Types of Cranes for Sale Turkmenistan | Industrial Crane & Hoist

Overview of types of overhead cranes, gantry cranes, jib cranes for sale at good price. Get crane design for your workshop, warehouse & facility at cost-effective price.

Category: Turkmenistan

Your Trusted Overhead Crane Manufacturer & Supplier

Comprehensive Guide to Cranes for Sale in Turkmenistan

All Types of Overhead Industrial crane and Hoist Design for Your Workshop, Warehouse & Facility at Cost-effective Price

Overview of types of overhead cranes, gantry cranes, jib cranes for sale at good price. Get crane design for your workshop, warehouse & facility at cost-effective price.

Turkmenistan boasts a diverse industrial landscape, encompassing key sectors vital for its economic development. From gas processing plants to petrochemical refineries, power plants, construction yards, metalworking workshops, warehouses, automotive manufacturing, textile production, shipbuilding, and mining workshops, the industrial spectrum is vast and dynamic. In this thriving environment, the efficient handling of materials becomes paramount for seamless operations and increased productivity.

Overhead Cranes for Sale in Turkmenistan

Overhead cranes are versatile lifting systems that play a pivotal role in various industrial applications across Turkmenistan. Understanding the types, designs, and capacities of these cranes is crucial for businesses looking to optimize their material handling processes.

- Crane Design & Capacities: Single girder design, ideal for lighter loads and cost-effectiveness, with capacities typically up to 20 tons.

- Tailored Features for Operation in Turkmenistan: Adjustable spans, various lifting capacities, and customization for specific industry requirements.

- Applicable Industries: Small to medium-scale manufacturing, workshops, warehouses, and assembly lines.

- Industrial Locations in Turkmenistan: Industrial zones in cities like Ashgabat, Turkmenabat, Dashoguz, and Mary.

- Typical Crane Project Locations: Factories, workshops, and manufacturing units within industrial areas.

- Crane Design & Capacities: Two girder design offering higher lifting capacities, often ranging from 5 to 500 tons.

- Tailored Features for Operation in Turkmenistan: Increased lifting heights, larger spans, and customization based on specific industry needs.

- Applicable Industries: Heavy manufacturing, steel mills, power plants, and large-scale industrial operations.

- Industrial Locations in Turkmenistan: Major industrial centers across the country including Turkmenbashi and Balkanabat.

- Typical Crane Project Locations: Large manufacturing facilities, industrial complexes, and infrastructure projects.

Freestanding Monorail Overhead Cranes

- Crane Design & Capacities: Operate along a single beam or rail, suitable for linear material handling within specific paths with capacities up to 15 tons.

- Tailored Features for Operation in Turkmenistan: Customizable lengths, load capacities, and adaptability for linear material movement.

- Applicable Industries: Assembly lines, painting booths, and industries requiring linear material transfer.

- Industrial Locations in Turkmenistan: Manufacturing plants in cities like Turkmenabat and Balkanabat.

- Typical Crane Project Locations: Production lines, workshops, and specialized manufacturing processes.

Specialized Overhead Crane Types

Explosion-Proof Overhead Cranes:

- Tailored Features for Operation in Turkmenistan: Designed for hazardous environments in chemical plants or refineries, ensuring safety.

- Applicable Industries: Chemical plants, oil refineries, and gas processing facilities.

- Industrial Locations in Turkmenistan: Lebap and Ahal regions known for chemical industries.

- Tailored Features for Operation in Turkmenistan: Equipped with magnets for handling ferrous materials efficiently.

- Applicable Industries: Metalworking industries, recycling plants, and scrapyards.

- Industrial Locations in Turkmenistan: Various industrial zones across the country.

- Tailored Features for Operation in Turkmenistan: Specifically designed for bulk material handling.

- Applicable Industries: Mining, bulk material handling, and heavy industries.

- Industrial Locations in Turkmenistan: Areas with mining activities like the Dashoguz region.

For specific information regarding availability, technical details, and sales of these overhead cranes in Turkmenistan, it's recommended to contact local crane suppliers, dealerships, or manufacturers operating within the country. They can provide insights into available models, technical specifications, pricing, and project references in Turkmenistan. Additionally, visiting industrial zones or attending relevant trade shows within the country may also offer valuable information on overhead crane options available for sale.

Applications Across Industries

Overhead cranes find extensive use across various industrial sectors in Turkmenistan:

- Gas Processing Plants: Used for handling heavy equipment and materials in gas processing and refining operations.

- Petrochemical Refineries: Employed for lifting and moving components during maintenance and construction in refineries.

- Power Plants: Facilitate the installation and maintenance of heavy machinery in power generation facilities.

- Construction Yards: Essential for lifting and positioning materials in construction projects.

- Metalworking Workshops: Ideal for material handling in metal fabrication and machining processes.

- Warehouses and Distribution Centers: Efficiently move and organize goods within storage facilities.

- Automotive Repair and Manufacturing: Support the assembly and maintenance of vehicles in automotive facilities.

- Textile Production Facilities: Aid in the movement of raw materials and finished products in textile manufacturing.

- Shipbuilding and Repair Yards: Handle large and heavy components during ship construction and repair.

- Mining Workshops: Essential for lifting and transporting heavy materials and equipment in mining operations.

Gantry Cranes for Sale in Turkmenistan

Gantry cranes are essential material handling solutions known for their versatility and ability to lift heavy loads across diverse industries in Turkmenistan. Understanding the common and specialized types, along with their applications and benefits, is crucial for businesses seeking optimal crane solutions.

- Crane Design & Capacities: Equipped with a single girder, suitable for lighter loads and smaller spans.

- Tailored Features for Operation in Turkmenistan: Adjustable heights, various lifting capacities, and customization for specific industry requirements.

- Applicable Industries: Small-scale manufacturing, storage yards, and workshops.

- Industrial Locations in Turkmenistan: Industrial zones in cities like Ashgabat, Turkmenabat, and Mary.

- Typical Crane Project Locations: Storage yards, construction sites, and smaller industrial units.

- Crane Design & Capacities: Two girder design offering higher lifting capacities and stability for heavier loads.

- Tailored Features for Operation in Turkmenistan: Increased lifting heights, larger spans, and customization based on specific industry needs.

- Applicable Industries: Heavy manufacturing, warehouses, and large-scale construction.

- Industrial Locations in Turkmenistan: Major industrial centers including Turkmenbashi and Balkanabat.

- Typical Crane Project Locations: Large industrial facilities, construction sites, and material handling areas.

Rubber-Tired Gantry (RTG) Cranes

- Crane Design & Capacities: Mounted on wheels, allowing mobility, primarily used in ports for container handling.

- Tailored Features for Operation in Turkmenistan: High maneuverability, adjustable heights, and capacities suitable for port operations.

- Applicable Industries: Ports, container terminals, and logistics hubs.

- Industrial Locations in Turkmenistan: Turkmenbashi Port and other major ports in the country.

- Typical Crane Project Locations: Container yards, port terminals, and intermodal facilities.

Rail-Mounted Gantry (RMG) Cranes

- Crane Design & Capacities: Run on rails, providing efficient container handling in port and intermodal environments.

- Tailored Features for Operation in Turkmenistan: Rail-mounted system, high stacking capacities, and container handling capabilities.

- Applicable Industries: Ports, container terminals, and intermodal logistics.

- Industrial Locations in Turkmenistan: Major ports and container yards.

- Typical Crane Project Locations: Container terminals, rail yards, and logistics centers.

Portable or Mobile Gantry Cranes

- Crane Design & Capacities: Portable units with movable legs, offering flexibility in various work environments.

- Tailored Features for Operation in Turkmenistan: Mobility, adaptability to different terrains, and lower lifting capacities for versatile use.

- Applicable Industries: Construction sites, workshops, and maintenance activities.

- Industrial Locations in Turkmenistan: Construction sites, smaller workshops, and repair yards.

- Typical Crane Project Locations: Construction sites, warehouses, and temporary work areas.

Adjustable Height Gantry Cranes

- Crane Design & Capacities: Designed with adjustable heights, allowing flexibility in lifting and positioning.

- Tailored Features for Operation in Turkmenistan: Variable height settings, various lifting capacities, and adaptability for different tasks.

- Applicable Industries: Warehousing, maintenance operations, and workshops.

- Industrial Locations in Turkmenistan: Warehouses, repair facilities, and manufacturing units.

- Typical Crane Project Locations: Warehouses, workshops, and facilities requiring height-adjustable lifting.

Specialized Gantry Crane Types

- Tailored Features for Operation in Turkmenistan: Equipped with a cantilever for reaching obstructed areas, suitable for specific construction or industrial setups.

- Applicable Industries: Construction sites with structural limitations, specialized industrial setups.

- Industrial Locations in Turkmenistan: Varies based on construction or industry-specific projects.

- Typical Crane Project Locations: Sites with obstructed structures or areas.

- Tailored Features for Operation in Turkmenistan: Supported by one leg or side, suitable for limited space operations.

- Applicable Industries: Industries with space constraints or specialized layouts.

- Industrial Locations in Turkmenistan: Manufacturing plants with limited space, warehouses with specific layouts.

- Typical Crane Project Locations: Industrial units or facilities with limited operating space.

- Tailored Features for Operation in Turkmenistan: Specifically designed for efficient handling of shipping containers in ports or container terminals.

- Applicable Industries: Port operations, container terminals, and logistics hubs.

- Industrial Locations in Turkmenistan: Major ports and container handling facilities.

- Typical Crane Project Locations: Container terminals, logistics centers, and intermodal yards.

For detailed information, availability, and specific project references within Turkmenistan, it's advisable to reach out to local gantry crane suppliers, dealerships, or manufacturers. They can provide insights into available models, technical specifications, pricing, and any ongoing sales or promotions within the country. Additionally, visiting industrial zones or attending relevant trade shows within the country may offer valuable information on gantry crane options available for sale.

Applications and Benefits

Gantry cranes find applications across various industries in Turkmenistan, each type catering to specific needs:

- Shipbuilding and Repair Yards: Ship-to-shore gantry cranes facilitate efficient loading and unloading of ship components and materials.

- Construction Yards: Portable gantry cranes offer flexibility in lifting and moving construction materials.

- Warehouses and Distribution Centers: Adjustable height gantry cranes enhance the efficiency of material handling in storage facilities.

- Automotive Manufacturing: Cantilever gantry cranes assist in reaching over obstacles during vehicle assembly.

- Mining Workshops: Double girder gantry cranes handle heavy mining equipment and materials.

Jib Cranes for Sale in Turkmenistan

Jib cranes are versatile material handling solutions known for their ability to provide precise lifting and maneuvering in restricted spaces. Understanding the common and specialized types, along with their applications across various industries, is crucial for businesses seeking efficient crane solutions in Turkmenistan.

- Crane Design & Capacities: Fixed lifting solution mounted on walls or columns, ideal for localized lifting within a specific area.

- Tailored Features for Operation in Turkmenistan: Variable capacities, adaptable reach, and maneuverability.

- Applicable Industries: Workstations, assembly lines, and maintenance areas.

- Industrial Locations in Turkmenistan: Manufacturing units, workshops, and maintenance facilities.

- Typical Crane Project Locations: Specific workstations, production lines, and maintenance bays.

- Crane Design & Capacities: Independent cranes with freestanding support columns, providing versatile lifting solutions.

- Tailored Features for Operation in Turkmenistan: Variable capacities, customizable heights, and adaptability for different industries.

- Applicable Industries: Warehouses, manufacturing, and material handling applications.

- Industrial Locations in Turkmenistan: Various industrial setups, warehouses, and storage yards.

- Typical Crane Project Locations: Warehouses, loading docks, and manufacturing units.

Articulating Jib Cranes

- Crane Design & Capacities: Feature pivoting arms with multiple pivot points for flexibility and extended coverage.

- Tailored Features for Operation in Turkmenistan: Variable reach, adaptability for confined spaces, and versatile load handling.

- Applicable Industries: Compact work areas, assembly lines, and tight production spaces.

- Industrial Locations in Turkmenistan: Manufacturing units, workshops, and confined production areas.

- Typical Crane Project Locations: Workstations, assembly cells, and production lines with restricted space.

Specialized Jib Crane Types

Cantilever Jib Cranes

- Tailored Features for Operation in Turkmenistan: Specifically designed with a cantilevered arm for reaching over obstacles or obstructions.

- Applicable Industries: Specialized production units, construction sites with structural obstacles.

- Industrial Locations in Turkmenistan: Varies based on specific project requirements.

- Typical Crane Project Locations: Sites with overhead obstructions or structural limitations.

- Tailored Features for Operation in Turkmenistan: Equipped with motorized rotation for precise load positioning.

- Applicable Industries: Industries requiring precise load handling and positioning.

- Industrial Locations in Turkmenistan: Manufacturing, precision engineering, and assembly lines.

- Typical Crane Project Locations: Workstations, assembly cells, and manufacturing lines requiring accurate load placement.

Applications Across Industries

Jib cranes find diverse applications across industries in Turkmenistan:

- Construction Yards: Wall-mounted jib cranes aid in lifting and positioning construction materials.

- Metalworking Workshops: Free-standing jib cranes facilitate efficient material handling in metal fabrication and machining processes.

- Automotive Repair and Manufacturing: Articulating jib cranes provide precise lifting for vehicle assembly and maintenance.

- Mining Workshops: Cantilever jib cranes reach over obstacles to handle heavy mining equipment and materials.

- Textile Production Facilities: Mast-type jib cranes assist in lifting and moving textile materials during production.

- Warehouses and Distribution Centers: Motorized rotation jib cranes streamline the loading and unloading of goods.

The adaptability and precision of jib cranes make them valuable assets in industries where spatial constraints require strategic and efficient material handling solutions.

Electric Hoists for Sale in Turkmenistan

- Hoist Design & Capacities: Utilizes wire ropes for lifting heavier loads in various industries, often used in applications requiring higher capacities.

- Tailored Features for Operation in Turkmenistan: Variable lifting capacities, adaptability to different industries, and customizable speeds.

- Applicable Industries: Manufacturing, construction, and heavy-duty material handling.

- Industrial Locations in Turkmenistan: Industrial zones in cities like Ashgabat, Turkmenabat, and Balkanabat.

- Typical Hoist Project Locations: Construction sites, manufacturing units, and heavy industrial facilities.

- Hoist Design & Capacities: Utilizes chains for lifting lighter to moderate loads in various applications, suitable for lower capacity needs.

- Tailored Features for Operation in Turkmenistan: Variable capacities, compact design, and adaptable to diverse industries.

- Applicable Industries: Workshops, small-scale manufacturing, and assembly lines.

- Industrial Locations in Turkmenistan: Smaller manufacturing units, repair shops, and maintenance facilities.

- Typical Hoist Project Locations: Workstations, maintenance bays, and assembly cells.

- Hoist Design & Capacities: Specifically designed for use on monorail systems, offering linear material handling solutions.

- Tailored Features for Operation in Turkmenistan: Suitable for material movement along a defined path, adaptable to various industries.

- Applicable Industries: Assembly lines, painting booths, and material transfer along a fixed path.

- Industrial Locations in Turkmenistan: Manufacturing plants with linear material movement needs.

- Typical Hoist Project Locations: Production lines, conveyor systems, and material transfer stations.

Specialized Electric Hoist Types

Explosion-Proof Electric Hoists

- Tailored Features for Operation in Turkmenistan: Built to operate safely in hazardous environments with explosion risks.

- Applicable Industries: Chemical plants, oil refineries, and gas processing facilities.

- Industrial Locations in Turkmenistan: Regions with chemical industries like Lebap and Ahal.

- Typical Hoist Project Locations: Hazardous areas within industrial facilities.

Low-Headroom Electric Hoists

- Tailored Features for Operation in Turkmenistan: Suitable for applications with limited vertical space, offering efficient lifting solutions.

- Applicable Industries: Workspaces with restricted headroom, workshops, and specific manufacturing setups.

- Industrial Locations in Turkmenistan: Various industrial units or workshops requiring limited vertical space solutions.

- Typical Hoist Project Locations: Areas with constrained overhead space.

Stainless Steel Electric Hoists

- Tailored Features for Operation in Turkmenistan: Resistant to corrosion, suitable for environments with moisture or chemical exposure concerns.

- Applicable Industries: Food processing, pharmaceuticals, and environments where hygiene is crucial.

- Industrial Locations in Turkmenistan: Food processing facilities or pharmaceutical plants.

- Typical Hoist Project Locations: Hygienic environments, clean rooms, and areas with chemical exposure concerns.

For specific information regarding availability, technical details, and sales of these electric hoists in Turkmenistan, it's recommended to contact local hoist suppliers, dealerships, or manufacturers. They can provide insights into available models, technical specifications, pricing, and project references in Turkmenistan. Additionally, visiting industrial zones or attending relevant trade shows within the country may offer valuable information on electric hoist options available for sale.

For specific information regarding availability, technical details, and sales of these jib cranes in Turkmenistan, it's recommended to contact local jib crane suppliers, dealerships, or manufacturers. They can provide insights into available models, technical specifications, pricing, and project references in Turkmenistan. Additionally, visiting industrial zones or attending relevant trade shows within the country may offer valuable information on jib crane options available for sale.

Applications and Advantages

Electric hoists find applications across various industrial sectors in Turkmenistan, each type catering to specific needs:

- Gas Processing Plants: Wire rope electric hoists handle heavy components in gas processing and refining.

- Automotive Repair and Manufacturing: Chain electric hoists assist in lifting and positioning vehicle parts during assembly.

- Warehouses and Distribution Centers: Monorail electric hoists streamline linear material handling within storage facilities.

- Chemical Plants: Explosion-proof electric hoists ensure safe material handling in potentially hazardous environments.

- Construction Yards: Low-headroom electric hoists maximize lifting height in confined construction spaces.

- Mining Workshops: Dual-speed electric hoists offer precise control in lifting heavy mining equipment.

- Food Processing Industries: Stainless steel electric hoists resist corrosion in environments with stringent hygiene requirements.

The advantages of electric hoists include their efficiency, precision, and adaptability to various lifting requirements.

Considerations for Crane Buyers

Choosing the right crane is a crucial decision for businesses in Turkmenistan, and several factors play a pivotal role in the selection process. Understanding these considerations is essential for making informed decisions that align with the unique needs of each industry.

Factors Influencing Crane Selection

Load Capacity and Lifting Requirements

Determining the load capacity of a crane is the foundation of any successful material handling operation. Crane buyers must carefully assess the heaviest loads they anticipate lifting regularly and choose a crane with the appropriate capacity. Considerations should also include potential future growth in load requirements to ensure the selected crane remains effective over time.

Durability and Resistance to Harsh Environments

Industries in Turkmenistan often operate in challenging environments, such as those found in gas processing plants, petrochemical refineries, and mining workshops. Crane buyers need to prioritize durability and choose cranes that can withstand harsh conditions, including exposure to corrosive substances, extreme temperatures, and other environmental factors.

Safety Features and Compliance Standards

Safety is paramount in industrial settings, and cranes must adhere to strict safety standards. Crane buyers should prioritize features such as overload protection, emergency stop systems, and advanced control technologies that enhance overall safety. Ensuring compliance with industry-specific and international safety standards is a non-negotiable aspect of crane selection.

Customization for Specific Applications

Each industry has unique material handling requirements, and crane buyers should seek customization options that align with their specific applications. Custom features may include specialized attachments, adjustable configurations, or automation capabilities tailored to the demands of the industry. Investing in customized solutions ensures that the crane seamlessly integrates into existing workflows, maximizing efficiency.

Technical Specifications and Configurations

Understanding the technical specifications and configurations of cranes is vital for ensuring optimal performance and seamless integration into the specific industrial workflows of Turkmenistan. Crane buyers should carefully evaluate these technical aspects to make informed decisions.

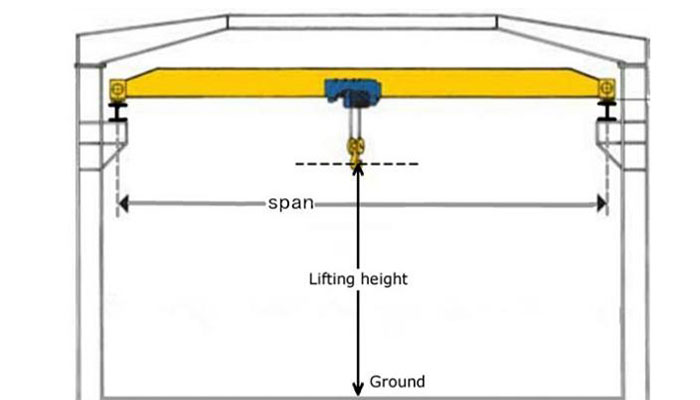

Crane Span, Lifting Height, and Speed

- Crane Span: The span refers to the horizontal distance covered by the crane. Buyers must assess the dimensions of their workspace to determine the appropriate span that ensures comprehensive coverage without unnecessary excess.

- Lifting Height: The lifting height is the vertical distance the crane can raise a load. It is crucial to choose a crane with sufficient lifting height to meet the specific requirements of the industry. Consider factors such as building height and the need for precise positioning.

- Speed: The speed of the crane in terms of hoisting, traversing, and trolley movement impacts overall operational efficiency. Crane buyers should balance the need for speed with the safety and stability requirements of their operations.

Control Mechanisms and Automation

- Control Mechanisms: The control system of a crane influences its ease of operation and precision. Buyers can choose between traditional pendant controls and advanced radio remote controls. The type of control mechanism should align with the complexity of the lifting tasks and the preferences of operators.

- Automation: Automation features enhance the efficiency and safety of crane operations. Automated systems can include features like programmable logic controllers (PLCs), collision avoidance systems, and smart sensors. Investing in automation can lead to smoother workflows and reduced reliance on manual intervention.

Integration with Existing Systems

Compatibility: Crane buyers should assess how well a new crane can integrate with existing systems within the facility. This includes compatibility with other material handling equipment, warehouse management systems, and safety protocols. Seamless integration minimizes disruptions and enhances overall operational synergy.

Cost Analysis and Return on Investment

Considering the financial aspects of crane purchases is crucial for businesses in Turkmenistan. A comprehensive cost analysis, including both initial and ongoing expenses, allows crane buyers to assess the overall investment and anticipate the return on investment (ROI) over time.

Initial Investment Costs

- Crane Purchase Price: The upfront cost of acquiring the crane is a significant component of the initial investment. This includes the base price of the crane itself, along with any additional features or customization requested.

- Shipping and Import Fees: For international purchases, such as those from global suppliers, shipping and import fees contribute to the overall cost. Buyers should factor in these expenses to avoid unexpected financial burdens.

- Installation Costs: The cost of installing the crane in the designated workspace includes labor, equipment, and any necessary modifications to the facility. A thorough evaluation of installation expenses ensures accurate budgeting.

Installation and Maintenance Expenses

- Professional Installation: Hiring professionals for the installation process is a critical expense. Professional installation ensures the crane is set up correctly, adhering to safety standards and manufacturer guidelines.

- Training Programs: Training operators on the proper use and maintenance of the crane is an ongoing expense. Investing in comprehensive training programs contributes to the safe and efficient operation of the crane.

- Routine Maintenance: Regular maintenance is essential for ensuring the longevity and optimal performance of the crane. Buyers should budget for routine inspections, repairs, and replacement of parts to prevent unexpected breakdowns.

Projected Operational Efficiency Gains

- Increased Productivity: A well-selected and properly maintained crane contributes to increased productivity by streamlining material handling processes. Buyers should project the operational efficiency gains resulting from the crane's capabilities.

- Reduction in Downtime: A reliable crane minimizes downtime due to breakdowns or inefficiencies. Reduced downtime contributes to uninterrupted operations, preventing delays and potential financial losses.

- Enhanced Safety: Safety features and compliance contribute to a secure working environment. The avoidance of accidents and injuries positively impacts the overall efficiency and financial stability of the operation.

Identifying Reliable Crane Suppliers and Manufacturers

Selecting a reliable crane supplier or manufacturer is a crucial step in ensuring the success of any material handling operation. This section provides an overview of both local suppliers in Turkmenistan and reputable international crane manufacturers.

Overview of Local and International Suppliers

Local Suppliers in Turkmenistan

Turkmenistan may have local suppliers offering a range of cranes suitable for various industries. When considering local suppliers, crane buyers should assess factors such as:

- Reputation: Investigate the reputation of local suppliers by reviewing customer feedback, testimonials, and references. A supplier with a positive track record is more likely to provide quality products and services.

- Service and Support: Evaluate the level of service and support offered by local suppliers. Timely maintenance, responsive customer service, and quick availability of spare parts are essential considerations.

- Compliance: Ensure that local suppliers comply with industry standards and safety regulations. Compliance contributes to the reliability and safety of the purchased cranes.

International Crane Manufacturers

Opting for international crane manufacturers widens the range of available options and introduces the potential for cutting-edge technology. Key considerations when exploring international options include:

- Product Range: Evaluate the product range offered by international manufacturers. A diverse range allows buyers to select a crane tailored to their specific needs and industry requirements.

- Quality Standards: International manufacturers often adhere to stringent quality standards. Assess certifications, such as ISO standards, to ensure the cranes meet international quality benchmarks.

- Global Presence: Manufacturers with a global presence may offer better support and after-sales services. Consider the availability of service centers, technical support, and spare parts distribution.

- Innovation and Technology: International manufacturers may incorporate the latest technological advancements in crane design. Assess the level of innovation in their products to ensure alignment with industry trends.

Choosing between local suppliers and international manufacturers depends on various factors, including the specific requirements of the industrial sector, budget constraints, and the level of technological sophistication desired.

Choosing Crane Suppliers

Choosing the right crane supplier is a critical decision that influences the success of material handling operations in Turkmenistan. This section outlines key factors to consider when evaluating crane suppliers.

Reputation and Experience

- Reputation: Investigate the reputation of potential crane suppliers by researching customer reviews, testimonials, and case studies. A supplier with a positive reputation is likely to deliver reliable products and services.

- Experience: Consider the supplier's experience in the industry. Longevity and a history of successful projects demonstrate a supplier's ability to meet customer expectations and navigate challenges.

Customization and Technical Expertise

- Customization: Assess the supplier's ability to provide customized solutions. Industries in Turkmenistan may have unique material handling requirements, and a supplier capable of tailoring cranes to specific needs adds significant value.

- Technical Expertise: Evaluate the technical expertise of the supplier's team. A knowledgeable and skilled workforce ensures that the supplied cranes are designed, installed, and maintained with precision.

Compliance with Standards

- Adherence to Standards: Verify that the crane supplier adheres to industry standards and safety regulations. Compliance ensures that the supplied cranes meet essential safety requirements and operate reliably in the intended environment.

Installation, Maintenance, and After-Sales Support

- Installation Services: Consider the supplier's installation services. A supplier that offers professional installation ensures that the crane is set up correctly, contributing to safety and optimal performance.

- Maintenance Programs: Assess the availability of maintenance programs offered by the supplier. Regular maintenance is crucial for extending the lifespan of the crane and preventing unexpected breakdowns.

- After-Sales Support: Evaluate the quality of after-sales support provided by the supplier. Responsive customer service, quick resolution of issues, and the availability of spare parts contribute to a positive post-purchase experience.

