Explosion Proof Electric Hoist Specifications 3 Ton, 5 Ton,10 Ton

Explosion proof electric hoist for hazardous application, mining, oil, gas & paining workshops, etc. Explosion proof hoist specification for reference.

| Hoist type | BCD wire rope hoists with features of explosion proof , spark resistance and flame proof |

| Lifting Capacity | 500kg-50 ton |

| Lifting Height | 3 m to 100 m |

| Working Class | M3, M4 |

Category: Hoist and Crane Specifications

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Explosion Proof Electric Hoist Specifications 3 Ton, 5 Ton,10 Ton

Safe Electric Hoist for Hazardous Application

Main features of explosion proof electric hoist

- Compact structure, light, safe, and dependable;

- Compact structure, light, safe, and dependable;

- Explosion-proof hoist exposed parts are all made of non-sparking materials for dependable explosion-proof performance.

- Exd II BT4 or Exd II CT4 is the explosion-proof mark, and the temperature class is an explosive gas mixture of the T1-T4 group (see table 1 and 2)

- GB3836-2000 planning and design, manufacture, and acceptance

- Main application of explosion proof hoist

- Hanging from an Ibeam and moving in a straight or curved line

- The explosion-proof hoist can be installed in a fixed support and used with an explosion-proof single or double beam crane to lift heavy materials.

- Class B and C of type I and type II, places explosive danger with the temperature group of T1-T4.

Appendix:

- Grade "explosive-proof"

- There are two types of electrical equipment that, when used under certain conditions, will not result in an explosive burning environment:

- Type I: underground coal mine electric equipment

- Except for underground coal mines, all other explosive environments using electric equipment are classified as Type II..

Type II can be divided into IIA/ IIB/ IIC.

Table 1 | |||||||||||

T1 | T2 | T3 | T4 | T5 | T6 | ||||||

450 ℃ | 300 ℃ | 200℃ | 135 ℃ | 100 ℃ | 85℃ | ||||||

Table 2 | |||||||||||

temperature group | T1 | T2 | T3 | T4 | T5 | T6 | |||||

class | |||||||||||

Ⅱ A | methane, toluene, methyl ester, ethane, propane, acetone, acrylic acid, benzene, styrene, carbon monoxide, acetic ether, acetic acid chlorobenzene, methyl acetate, ammonia | methanol, ethanol, ethyl benzene, propanol, propylene, butanol, butane, butyl acetate, amyl acetate,cyclopentane | Pentane, amyl alcohol, hexane, hexanol, heptane, octane, ring ethanol , turpentine, naphtha, petroleum, (including gasoline), fuel oil, amyl alcohol tetrachloro | Acetaldehyde, trimethylamine | ethyl nitrite | ||||||

Ⅱ B | Propylene, dimethyl ether, town gas | Butadiene, propylene oxide, ethylene | Dimethyl ether, acrolein, and hydrocarbon | diethyl etherethyl oxide | |||||||

Ⅱ C | Hydrogen, water gas | Acetylene | carbon disulfide | ethyl nitrate | |||||||

Applicable scope and working conditions- This crane is used in ambient temperature of -25℃~+40℃,humidity≤,elevation under 1000m,power supply is 3-ph, 380V,50HZ (can change as user demand).

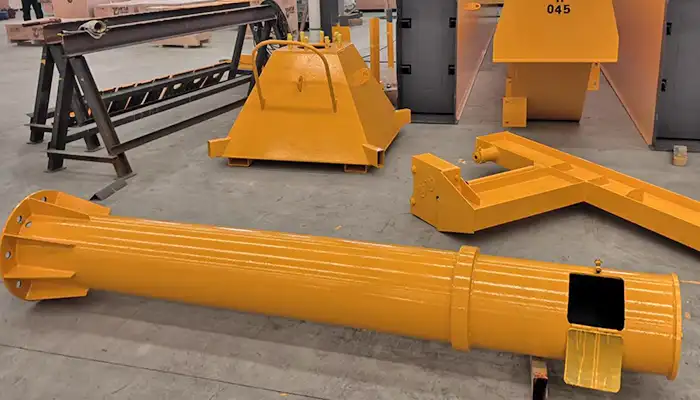

Main structure and characters of explosion proof electric hoist

Classification and product specifications

Explosion-proof single speed type and explosion-proof double speed type.

Note: single speed explosion-proof traveling electric hoist, with the capacity 5t and lifting height 9m, can be signed as BCD 5t-9m.

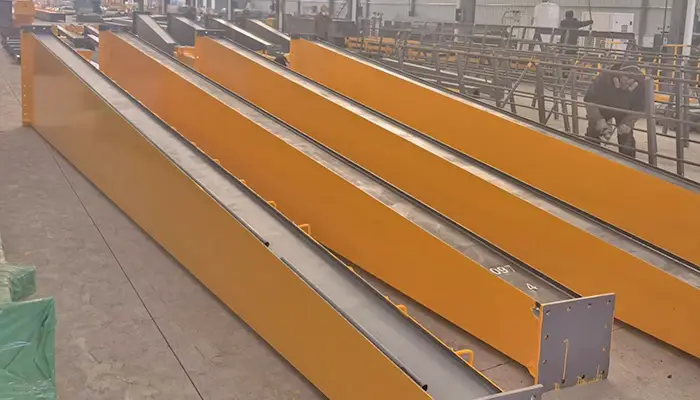

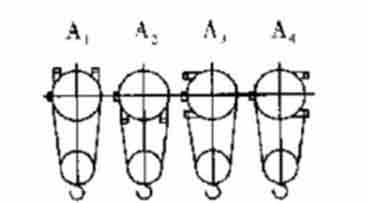

Structure Layout

Stationary type and operation type both included.

As shown on the right: A1、A2、A3、A4 separately fixed on the up, down, left and right side. A2 always used on the trolley of double beam crane with hoist. It is usually operation type without special explanation, traveling along with beams.

Lifting motor

- Adopt professional manufactured fully enclosed tapered rotor asynchronous explosion-proof series motor

- Max torque is 2 or 3 times more than full-load torque, safe and reliable when using

- Grade B or F insulation, motor protection degree IP44/IP54

Speed reducer

- Adopt standard module cylindrical gear, easy for maintenance, all installed anti-friction bearing

- 2.The gears and gear shaft are made of high strength heat-treated alloy steel.

- 3.High quality cast iron shell, machined to shape, assembly rigor, dust proof.

- 4.The reducer is a separate part that is easy to assemble and disassemble.

- 5.Reliable and efficient driving.

Hook

- 1.The hook end is made of cardboard.

- 2.Stainless steel hook head when the explosion-proof degree is DIIT4.

Traveling mechanism

Traveling motor

- 1. Flameproof BZDY series conical rotor three-phase asynchronous motor, flat brake, small braking torque, slow braking process to avoid parking hanging heavy objects shaking.

- 2. S4 motor working duty, 25% benchmark load sustained rate, 120 times equivalent starting per hour

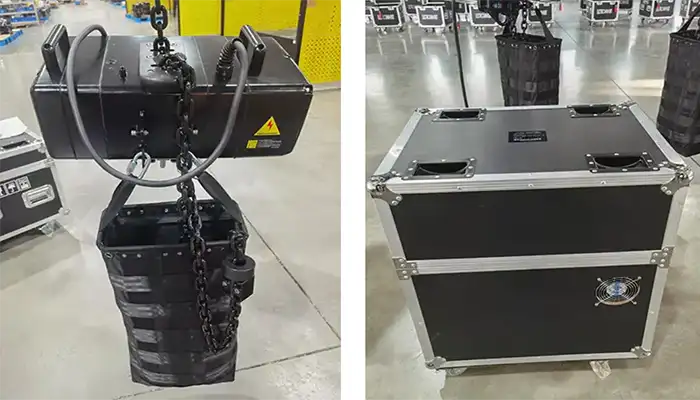

Electric equipment

- Explosion-proof type electric control box, explosion-proof type control board, and explosion-proof limiting stopper are included.

- With dedicated explosion-proof up and down traveling protection of fire stopper limit device.

- With an overload limit of the explosion-proof type.

Other features are the same as with a standard electric hoist.

Note:mechanical components take explosion-proof measures. In order to prevent electric hoist crash and impact cause high temperature spark when traveling, we should deal with some relevant parts.

- (1)The correct amount of machine oil should be injected into the lifting and running reducer.

- (2)Reel of grease-coated wire rope.

- (3)Stop block in the limited rod and limit apply joint made of bronze or stainless steel

Explosion proof rope guide

Explosion proof pendent control

Explosion proof travelling trolley

Explosion proof limitor

Main Parameters of explosion proof electric hoists

Our company primarily manufactures explosion proof electric hoist series with lifting capacities ranging from 0.25 to 63 tons, lifting heights ranging from 1100 meters, and low working class M3. We also design and manufacture non-standard series products based on your specifications.

BCD type explosion-proof electric hoist specification 3 ton | ||||||||

Lifting speed normal speed(slow speed) | m/min | 8(0.8) | ||||||

Traveling speed | m/min | 10 | ||||||

Lifting motor | kw | 4.5/0.4 | ||||||

Traveling motor | kw | 0.4 | ||||||

Traveling rail | 20a~32c | |||||||

Lifting height | m | 6 | 9 | 12 | 18 | 24 | 30 | |

Min curvature radius | m | 2.0 | 2.0 | 2.0 | 2.5 | 3 | 4 | |

Dead speed(single speed) | kg | 332 | 352 | 392 | 432 | 472 | 512 | |

Dead weight(double speed) | 411 | 431 | 471 | 511 | 551 | 591 | ||

BCD type explosion-proof electric hoist specifications 5 ton | ||||||||

Lifting speed nomal speed(slow speed) | m/min | 8(0.8) | ||||||

Traveling speed | m/min | 10 | ||||||

Lifting motor | kw | 7.5/0.8 | ||||||

Traveling motor | kw | 0.8 | ||||||

Traveling rail | 25a~63c | |||||||

Lifting height | m | 6 | 9 | 12 | 18 | 24 | 30 | |

Min curvature radius | m | 2.5 | 2.5 | 2.5 | 3 | 4.0 | 5.0 | |

Dead speed(single speed) | kg | 479 | 502 | 550 | 595 | 610 | 685 | |

Dead weight(double speed) | 617 | 640 | 688 | 733 | 778 | 823 | ||

BCD type explosion-proof electric hoist specifications 10 ton | ||||||||

Lifting speed nomal speed(slow speed) | m/min | 7(0.7) | ||||||

Traveling speed | m/min | 10 | ||||||

Lifting motor | kw | 13/1.5 | ||||||

Traveling motor | kw | 0.8 | ||||||

Traveling rail | 25a~63c | |||||||

Lifting height | m | 6 | 9 | 12 | 18 | 24 | 30 | |

Min curvature radius | m | 2.5 | 3.5 | 4 | 6 | 7.5 | 9.0 | |

Dead speed(single speed) | kg | 794 | 914 | 1034 | 1234 | 1434 | 1634 | |

Dead weight(double speed) | 1070 | 1190 | 1310 | 1510 | 1710 | 1910 | ||

Main Projects

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch