Bridge Cranes, EOT Cranes & Overhead Crane Capacities 1–100 Ton

Explore overhead crane options from 1 ton to 100 tons. Compare specifications, features, applications & price ranges in one place.Get your overhead crane!

Category: Ton & Price

Your Trusted Overhead Crane Manufacturer & Supplier

Bridge Cranes, EOT Cranes & Overhead Crane Capacities 1–100 Ton

Introduction of Overhead Crane Capacities & Tonnages

Overhead cranes are essential tools in many industries. You'll find them in factories, warehouses, construction sites, and even shipyards. Their main job? Helping to lift and move heavy loads safely and efficiently. Without the right crane, handling large materials or equipment would be slow, risky, and sometimes impossible.

One of the most important things to understand before buying or operating an overhead crane is its capacity — basically, how much weight it can safely lift. This isn't just a number on paper. It directly affects how well the crane performs, how safe it is to use, and how long it will last. Choosing the wrong capacity can lead to costly repairs, downtime, or worse — accidents.

In this guide, we'll cover everything you need to know about overhead crane capacities. We'll talk about:

- What crane capacity really means

- How to choose the right capacity for your needs

- The differences between small and large capacity cranes

- Important factors that affect capacity, like lifting height and span

- Practical tips on maintenance and safety based on crane size

By the end, you'll have a clear picture of how to match the right crane capacity to your business or project. This will help you buy smarter and work safer.

What Are Overhead Cranes?

Overhead cranes are lifting machines that move loads across a workspace using a bridge-like structure suspended above the ground. They're often used in workshops, factories, and warehouses where lifting heavy materials needs to be done quickly, safely, and with minimal floor interference.

Unlike mobile or tower cranes, overhead cranes are fixed in place and run along a set of rails, usually mounted on runway beams or building columns. This setup allows precise and controlled material handling without needing to shift anything on the floor.

Basic Components of an Overhead Crane:

- Bridge: The horizontal beam that spans the width of the crane's working area.

- Runways: Tracks that guide the bridge crane along the building's length.

- Hoist and Trolley: The lifting unit that moves side to side along the bridge while raising or lowering loads.

- Controls: Can be pendant-controlled, radio-controlled, or fully automated, depending on the system.

Different Types of Overhead Cranes:

Overhead cranes come in several configurations based on their structure and how they move loads:

- Single Girder Overhead Crane1 Ton to 20 Ton : Has one main bridge girder. Lighter in design and typically used for capacities up to 20 tons.

- Double Girder Overhead Crane3 Ton to 320 Ton : Has two main bridge girders. Suitable for higher lifting capacities, up to 100 tons or more.

- EOT Crane (Electric Overhead Traveling Crane): A broad term that includes both single and double girder types powered electrically and moving along tracks.

- Underslung (or Suspension) Cranes 1 Ton to 10 Ton : Hang from the ceiling or structure above and are great for facilities with tight floor space.

- Top-Running Cranes3 Ton to 320 Ton : Run on top of runway beams, suitable for heavier loads and larger spans.

Typical Capacity and Applications:

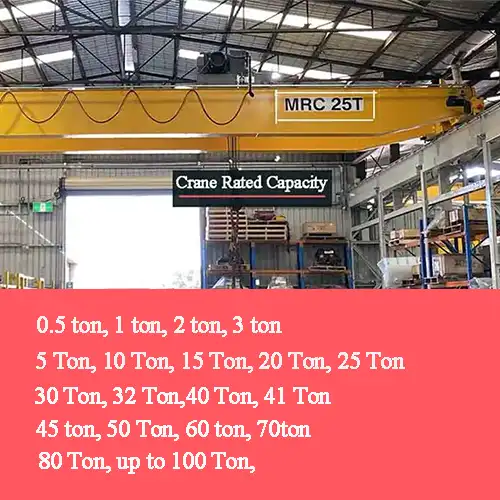

- Light-Duty Cranes: 0.5 ton, 1 ton, 2 ton, 3 ton — common for light manufacturing, tool rooms, or small part handling.

- Medium Capacity Cranes: 5 ton, 10 ton, 15 ton, 20 ton — often used in workshops, steel warehouses, and fabrication plants.