By prioritizing these factors, crane buyers can confidently choose a supplier that aligns with their specific needs, ensuring a smooth and successful integration of overhead cranes into their operations.

Guidance on Installation, Maintenance, and After-Sales Support

Selecting a crane supplier extends beyond the initial purchase; it involves ongoing collaboration for installation, maintenance, and after-sales support. This section provides essential guidance on these critical aspects.

Installation Services

- Professional Installation: Opt for suppliers that offer professional installation services. Skilled technicians ensure that the crane is set up correctly, adhering to safety standards and manufacturer guidelines.

- Timely Installation: Assess the supplier's track record in terms of installation timelines. Timely installation minimizes disruptions to operations and allows businesses to swiftly incorporate the new crane into their workflows.

Maintenance and Repair Support

- Scheduled Maintenance Programs: Choose suppliers that provide scheduled maintenance programs. Regular maintenance is crucial for identifying potential issues before they escalate, ensuring the crane's longevity and optimal performance.

- Responsive Repair Services: Evaluate the supplier's responsiveness in providing repair services. A quick turnaround for repairs minimizes downtime, allowing businesses to resume operations promptly.

After-Sales Support and Training

- Comprehensive After-Sales Support: Prioritize suppliers offering comprehensive after-sales support. This includes responsive customer service, technical assistance, and guidance on maximizing the crane's capabilities.

- Operator Training Programs: Suppliers should offer training programs for crane operators. Well-trained operators contribute to safe and efficient crane operations, reducing the risk of accidents and enhancing overall productivity.

- Availability of Spare Parts: Ensure that the supplier maintains an inventory of essential spare parts. Quick access to spare parts facilitates swift repairs, minimizing disruptions caused by unforeseen breakdowns.

By prioritizing suppliers that excel in installation services, maintenance and repair support, and after-sales assistance, crane buyers in Turkmenistan can establish long-term partnerships that contribute to the success of their material handling operations.

Conclusion and Future Prospects

In Turkmenistan's diverse industrial landscape, the choice of overhead cranes, gantry cranes, jib cranes, and electric hoists depends on the specific needs of various sectors. Understanding the applications and benefits of each crane type is crucial for making informed buying decisions.

Considerations such as load capacity, durability, safety features, and customization options play a pivotal role in selecting the right crane. Buyers should assess technical specifications, integration capabilities, and financial aspects to ensure a well-rounded and informed buying decision.

As technology continues to advance, the crane industry is poised for significant developments. Businesses in Turkmenistan can anticipate the following trends and opportunities:

The integration of smart technologies, automation, and data analytics into crane systems is expected to enhance efficiency, safety, and overall performance. Remote monitoring, predictive maintenance, and advanced control systems will become more prevalent, offering businesses greater control over their material handling processes.

Turkmenistan's ongoing infrastructure development projects present opportunities for the crane industry. As new facilities, warehouses, and manufacturing plants emerge, the demand for modern, efficient cranes will likely increase. Crane suppliers and manufacturers can align their offerings with the evolving needs of these projects.

Turkmenistan's industrial sectors can benefit from exploring global market options for crane procurement. International suppliers and manufacturers bring diverse product ranges, advanced technologies, and extensive experience, contributing to the growth and competitiveness of the local industries.

In conclusion, Turkmenistan's steel industry and various industrial sectors can optimize material handling operations by strategically selecting and utilizing the right cranes. The guide has provided insights into crane types, key considerations for buyers, and future trends, empowering businesses to make informed decisions for enhanced operational efficiency.

For continuous success, it is essential for businesses to stay abreast of technological advancements, embrace innovations, and forge partnerships with reliable crane suppliers that offer not only quality products but also comprehensive support throughout the crane's lifecycle.

This comprehensive guide aims to serve as a valuable resource for businesses in Turkmenistan navigating the complexities of crane selection and integration. By leveraging the insights provided, industries can elevate their material handling capabilities and contribute to the overall growth and development of Turkmenistan's industrial landscape.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch