Complete Electric Winch Buyer's Guide – Types & Components

Electric Winch for Sale. Complete Electric Winch Buyer's Guide on winch types, components & key considerations for horizontal pulling & vertical Lifting

Category: Featured

Your Trusted Electric Winch Manufacturer & Supplier

Electric Winch for Sale

Complete Electric Winch Buyer's Guide

Types, Components, and Key Considerations for Horizontal Pulling & Vertical Lifting

Introduction

Electric winches are essential tools in many industries. They provide reliable solutions for lifting, pulling, and moving heavy loads, making tasks that would otherwise take hours or require multiple workers much easier. With the right electric winch, you can improve efficiency while maintaining safety in demanding environments.

These machines are not just for one type of job—they are versatile. You'll see them in civil construction projects, helping lift steel beams or position concrete panels. In plant construction or renovations, they assist in installing machinery and equipment. They are also widely used for small equipment installation, material upgrading, and transformation projects, where precision and control are critical. In road construction, winches help move heavy sections of structures or road equipment. In mining operations, they play a key role in hoisting materials safely from deep shafts or rough terrain.

When requesting a quotation for an electric winch, providing clear and complete specifications is not optional—it's necessary. Suppliers need detailed information about the load weight, lifting height, rope length, operating speed, voltage, and installation type. Including these details ensures the quotation is accurate, the winch meets your operational needs, and it will perform reliably over time. Skipping this step can result in mismatched equipment, increased maintenance, or even safety hazards.

8 ton electric winch for sale

10 ton electric winch for sale

Key practical points to include in your RFQ:

- Load weight and type of load: Know the heaviest item you'll lift or pull.

- Lifting height or pulling distance: Measure accurately to choose the correct rope length and drum capacity.

- Operating speed requirements: Some jobs need faster movements; others need precise, slow control.

- Voltage and power supply: Confirm compatibility with your site's electrical system.

- Installation method: Floor-mounted, wall-mounted, ceiling-mounted, or crane-mounted? Each has different space and support requirements.

- Working environment: Indoor, outdoor, dusty, wet, or high-temperature conditions affect motor and brake choices.

Providing these details not only speeds up the quotation process but also ensures the winch you purchase will work safely, efficiently, and with minimal downtime.

Determine Your Winch Operation Type

Before choosing an electric winch, it's important to clearly define the type of operation you need. This decision affects the winch's design, capacity, speed, and installation method. Broadly speaking, winch operations fall into two categories: horizontal pulling and vertical hoisting. Understanding the differences can save time, reduce costs, and improve safety.

Horizontal Pulling Winches

Horizontal pulling winches are designed to move loads across a surface rather than lift them vertically. They are commonly used in situations where objects need to be dragged, towed, or repositioned without lifting them off the ground.

Typical applications include:

- Towing vehicles or machinery across construction sites or workshops.

- Material transport on rails, carts, or flat surfaces.

- Sliding or repositioning heavy equipment during installation or maintenance.

- Small equipment relocation, where precise control over movement is required.

These winches are often referred to as pulling winches or rope winches. They can be equipped with steel wire ropes or synthetic ropes depending on the load type and surface conditions. Horizontal winches are valued for their ability to handle steady loads over long distances and often feature variable speed controls to match the task requirements.

Vertical Hoisting Winches

Vertical hoisting winches are designed to lift and lower loads vertically. They are commonly used when objects need to be raised to a certain height or lowered safely to the ground.

Typical applications include:

- Lifting loads such as steel beams, concrete panels, or machinery parts.

- Machinery installation, where precise vertical positioning is critical.

- Steel and structural lifting in construction and fabrication workshops.

- Concrete handling on construction sites or plant installations.

These winches are typically referred to as hoisting winches or electric hoists. They require careful selection of drum size, rope capacity, motor power, and brake type to ensure safe vertical movement. Some vertical winches include dual-speed motors to allow slow, precise lifting or faster operation when moving lighter loads.

Practical Tips for Choosing Between Horizontal and Vertical Winches

Practical tips for choosing between horizontal and vertical winches:

- Evaluate whether your load will mostly be moved along a surface or lifted vertically.

- Consider environmental conditions—wet, dusty, or confined spaces can affect rope choice and motor protection.

- Determine space and mounting options, as some operations require floor, wall, ceiling, or crane-mounted winches.

- Match the load weight and distance/height with the winch's rated capacity and rope length.

By clearly defining the operation type, you can select a winch that is safer, more efficient, and tailored to your project needs.

Advantages of Modern Electric Winches

Modern electric winches are built to handle heavy loads safely and efficiently while being easy to install and maintain. They offer practical features that improve performance, provide flexibility for different applications, and ensure long-term reliability.

- Reasonable Structural Design and Durable Construction

Strong frames and reinforced components allow winches to handle heavy and frequent use without damage. - Easy Installation and Maintenance

Modular designs make mounting simple on floors, walls, ceilings, or cranes, with accessible parts for routine checks. - High Efficiency and Stable Performance

Smooth, consistent operation with high-quality motors and gear systems ensures precise control and long service life. - Competitive Pricing with Top-Quality Components

Durable materials at reasonable prices reduce replacement costs while maintaining reliable operation. - Dual-Speed Operation: Low-Speed and Normal-Speed

Low speed for precise lifts and normal speed for faster material movement, adaptable to different tasks. - Large Drum Rope Capacity

Supports higher lifting heights or longer pulling distances without extra ropes, ensuring controlled operation.

Popular Electric Winch Models and Specifications

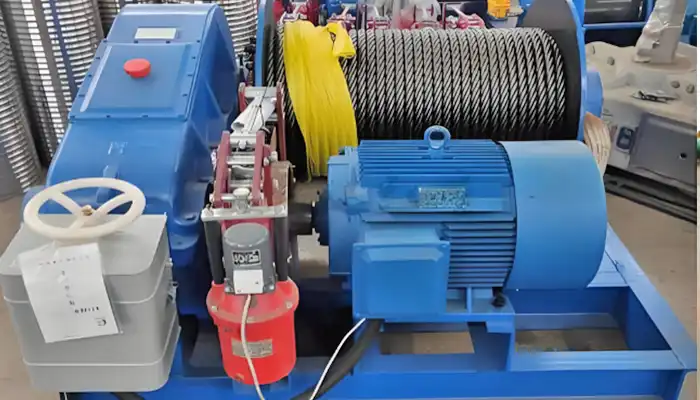

JM Series (Large Capacity Hoisting Winches)

| Type | Rated Load (kN) | Rated Speed (m/min) | Rope Capacity (m) | Motor Power (kW) | Overall Dimension (mm) | Total Weight (kg) |

|---|---|---|---|---|---|---|

| JM10 | 100 | 8 | 250 | 22 | 2100×1350×980 | 2800 |

| JM16 | 160 | 10 | 500 | 37 | 3600×2100×1700 | 8700 |

| JM32 | 320 | 9 | 700 | 75 | 3980×2740×2100 | 16000 |

| JM50 | 500 | 9 | 700 | 90 | 4850×2980×2300 | 21000 |

JK Series (Medium & Small Electric Winches)

| Type | Rated Load (kN) | Rated Speed (m/min) | Rope Capacity (m) | Motor Power (kW) | Overall Dimension (mm) | Total Weight (kg) |

|---|---|---|---|---|---|---|

| JK1 | 10 | 22 | 100 | 4 | 620×701×417 | 300 |

| JK3.2 | 32 | 25 | 200 | 15 | 1325×1335×840 | 1200 |

| JK10 | 100 | 30 | 300 | 55 | 2250×2500×1300 | 5100 |

Types of Electric Winches for Different Working Conditions

Electric winches are designed to meet a wide range of industrial requirements. Different models vary in capacity, speed, rope type, and drum size, making them suitable for specific lifting or pulling tasks. Understanding the features, main specifications, typical applications, and special considerations will help buyers select the right winch for their operations.

JMM Large Capacity Friction Winch

Overview: Heavy-duty winch for industrial and construction use. Designed for lifting large loads with precise control.

Main Specifications:

- Rated Capacity: 100–500 kN

- Lifting/Hoisting Speed: 8–10 m/min

- Rope Capacity: 250–700 m

- Motor Power: 22–90 kW

- Drum Type: Cast or steel plate drum

Typical Applications:

- Steel structure installation, heavy machinery lifting, plant construction, and mining hoisting.

Special Attention:

- Ensure proper mounting and alignment due to high load.

- Confirm rope length matches lifting height requirements.

JKL Manual Rapid Humping Winch

Overview: Portable, manually operated winch for temporary or mobile applications. Quick setup without needing power supply.

Main Specifications:

- Rated Capacity: 10–50 kN

- Operation: Manual humping

- Rope Length: 100–200 m

- Rope Type: Steel wire rope

Typical Applications:

- Temporary site operations, small equipment relocation, and on-site adjustments.

Special Attention:

- Suitable for lighter loads only.

- Requires careful operator handling for safety.

JKD Electric Portable Planetary Drive Winch

Overview: Compact and mobile electric winch with planetary gear system for smooth, controlled operation.

Main Specifications:

- Rated Capacity: 20–80 kN

- Hoisting/ Pulling Speed: 20–25 m/min

- Rope Capacity: 120–250 m

- Motor Power: 5.5–45 kW

Typical Applications:

- Mobile lifting, temporary setups, and short-term material positioning.

Special Attention:

- Verify site power supply compatibility.

- Inspect planetary gears regularly under frequent heavy use.

JK Fast-Speed Electric Winch

Overview: High-speed winch for horizontal pulling and material transport, suitable for medium loads over long distances.

Main Specifications:

- Rated Capacity: 32–100 kN

- Pulling Speed: 25–30 m/min

- Rope Capacity: 200–300 m

- Motor Power: 15–55 kW

Typical Applications:

- Horizontal pulling, construction material transport, industrial workshop operations.

Special Attention:

- Do not exceed rated load at high speed.

- Monitor rope wear and tension during frequent use.

JM Slow-Speed Electric Winch

Overview: Low-speed winch designed for precise lifting of heavy loads, providing stable operation and safety.

Main Specifications:

- Rated Capacity: 100–500 kN

- Lifting Speed: 8–10 m/min

- Rope Capacity: 250–700 m

- Motor Power: 22–90 kW

Typical Applications:

- Heavy machinery installation, steel/concrete lifting, precision plant operations.

Special Attention:

- Regular maintenance of brakes and motors is critical.

- Always use within rated load and lifting height.

Marine Anchor Winch & Electric Mooring Winch

Overview: Specialized for marine environments with corrosion-resistant components, designed for anchors and mooring lines.

Main Specifications:

- Rated Capacity: 50–250 kN

- Rope Capacity: 100–500 m

- Motor Power: 15–75 kW

- Special Design: Saltwater-resistant materials, heavy-duty drum

Typical Applications:

- Shipyards, docks, offshore platforms, maritime lifting, and mooring operations.

Special Attention:

- Regular inspection for saltwater corrosion.

- Proper alignment and installation to handle heavy anchor or mooring loads.

Key Considerations for RFQ Submission

When requesting a quotation (RFQ) for an electric winch, providing complete and accurate information is crucial. The more details you supply, the more precise the supplier's recommendation and quotation will be. Incomplete or vague specifications can lead to mismatched equipment, higher costs, or operational issues. Below are the key considerations for both horizontal pulling and vertical hoisting winches.

Horizontal Pulling Winches

Horizontal winches are used for dragging or moving loads along a surface. Providing detailed information ensures the winch can handle the load efficiently and safely.

A. Horizontal Pulling Winches (Pulling / Rope Winches)

| Item | Details to Provide | Notes / Tips |

|---|---|---|

| Load Weight & Pulling Capacity | Maximum load to be pulled | Include 20–30% safety margin |

| Rope Length & Type | Required rope length; steel wire or synthetic | Depends on load, surface, and environmental conditions |

| Voltage & Motor Power | Site power supply (e.g., 380V, 415V) & desired motor power | Ensures compatibility and efficient operation |

| Operating Speed | Desired pulling speed | May affect motor selection and rope life |

| Ground / Track Conditions | Surface type (floor, rail, flatbed, uneven terrain) | Influences traction and mounting requirements |

| Working Environment & Special Requirements | Temperature, moisture, dust, corrosive conditions, explosion-proof needs | Helps choose rope type, motor protection, and materials |

- Load Weight & Pulling Capacity

Specify the heaviest load to be moved. This determines the winch's rated pulling capacity and ensures the motor and drum can handle the task without strain. Always include a safety margin (typically 20–30%) above the maximum load. - Rope Length & Type

Indicate the required rope length and whether a steel wire rope or synthetic rope is preferred. Rope choice depends on the load, surface conditions, and environmental factors (e.g., abrasion, moisture, chemicals). - Voltage, Motor Power, & Operating Speed

Specify the power supply available at your site (e.g., 380V, 415V, or 440V) and the desired operating speed. This ensures compatibility with your electrical system and that the winch operates efficiently. - Ground or Track Conditions

Describe the surface or track along which the load will be pulled. Smooth floors, rails, flatbed carts, or uneven terrain all influence rope type, traction requirements, and winch mounting. - Working Environment & Special Requirements

Include conditions like temperature extremes, humidity, dust, or corrosive environments. If the winch needs explosion-proof components or waterproofing, specify it clearly.

Vertical Hoisting Winches

Vertical winches lift loads vertically and are used in construction, workshops, plant installation, and mining. Accurate details help ensure safe and reliable lifting.

| Item | Details to Provide | Notes / Tips |

|---|---|---|

| Lifting Weight & Height | Maximum load and lifting height | Determines drum size, motor power, and brake requirements |

| Rope Capacity & Type | Required rope length; steel wire or synthetic | Select rope type based on load and application |

| Voltage & Motor Power | Available site voltage and desired motor rating | Ensure compatibility and efficiency |

| Hoisting Speed | Low-speed for precision or normal-speed for general lifting | Dual-speed motors are recommended for flexibility |

| Installation Method | Ceiling, wall, floor, or crane-mounted | Influences support structures and safety measures |

| Working Environment & Special Requirements | Temperature extremes, dust, moisture, chemical exposure, explosion-proof requirements | Ensures winch durability and compliance |

- Lifting Weight & Height

Specify the maximum weight to be lifted and the required lifting height. These details affect drum size, rope capacity, motor power, and brake requirements. - Rope Capacity & Type

Indicate the rope length needed for the lift and the preferred rope type. Steel wire ropes are standard for heavy-duty lifting, while synthetic ropes may be chosen for lighter loads or special applications. - Voltage, Motor Power, & Hoisting Speed

Provide the power supply available and the desired lifting speed. Dual-speed winches are useful for precision lifts or heavy loads. - Installation Method

Describe how the winch will be mounted—ceiling, wall, floor, or crane-mounted. Installation affects structural support, safety measures, and overall system design. - Working Environment & Special Requirements

Specify environmental conditions such as temperature, moisture, dust, chemicals, or potential explosion hazards. Include any special requirements for outdoor use, noise restrictions, or high-frequency operations.

Practical Tip

Buyers should collect all these details in a checklist before contacting suppliers. Including complete information ensures the recommended winch matches operational needs, reduces the risk of downtime, and improves long-term safety and efficiency.

Practical Checklist (Buyer Use)

- Define maximum load and required safety margin

- Specify rope type and total length

- Confirm available voltage and motor specifications

- Indicate operating or lifting speed requirements

- Describe surface, track, or installation method

- Detail environmental conditions and special requirements

Installation & Support Services

Getting your electric winch up and running smoothly depends not just on the equipment, but also on how it's installed and supported. Reliable suppliers offer multiple ways to ensure your winch operates safely and efficiently from day one.

Installation Options

- On-Site Installation: A professional team can handle full installation and testing at your facility. This ensures proper mounting, alignment, and load handling.

- Remote Guidance: For remote or temporary sites, step-by-step instructions or video support help your team set up the winch correctly.

Experience You Can Trust

With over 10 years of experience and 3,000+ projects completed, the supplier has a proven track record. Both end-users and agents benefit from guidance that ensures safe, timely, and reliable operations.

Buyer Benefits

- Reduced downtime and faster commissioning.

- Technical guidance tailored to your working environment.

- Reliable solutions designed for your specific load, lifting height, or pulling requirements.

Extra Opportunities

- Independent sales representative programs with generous commissions.

- Risk-free partnership options for agents seeking industrial winch sales opportunities.

Quick Reference for Buyers

- Decide whether on-site or remote installation is needed.

- Confirm supplier's experience and project history.

- Verify availability of technical support and after-sales service.

- Consider agency or sales representative opportunities if relevant.

Frequently Asked Questions (FAQ) – Electric Winches and Industrial Lifting

Q1: How do I know which winch type is right for my application?

A: It really depends on what you need to move and how. If you're lifting loads vertically, a hoisting-style winch is best. For moving equipment or materials across a floor or along a track, a pulling winch works better. The load weight, lifting height, and rope length all play a role in selecting the right model. Sharing these details with your supplier makes a huge difference in getting a solution that works safely and efficiently.

Q2: What's the difference between steel rope and synthetic rope? Which should I choose?

A: Steel rope is robust, durable, and suited for heavy industrial use. It handles abrasion and extreme loads well. Synthetic rope is lighter and easier to handle, but it's better for lighter loads or applications where weight and flexibility matter. The working environment matters too—moisture, chemicals, and outdoor conditions can influence which type is more suitable.

Q3: Do I need a fast-speed or slow-speed winch?

A: That depends on your operation. Fast-speed models are great for moving loads quickly over long distances but aren't ideal for heavy or precise lifts. Slow-speed or dual-speed winches allow for controlled lifting of heavy machinery or sensitive equipment. Many buyers opt for dual-speed to cover both scenarios.

Q4: How do I make sure the winch will be compatible with my site's power supply?

A: It's important to provide your supplier with voltage details, available phases, and any limitations on amperage. This ensures the motor runs efficiently and avoids unexpected electrical issues on-site.

Q5: What should I consider about installation?

A: Installation affects safety and performance. Think about where the winch will be mounted—ceiling, wall, floor, or crane-mounted. Also consider supporting structures, alignment, and accessibility for maintenance. Some suppliers offer on-site installation, while others provide remote guidance if the site is remote or temporary.

Q6: How much rope do I need, and what about drum capacity?

A: The rope length should match your maximum lifting height or pulling distance. Drum capacity is equally important—too small, and you won't have enough rope; too large, and it can be unnecessarily bulky or expensive. Always share your working height, load, and operational cycles with the supplier to get the right configuration.

Q7: What about safety and maintenance?

A: Buyers often ask about brakes, overload protection, hook strength, and rope inspection. Regular maintenance is crucial—checking motors, drums, brakes, and ropes keeps operations safe and avoids downtime. Choosing high-quality components upfront saves headaches later.

Q8: Can I use a portable winch for temporary or mobile operations?

A: Absolutely. Portable electric or manual winches are ideal for sites without permanent installations. They're flexible and quick to set up, but you should ensure they meet your load and lifting requirements.

Q9: How do I get a precise quotation from suppliers?

A: The key is detailed specifications: load weight, lifting height or pulling distance, rope type and length, motor voltage, speed, and installation environment. The more detailed your info, the more accurate the recommendation and quotation.

Conclusion

Selecting the right electric winch—whether a rope winch, pulling winch, or hoisting winch—is critical for achieving safe, efficient, and reliable operations. The right choice reduces downtime, improves productivity, and ensures long-term durability.

Providing detailed specifications and clear information about your working conditions allows suppliers to recommend the most suitable winch and deliver an accurate quotation.

Pay attention to the quality of key components—including the motor, brake, wire rope drum, and hook—to maximize performance, ensure safety, and extend the service life of your equipment.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch