fatigue during repetitive lifting tasks.

- Provides repeatable accuracy for laser welding or micro-assembly.

Tip for Buyers: Perfect for facilities where precision and small workspace are priorities.

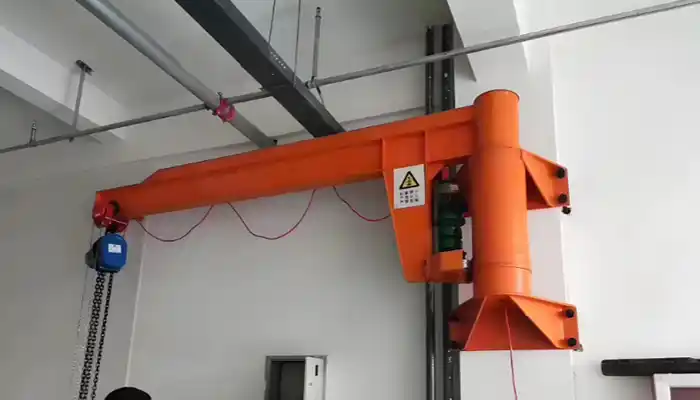

Jib Cranes (0.2–2 t)

Where They Work Best:

- Localized workstations or small assembly tables where movement needs to be flexible. Jib crane options: 2 ton wall mounted jib cranes and 2 ton floor mounted jib cranes

Why Buyers Choose Them: Jib cranes give easy access to parts and trays, with the ability to rotate and extend reach. They’re ideal for frequent micro-laser tasks or workstation rotation.

Key Features:

- Rotation arm for flexible positioning.

- Adjustable reach to cover multiple stations.

- Compact footprint to maximize workspace efficiency.

Practical Benefits:

- Smooth and controlled lifting of delicate items.

- Reduces operator strain and repetitive motion fatigue.

- Flexible placement allows multiple workstations to share a single crane efficiently.

Tip for Buyers: Consider jib cranes when parts need to move frequently or rotate, such as trays with gemstones or electronic components.

Selecting the Right Capacity for Jewelry & Micro Electronics Cranes (0.2–2 t)

Choosing the right crane capacity is more than picking a number—it’s about ensuring safety, precision, and smooth workflow. In jewelry and micro-electronics laser work, every tray, gemstone, or tiny electronic component adds weight, and lifting attachments like clamps or vacuum lifters add a little more.

A practical approach is to calculate the total load:

Total Load = Tray + Component + Lifting Attachments + Safety Margin (20–30%)

For most jewelry or micro-electronics laser applications, the typical crane range is 0.2–2 t. This is usually enough to handle trays, shielding, and other small laser accessories safely.

Practical Tip for Buyers:

- Always round up rather than underestimating capacity. Overloading even slightly can damage delicate components or stress the crane.

- Consider future expansion—if your trays or assemblies get slightly larger, a bit of extra capacity now can save headaches later.

- Don’t forget attachments and work-in-progress trays; they add weight and need to be included in your calculation.

Key Features Buyers Should Consider for Small Cranes

Even with the right capacity, a crane won’t deliver optimal results unless it has the features needed for micro-laser precision and safety. For 0.2–2 t cranes, these features make a big difference:

- Precision & Positioning: Crucial for micro-laser welding, jewelry repair, and electronics assembly where micrometer-level accuracy matters.

- Rotation / Tilt Attachments: Allows angled assembly or working with irregular parts without manually repositioning trays.

- Compact Footprint: Fits tight workstations and lab benches without interfering with operators or other equipment.

- Safety Features: Emergency stop, overload protection, and interlocks ensure operator and component safety.

- Attachment Support: Compatibility with clamps, vacuum lifters, or custom trays protects delicate parts and simplifies repetitive handling.

Practical Insight for Buyers: Look for cranes that combine fine positioning with ergonomic operation. In small labs, these features save time, reduce errors, and prevent material damage.

Typical Locations for Small Cranes in Jewelry & Micro Electronics Facilities

Where you place your crane is just as important as the crane itself. In jewelry repair labs or micro-electronics workshops, space is often tight, and precision is critical. A well-placed mini overhead or jib crane ensures that trays, laser heads, and components move smoothly without disrupting workflow or risking damage.

Small cranes are usually installed in areas where repetitive, precise movement is needed, or where operators handle multiple trays or delicate components in succession. Proper placement not only improves efficiency but also reduces the risk of mistakes and operator fatigue.

Common Locations for 0.2–2 t Cranes

- Workstation Benches for Laser Micro-Welding: Cranes at individual benches lift and position tiny trays, jewelry pieces, or micro-electronics parts directly in front of the laser, allowing operators to focus on precision work.

- Small Assembly Lines or Shared Micro-Laser Stations: In labs where multiple operators work side by side, a small crane can serve several stations, moving components safely between benches or along a short production line.

- Areas Requiring Repetitive Movement of Precision Trays or Laser Heads: Anywhere trays or components must be repeatedly positioned under a laser, a mini overhead or jib crane saves time, prevents errors, and protects delicate parts.

Practical Tip for Buyers:

- Look for adjustable reach and rotation so a single crane can serve multiple stations.

- Ensure the footprint is compact to avoid interfering with other equipment.

- Consider safety features such as emergency stops and interlocks in locations with high operator traffic.

Benefits of Using 0.2–2 t Cranes in Micro-Laser Operations

Small cranes in jewelry and micro-electronics facilities aren’t just tools—they’re key to smooth, safe, and efficient laser operations. Even though they handle tiny loads, the impact on workflow, product quality, and operator safety is significant. Choosing the right crane ensures your team can focus on precision laser work instead of worrying about lifting, moving, or aligning delicate components.

Practical Benefits for Buyers

- Safety: Protects operators from repetitive strain and reduces the risk of accidents. At the same time, delicate parts—like jewelry pieces, micro-circuits, or thin sheets—are safely handled without drops, bends, or scratches.

- Precision: Fine positioning and rotation capabilities ensure trays, components, or laser heads are aligned exactly where they need to be. This is crucial for micro-laser welding, jewelry repairs, or electronics assembly where even slight misalignment can ruin a part.

- Efficiency: By reducing manual handling and repetitive lifting, small cranes speed up workflow and allow operators to focus on the laser process. Multiple trays or workpieces can be moved smoothly across workstations, increasing throughput.

- Return on Investment (ROI): Minimizes mistakes, material damage, and downtime. Every time a delicate part is handled correctly the first time, you save time, labor, and replacement costs, making these cranes an essential investment for any high-precision laser operation.

Practical Tip for Buyers:

- Even for tiny loads, don’t skip on safety and positioning features—they directly affect productivity and component integrity.

- Look for compact, ergonomic designs to fit crowded workstations without limiting movement.

Buyer Insights: Why 0.2–2 t Cranes Are Popular for Jewelry & Micro Electronics

Small cranes in the 0.2–2 t range have become a go-to solution for jewelry repair labs and micro-electronics workshops, and it’s easy to see why. These cranes strike a balance between precision, safety, and practicality, making them ideal for delicate laser operations without taking up too much space or budget.

For buyers, the appeal is not just the crane itself—it’s how well it fits into existing workflows, protects parts, and supports operators. Understanding why this range is popular helps guide purchasing decisions for labs or small production lines.

Key Buyer Insights

- Flexible Installation: Small cranes can be easily installed in tight workstations, compact labs, or shared assembly areas, giving operators smooth access to trays, laser heads, or micro-components.

- Cost-Effective: They provide all the necessary features for precision work without overinvesting in oversized equipment. Buyers get functionality without unnecessary expenses.

- Scalable for Multiple Workstations: A single crane or multiple units can serve several small workstations, making it easier to expand operations while keeping a minimal footprint.

- Customizable for Specific Applications: Attachments such as clamps, vacuum lifters, rotation arms, and fine positioning options can be tailored to the lab’s exact workflow needs, protecting delicate parts and improving operator efficiency.

Practical Tip for Buyers:

- Consider your workspace layout, number of workstations, and types of components when choosing attachments and rotation options.

- Small cranes are most effective when integrated thoughtfully into existing laser benches and micro-assembly lines, not just placed anywhere.

FAQ for Buyers: 0.2–2 t Cranes for Jewelry & Micro Electronics Laser Work

When selecting a small crane for jewelry repair or micro-electronics laser operations, buyers often face similar challenges. This practical FAQ addresses the most common questions to help you make confident, technically sound decisions.

Which crane type is best for micro-laser work?

For micro-laser stations, mini overhead cranes or small jib cranes (0.2–2 t) are the preferred options. Mini overhead cranes excel at precise lifting over individual benches, while jib cranes offer flexible rotation and reach for localized tasks. Both options protect delicate parts and significantly reduce operator fatigue.

How do I calculate the total load for delicate trays and components?

The total lifting load should always include tray weight + component weight + lifting attachments + a 20–30% safety margin. Even though jewelry pieces and micro-electronic components are light, accounting for all accessories ensures safe operation without overstressing the crane or risking damage to sensitive parts.

What crane features ensure laser welding accuracy?

To maintain laser welding precision, look for cranes equipped with fine positioning for micrometer-level alignment, rotation or tilt attachments for angled assemblies, smooth electric hoist control for stable lifting, and a compact footprint that avoids interference with the laser workspace. These features reduce rework and protect delicate components.

How can cranes improve workflow in small lab or production spaces?

Small cranes minimize manual handling and repetitive lifting. This frees operators to focus on laser operations, allows safe movement of trays between workstations, increases throughput, reduces handling errors, and enables multiple workstations to share a single crane through rotation or adjustable reach.

Practical Tip for Buyers

Even in compact labs, never compromise on safety or positioning accuracy. A properly selected 0.2–2 t crane improves productivity, reduces material loss, and protects both operators and high-value jewelry or micro-electronic components.

Conclusion: Why 0.2–2 t Cranes Are a Smart Choice for Micro-Laser Work

When it comes to jewelry repair or micro-electronics laser operations, small doesn’t mean insignificant. Mini overhead and jib cranes in the 0.2–2 t range play a vital role in keeping workpieces safe, operators comfortable, and workflows smooth.

These cranes do more than lift—they position trays, rotate components, and integrate with delicate laser operations without taking up extra space or complicating the workstation. Choosing the right crane can make the difference between a smooth, efficient process and costly mistakes.

Why Buyers Should Care

- Safety First: Protects delicate trays, gemstones, and micro-components from drops or bending.

- Precision Matters: Fine positioning and rotation ensure each piece aligns perfectly under the laser.

- Workflow Efficiency: Reduces manual handling, allowing operators to focus on tasks that require skill.

- Long-Term Value: Minimizes rework, prevents material loss, and supports consistent output across multiple workstations.

Bottom Line for Buyers

Investing in a well-chosen 0.2–2 t crane is more than just purchasing equipment—it’s a practical, long-term decision. It safeguards high-value materials, improves efficiency, and ensures your lab or micro-electronics facility can scale safely and effectively as production needs grow.