AI Hook Centering & Smart Crane Control for Productivity

Boost workshop efficiency with AI hook centering and smart crane automation. Improve safety, accuracy, and lifting speed with next-gen intelligent crane control.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

AI Hook Centering and Smart Crane Control:

Boost Workshop Productivity with Smart Crane Automation

Introduction: Why Smart Crane Automation Matters Today

Modern workshops face daily risks like crane skew, hook sway, blind spots, and operator fatigue, which can quickly lead to downtime, near-misses, or accidents. Smart crane automation helps prevent these issues and improves lifting safety and efficiency.

Why These Risks Keep Happening

Traditional crane operation relies heavily on the operator’s judgment. Even experienced operators face limitations:

- They can’t always see the hook clearly.

- Blind spots appear when loads block the line of sight.

- Long shifts lead to slower reactions.

- Manual corrections take time and are not always precise.

Why Manual Control Is No Longer Enough

Modern workshops move materials faster and handle heavier loads, tighter aisles, and higher customer expectations. Relying solely on manual control leads to:

- Inconsistent lifting accuracy between operators.

- Higher risk of side pull due to misaligned hooks.

- More load sway during sudden speed changes.

- Delayed response when unexpected events occur on the shop floor.

AI + Automation: A Practical Way Forward

AI hook centering and smart crane automation improve everyday lifting tasks without replacing skilled operators. Key benefits include:

- Watching the hook when operators can't.

- Detecting angle deviations before the lift.

- Correcting skew and sway in real time.

- Assisting operators with smooth, predictable movements.

- Reducing fatigue by automating repetitive alignment work.

Benefits of Smart Crane Automation

Smart crane automation ensures lifting is safer, smoother, and more reliable. As workshops adopt this technology, it becomes the new standard for stable and efficient operations.

Core Problem: Hook Misalignment & Crane Sway

Hook alignment seems simple, but most lifting risks start when the hook isn't centered or stable. Misalignment makes lifting harder, slower, and less safe in daily workshop operations.

Manual Operation Challenges

Operators rely heavily on manual judgment when guiding the hook, which comes with built-in limitations even for skilled operators:

- Centering the Hook Is Not Easy: A small deviation—sometimes only a few centimeters—can turn into a side pull once the load leaves the ground.

- Visibility Is Not Always Guaranteed: Operator line of sight may be blocked by tall loads, machine layouts, shadows under beams, or crowded workshop areas. Even a moment of poor visibility can lead to misalignment.

- Human Attention Isn't Perfect: During repetitive lifts, operators naturally lose focus. Fatigue, noise, and pressure to work faster all affect reaction time.

- Minor Errors Turn Into Bigger Problems: A small angle on the hook can quickly become sway, twisting, or crane skew once movement starts.

Safety Issues Caused by Misalignment

Misaligned hooks affect the entire lifting system. The risks are frequent in workshops, steel mills, and fabrication plants.

Side Pull from Hook Angle Deviations

Lifting a load at an angle causes sideways force on the hoist drum and wire rope, which can:

- Damage the hoist

- Bend components

- Cause the load to jerk unexpectedly

Crane Skew and Structural Stress

If one end of the bridge moves faster than the other, the crane skews, leading to:

- Uneven wheel pressure

- Rail wear

- Wheel grinding

- Potential derailment in extreme cases

Load Sway During Travel

A swinging load can:

- Collide with machines or stored materials

- Force workers into unsafe areas

- Slow down lifting cycles as operators wait for sway to settle

Daily Operational Challenge

Hook misalignment and sway are not rare—they are daily operational challenges that grow with every lift. Improved control, better detection, and automated corrections are essential in modern crane systems.

What Is AI Hook Centering? (The Smart Safety Foundation)

AI hook centering is the core system that keeps every lift controlled, predictable, and safe. It works quietly in the background, checking hook position, correcting angles, and supporting operators throughout the lifting cycle.

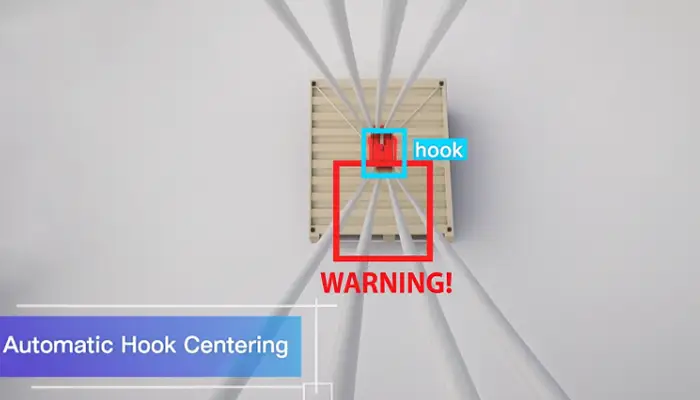

automatic hook centering - warning when the hook is not centered.

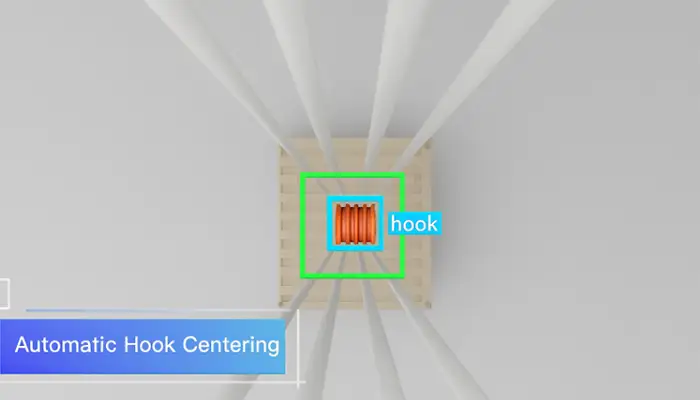

atuomatic hook centering for automatic overhead cranes for various industrail use

Automatic Detection of Unsafe Hook Angles

Before the operator lifts the load, AI analyzes the hook.

How It Works

- AI sensors measure the hook angle from multiple directions. Even slight tilts or shifts are detected.

- The system checks whether the hook is properly centered over the load. If not, it holds the lift and warns the operator.

Why This Matters on the Shop Floor

- Prevents lifting with a hidden side angle.

- Reduces the chance of rope twisting or drum damage.

- Helps new operators avoid common mistakes at the start of a lift.

By spotting misalignment early, unsafe lifts are stopped before they begin.

Auto-Correction Before the Lift

Detection is only half of the work. The system then automatically corrects the problem.

What the System Does

- Adjusts bridge and trolley movement automatically when the hook is off-center.

- Places the hook directly above the load, inside the "safe zone."

- Ensures the load rises straight up without side pull.

Practical Benefits

- Avoids side-pull forces that cause bending or sudden load jerks.

- Reduces wear on rope, bearings, and trolley wheels.

- Keeps the lifting structure healthier over long-term use.

The operator simply confirms the lift; the AI handles alignment automatically.

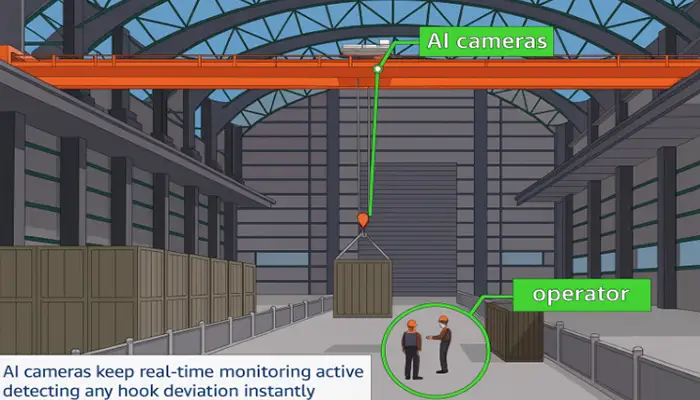

Continuous Monitoring During Travel

AI hook centering remains active while the load is lifted and moved.

What the AI Cameras Do

- Track hook and load angle in real time, even when the operator's view is blocked.

- Monitor for sway, sudden shifts, or unexpected movement.

- Detect deviations and make corrective adjustments instantly.

Why This Makes the Lift Safer

- Maintains stable hook alignment during crane movement.

- Reduces risk of sway hitting equipment or stored materials.

- Helps operators work confidently in tight or busy workshop environments.

With constant monitoring, the system supports the operator every second the load is in motion.

Smart Crane Control Technologies That Transform Workshop Operations

Smart crane automation is a full set of technologies working together to make lifting smoother, safer, and easier for operators. These core systems bring real improvements to everyday workshop operations.

Ai cermera monitoring to ensure crane safety

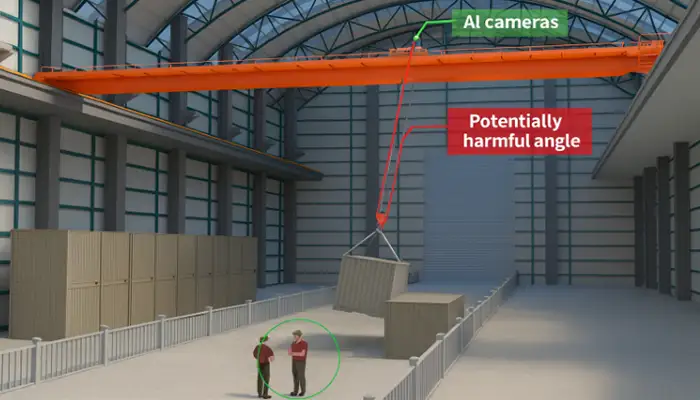

Ai cameras to reduce the potentially risks

AI Vision Cameras

AI vision cameras act as the crane's "eyes," giving awareness of everything around the hook and load.

What the Cameras Monitor

- Full 360° view of the hook, load, nearby equipment, and floor activity.

- Changes in hook angle or load position that operators may not see.

- Unexpected movement caused by bumps, vibration, or obstacles.

Why It Helps in Real Workshops

- Eliminates blind spots, especially when loads block the operator's view.

- Provides continuous tracking even during long travel distances.

- Alerts the system instantly when something abnormal occurs.

These cameras support safe and predictable lifting where humans cannot watch continuously.

Anti-Sway Automation

Anti-sway automation controls crane motion to keep loads steady, improving speed and safety.

How Anti-Sway Control Works

- AI calculates optimal acceleration/deceleration based on load weight, hook position, and travel distance.

- Ensures smooth crane movement without sudden jerks.

- Automatically adjusts travel speed to prevent swing.

Benefits for Operators

- Less waiting time for swing to stop.

- Easier load positioning in tight spaces.

- Faster overall lifting cycles without compromising safety.

Automatic Obstacle Detection & Emergency Braking

Prevents accidents when the hook or load encounters unexpected obstacles.

How the Protection Works

- AI cameras identify objects or structures ahead of the moving hook.

- If contact occurs, the system triggers rapid braking.

- Movement stops immediately to prevent further impact.

What This Prevents

- Damage to machinery, steel structures, and products.

- Harm to workers near the load path.

- Additional strain or twisting on crane components.

Crane Skew Detection & Auto-Correction

Crane skew causes long-term damage if uncorrected. Smart control constantly monitors wheel alignment.

What the System Detects

- Uneven wheel pressure between end carriages.

- Differences in bridge travel speed left vs. right.

- Early signs of rail wear or misalignment.

How Auto-Correction Works

- Balances travel speed on both sides.

- Adjusts acceleration to straighten the bridge path.

- Prevents skew before structural stress occurs.

Why This Matters

- Reduces wear on wheels and rails.

- Lowers the risk of derailment.

- Keeps the crane running smoothly with fewer repairs over time.

How Smart Automation Improves Lifting Accuracy

Smart automation improves safety, predictability, and ease of operation. These enhancements are visible immediately in busy workshops and steel-processing environments.

Precision Hook Positioning

Smart control handles the repetitive task of hook alignment, making it smooth and precise.

How It Helps

- No need for the operator to inch the hook forward, back, left, and right.

- Guides the hook directly to the target point, adjusting trolley and bridge automatically.

- Ensures consistent hook alignment across lifts, regardless of operator skill.

Practical Results

- Reduces the risk of lifting off-center.

- Starts every lift stable and predictable.

- Helps new or inexperienced operators work confidently.

Automation provides accuracy that manual operation rarely achieves.

Faster Load Positioning, Less Trial and Error

Smart crane control reduces delays caused by small adjustments and trial-and-error steps.

What Changes in Daily Operations

- Fewer adjustments mean shorter lifting cycles.

- Operators focus on workflow instead of micromanaging hook movement.

- Steel mills and workshops see immediate productivity gains.

Workload Benefits

- Operators experience less strain and fatigue.

- Lifting becomes intuitive and less stressful.

- Teams maintain faster production without rushing or cutting corners.

When trial-and-error disappears, lifting becomes smoother and faster.

Increased Efficiency in Complex Environments

Automation works reliably in busy, cluttered, or visually challenging workshops.

Where It Makes the Biggest Difference

- Cluttered work areas with mixed materials and irregular layouts.

- Narrow aisles where precision avoids collisions.

- Poor visibility zones blocked by loads or equipment.

- High-traffic sections shared with forklifts or production lines.

What the System Handles Automatically

- Keeps the hook stable even in tight spaces.

- Makes precise adjustments difficult to control manually.

- Ensures alignment when the operator cannot clearly see the hook or load.

Automation turns difficult lifting conditions into manageable routines, improving speed and safety.

Safety Benefits That Matter to Workshop Owners

Smart crane automation is a direct investment in protecting your people, equipment, and workflow. Safety improvements are practical, measurable, and immediately visible in daily operations.

Fewer Human Errors

Automation acts as a safety buffer when operators experience fatigue, stress, or distractions.

How Automation Reduces Errors

- AI keeps the hook centered even if the operator is tired or distracted.

- Real-time monitoring detects unsafe angles before lifting starts.

- Auto-correction prevents risky movements that rely on operator judgment.

What This Means for Owners

- Fewer incidents caused by rushed or inexperienced operators.

- More predictable lifting routines across the entire shift.

- A safer working environment without slowing production.

Automation supports operators where human limitations often appear.

Higher Operational Consistency

Smart systems maintain consistent safety standards across operators of varying experience.

Where Consistency Improves

- Hook alignment becomes uniform, lift after lift.

- Crane motion follows controlled speed curves, not individual habits.

- Safety checks happen automatically, not at someone's discretion.

Why It Matters

- Every operator performs at an "expert-level" baseline.

- Fewer workflow interruptions due to manual corrections.

- Operations stay smooth, even when new staff join.

Safety no longer depends on who is holding the controller.

Protecting People, Loads, and Structures

Smart control prevents small issues—hook deviation, sway, or obstacles—from escalating into serious accidents.

What the System Prevents

- Collisions with machines, tooling, racks, or building structures.

- Side pulls that create dangerous twisting forces on the crane.

- Load drops caused by unsafe lifting angles.

- Crane skew damage to rails, wheels, and structural beams.

Financial Advantages

- Lower repair costs for hoists, wheels, and rails.

- Less downtime caused by mechanical failures.

- Longer service life for major crane components.

Safety improvements directly reduce maintenance costs, providing tangible yearly benefits to owners.

Practical Applications for Workshops and Industrial Plants

Smart crane automation fits into many types of lifting environments where accuracy, safety, and repeatability matter. Below are the most common applications where AI hook centering and smart control bring real, everyday value.

Steel Mill Handling (Billets, Slabs, Coils)

Automation makes heavy and fast-paced steel mill operations safer and more manageable.

How Smart Automation Helps

- Corrects hook alignment for long or uneven loads like billets and slabs.

- Reduces sway when handling steel coils sensitive to side-pull forces.

- Supports operators during poor visibility or blocked views.

- Cuts cycle time during repetitive lifting between rolling lines and storage bays.

Real Safety Benefits

- Lower risk of side-pull accidents.

- Safer travel paths through crowded mill floors.

- Less wear on rails and wheels from crane skew.

Manufacturing Plants with Repetitive Lifting

Automation ensures the hook lands consistently in repetitive lifting environments.

Why It Works Well Here

- Automatic centering removes guesswork in high-frequency lifting.

- Anti-sway control keeps components stable during transfer.

- Operators can complete more cycles with less mental load.

Typical Applications

- Machine feeding and unloading.

- Component transfer between production stations.

- Pallet or fixture movement in assembly lines.

Leads to cleaner workflows and fewer lifting interruptions.

Mold Handling in Plastic Factories

Automation ensures precision and safety in tight mold-handling spaces.

How Automation Supports Mold Lifting

- Guides the hook directly to the mold lifting point.

- Stabilizes the load during slow or angled positioning.

- Prevents accidental sway that could damage molds or guide rails.

Practical Impact

- Faster mold changes.

- Lower risk of operators guiding molds by hand.

- Safer work in crowded mold storage areas.

Warehousing and Logistics Centers

Automation improves safe and efficient movement in busy warehouse environments.

Where Smart Control Helps

- Obstacle detection keeps crane movement safe in narrow aisles.

- AI vision cameras monitor hook position when visibility is blocked.

- Anti-sway reduces delays during long travel distances.

Benefits

- Safer multi-directional lifting in shared work zones.

- Reduced impact on stored goods and shelving.

- Faster material flow during peak activity.

Precision Assembly Workshops

Automation enables smooth, accurate placement in delicate assembly tasks.

Advantages of Smart Automation

- Smooth, stable movements for fine positioning.

- Consistent hook alignment reduces handling errors.

- Operators can focus on assembly, not fighting load sway.

Ideal Uses

- Positioning jigs, dies, and fixtures.

- Handling fragile or high-value components.

- Repetitive micro-positioning tasks during assembly.

What Buyers Should Look For in a Smart Crane Automation System

Choosing a smart crane automation system isn't just about picking the latest technology—it's about finding features that actually improve safety, efficiency, and workflow in your workshop. Not every system is the same, so here's a practical guide for buyers.

Compatible AI Camera System

The AI camera is the eyes of the system. Without reliable cameras, automation can't detect hook deviations or obstacles.

Key Considerations:

- Full 360° monitoring of hook, load, and surrounding area.

- High-resolution cameras that work in low light or cluttered environments.

- Integration with crane control system for real-time feedback.

Automatic Hook Centering Technology

This is the core feature that ensures every lift starts safe and precise.

Look for:

- Real-time detection of hook angles before lifting.

- Automatic adjustment to bring the hook back to the safe zone.

- Smooth, predictable movement that doesn't overload the crane structure.

Anti-Sway and Skew Correction Functions

Load swing and crane skew create risks and reduce efficiency. Effective systems automatically handle both.

Buyer Checklist:

- Anti-sway controls that stabilize the load during acceleration, travel, and stopping.

- Skew detection that monitors wheel loads and corrects misalignment.

- Automatic adjustments to prevent side-pull forces or structural stress.

Real-Time Obstacle Detection

Even minor collisions can damage loads or equipment. Look for systems that actively watch for obstacles.

What to Check:

- AI vision or sensor-based detection of objects in the crane path.

- Immediate alerts to the operator or automatic corrective action.

- Reliability in cluttered or busy workshop areas.

Emergency Braking Integration

Safety-critical events need instant action. Emergency braking protects personnel and equipment.

Important Features:

- Automatic stopping when the hook hits or skids on an obstacle.

- Smooth braking that prevents sudden load jerks.

- Integration with both bridge and trolley controls.

Compatibility with Existing Crane Structure

Upgrading should be practical, not require a full crane replacement.

Consider:

- Can the system be installed on your current bridge crane or EOT crane?

- Does it work with your existing hoist, trolley, and power supply?

- Minimal structural modifications needed for integration.

Data Logging and Remote Monitoring Capability

Smart automation systems can generate valuable operational data.

Why It Matters:

- Tracks crane performance, load cycles, and incidents.

- Enables preventive maintenance and reduces downtime.

- Supports remote monitoring for off-site management or multiple workshop locations.

ROI: Why AI Automation Pays Off Fast

Investing in smart crane automation isn't just about safety—it also makes solid financial sense. When used correctly, AI hook centering and smart control pay for themselves quickly through reduced costs, faster operations, and longer-lasting equipment.

Reduced Damage and Downtime

Manual errors often lead to collisions, dropped loads, or skewed movement that can damage the crane or surrounding equipment. Automation helps prevent these incidents.

Practical Benefits:

- Fewer repairs for hoists, trolleys, and bridge components.

- Less downtime waiting for fixes, keeping production flowing.

- Reduced disruptions in steel mills, manufacturing plants, or busy workshops.

Lower Maintenance Costs

When the crane moves loads safely and consistently, wear and tear decreases significantly.

How Automation Helps:

- Anti-sway and skew correction reduce stress on rails and wheels.

- Hook centering prevents side-pull forces that strain ropes and drums.

- Fewer emergency stops and collisions reduce component replacements.

Over time, this translates into noticeable savings on maintenance budgets.

Faster Lifting Cycles

Smart automation improves the speed and accuracy of every lift, eliminating trial-and-error positioning.

Operational Gains:

- Shorter cycle times per lift, boosting throughput.

- Operators spend less time adjusting hook alignment or waiting for sway to settle.

- More efficient material handling allows workshops to meet tight production schedules.

Fewer Accidents and Insurance Claims

Safer lifts mean fewer workplace incidents, which has both human and financial benefits.

Key Outcomes:

- Reduced risk of injuries to operators and nearby personnel.

- Lower insurance premiums due to fewer claims.

- Peace of mind knowing safety systems actively prevent common accidents.

Improved Equipment Lifespan

Cranes designed to operate consistently within safe parameters last longer. Automation helps achieve that.

Benefits for Equipment:

- Less stress on mechanical parts like rails, wheels, hoists, and drums.

- Fewer repairs and part replacements over time.

- Extended lifespan of major crane components, maximizing ROI from the original investment.

In short, AI hook centering and smart crane automation pay off quickly by combining safety, efficiency, and reduced operational costs. The investment isn't just in technology—it's in smoother workflow, lower risks, and measurable long-term savings.

Conclusion: The Future of Workshop Lifting Is Smart and Automated

Workshops and industrial plants are changing fast, and so are the demands on cranes. AI hook centering and smart crane control are no longer optional—they have become essential tools for keeping operations safe, efficient, and reliable.

Why Smart Automation Matters

- Safer operations: Automatic hook centering, anti-sway, and obstacle detection reduce accidents and protect both personnel and equipment.

- Faster and more accurate lifting: Operators can rely on the system to guide loads precisely, cutting down cycle times and improving workflow.

- Lower long-term costs: Reduced wear, fewer repairs, and minimized downtime help maximize the return on investment.

The Practical Takeaway for Workshop Owners

Upgrading to a smart crane system isn’t just about following trends—it’s about solving real, everyday problems: misaligned hooks, load sway, skew, and operator fatigue. Modern workshops that invest in automation experience smoother operations, higher productivity, and measurable safety improvements.

In short, AI-powered cranes support operators, protect assets, and make lifting smarter and more predictable. For any facility looking to stay competitive, reduce risk, and improve workflow efficiency, this technology is a must-have.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch