3 to 20 Tons Variable Speed EOT Cranes for CNC Metalworking Lines

Introduction

CNC metalworking production lines are busy places. You’ll find high-speed drilling machines working on thick steel plates, precision milling on flanges, and automated punching and marking on angle steels. Whether it’s tube sheets or structural components, everything moves fast—and everything is heavy. These aren’t small tools on a bench; they’re large, industrial-grade machines that deal with bulky parts all day long.

In this environment, overhead and bridge cranes aren’t just helpful—they’re essential. And not just any crane will do. Variable speed overhead cranes are especially well-suited for this type of work. Why? Because parts don’t just need to be lifted—they need to be moved smoothly, accurately, and safely.

When a crane moves too fast or too suddenly, you risk more than just damaging the material. You slow down the line, create bottlenecks, or worse, put workers at risk. That’s where variable speed control comes in. It gives you just the right amount of control to place a 2-ton steel plate exactly where it needs to go—without overshooting, without jerking, and without delay.

Here’s what variable speed overhead and bridge cranes bring to CNC production lines:

- Precise Positioning: Whether you’re placing a tube sheet into a milling machine or aligning a steel plate for drilling, variable speed cranes allow slow, inch-by-inch movement at the critical moment.

- Controlled Acceleration and Deceleration: Smooth starts and stops reduce swinging and wear on components, which also protects the CNC machines themselves from sudden impacts or misalignment.

- Safer Lifting Operations: Cranes with variable speed control allow operators to adjust lifting and traveling speeds based on the load type and working environment.

- Better Workflow in Tight Spaces: Many CNC setups operate in tight layouts. Variable speed cranes help navigate these spaces with fine movement control.

As CNC production lines continue to get faster and more automated, material handling has to keep up—without causing accidents or quality issues. That’s why more and more factories are switching to variable speed cranes. It's not just about lifting—it’s about lifting right.

Overview of CNC Metalworking Production Lines and the Role of Overhead Cranes in Material Handling

CNC metalworking production lines are designed for high output and repeatable precision. They consist of multiple machines working together across large factory floors, where heavy steel materials must move continuously, safely, and accurately between processing stages.

Why Material Handling Is Critical in CNC Lines

Steel components used in CNC production often weigh from hundreds of kilograms to several tons and are frequently long, wide, or irregular in shape. Overhead cranes—especially variable speed bridge cranes—are essential to move these materials accurately without damaging parts or machines.

High-Speed CNC Drilling and Milling Machines

These machines process steel plates, flanges, and tube sheets for pressure vessels, heat exchangers, and industrial structures. Plates are often 6–12 meters long and weigh 2 to 15 tons per piece.

Material Handling Needs:

- Precise lifting from storage racks to machine tables

- Careful removal and stacking after machining

- Protection of surface quality from impacts or scratches

Typical Crane Type & Capacity:

- Double girder overhead cranes with 10–20 ton capacity

- Equipped with magnetic lifters or clamps

- Variable speed control to prevent impact during placement

CNC Drilling and Marking Lines for Angles

Angle steels used in these lines are typically 6–12 meters long and are drilled and marked for transmission towers and steel structures.

Material Handling Needs:

- Straight, consistent feeding into machines

- Fast transfer of processed angles to unloading or sorting areas

Typical Crane Type & Capacity:

- Single girder or underslung cranes with 2–5 ton capacity

- Often combined with manual or powered spreader beams

- Smooth lifting to prevent bending or twisting

CNC Plate Punching, Drilling, and Marking Machines

These machines handle medium to large steel plates commonly used in bridge, construction, and machinery fabrication.

Material Handling Needs:

- Placing raw plates onto infeed rollers accurately

- Efficient offloading to maintain production speed

- Careful handling of sharp-edged parts

Typical Crane Type & Capacity:

- Double girder cranes with 5–15 ton capacity

- Lifting magnets, vacuum lifters, or custom grabs

- Variable speed drives for precise alignment

CNC Punching, Marking & Shearing Lines for Angles

These high-speed lines are used in tower fabrication and structural steel industries for punching, marking, and cutting angle steel.

Material Handling Needs:

- Fast handling of repeat batches

- Continuous feeding to avoid line stoppages

- Efficient sorting and stacking of finished parts

Typical Crane Type & Capacity:

- Overhead cranes with 3–10 ton capacity

- Multi-hook spreader bars or mechanical grabs

- Precise speed control for safe, fast operation

Why Variable Speed Overhead Cranes Are Essential

Handling heavy steel parts is not just about lifting—it's about accuracy, protection, and efficiency. Variable speed overhead cranes provide the control needed to keep CNC production lines running smoothly.

Practical Benefits:

- Smooth start and stop to prevent damage

- Load control to minimize sway

- Increased throughput between processes

- Improved operator safety in fast-paced environments

Crane Choices by Workshop Type:

- Small-to-medium halls: Single girder cranes (1–10 tons)

- Large factories: Double girder cranes (10–50 tons) with advanced controls

Types of Variable Speed Overhead & Bridge Cranes Used in CNC Production Lines

In CNC metalworking factories, materials like steel plates, angle bars, flanges, and tube sheets need to be moved safely, quickly, and accurately between machines. That's where variable speed overhead cranes come in—they're used in almost every stage of the production line. The type of crane you choose depends on the size of your workshop, the layout, and what kind of loads you're lifting every day.

Overview of Crane Types in CNC Production

Let's look at the most common types of variable speed overhead and bridge cranes and how they're used in real CNC production environments.

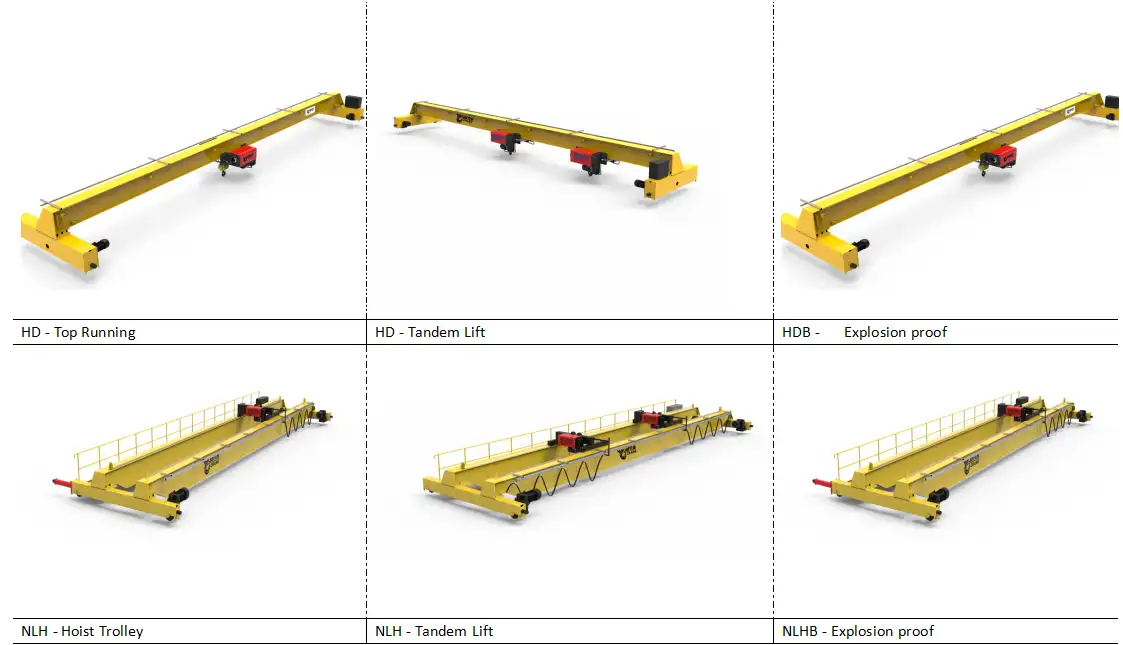

Single Girder Overhead Cranes (Variable Speed)

Crane Type: European style single girder overhead crane

Typical Capacity: 1 to 10 tons

Span: Up to 25 meters

Used In: Small-to-medium CNC fabrication workshops

Where Single Girder Cranes Are Used

- Loading and unloading steel plates into CNC drilling or punching machines

- Moving angle steel to marking or shearing lines

- Handling smaller flanges, flat bars, or bundled parts

Why Single Girder Cranes Work Well

- Good for lighter lifting tasks with less structural load on the building

- Works well in spaces with limited ceiling height

- Variable speed control gives better control when aligning parts into machines

- Easy to install and maintain for daily operations

Double Girder Bridge Cranes (Variable Speed)

Crane Type: European style double girder overhead crane top running crane design

Typical Capacity: 10 to 50 tons (up to 100 tons for heavy-duty use)

Span: 10 to 35+ meters

Used In: Large CNC steel processing and fabrication plants

Where Double Girder Cranes Are Used

- Lifting heavy steel plates (10–20 tons each) into high-speed drilling machines

- Transferring tube sheets and pressure vessel parts across stations

- Handling structural steel beams and large flanges after welding or drilling

Why Double Girder Cranes Work Well

- Can lift heavier and longer loads across wider spans

- Hoist sits between girders, allowing higher lifting height

- Stable movement across production lines, even with large, uneven loads

- Commonly used in multi-shift, high-output production lines

Top Running vs. Under Running Cranes

Top Running Cranes: Typical Capacity: 5 to 100 tons

- Rails sit on top of runway beams

- Great for heavy loads and high lifting heights

- Ideal for facilities with enough vertical space

- Suitable for mounting multiple cranes on the same runway

Under Running Cranes: Typical Capacity: 1 to 5 tons

- Runway beams hang from the ceiling

- Work well in low headroom or limited space

- Often used for light parts, tools, or compact CNC machines

Special Lifting Setups for CNC Production

- Magnetic Lifters: For lifting large steel plates without hooks or slings

- Vacuum Lifters: For delicate or finished plates with clean surfaces

- Spreader Beams: For lifting long parts evenly

- Double Hoists: For wide or flexible parts needing two lifting points

Practical Summary Table

| Crane Type | Typical Capacity | Common Use in CNC Production |

|---|---|---|

| Single Girder Crane | 1–10 tons | Loading small plates, flanges, angles |

| Double Girder Crane | 10–50 tons | Handling heavy plates, tube sheets |

| Top Running Crane | 5–100 tons | Large factories, high lifting needs |

| Under Running Crane | 1–5 tons | Compact shops, low ceilings |

Final Notes on Variable Speed Cranes

Variable speed overhead cranes make a big difference in production. They help move heavy loads without jerking, position parts precisely, and keep the CNC production line running efficiently without delays or accidents.

Key Features of Variable Speed Overhead & Bridge Cranes – And Why They Matter

In CNC production lines, steel parts need to move fast—but they also need to move carefully. Whether you're handling heavy plates, long angle steel, or tube sheets, it's not just about lifting—it's about lifting right. Variable speed cranes give operators more control, which makes the whole production line safer, smoother, and more efficient.

Why Variable Speed Features Matter in CNC Lines

Variable speed cranes are designed for precision handling. They allow operators to control movement smoothly, reduce risk, and keep CNC production lines running efficiently without unnecessary downtime.

Variable Speed Control (Stepless)

What it does:

- Lets you adjust the lifting and traveling speed based on the job.

- Move slow for delicate positioning, fast when traveling long distances.

Why Stepless Speed Control Is Needed

- CNC machines require precise part placement.

- Reduces shock and swing when handling heavy or long parts.

- Improves safety for both workers and machines.

Accurate Load Positioning

What it does:

- Helps stop the hook exactly where needed without overshooting.

- Allows slow, steady lowering of steel parts.

Why Accurate Positioning Is Critical

- Essential for loading raw plates into CNC machines.

- Prevents misalignment that could damage parts or equipment.

- Reduces time spent on manual repositioning.

Flexible Control Options

Types:

- Pendant control: Wired and simple for daily use.

- Remote control: Wireless operation while moving with the load.

- Cabin control: Suitable for large cranes and long travel distances.

Why Flexible Controls Improve Safety

- Provides better visibility during part placement.

- Allows operators to stay away from hazardous areas.

- Improves comfort and efficiency in large workshops.

Essential Safety Features

Built-in protections include:

- Overload limiters

- Emergency stop buttons

- Travel limit switches

- Optional anti-sway systems

Why Safety Systems Are Essential

- Protects workers and equipment from accidents.

- Prevents overloading and end-of-runway collisions.

- Anti-sway systems reduce dangerous load movement.

Energy-Efficient Motors and Regenerative Braking

What it does:

- Consumes less electricity during operation.

- Recovers energy during braking and deceleration.

Why Energy Efficiency Matters

- Lowers operating costs for all-day production lines.

- Reduces heat and wear on motors and brakes.

- Extends crane service life with less maintenance.

Final Summary

Variable speed cranes help CNC production lines run smoother, safer, and faster. They allow precise handling of heavy materials, reduce load swing, and prevent rough stops. In CNC environments where timing and accuracy matter, these features are not optional—they are essential.

Capacity and Specification Considerations

When selecting an overhead crane for CNC metalworking production lines, it's important to match the crane's capacity and specifications to the parts being handled and the workshop's layout. Below is a practical breakdown of the key factors to consider.

Small Components and Light Plates

Capacity Range: 1 to 5 tons

Used for handling smaller steel plates, thin flanges, and light components that require frequent movement but do not involve heavy lifting.

Medium Plates, Angles, and Flanges

Capacity Range: 5 to 20 tons

Suitable for medium-weight plates, structural angles, and heavier flanges commonly used in CNC drilling, punching, and milling production lines.

Heavy Beams and Large Structural Components

Capacity Range: 20 to 50+ tons

Designed for handling thick steel beams, large tube sheets, and heavy structural steel components typically found in large CNC fabrication workshops.

Span Length Considerations

Span Length: Commonly ranges from 10 meters up to 40 meters or more, depending on workshop layout.

Longer spans allow coverage of wider production areas but require stronger girders and supporting structures.

Lifting Height Requirements

Lifting height is determined by CNC machine height and workflow needs. Proper clearance ensures safe loading and unloading without interfering with surrounding equipment or structures.

Duty Classifications

- Cranes are classified (such as A5 or A6) based on operating frequency and load intensity.

- CNC production environments with frequent and heavy lifting should use cranes rated for A5 or A6 duty classes.

- Higher duty ratings ensure long-term durability, reliability, and operational safety.

Customization Needs

- Cranes can be customized to handle different shapes and uneven loads, such as angle steel or asymmetrical flanges.

- Special lifting attachments, magnets, or spreader beams can be added to distribute weight evenly.

- Customization improves handling efficiency and reduces the risk of load instability.

Final Recommendation

Choosing the right capacity, span, and specifications ensures the overhead crane matches the exact demands of your CNC metalworking production line. This results in safer material handling, smoother workflows, and longer equipment service life.

Benefits of Variable Speed Overhead & Bridge Cranes for CNC Production Lines

Variable speed cranes offer many practical advantages for CNC metalworking workshops:

- Streamlined Material Flow: Reduces manual lifting, lessens operator fatigue, and speeds up movement of parts between machines.

- Improved Product Quality: Provides gentle and precise load handling, preventing damage to steel plates, flanges, and other parts.

- Greater Flexibility: Easily moves parts of various sizes and weights across multiple stations and machines.

- Longer Equipment Lifespan: Smooth starts and stops reduce mechanical shock and protect motors and brakes, cutting down maintenance needs.

- Enhanced Workplace Safety: Safety features like overload protection and emergency stops lower accident risks and keep operators confident.

- Energy Efficiency: Efficient motor control and regenerative braking save electricity and reduce operational costs.

Practical Applications and Case Examples

Variable speed cranes are used in many CNC production scenarios:

- Loading High-Speed CNC Machines: Safely lifting steel plates, flanges, and tube sheets into drilling and milling machines with accurate positioning.

- Transporting Structural Angles: Moving angles smoothly between punching, marking, and shearing stations to keep production flowing.

- Handling Heavy, Bulky Parts: Managing large components in automated CNC lines with minimal load swing for safer operations.

Real-Life Case Studies

Some factories reduced downtime by up to 20% after installing variable speed cranes.

- Improved throughput and product quality have led to better overall efficiency.

- Operators report easier and safer handling with less fatigue.

Selecting the Right Variable Speed Crane for Your CNC Production Line

When choosing a variable speed crane, consider these key factors:

- Load Weights and Frequency: Understand the typical weights of your parts and how often you need to lift them.

- Handling Complexity: Consider if your loads are simple or if they have unusual shapes or require special attachments.

Crane Type

- Single Girder Cranes: Best for lighter loads and smaller workshop spans.

- Double Girder Cranes: Ideal for heavy, bulky parts and longer spans.

- Control Systems and Safety: Choose crane controls (pendant, remote, or cabin) that suit your operators and safety needs.

- Future Growth and Automation: Plan for scalability. Select cranes that can integrate with automation or smart factory systems to keep up with evolving production demands.

Variable speed overhead and bridge cranes are essential tools for modern CNC metalworking production lines. Investing in the right crane solution not only boosts productivity but also improves safety and maintains high product quality.

Ready to improve your CNC production with a variable speed crane? Contact us today for expert consultation, customized crane solutions, and free quotations.