- Heavy-Duty Cranes: 25 ton, 50 ton, 100 ton and above — used in heavy industries like shipyards, steel mills, and power plants.

Hot-Sale Overhead Bridge Crane Capacities (Quick Overview)

- Single Girder Cranes Capacities: 1T, 2T, 3T, 5T, 10T, 15T, 16T, 20T. Light to medium-duty use – workshops, warehouses, routine lifting.

- Double Girder Cranes Capacities: 5T, 10T, 16T, 20T, 25T, 30T, 32T, 40T, 50T, 100T. Heavy-duty lifting – ideal for long spans, industrial production lines.

- European Standard (FEM/DIN) Capacities: 5T, 10T, 12.5T, 16T, 20T, 25T up to 80 Ton, Customized up to 320 Ton .Compact, precise, energy-efficient – suitable for frequent operations.

- Explosion-Proof CranesCapacities: 1T, 3T, 5T, 10T. Customized up to 320 Ton, For hazardous areas – oil, chemical, gas industries.

- Electromagnetic Cranes Capacities: 5T, 10T, 20T, 32T.Handling steel products – plates, billets, scrap.

- Grab Bucket Cranes Capacities: 5T, 10T, 16T, 20T.Bulk materials – sand, coal, ore.

- Foundry/Ladle Cranes Capacities: 10T, 20T, 50T, 100T, 160T.Molten metal lifting – for steel plants and casting workshops.

- Dual Hook Cranes Configs: 20/5T, 30/10T, 50/10T.For long, oversized, or unbalanced loads.

- Crane Kits (No Main Girder) Capacities: 2T, 3T, 5T, 10T, 20T.Modular supply – for local fabrication or overseas assembly.

Overhead Crane Capacity

Now let's talk about the main topic — crane capacity. This is the most crucial detail every buyer should understand before selecting a crane.

What Does Crane Capacity Mean?

Crane capacity is the maximum weight a crane is designed to safely lift. This includes not just the load, but also any lifting attachments like slings, hooks, or magnets. If your crane is rated for 10 tons, it must never lift more than that — or even close to it regularly — unless the design allows.

It's easy to assume the number on the label is flexible. It's not. The capacity is based on the crane's structural strength, hoist rating, motor power, braking system, and safety margins.

Rated Load vs. Actual Load

- Rated Load/ Crane Rated Capacity : The maximum lifting capacity as specified by the manufacturer.

- Actual Load: The real load being lifted, including rigging gear and accessories.

Even if the item being lifted weighs only 8 tons on a 10-ton crane, adding a spreader beam or lifting clamp could push the total closer to the limit. So always calculate the total lifting weight.

So, a 10-ton crane designed for light use isn't the same as a 10-ton crane designed for continuous operation in a steel plant.

Why Crane Capacity Matters for Safety

Operating a crane beyond its rated capacity can cause:

- Structural damage to the crane frame or girders

- Motor or hoist failure

- Brake slipping or loss of control

- Accidents and injuries — which could be serious or fatal

- Insurance issues and downtime due to equipment damage

Capacity Is Not Just About Size — It's Part of the Design

When a crane is designed, engineers consider:

- Working load limit (WLL)

- Duty class (A1 to A8, or FEM classifications)

- Lifting height and hook approach

- Frequency of use and load cycles

How Capacity Impacts Crane Selection and Safety

Selecting the right crane capacity isn't just about picking a number that matches your load weight. It's about finding the balance between performance, safety, and long-term usability. Many crane buyers make the mistake of either underestimating or overspending on capacity — both can lead to issues down the line.

Matching Capacity to Your Load Requirements

Every crane must be able to handle the maximum expected load — not just the average. This means considering not only the heaviest item you'll lift, but also the lifting frequency and potential future changes in your workload.

- Start by listing all items to be lifted and their weights.

- Consider whether loads will be lifted individually or bundled.

- Take into account any additional lifting accessories like grabs or magnets, which also add weight.

Consequences of Undersizing or Oversizing Capacity

Going below what you need is dangerous. Going too far above what you need? That's expensive — and sometimes unnecessary.

If the crane is under-capacity:

- There's a risk of overload and structural failure.

- The crane may wear out faster due to stress.

- Operations may be halted due to safety concerns or restrictions.

If the crane is over-capacity:

- You may pay more for a heavier-duty system that isn't required.

- Larger cranes often require stronger foundations and support structures, increasing installation costs.

- The hoist and trolley may move slower if oversized.

Safety Margins and Factors of Safety in Crane Design

Every overhead crane is built with a factor of safety — an extra margin beyond its rated capacity. But this doesn't mean you can exceed the rated load.

- For example, a 10-ton overhead crane is designed to safely lift 10 tons or less, even though its components may handle more under controlled conditions.

- Safety factors vary depending on local standards (like FEM, CMAA, or ISO) and crane classifications (A5, A6, etc.).

Don't rely on this safety buffer to justify lifting more than the rated load. It's there for unexpected dynamic loads, not poor planning.

Capacity and Operational Limitations

Crane capacity also affects how the crane is built and what it can do.

- Lifting height: Higher-capacity cranes often require larger hoists, which may affect hook travel.

- Span: Wide-span cranes carrying heavy loads need stronger, often double-girder, designs.

- Speed: High-capacity cranes may lift more slowly for safety and stability.

- Structural requirements: Heavier loads demand more robust runways, columns, and foundations.

Practical Tip: Before choosing a capacity, involve your crane supplier in a conversation about your operations, building dimensions, and future needs. A small adjustment in capacity today could save major retrofits tomorrow.

General Overhead Cranes Capacity Range

Understand What Each Ton Capacity Really Means for Your Workshop or Plant

- Best for small workshops, maintenance tasks, and handling light tools or equipment.

- Typically single girder design, compact, and easy to install.

- Common in assembly lines, repair shops, and light-duty operations.

- Ideal when space and budget are limited.

- Suitable for light parts movement and tooling operations.

- Often used in plastic manufacturing, electronics, and small industrial settings.

- Offers slightly more flexibility than 1-ton cranes without significant structural demands.

- Available with low-headroom or underhung configurations.

- A popular choice for general industrial use.

- Handles medium loads efficiently and economically.

- Used in warehouses, fabrication plants, machine shops, and metalworking.

- Available in single or double girder designs depending on span and height.

- Suitable for heavier lifting in medium-sized factories.

- Commonly double girder for higher lifting height and longer spans.

- Frequently used in steel processing, machine assembly, and tooling plants.

- Offers higher lifting speeds and better performance.

- Designed for heavy-duty lifting with greater load frequency.

- Always double girder; may require a more robust support structure.

- Typical in large fabrication shops, foundries, and steel service centers.

- Customization may be needed for specific lifting requirements.

- Built for major lifting tasks in heavy industry.

- Double girder with high-strength hoisting mechanisms and structural components.

- Applied in shipyards, steel plants, and large-scale manufacturing operations.

- Requires detailed planning and experienced installation.

- Used in extremely heavy lifting scenarios, often with complex controls.

- Custom-engineered cranes with multiple hoists or two trolleys.

- Found in hydroelectric plants, shipbuilding yards, and steel mill operations.

- Demands the highest level of safety, coordination, and engineering expertise.

Design, Price, and Application Comparison by Capacity

Design, Price, and Application Comparison by Capacity

| Capacity | Typical Girder Type | Common Applications | Price Level | Lifting System |

|---|---|---|---|---|

| 1–2 Ton | Single | Light-duty workshops, tool handling | Low | Chain or wire rope hoist |

| 5–10 Ton | Single or Double | General industry, machine shops | Moderate | Standard wire rope hoist |

| 20–50 Ton | Double | Heavy-duty plants, fabrication, steel | High | Motorized trolley with hoist |

| 100 Ton & Above | Custom Double | Specialized industries, energy, shipyard | Very High | Multi-hoist or dual trolley |

Key Buyer Considerations

Key Buyer Considerations

- Always choose crane capacity with future growth in mind—not just today's heaviest load.

- Consider building structure, runway beam compatibility, and electrical supply.

- Discuss your specific lifting frequency, working environment, and safety standards with the crane supplier.

- Work with experienced manufacturers to ensure optimal system design and long-term value.

Design, Price, and Application Comparison by Capacity

| Capacity | Typical Girder Type | Common Applications | Price Level | Lifting System |

|---|---|---|---|---|

| 1–2 Ton | Single | Light-duty workshops, tool handling | Low | Chain or wire rope hoist |

| 5–10 Ton | Single or Double | General industry, machine shops | Moderate | Standard wire rope hoist |

| 20–50 Ton | Double | Heavy-duty plants, fabrication, steel | High | Motorized trolley with hoist |

| 100 Ton & Above | Custom Double | Specialized industries, energy, shipyard | Very High | Multi-hoist or dual trolley |

Single Girder Overhead Crane Price Overview (1–20 Ton)

| Capacity | CD/MD (USD) | Low Headroom | Underslung | FEM/DIN | Offset Trolley | Manual (Max 5T) |

|---|---|---|---|---|---|---|

| 1T | $1,830–5,100 | $1,920–5,360 | $1,830–5,100 | $4,750–8,800 | $2,930–9,180 | $840–1,800 |

| 2T | $2,000–5,900 | $2,100–6,200 | $2,000–5,900 | $4,800–10,380 | $3,200–5,220 | $880–1,900 |

| 3T | $2,130–7,680 | $2,240–8,100 | $2,130–7,680 | $4,980–11,050 | $3,400–13,800 | $930–2,000 |

| 5T | $3,130–8,680 | $3,290–9,120 | $3,130–8,680 | $5,580–12,200 | $5,000–15,600 | $1,600–3,060 |

| 10T | $3,890–12,000 | $4,085–12,600 | $3,890–12,000 | $7,400–17,300 | $6,220–21,600 | – |

| 16T | $4,180–13,100 | $4,400–13,800 | – | $11,700–22,800 | $6,680–23,500 | – |

| 20T | $7,100–18,300 | $7,500–19,300 | – | – | $11,360–32,940 | – |

Note:

- Manual types only available up to 5 tons.

- FEM/DIN and Offset Trolley are advanced, costlier options.

- Prices vary with span, lift height, power supply, control system, and customization.

Double Girder Overhead Crane Price Guide (5–50 Ton)

| Capacity | Standard | Low Headroom | FEM/DIN | Heavy-Duty Custom |

|---|---|---|---|---|

| 5T | $5,800–72,000 | $6,500–75,000 | $7,500–78,000 | $8,500–82,000 |

| 10T | $6,500–79,000 | $7,200–82,000 | $8,400–85,000 | $9,600–89,000 |

| 16T | $7,800–86,000 | $8,500–89,000 | $10,000–92,000 | $11,500–96,000 |

| 20T | $8,600–95,000 | $9,300–98,000 | $11,200–102,000 | $13,000–106,000 |

| 25T | $9,800–110,000 | $10,500–113,000 | $13,200–116,000 | $15,000–120,000 |

| 32T | $11,200–118,000 | $12,000–122,000 | $15,000–126,000 | $17,500–130,000 |

| 40T | $13,000–126,000 | $13,800–130,000 | $16,800–135,000 | $19,000–140,000 |

| 50T | $14,800–135,000 | $15,600–139,000 | $18,200–145,000 | $21,000–150,000 |

Note:

Pricing depends on crane classification (A3/A4/A5), span, lift height, and custom specs. FEM/DIN and heavy-duty types typically include enhanced structural and control features.

Main Types of Overhead Cranes and Their Typical Crane Capacity Ranges

Understand Which Crane Type Suits Your Load, Space, and Operation Needs

Overhead cranes are classified by their structural design and application type. Each type has a typical capacity range suited for specific industries, building layouts, and lifting requirements.

Single Girder Overhead Cranes

- Typical Capacity Range: 1 ton to 20 tons

- Best For: Light to medium-duty applications

- Features: Economical and compact, Lower lifting height compared to double girder, Easy installation and maintenance

- Common Use Cases: Machine shops, light manufacturing, warehouses

Double Girder Overhead Cranes

- Typical Capacity Range: 5 tons to 100+ tons

- Best For: Medium to heavy-duty applications

- Features:Greater lifting height and span, Can support walkways and maintenance platforms,Suitable for frequent and continuous lifting

- Common Use Cases: Steel plants, fabrication shops, assembly lines

Top Running Overhead Cranes

- Typical Capacity Range: 5 tons to 300+ tons

- Best For: Heavy lifting with high lifting height requirements

- Features:Crane runs on top of runway beams, Allows maximum floor space usage, Ideal for heavy equipment or large-span workshops

- Common Use Cases: Power plants, heavy equipment assembly, shipyards

Underrunning (Underhung) Overhead Cranes

Underrunning (Underhung) Overhead Cranes

- Typical Capacity Range: 0.5 ton to 10 tons

- Best For: Low-ceiling or restricted-height areas

- Features:Crane hangs from the bottom flange of runway beams, Often integrated into building structure, Best for light and medium-duty lifting

- Common Use Cases: Electronics assembly, clean rooms, compact production zones

Explosion-Proof Overhead Cranes

Explosion-Proof Overhead Cranes

- Typical Capacity Range: 1 ton to 100 tons

- Best For: Hazardous environments with gas, dust, or flammable materials

- Features:Equipped with explosion-proof hoists and control systems, Compliant with ATEX, IECEx, or other safety standards,

- Common Use Cases: Chemical plants, oil & gas, mining, paint shops

Magnetic or Electromagnetic Overhead Cranes

Magnetic or Electromagnetic Overhead Cranes

- Typical Capacity Range: 5 tons to 50+ tons

- Best For: Handling ferrous metal products like billets, scrap, or plates

- Features:Equipped with electromagnetic lifting devices,Rapid lifting and release of magnetic materials

- Common Use Cases: Steel mills, scrap yards, foundries

Grab Bucket Overhead Cranes

- Typical Capacity Range: 5 tons to 30+ tons

- Best For: Bulk material handling such as sand, coal, or ore

- Features:Fitted with mechanical or hydraulic grab buckets,Suitable for automatic or semi-automatic operation

- Common Use Cases: Waste handling, cement plants, bulk terminals

Summary Table: Overhead Crane Types and Capacity Ranges

Summary Table: Overhead Crane Types and Capacity Ranges

| Crane Type | Typical Capacity Range | Common Applications |

|---|---|---|

| Single Girder | 1 – 20 tons | Light industry, workshops, basic logistics |

| Double Girder | 5 – 100+ tons | Heavy-duty manufacturing and steel plants |

| Top Running | 5 – 300+ tons | High-span, high-capacity lifting areas |

| Underrunning (Underhung) | 0.5 – 10 tons | Low headroom or small workspaces |

| Explosion-Proof | 1 – 100 tons | Hazardous or flammable environments |

| Magnetic/Electromagnetic | 5 – 50+ tons | Ferrous materials handling |

| Grab Bucket | 5 – 30+ tons | Bulk materials in ports, energy, and waste |

Key Capacity-Related Factors to Consider

When selecting an overhead crane, understanding the capacity alone isn't enough. Several important factors influence the actual lifting capability and safe operation of the crane. Let's break down some of these critical considerations.

Load Charts and How to Read Them

Load charts are like the crane's instruction manual on lifting limits. They show the maximum load the crane can safely handle at different configurations, such as various spans and lifting heights. Knowing how to read these charts helps you avoid overloads and ensures your crane matches your specific lifting scenarios.

- Shows maximum load limits at different boom lengths or spans

- Accounts for lifting height and boom angle

- Important for planning lifts and preventing accidents

Safety Factors and Regulations

Crane capacities are not just about lifting the heaviest load but doing so safely. Safety factors are built into crane designs to provide a margin above the rated load. Additionally, local and international regulations set strict standards to protect operators and equipment, so compliance is mandatory.

- Common safety factor ranges from 1.25 to 1.5 times the rated load

- Adherence to standards like OSHA, ANSI, or ISO is crucial

- Regular inspection and certification help maintain safety compliance

Impact of Lifting Height and Span on Capacity Requirements

The higher you need to lift and the longer the crane's span, the greater the strain on its components. This means capacity ratings can change depending on the crane's working envelope. It's vital to consider these when sizing your crane.

- Increased lifting height may reduce lifting capacity

- Longer spans require stronger structures and motors

- Must balance capacity with the facility's physical constraints

Environmental and Operational Factors Affecting Capacity Needs

Your crane will not work in a vacuum. Temperature, humidity, dust, and even the frequency of use impact capacity and maintenance needs. Harsh environments may require cranes with special protections or reduced capacity ratings for safety.

- Corrosive or explosive environments need specially rated cranes

- Frequent heavy lifts demand robust components and higher safety margins

- Indoor vs. outdoor use affects design and capacity considerations

Common Applications for Different Capacities

Choosing the right overhead crane capacity depends largely on what you need to lift and where. Different industries and tasks call for cranes of varying strengths. Let's look at typical uses for light, medium, and heavy-duty cranes.

Light-Duty Cranes (1–5 Tons)

These cranes are popular in workshops, small factories, and assembly lines where loads are relatively light but frequent. They are compact, easy to operate, and ideal for lifting tools, machine parts, or small assemblies.

- Used in small to medium manufacturing plants

- Perfect for material handling and parts assembly

- Often designed for ease of movement and precision

Medium-Duty Cranes (10–20 Tons)

Medium-duty cranes serve well in larger manufacturing facilities, warehouses, and construction sites. They handle bigger components, palletized goods, or machinery parts. Their capacity allows for flexibility across many industries.

- Common in automotive, aerospace, and general manufacturing

- Suitable for loading and unloading heavy materials

- Often feature longer spans and higher lifting heights

Heavy-Duty Cranes (50 Tons and Above)

Heavy-duty cranes are the workhorses in demanding industries like steel mills, shipyards, and heavy machinery plants. These cranes move massive steel plates, ship sections, or heavy equipment. They are built tough and often customized for specific heavy lifting tasks.

- Essential in metal processing and fabrication plants

- Used in shipbuilding and large-scale construction

- Designed to withstand harsh conditions and continuous use

By matching crane capacity to your application, you can improve efficiency, safety, and cost-effectiveness in your lifting operations.

Maintenance and Inspection Tips Based on Capacity

Crane capacity isn't just about how much weight a crane can lift — it also influences how you maintain and inspect the equipment. Larger capacity cranes often have more complex parts and heavier loads, which means they need more frequent and detailed care.

For smaller cranes (1–5 tons), maintenance tends to focus on ensuring smooth operation and preventing wear in motors, brakes, and controls. These cranes usually run more frequently, so regular checks prevent unexpected downtime.

Medium and heavy-duty cranes (10 tons and above) face greater stress on their structural components, hoists, and cables. You'll want to watch for signs of fatigue, corrosion, or mechanical wear. Proper lubrication, alignment checks, and load testing become critical to avoid failures.

Key maintenance tips by capacity:

- Light-duty cranes: Frequent visual inspections; keep components clean and lubricated

- Medium-duty cranes: Monitor wire ropes, hooks, and brakes for wear; schedule regular load tests

- Heavy-duty cranes: Conduct thorough structural inspections; use certified inspectors for load testing; adhere strictly to safety regulations

Professional inspections and load testing are essential, especially for higher-capacity cranes. These checks verify that the crane can safely handle its rated loads, reducing risks and extending equipment life.

Conclusion

Understanding crane capacity is a vital step in choosing the right overhead crane. It affects everything from safety and performance to maintenance and cost. Buyers who take the time to learn about capacity details make smarter, safer investments.

If you're planning to buy or operate an overhead crane, don't hesitate to reach out to experienced manufacturers and suppliers. They can help tailor a solution that fits your exact needs.

For more practical tips and deep dives into crane capacities, make sure to subscribe to our channel. We'll help you get the most out of your crane investments with clear, useful information.

FAQ Section

What happens if I exceed crane capacity?

Exceeding the crane's rated capacity can be very dangerous. It puts extra stress on the structure, hoist, and control systems, which may lead to equipment failure, accidents, or serious injuries. Always stick to the load limits shown on the crane's load chart to keep operations safe.

Can I upgrade crane capacity later?

Sometimes, yes. Upgrading capacity depends on the crane's original design and structure. Some cranes allow modifications like stronger hoists or reinforced girders, but this usually requires a professional engineering assessment and approval. It's best to plan capacity needs carefully from the start to avoid costly upgrades later.

How to verify crane capacity before purchase?

Before buying, review the crane's technical specifications, including load charts and certification documents. Ask the manufacturer or supplier for detailed capacity ratings and any test results. If possible, inspect the crane or see it in operation. This helps ensure the crane will meet your lifting requirements safely.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch